UV Curing Chamber

- The printing accuracy is up to 0.05mm that makes all printed prototypes highly smooth and accurate.

- The FDM 3D printer uses materials such as ABS, PLA, nylon, TPU, PVA, PC etc.

- The printer supports small to large sizes of printing of up to 1000x1000x1000mm.

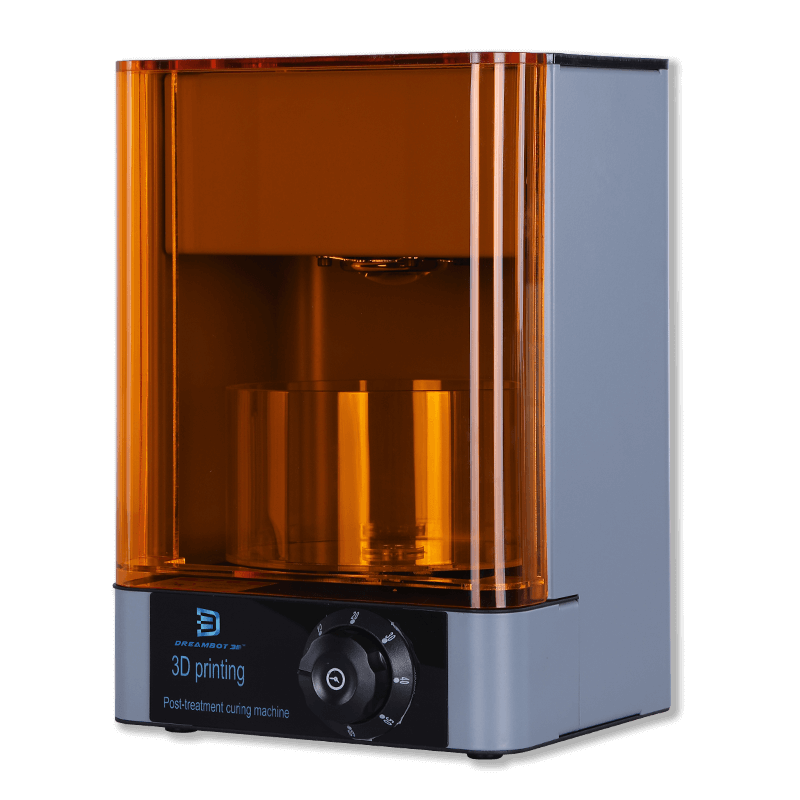

UV Curing Chamber Introduction

Dreambot3D UV curing chamber makes use of UV lights at 360 degrees to cure prints made with photopolymer resins. The post curing process is necessary in order to increase the hardness and durability of the printed object.

The UV curing chamber performs a post curing process because after the resin 3D printer prints the final shape, the polymerisation reaction is not completed. This means that the printed object is yet to reach its full mechanical properties. This process is achievable with the UV curing chamber.

Dreambot3D UV curing chamber allows you to create objects with characteristics that cannot be achieved through other means.

- The Dreambot3D UV curing chamber is used for post curing resin 3D printed objects to ensure that they are strong, most especially parts that are used for heavy functional purposes.

- TheUV curing chamber uses the UV-LED purely as its light source. This UV-LED is protected with an enclosure that prevents the UV rays from getting in and out of the machine.

- The light wavelength of the UV curing chamber is 406nm which is superior to other UV curing chambers that have lower wavelengths.

- Dreambot3D UV curing chamber is equipped with a steel plate turntable that rotates at a speed of 15/rpm. This enables a 360 degree curing process, that allows all angles of printed objects to be cured and perfectly exposed.

- The UV curing chamber is simple to use. This is because the UV curing chamber is equipped with function buttons that are properly labelled in English and Chinese. It contains the power button, timer, start and pause button, etc. You can easily monitor and document the curing process.

- Dreambot3D UV curing chamber comes with venting on both sides of the machine that allows air cooling, which prevents overheating of the UV curing chamber.

- The maximum curing size is 150*150*160mm and the entire machine weight is 3kg. This makes it suitable for all applications and it only requires small space. The UV curing chamberis also easy to transport.

- The UV curing chamber is compatible with photosensitive, rigid, ductile, flexible as well as cast resins.

- The light power is 40W and the heating power is 70W. This means that the power requirement is minimal, no extra charges on power use.

- Dreambot3D UV curing chamber gives the 3D printer objects the necessary details even after 3D printing them, at the same time, making them strong for mechanical uses.

- The UV curing chamber reduces cost and improves the efficiency of printing.

- The heating process is fast with the heating chamber reaching 60 degree celsius. This speeds up the curing process and maximizes the physical properties of the resin 3D models.

- The UV curing chamber has an automatic temperature control such that the inner chamber and lamp heads give curate temperature control. This stabilizes the temperature of the UV curing chamber.

- The UV curing chamber uses a special control system that contributes to the ease of use.

- The 3-sided light source and the heating function can be switched on and off separately.

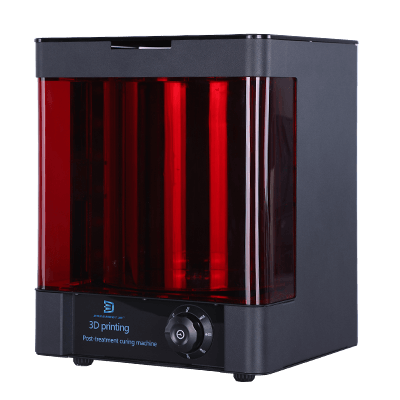

| Model | CL-100 | CL-200 | CL-380 |

| Photo |  |  |  |

| Supply voltage | Input 110/220 output 12V | Input 110/220 output 12V | Input 110/220 output 12V |

| Power | 50W | 50W | 60W |

| Fixed line range | D150*H100mm | D215*H220mm | D380*H230mm |

| Timing range | 2-60 min | 2-60min | 2-60min |

| Fixed line band | 400-405 mm | 400-405mm | 400-405mm |

| Curing method | Solidification in water | Solidification in water | Solidification in water |

| Equipment size | W220*D200*H315mm | W300*D265*H375mm | W430*D430*H355mm |

| Weight | 6kg | 10kg | 16.5kg |

Test your part

We provide sample testing service, allowing you to check the working quality of our UV curing box before placing an order

3D printers for your choice

ME-192 LCD 3D Printer

The ME-192 printer is a compact size with a printing volume of 192*120*270mm, this makes it suitable for small size applications like jewelry mold printing.

DB-345 LCD 3D Printer

The DB -345 is a compact size with a printing volume of 345*195*335mm, suitable for lab use and other mini sized applications.

DB-550 LCD 3D Printer

The DB-550 3D printer is used for industrial 3D printing requirements. The machine has the right speed, precision and resolution needed for complex objects.

buying guide of UV Curing Chamber

Introduction to the curing of photosensitive resin

It is a fact that in recent years, modern 3D printing technology and UV curing process have been developed rapidly. As an advanced and modern production technology, 3D printing technology has been widely used to manufacture different complex and high-precision objects in different sectors.

As per the information, during the 1980s, the concept of 3D printing technology and 3D printer was proposed. After that, the technology has been developed significantly faster, and with time, different new technologies appeared, for example, UV curing chamber or 3D printing UV curing box. As per some reports, among all the 3D printing methods, photo-curing or UV-curing 3D printing was the earliest 3D printing technology and still in use.

Speaking more about it, this form of 3D printing is based on the photopolymerization technique, and models or products are made using photosensitive liquid resin. The resin is cured under light irradiation. So, after printing, the models could be separated from resin quickly and relatively easily. Due to the superfast and high precision polymerization rate of this method, the 3D-printed model can be rapidly printed.

Based on the control system and the principle of pattern formation, photo-curing 3D printing has various methods, for example, SLA- Stereo Lithography Appearance, DLP- Digital Light Processing, LCD- Liquid Crystal Display, holographic 3D printing, and MJP- Multi-Jet-Printing. UV curing 3D printing method has high precision, high printing speed, and the printing model that is made using the UV curing machine will have a smooth surface.

All you need to know about the UV curing

To create premium quality products, choosing the ideal printing technique is crucial. An effective 3D printing method can be a significant difference between making products of great quality or good quality. A solution is there, and it is a proven technique to create stunning-looking products. UV curing station or box is the answer.

Speaking about the UV curing method, it is referred to as the ultraviolet curing method and is widely used as a post-processing method in LCD 3D printing. It is the photochemical process where a powerful UV light source is used to instantly cure adhesives, inks, and coatings. This offers a lot of advantages compared to the traditional curing and drying methods. Some of the significant benefits of using a UV curing box are:

- A significant reduction in the rate of rejected products

- Increase in production speeds

- Facilitate super bonding in the products

- Improvement in scratch and solvent resistance

Using UV Curing

Introduced during the 60s, a UV curing chamber for 3D printing is now widely available in the market, and one can get a machine under the budget. These machines are commonly used in different industries such as glass decorating, plastic decorating, electronics, jewelry, graphics arts, automotive and more.

As a multi-billion-dollar industry, this particular method covers around 5 percent of the global industrial coating market. It can be said that the UV resin curing method has displaced the water-based and solvent-based thermal drying process as this process is very fast and effective.

How does the process work?

Adding post-curing to the 3D printing process, especially in stereolithography, can help you get the best quality products, which can significantly enhance performance and strength. This is where you can use a UV light curing box. All the UV curing system works through a straightforward process.

In general, UV curing uses light through a photochemical reaction. The process doesn’t use heat. Liquid monomers and oligomers are combined with some photo-initiators before exposing to the UV energy source. After a few seconds or minutes, the products to be cured will harden instantly.

Exploring some benefits of using UV curing in manufacturing

The benefit of UV resin curing in different manufacturing applications is constantly growing. Do you know that most of the 3D models or action figures created using LCD 3D printers are cured using a UV resin curing chamber? Most of the manufacturing processes use UV light sources for the items you encounter regularly.

Some essential items, such as bottles cap, food cans, soda cans, lids on jars, plastic cups, luxury vinyl tile flooring, pet food bags, magazine covers, car headlights, and more, have been cure under this process.

Most manufacturers have understood the significant benefits of utilizing the UV curing method in their manufacturing process. UV curing is a green technology as UV chemistries that include adhesives, coatings, and inks are 100 solids, and they don’t release VOCs into the atmosphere. If you look at other technologies, for example, the convention thermal drying process, these processes produce VOCs and HAPs- Hazardous Air Pollutants.

- UV curing can significantly improve the physical properties of the product

Producers generally consider using a UV curing system for printing as the process dramatically improves gloss as well as ensures a better level of resistance against scratches and abrasion. On the other hand, such systems offer a greater level of strength, chemical resistance, adhesion, elasticity, and this can also enhance the products’ resistance.

- Faster production capacity

The production process that requires less space will facilitate a better production speed. As this method involves little labor, you will get more resources to improve your overall production capacity. With the best UV curing chamber, you will be able to witness higher throughput, fewer hours of downtime, and better utilization of the machine. All these things will significantly improve the capacity of your plant. So, get one now and increase productivity.

- Lowers the work in process

If you want to lower the manufacturing cycle time, then it’s time to deploy a UV light curing box in your production process. By significantly lowering the work-in-progress, UV resin curing systems will help you save capital while increasing the cash flow.

As the resin-made product will never cure unless they are exposed to UV light, you can leave those products overnight, knowing that the coating or ink will not dry. Besides, unused resins can be left in the machine. This can be very advantageous for you if you are working in graphic arts printing or using your UV curing box for plastic decorating machines.

- UV curing is proved to be effective in reducing scrap.

The process of UV curing can be completed within a few seconds. That means you can easily spot any curing problems immediately. Therefore, with such curing systems, you will enjoy a massive level of reduction in the amount of scrap produced.

For example, the standard adhesive can take many days to cure. After that, you will have to carry out quality control testing. However, during this process, you may end up with a lot of scrap parts.

In most UV curing systems, there are various quality control procedures that you can follow to carefully inspect coating, ink, and adhesive application much before starting the UV curing process.

After knowing all these benefits, it can be said that getting a UV curing machine for 3D printing can be a great idea. But the question is how to choose the right UV curing chamber? Well, to help you out, we have written down some important information. Going through the information, you will be able to pick a suitable machine for you. Have a look.

1.1, The principle of 3D printer printing resin

Speaking about resin 3D printing, this is considered as an umbrella term under the 3D printing technologies where the UV rays cure the resin or liquid photopolymers. It cures the material layer by layer and turns that into solid 3D models.

Well, resin 3D printing is not the official title, but as the machine works with resin, it will be an easy way to understand this printing technology. In some cases, VAT polymerization and Stereolithography printing terms are used.

The factors that define resin 3D printing

- They utilize the principle of photopolymerization to make the objects.

- They operate based on the codes. The printing machine creates the codes from the uploaded digital model.

- As a printing material, the resin 3D printing uses UV or photopolymer resin.

- The printing material is stored in a resin tank.

One of the primary principles of 3D printer printing resin is photopolymerization. In simple words, this is a chemical reaction of resin where the properties of resin change when exposed to the UV light source. The scientific name for such liquids or resins is photopolymers or light-activated resins.

There are various types of photopolymerization reactions. Besides, the outcomes also vary. However, the one that is widely used in the field of 3D printing is solidifying. Under this process, the liquid resin turns solid under the UV light source. Well, the sources of light can be different, for example, projectors, LCD panels, lasers, and more.

Exploring some major advantages of resin 3D printing

- Great details- Under this printing, liquid photopolymers are loaded into the printer. These resins are much easier to shape, and you can easily create complicated geometries. This may not be possible in the case of filaments.

- Super smooth surface- Even though layer lines will be there in the prints, but they will very small and invisible.

- Different types of materials- You will find different types of resins that can cover various applications and requirements. Each type of photopolymer resin includes different working components needed for the reactions as well as additives like dyes and functional supplements.

- Support doesn’t affect the surface- The tank is filled with resin across the perimeter. Suppose there is a few overhangs, they can be attached to parts during the curing process.

- Faster production- If you compare this with other types of prototyping techniques, you will find that resin 3D printing is very fast, and advanced machines can print high-quality models at a faster rate.

- Lower costs- For different applications, such as custom dental devices, master molds for jewelry, and prototypes, resin 3D printing can save the budget.

- The models will be waterproof- Compared to filament printing materials, photopolymers come out waterproof as well as solid. The models will not absorb moisture and can be used for different water-tight applications.

Understanding the technology- It is all about UV lights

The primary technology behind the resin 3D prints is stereolithography. Here is a complete explanation of how the Stereolithography process works.

- First, the roller of the printer applies a thin layer of liquid polymer. As the resin is in liquid form, it will spread out over the printing platform properly, ensuring that each layer has a perfect level of consistent thickness.

- The liquid resin is UV sensitive. When stuck by the UV laser produced by the 3D printer, the resin begins to change from a liquid state to a solid. In general, the UV laser source creates the outlines of the model to be printed onto the resin layer. And the UV rays harden the parts. The remaining resins that are not touched by the light source will be in liquid form.

- This process is repeated until the model is completed. Once the printing process is done, and the entire model has been printed, the build platform will be raised out of the resin tank. This will make the excess liquid flow away. Those resins can be reused later for making other 3D models.

- Once done, remove the printed model and complete the other process, such as removing support structure, smoothen the surfaces, and more manually.

Understanding the post-processing

If you compared it to other 3D printing techniques, you would find that resin 3D printing always needs post-processing. Some of the significant post-processing methods are:

- Washing – It is used to remove uncured resin leftovers. For this, the 3D-printed model is put into water or alcohol and then left dry on the paper towels.

- Support removal- This method includes the removal of supporting structures from the 3D-printed object. Based on the models you are making, the printing process will support and hold things properly. In general, such support structures are very easy to remove. However, the process is a little time-consuming.

- UV curing – When the parts finish printing, they remain on the print bed in an unactive or green state. That means even though the parts have attained their final form, they have not attained the polymerization reaction. Through the UV curing using a UV resin curing station,you can activate all the mechanical properties of the model. The UV rays will strengthen as well as solidify the model.

Apart from these post-processing steps, resin 3D printing can include some other types of post-processing. For example:

- Sanding – The post-processing method removes taps from areas touched by supports and then properly smooths the surface. For this, you can use wet sanding or dry sanding tools. With wet sanding, you can get a smoother surface. This process can be carried out after the UV curing process.

- Patching the escape holes- To lower the photopolymer’s cost, some models come with a hollow design. So, these models can have escape holes to release resin. However, they will not look aesthetically pleasing. Under the patching process, these holes are manually closed using resin.

- Finishing- This post-processing method includes covering the 3D-printed parts using special compositions in order to strengthen the parts and eliminate any imperfections. Some manufacturers go for priming. This is generally done before UV curing as a coating can help to prevent material from over curing under UV light.

- Painting and polishing- Utilizing different special compounds, polishing and painting are done to attain a clear and smooth surface. If you want a glass-clear look, go for this method.

All the post-processing methods can be carried out manually or using special devices. Post-curing is essential for different resins. After the post-curing, resins can attain the best functional properties. So, if you are involved in resin 3D printing, using the best resin printer curing station will offer you a lot of benefits.

1.2, Analysis of the types of 3D printed resins

3D printing has the ability to quickly convert digital design files into physical objects utilizing CAD-Computer Aided Manufacturing. These machines can process different types of resins, and some of the most popular resins are:

- Standard rigid resin

This type of resin is used for artwork, handmade model making, jewelry model making, and various DIYs. Such resins have high precision, and the models can be clear details and smooth surfaces. With this, you can enjoy stable printing with low viscosity, and standard rigid produces low odor.

- ABS resin

This resin demonstrates high toughness and hardness. There will be a low shrinkage level, and the printing size will be very accurate. It offers better printing stability. ABS resin is widely used for industrial design verification, mode manual, small-batch parts, fixture production, and more.

- High hardness resin

With some impressive properties like low shrinkage, high printing stability, and high hardness, this resin supports broad applicability. It is used for fixture production and for the production of small-batch parts.

- Elastic resin

As the name suggests, this resin demonstrates a strong elasticity and a higher level of toughness, and a good resilience level. The models printed using elastic resin will have an impressive tear resistance quality. The resin is used for sealing rings, sample preparation, and shoe material design verification.

- High-temperature press film resin

It supports a short curing time. During the forming process, it will not deform, and the finish products will have a smooth surface and high precision. This material is ideal for dentistry, watches, jewelry, toy design, handicraft design, and more.

Introduction to the UV curing chamber (Arpit)

UV Curing is an approach by which the Ultra Violet lights start a photochemical reaction. This reaction helps you generate a network of cross-linked network of polymers that enables you to increase the durability of the element you are using it in. One such essential process where you adapt UV curing is 3D printing. When it comes to 3D printing, the UV curing Chamber is the part that initiates the UV Curing process.

The UV Curing machine makes uses of the Ultra-violet ray or the lights to dry up the printed material. Every 3D printing machine you know uses the cured ink. However, these cure inks do not get evenly distributed in the printed material. In such cases, the UV Curing station in the curing machine initiates the process of curing to distribute the ink evenly on the surface of the printing material. However, another preeminent significance of the UV curing box is it even makes the printing more durable.

When the ultraviolet lights in the UV resin Curing chamber fall on the inks, it instantly dries up the ink and eliminates the chances of spreading out of the ink. The UV curing was got initially developed for the drying of nail polishes. However, later it rapidly expanded in the commercial industries like printing. The adaptation of the UV curing process in 3D printing has always been a profitable investment. This is because; when the UV lights cure the printed ink instantly, the wet ink gets no chance to spread out. That is why it offers you much more detailed 3D printing.

Besides, the most satisfying significance of the UV curing chamber is it is weather resistant. That curing process makes your 3D printing resistible to any weather. And it also achieves an enhanced resistivity to the fading. Further, the UV curing process in the UV curing chamber is also environment-friendly. It produces only a few VOC’s Odor that is not harmful to the environment.

The UV curing chamber delivers consistent UV lighting at 360o. This helps you cure your prints that come with Photopolymer resins. Every UV curing chamber these days comes with a 360o turntable. This turntable starts rotating when the curing process starts. This, as a result, offers you a more steady and consistent output. The curing Chamber also has a reflective mirror inside it that reflects the UV light for efficient 3D printing.

There are even some UV curing chambers that use mercury lamps. These mercury lamps in the curing Chamber employ UV LEDs. The UV LEDs are the light source that doesn’t produce any Ozone. The curing Chamber in the modern-day printing machine focuses on being more environment-friendly for sustainable development.

2.1, The Principle of resin curing machine

The Resin curing machine works on the principle of photopolymerization of resin. In this method of instant prototyping, the 3D printer uses certain UV lights in its curing Chamber to heat and cure the resins. The UV has the quality to cure the resins under UV light or heat. The resins are known as photosensitive resins. Based on the file, or the print that you enter, the resins cure them layer by layer to obtain a highly efficient object.

The working of resin curing machine

In 3D printing, you must be aware of stereolithography. This is an additive printing approach that is more popularly known as Resin 3D printing. The printing prototype uses resins to obtain higher and maximum accuracy in the manufacturing object. Further, the resins also deliver a fine and smooth finish on the surface. However, as this printing approach uses liquid epoxy resins to print, it needs instant drying and curing to get a durable print and in-depth detail. This is where the resin-curing 3D printing machines come into use.

These machines come with the same principle. It uses a light source, primarily UV light, to offer rapid drying to the liquid epoxy. After providing the precise UV heating, the resins then become hardened plastics.

The resin curing machine gets equipped with a curing chamber. This Chamber contains the liquid epoxy resins to cure the print. The Chamber also has a turntable that rotates 360o to offer you precise curing. The turntable in the curing machines also has reflective mirrors to offer an even quicker drying of the resins.

The main stages of Resin curing

There are different layers in resin 3D printing that makes the complete outcome. So, there will be different stages of resin curing as well. in the first stage, the ultraviolet ray scans the complete surface of the resin in the 3D printing object. Further, in the next step, the resins then get converted to a solid polymer by using the Ultra Violet light and heat. After completing the first layer, then the UV heat cures the subsequent layers.

Once the curing process completes, then the object gets removed from the UV curing chamber.

Stages of the curing process

- Laser beams or the UV rays scan the surface of the resins

- The platform gets lowered where the UV heat can reach up to all the portions

- Then the laser polymerizes the following layers

2.2, Why does the resin after 3D printing need to be cured by a UV curing machine?

When you are complete with your 3D printing from a resin printer, you can witness that the print is still soft and sticky. This is because; the use of liquid epoxy resin doesn’t dry up quickly. In such cases, the print that you are getting to obtain needs either direct sun rays or UV rays to get hardened.

However, every business wants to deliver its services in the shortest time possible in the commercial industry. They use a UV curing machine to get rapid results. Further, the process of curing the resins after 3D printing is essential as it makes your print look smoother and eliminates any reactions. The most vital reasons that business uses curing process is for achieving the in-depth detail.

The resin itself is famous for offering detail printing. But if it doesn’t dry up rapidly, you will lose the details that you have obtained. This is why you need to cure resins after you are complete with your printing.

The curing of resins will also make your 3D printing exceptionally durable. However, you should also make sure that you are not over-curing the object. Over curing your 3D printing can make it more complex and more brittle that won’t look precise. You may also lose your details.

The scientific reason why does you need to cure the resins after the 3D printing?

When you are printing any 3D object using the epoxy polymer, the printing process includes the cross-linking of the polymers. However, after the cross-linking of the polymers, the polymers must get adequately align with each other.

The proper alignment only will offer you the best outcome. It is much similar to tempering the steel. After getting its shape at a temperature, the steel then cools so that it can achieve more tensile strength. Similarly, in 3D printing, you need to cure the resins to achieve tensile and flexural strength.

The post-curing process is essential in 3D printing because achieving strength at room temperature takes a lot of time and can ruin the shape of 3D printing. However, with the help of UV curing, you can get the maximum durability and adequately align the polymers.

2.3, What are the benefits of the UV curing chamber?

There are several advantages that you get from the use of curing Chamber. However, one of the primary advantages that you are calling from the UV curing chamber is faster material processing. Yes! Every business would want to deliver their materials in a competitive time.

In such cases, UV lighting helps you the most. The UV rays speed up the process of 3D material processing. It rapidly hardens the resins and offers instant durability. This, as a result, helps you deliver the outcomes more efficiently.

Here are some other advantages that you get

Saving the time

The resins to dry up need the direct rays of the sun and much time. However, if you use the UV chambers to dry up the resins, you will obtain the end product within a small duration. Further, this helps the commercial industries to be client-centric and deliver requirements within significantly less time. Saving time also decreases the efforts and human resources. This is why you should use the resin curing chamber after the completion of your 3D printing.

Elimination of flaws and errors

Before introducing the UV chambers, the people used to apply a spot of ink or any final coat to help it dry faster. However, this also brings in the flaws and errors in 3D printing. Further, 3D printing end products demand to add details in it. In such cases, the UV chambers help you eliminate all the flaws and errors. You can achieve the precision and perfect finish to the outcome.

Offer quality

Another great advantage that you get from the UV chambers is the quality of the finished products. As the UV chambers speed up the process of drying, you will get durability much faster. Further, this will lead you to avoid any flaws. So, you can offer the best quality of finished products to your clients.

Offers consistency

One of the best perks that you get from UV curing is consistency. The processing of the materials takes uniform time. It also reduces the flaws and errors, which takes you to a state where you deliver a consistent and qualitative outcome to your clients.

Decrease in the manufacturing time

3D printing is mainly used in the industry where big products get manufactured. The automobile industry is one such industry that uses 3D models to get an idea about their new design. However, the slow manufacturing of the 3D model can increase the manufacturing time. They have to choose after a lot of modifications. But with UV chambers, they can achieve the final model faster. This is why most of the industry used the UV curing approach in their manufacturing.

Lesser space needed for drying up

In most manufacturing, industries spaces get acquired by the fresh models that kept drying. This decreases their space to keep the finished product. However, you will not have to find spaces to dry up the 3D model in cases of UV-cured model. You can eliminate the need for space.

Aligns the resins efficiently to make them durable

The most satisfying thing about UV curing is the durability that you get in the end product. Yes! The UV curing process aligns the resins efficiently that helps you in achieving the durability that you need. Moreover, you will get all the strength, hardness, durability that you require.

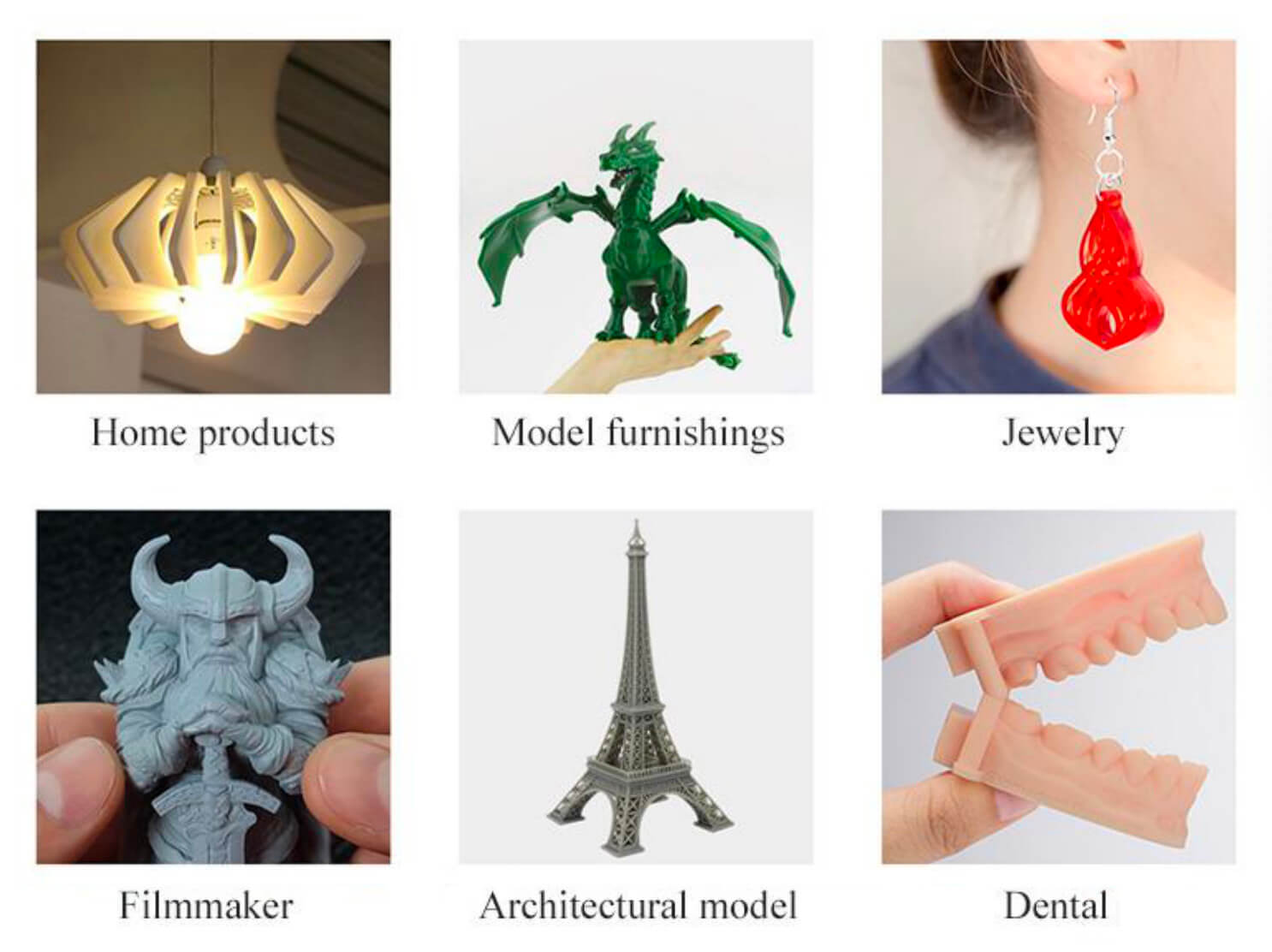

Application Field of UV Curing Chamber

UV curing chamber is definitely a promising instrument when it comes to the scope for innovation. The applications of UV and UV curing have become popular in many known industries, including optical fiber, hardwood flooring, and printing.

Generally, people are confused about the applications of UV light and associate it with the sun and skin cancer. On the other hand, people should also note that ultraviolet light is not always harmful and presents many promising results when used with different technologies.

One of the common applications of ultraviolet light is disinfection and sterilization in different hospitals.

With a UV resin curing chamber, creators could develop completely new pieces of equipment according to a particular prototype. UV curing gives the most important benefit of adhesive bonding of UV resin for attaching parts together.

In addition, it also ensures the proper design of sites that are inaccessible. The applications of UV curing depend on inks, adhesives, and coatings which are generally 100% solids and do not emit volatile organic compounds or VOCs. Furthermore, UV cured coatings are also gaining prominent levels of recognition for their better physical properties in comparison to thermally dried coatings.

All of these implications point out the necessity of learning about the applications of UV curing machine in different cases. Here is an outline of the different ways in which UV curing is transforming the domain of manufacturing.

3.1 Jewelry

Resins are one of the first things that you should take into account when discussing UV curing. UV resin curing box is a helpful instrument to get some of your favorite jewelry designs developed in physical form. The UV resin used in the case of jewelry is derived from natural elements or artificially created resins. The resin has the unique property of insolubility with water, thereby implying higher viscosity.

The viscosity of the UV resin is one of the foremost reasons for using them in UV curing to produce exceptional jewelry designs. Interestingly, the resin for jewelry is an advanced variant that can be easily cured within a short time period by utilizing ultraviolet radiation.

The different types of jewelry castings that you can use with a resin curing chamber with UV light indicate the foremost advantage of UV curing, i.e., comprehensiveness. It is possible to use UV curing for modifying resin design patterns with different types of jewelry such as rings, tie pins, earrings, bracelets, and cufflinks.

The best thing about the applications of UV curing for manufacturing jewelry is the easy accessibility of UV resins. Furthermore, the cost of UV resins for jewelry is also very reasonable, thereby allowing flexibility for all designers and manufacturers.

UV resin curing chamber is compatible with UV resin that is available in different sizes of bottles. The large bottles don’t cost much, and you also have the flexibility of choosing the size according to your project. The effectiveness of the machine matters significantly for UV curing in the case of jewelry. Users need to buy suitable flashlights, lamps, or nail curing lights with UV resin and take the effectiveness of the machines into account. Most probably, a 4-watt UV lamp could work well and give your curing for jewelry within two to three minutes.

UV curing applications for jewelry also include references to the simplicity of choosing the type of resins. The hard and soft UV resins are suitable for different types of outcomes in jewelry manufacturing. For example, the hard resin is suitable for mold applications or bezel filling in jewelry. On the other hand, soft resin, as the name implies, is very flexible in nature and can utilize a wide assortment of ornate designs.

3.2 Dental

UV light curing box also finds applications in the field of dentistry. The growth in demand for curing light has been effectively observed with the rising popularity of resin composites as well as light-cured materials. You would find the dental curing light as the foremost ingredient in dental practice routines. Earlier designs of UV curing lights have given way to LED and halogen lights becoming the common alternative. Many people have doubts about what is the exact application of the ‘blue light’ used by dentists. It is a curing light and helps in the polymerization of resin-based composites. Basically, a UV curing machine helps in solidifying the fillings inserted in teeth by dentists.

The use of UV curing in dental care started way back in 1969. The first light-curing resin composites made a mark in restorative dentistry and gained attention. The UV light polymerizing devices helped in the photopolymerization of dental composites and started a new benchmark in dental care.

The arrival of light-curing was a promising innovation at par with the use of adhesives for bonding composites to the enamel. However, problems with the initial UV curing apparatus in dental care primarily came from the shorter wavelengths of UV radiation energy. Subsequently, UV light curing machines in dental care applications found new design improvements with the introduction of functionalities such as QTH or quartz-halogen bulbs and PAC or plasma-arc curing.

However, the most prominent change in the design of UV curing machine in the field of dental applications came in the later part of the 1990s. The arrival of LEDs served as a game-changing intervention as it helped in offering light in the blue-visible spectrum.

Since then, LED UV curing machine has become a reliable alternative for dental treatments involving the use of light-cured composites. The interesting aspect about modern UV light curing machines in dental care also refers to the evolving designs of the machines.

UV light curing machines for dentists come with a selection of different curing tips. As a result, they can help in reaching different areas of the patient’s mouth easily without causing any discomfort. At the same time, the modern advancements in the use of UV curing for dental composite treatments also give the flexibility for addressing various restoration sizes.

The instruments for UV curing in dental care also provide the ease of calibrating the curing light to the selected frequency. This can be considerably helpful for long-term prospects of using UV curing in dentistry.

3.3 Anime Figure

The next most crucial area of application for a 3D printer curing station is evident in the production of anime figures. Wherever you look, three-dimensional or 3D printing, also referred to as additive manufacturing, is always a notable topic of discussion. It has found applications in the manufacturing of new machines, medical devices, and clothing, as well as action figures.

Now, this is where you can find the most promising application of UV curing for 3D printing. UV curing is important for a critical subset of additive manufacturing, stereolithography, which involves the creation of a computer-designed object into a solid 3D figure. The faster prototyping with reliable dimensional accuracy through UV curing provides many advantages in creating anime figures.

UV curing can help in creating almost any 3D shape alongside manufacturing multiple copies of figures on a single platform. The interesting factor about the use of UV curing in creating anime figures is the ability to scale the size of the models according to requirements. The application of a resin 3D printer curing station could show you how UV curing is helpful for manufacturing anime figures.

The process begins with a 3D computer image that is converted into a ‘sliced up’ version, including various thin layers. Inside the machine, a solid-state laser would then draw the layers included in the file on the platform. The platform, suspended in a vat of UV curing resin, serves as an important foundation for creating anime figures.

UV curing treatment would then involve contact of the UV laser beam with the resin composites. Subsequently, it would lead to activation of photo-initiators and help in immediately curing the resin composite to a solid polymer state. The platform then comes down slowly and allows the UV resin to flow over the solid polymer layer.

Subsequently, the laser would repeat the drawing process and build the 3D impression of the object according to each layer before completing the final product. It is important to note that the quality of anime figures created with UV curing machines depends a lot on the selection of UV curing resin.

The use of UV curing for creating anime figures has given the adequate foundation for ensuring functional testing or prototyping. When you can create identical 3D figurines based on the designs on your computer, it is reasonable to use the technology for a greater purpose.

3.4, Crafts

As discussed above, 3D printing is popularly known as additive manufacturing, and in this technology, the machine creates 3D objects using resins and filaments. Based on the type of machines you are using, you can create very thin layers, and that’s why 3D printing is quite popular in craft making. Making crafts, especially crafts with complex patterns and designs can be very challenging and time taking. However, the introduction of 3D printers and a resin 3d printer curing station has made the entire craft-making process a lot faster and easier.

There is no need to create objects from blocks or other materials through the hand-carving process. Using 3d printer, you can get the object done within a few minutes. The 3D printer layers the filaments or resins until the machine finishes the model making. Instead of crafting the design by hand, you can use 3D modeling software to create it. All the artists and crafters can take advantage of the advanced features of the 3D printers and UV curing machines to take their crafting ability to the next level.

Well, filaments are suitable to make crafts, but when it comes to fine detailed crafts and objects, you should go for a resin 3D printer, like an LCD 3D printer. Objects made of an LCD 3D printer require post-processing, and this is where you can use a 3d printing UV curing box to give your crafts a stunning look and to make their surface smooth. These technologies are now replacing the traditional craft-making process. How? Let’s discuss about this.

3D model design

After getting an idea of what you want to make, you can create a 3D model of your pictures using different 3D modeling software. Earlier, artists or crafters used to make the design on paper. Now, you can instantly create digital design files or CAD files and slice the design using a slicer so that a 3D printer can print it. What’s more? You can also make a perfect replica of any object by scanning the object using a 3D scanner.

Printing the model

In the 3D printing process, the only time taking a step is creating or designing the model. The rest of the processes are quite straightforward. After creating the design, all you need to do is to transfer the digital design file to the 3D printer, and the printer will carry out the printing process. You can use both the LCD 3D printers or FDM 3D printers. For the best result, we will suggest you go for an LCD 3D printer. Here the liquid resins are cured with the help of UV rays. The entire printing process, based on the complexity of the object, can take a few minutes to a few hours.

UV curing

Once done, the objects are post-processed. This is where you will need a UV resin curing chamber. This is generally carried out to give the object a solid and smooth surface. The resin used in the objects reacts when it comes into contact with UV rays, and the process hardens the object. It will only take a few seconds. This process will significantly improve the properties of the objects by making them chemical and scratch-resistant. Besides, bond strength also increases.

Some benefits to understand

These machines have enabled the users to create a perfect and accurate prototype or crafts within a few hours. These machines are for all, from hobbyists to professional product manufacturers. Both the LED UV curing machine and the 3D printer offer the following impressive possibilities:

- Faster and better testing

- Rapid product prototyping

- Conduct comparisons and more.

With a lot of opportunities offered by the 3D printers, now you can craft objects that will look realistic and last for a year. Besides, in some cases, this technology is also used for artifact creation, archelogy, and restoration of an object. All you need to do is to complete the resin printing by creating the object and post-curing them with UV rays. This will dry up your object faster and harden the prints’ outer surface.

3.5, Shoes

Keep growing in this highly competitive business world means you will have to introduce different new products. This is what the shoemakers are doing. And for this, they are now using modern 3D printing technology. For them, 3D printing or LCD 3D printing technology has improved their product innovation cycle, and they are making unique shoes to meet the customers’ demand.

This modern manufacturing technology can help the industry in making highly customized or tailored shoes. You can use it for making shoe soles and mass production of 3D-printed shoes. Traditionally, shoe soles were used to be made from wooden molds using hands, which was a very time-consuming process. Besides, if there is something wrong with the design, you will have to create a new mold. Making every change can take up to four hours. But now, with 3D printing, you can craft a prototype of the shoes within a few minutes. Besides, wooden molds are getting replaced with 3D-printed molds. As a result, you will enjoy a super-efficient process, complex patterns, shorter production time, and more.

In the footwear market, 3D printing covers around 0.4 percent of total revenue. But it has been predicted that it will reach 1.5 percent by the end of 2029 as more shoe manufacturers are now using 3D printers and UV curing systems for printing shoe molds and other shoe parts.

What types of 3D printing technology are used for this?

One of the most widely used 3D printing methods used in the shoemaking industry is photopolymerization. This method includes resin-based printing and UV light processing. It is also known as stereolithography. The UV light source is carefully applied onto the liquid resin to make it hard and make the object layer by layer. Polyurethane, faster printing speed, flexible printing material, faster curing process, and better accuracy have made the 3D printers and best resin print curing station quite popular in this industry.

Leading companies like Adidas, Under Armor, Nike, and New Balance, are using 3D printing technology to make 3D-printed sneakers. For instance, Adidas has made FutureCraft using this technology. This is made using the DLS process and a UV curing machine partnered with Carbon 3D.

Well, starting from designing to the final products, in the shoemaking industry, it is quite essential to make perfect shoe molds. Traditionally, the molds are carved from wood, and the accuracy of the mold will significantly depend on the skills of the craftsman. While CNC machines are reasonable, it is very challenging to make an intricate pattern using this. But now, by combining 3D printing with UV curing, you change the shoe production process. It will only take a few seconds to make shoe molds. For this, you use an LCD 3D printer to make a mold from resin.

3D printing technology has replaced the way of designing shoes and molds. You don’t have to draw the design on paper. Just directly make the design utilizing the software and send that for printing. When you design using software, it will be accurate, and you can easily detect the flaws and make necessary changes before the final production.

The creation of molds

- The shoe molds are first designed with the help of 3D modeling software, and a CAD file is created.

- Once done, the digital design is sliced using slicing software, making it ready to be used by the 3D printer. The slicing software converts the design into G-code.

- Now, the file is transferred to the 3D printer, and the printer starts making the mold using UV light, hardening the resin.

- After that, the molds are placed into a UV curing box to harden the mold surface and make them durable.

Now, you have the molds that can be used with shoe uppers to produce the shoes. If you compare this process with the traditional ones, you will find the latest process is much faster and easier. What’s more, you can also create molds with a level of detail.

3D printing technology also has enabled shoe manufacturers to create customized shoes for their customers. They can now take an accurate measurement of feet using a 3D scanner and create the design for the molds. In fact, this can be done within 10 to 15 minutes.

Why should combine the 3D printing and UV curing

To mass-produce midsoles or soles

The shoe manufacturers are now using these technologies to mass-produce shoe soles or midsole. For example, companies like Adidas and Carbon have come up with an efficient workflow for making midsoles using 3D printing with lattice geometries.

To create customized shoes.

Do you know that the first product that was made using the 3D printers in this industry was orthopedic insoles? Different companies are now making insoles using 3D printing and UV curing process for shoes, sports footwear, and boots to offer better comfort to the users. They can easily adapt to the size of the users’ feet.

Durable soles and molds

Forget about metal and wooden-made soles or molds that may not last long and become useless after using them to make a few pairs of shoes. It’s time to create them using resins. After 3D-printed the molds or soles, you need to cure the resin using a UV resin curing box. The final product will be very durable and will last for years.

It will be easier to make designer and luxury products

It is a fact that 3D printing technology is widely used for making design footwear products, and people love them. For example, custom-crafted heels. Like Ross Lovegrove, Van Harpen, Cristina, and more, all the well-known designers are using these devices to make their creations.

So, if you are planning to create your footwear business, you should get the best 3D printer and a UV curing box to enjoy perfect growth in this industry.

3.6, Drone

With tome, drones, and UAV- Unmanned Aerial Vehicle are becoming more common. These are used in different industries, for example, military, cinema, security, aerospace, agriculture, and more. Both 3D printing and UV curing methods can be very useful in making Drone, or you can also use them for your own drone projects. In fact, these can be utilized to work in the resistance and design of the drones.

With 3D printing, you can enjoy rapid prototyping. However, it is also possible to make a complete drone using this. First Person View quadcopter drone, micro drone, pocket drone, radio-controlled Drone, and more can come to life with the help of 3D printing technology.

By combining these two technologies, you can easily make your own functional drones. Besides, it is an ideal way to customize the drones that will fit your needs. Compared to the traditional manufacturing methods, you will find the 3D printing and UV curing process much cheaper, and the product manufacturing process is also fast. As you will be taking the help of the LCD 3D printers and resins, it is now possible to make lightweight Drone and faster Drone. So, this will be a smart choice for you.

One of the significant advantages of 3D printing parts will be they can be custom. Furthermore, these will be generally inexpensive if you already have resins, a 3D printer, and a UV LED curing machine.

Just make the design digitally, 3D-print different parts of the drones, and then all you need to post-cure the details using the UV curing system. Now, the durable parts are set to be used. So, what are you waiting for? Search for the best UV curing chamber and buy it now.

3.7, Car parts and the car model

Talking about the global automotive industry, 3D printing is a primary game-changer. Well, 3D printers used to be a tool for prototyping, and it still is. However, 3D printing technology has now made its way to the car manufacturing process. Don’t feel surprised about that as different car manufactures are now using this technology to build cars.

With time, the technology has been recognized as severe manufacturing technology and not just as a medium to build a good prototype or proof of concept. Nowadays, vehicle producers are looking for different ways to lower the weight of the product. Besides, different studies have proved that lighter cars will consume less fuel, and they are environmentally friendly.

For this, you need to optimize the parts’ design, and this can be done by using 3D printing and UV curing. For example, car manufacturer Volkswagen redesigned a reinforced A-pillar window support with the help of 3D printing. The most important thing about this part is, it weighs around 75 percent less than the original version.

So, with this technology, you can develop lighter structures, all thanks to its unique and innovative design patterns, for example, lattices, or you can lower the number of parts by making the suited design of the components.

3D printing and UV curing reshaping the process of prototyping

Prototyping has been an everyday use case for 3D printers in this industry. The entire prototyping process now can be carried out at a vastly increased speed. While facilitating rapid prototyping, 3D printing technology has dramatically revolutionized product development methods.

Using a UV resin curing station, you can quickly fabricate a prototype of a physical part. It is also possible to scale the model of an entire car. It has made it possible to turn unique ideas into better proofs of concepts. All the processes will take just a few minutes based on the size and design of the object.

The concepts can be processed into high-fidelity prototypes that will match the end results. This will further help the products to go through the validation stages required for mass production.

No matter what is the design and pattern, the parts can be produced faster, and you will get durable parts. It may be noted the UV curing process can make the resin-printed parts waterproof, scratch-resistant, and robust. Give it a try now.

How to buy a UV curing chamber

If you search for a UV resin curing chamber, you will find a lot of models from different brands. The features and specifications will vary from one model to another. This will make the buying process a little challenging. To help you in this, we have listed down a few essential points to consider. Have a look.

4.1, The types of 3d printers (LCD, SLA, or DLP?)

Before buying a UV resin machine, you should understand the different types of 3D printers. Here, we will cover DLP, SLA, and LCD 3D printers.

SLA 3D printing is the original 3D printing invention and is widely used by different well-known companies such as Form Labs, 3D System, and more. The SLA 3D printers use laser light to cure the liquid resin selectively by properly scanning the surface. When the resin cures, it turns into the plastic at the spots where the laser touches the resin.

DLP 3D printers utilize a projector to selectively cure the resin. These printers are much faster than Laser SLA 3D printers. The reason behind this is the machine’s powerful projector can flash the entire layer at once. The light produces from the LEDs is guided to the DMD chip. The DMD chip then creates the actual curing pattern.

Speaking about LCD 3D printers, they are the latest developments in the industry. The printers use an affordable LCD screen instead of DMD chips. This method works by the LED’s illuminating on the LCD panel. The LCD panel creates the required curing pattern. The spots where the UV light hits the resin will become hard. For a faster 3D printing process, you can go for LCD 3D printers.

4.2, What is the size of the cured resin product

Keep in mind the size of the resin product that you want to cure while buying a UV light curing box. It is advisable to go for a bigger size, like 800x800x800mm, as this will support most of the model and you can UV cure the entire model at a time.

4.3, Choose a reliable brand

When you choose a reliable brand, you can expect to get the best UV curing chamber for 3D printing with all the required features. Besides, the machines will work smoothly without developing any issues. Furthermore, only a reliable brand can offer you good after-sale services.

4.4, Safety configuration of the machine

Make sure that the machine lets you change the power output level and diagnostic information when it faces a problem. Besides, make sure that you can easily monitor different critical aspects of the UV curing machine. Always go for a fully enclosed machine for a better level of safety.

4.5, Consider whether the price of the machine is acceptable

You can quickly get a good quality 3d printing UV curing box under USD 100 to USD 300. But make sure that it has all the required features, and the size is decent. And choose a machine that can support different resins or filaments so that you don’t have to buy a new machine for every resin.

4.6, Consider the supplier’s after-sales service capability

Buy the machine from a brand that can offer faster and 24×7 after-sale services. A good brand will offer you engineers who will be available to service machinery overseas. Besides, they will also offer online support to resolve the issues.

4.7, Consider the service life of the machine

As you will be spending a few dollars in buying the machine, you need to make sure it can run for a decent time period. Well, if it works for 6 to 7 years, then the investment is suitable. Ask the manufacturer about this.

4.8, Consider the maintenance cost of the machine

A machine that requires frequent maintenance can affect your production cost. So, choose a machine that requires less maintenance and can run properly with little care. For this, it is advisable to choose a reliable brand.

Frequently asked questions of the UV curing chamber

What is UV curing Chamber?

UV curing chamber is used for UV curing in resin 3D printing. UV curing is a high-speed, solvent-less, and low-temperature photochemical process, and it utilizes high-intensity electronic ultraviolet light to change different photo-reactive substances. The UV curing machines create a polymerization process which is also called drying. The cured substances will secure, and you will get a robust product.

How long does UV resin take to cure in sunlight?

As per some studies, if you are using UV resin, then it can take around 20 minutes to cure the layer using a 3D printing UV curing box. Well, in the case of sunlight, it can take a few hours. But it won’t be much effective, and sometimes you may face an over-curing issue.

What does UV curing do?

UV curing is the process of perfectly irradiating ultraviolet rays into UV curing resin to cure the resin-made 3D objects within a few minutes. The process uses ultraviolet light, and this is where it gets the name. In general, UV curing resin includes oligomers, monomers, photopolymerization initiators, and different additives. When they come into contact with UV light, they undergo a chemical reaction called a photopolymerization reaction.

How long does it take to cure resin prints?

As per the experts, a miniature resin 3D print can be cured within a few minutes. However, an average size print can take around 12 to 15 minutes to cure. For faster results, you can use the best printing curing machine.

Why is UV resin tacky after curing?

Sticky resin is generally caused due to under mixing or inaccurate measuring. Some of the common sticky resin issues are; Liquid or runny resin. You need to scrape off liquid resin and pour a fresh coat of resin. Sticky or tacky resin is caused by not mixing thoroughly or curing the resin at an inappropriate temperature. Try to set the accurate temperature in the machine to avoid such issues.

Can you cure UV resin without UV light?

Yes, it can be possible, but the result may not be good. You can place the resin-made 3D object in the sun if you don’t have a LED UV curing machine. However, be careful that this process can take longer, and the curing process could be less effective. So, always use a 3D resin curing box.

Why is my UV resin not curing?

This could happen when the resin interacts with oxygen. To solve this issue, you can leave the model for longer under the LED UV curing systems for printing, and you can try by using different wavelengths.

How long does it take to cure UV glue?

The primary catalyst for the photochemical reaction is the UV wavelength. It causes the polymer or glue to harden instantly. In some cases, the UV glue will harden within three seconds when exposed to UV. Sometimes, it can take around 10 to 20 seconds.

How long does UV glue last?

Well, UV glues are developed to last for a permanent time. However, the adhesion quality will depend on the environment under which the objects will be used. But you can expect better results with the UV curing process.

How do UV resins work?

Speaking about UV resins, they are from the group of synthetic resins. Resins are quite different from epoxy resin in terms of how they are processed. UV resin is cured using the UV resin curing Chamber, and it only takes a few minutes. The resins can be used without combining them with any hardener. UV light source is used to harden resins, inks, and glue by creating a photochemical reaction.

Can you put metal in a UV lamp?

Yes, you can. Remember that metals are entirely unaffected by UV lamps as they have free electrons that absorb photon energy, and for this, they don’t need to go through any bond dissociation or energy transitions.

What is 3d printing curing?

3D printing curing is all about curing the resin. Under this process, resins are exposed to the UV light that triggers the development of additional chemical bonds. As a result, your 3D-printed resin objects will become more robust and durable. For this, you can use a UV resin curing chamber.

Why curing process is essential in printing?

Almost all the manufacturers are using UV curing systems for printing as it can significantly improve gloss. Besides, the objects will become resistant to scratches and abrasion. On the other hand, such systems offer greater strength, better elasticity, adhesion, chemical resistance, and more.

How do you tell if UV resin is cured?

The duration of the UV resin curing process will depend on different factors and the workpieces. For example, for the small pendant, the process may take 100 to 180 seconds. If the layer is thicker or you are curing a larger object, then the curing time will be more. However, to check if the resin is cured or not, you can check the surface condition by using a toothpick. If it feels soft, then the object needs more curing.

Is UV resin toxic after curing?

Remember that uncured resin is a little toxic as they have different harmful chemical properties. However, when you cure the resin using a 3D resin curing station, the chemical properties will begin to change. So, the cured resin is safe to touch and use.

Can I leave resin outside to cure?

Keep in mind the UV resin will not harden properly if the temperature is low. So, during the cold months, you can leave resin outside to cure. Besides, if the outside temperature is very hot, then this can lead to an over cure. So, experts always suggest using a portable UV curing machine for proper curing of the product.

How do you cure resin 3d prints?

Well, you can do that in different ways. For example, you can buy a professional UV curing station. Such machines are affordable and will be the ready-made solution for you. The final result will be awe-inspiring. Besides, you can create your own UV curing system by buying all the parts. But this can be a very costly option. Another thing that you can do is using a natural UV ray. If you don’t have a budget to buy a machine, then this could work. UV rays are best known to come from the sun. How to cure using the sun’s UV rays? Here are the steps. Well, this option may be a little time taking, but sometimes it works. However, the outcome may not be impressive. You can dip the resin 3D-printed model in a bath of water and then leave it post-cure. Or you can directly place the model under the sun. The entire process can take up to 30 minutes. Besides, you need to evaluate the quality by checking the model constantly. So, it will be better for you to use a UV curing chamber.

What happens if you get UV resin on your skin?

You can simply wash your skin with water and soap. Well, you may not develop any reaction the first few times, but when the skin’s resistance to resin exposure lowers with time, you can experience serious skin issues.

Conclusion

The major advantage of UV curing processes lies in the speed at which 3D models can be ready for shipping. Besides, this also can lower the flaws as well as errors. As a result, you will get a higher quality of the products.

If you really want to boost up your production process with a 3D printer, you will also need the best UV curing Chamber to UV cure the resin-made model faster and efficiently. Follow the above-mentioned points to buy a suitable machine for your requirements.

Don’t worry about the budget as they will come under your budget. Another important thing is always prefer to buy the UV curing chamber for 3D printing from a reliable brand.