3d laser scanner china

- High-precision: 0.02mm

- High speed scanning: 2020000 measures/s,30 beams

- Depth of field: ±360mm

- 30 blue laser lines, 22 cross laser lines +7 parallel blue laser lines + 1 laser line

3d laser profile scanner

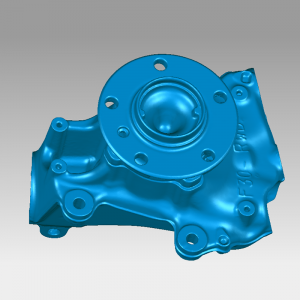

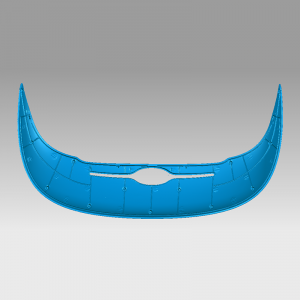

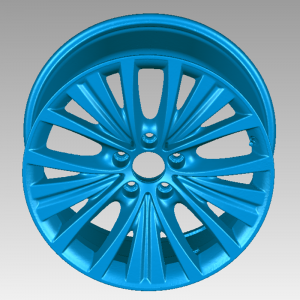

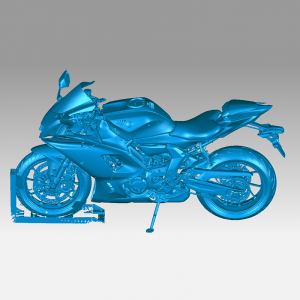

A 3D laser profile scanner measures the distance between the object and the scanner after projecting a laser beam onto an object’s surface. The scanner typically projects a laser light pattern onto the surface of the object using a laser line or dot projection technology. After being reflected back to the scanner, the light is then caught by a sensor, which calculates how long it takes the laser light to return.

The scanner may create a point cloud of the object’s surface by traveling around and taking several measurements. The surface of the object is represented by a collection of 3D points known as a point cloud, which can be used to model the thing digitally.

The accuracy and resolution of the scanner are dependent on a number of variables, including the laser strength, the sensor technology, and the distance between the scanner and the object. The scanner can be handheld or tripod-mounted. The final 3D model can be applied to many different tasks, including quality assurance, reverse engineering, inspection, and even 3D printing.

| Product model | T22+ |

| Scan mode | Handheld scanning |

| Scanning accuracy | 2020000 times |

| Volume accuracy | s 360mm, * positioning with the help of mark points |

| Space point distance | 0.2mm ~2mm |

| Single chip scanning range | 300x250mm |

| Depth of field | ±360mm |

| Scanning speed | 14 beams, 480000 points / S |

| Light source | Class II laser (eye safety) |

| Splicing mode | Feature stitching / mark point stitching |

| Texture scanning | support |

| Working center distance | 400mm |

| Special scanning object processing | Transparent, reflective, individual dark black objects can not be directly scanned, need to spray powder first. It is necessary to add shelter to avoid strong light interference |

| Outdoor operation | OBJ,STL,ASC,PLY,P3,3MF |

| data format | Support the output of direct 3D printing model |

| Printable data output | 1.13kg (including transmission line) |

| Scanning head weight | Win7, win8, win10, 64 bit |

| System support | Graphics card: NVIDIA gtx770 and above, video memory: > 4G, |

| Computer requirements | processor: i7 and above, Memory: 16g and above, port: high speed usb3.0 |

- High accuracy: Dreambot3D 3D laser scanners capture 3D models with a high degree of accuracy, making them valuable in a variety of fields like engineering, manufacturing, and architecture.

- User-friendly: The scanners are made to be simple to use, with straightforward software that enables quick and effective scanning.

- High speed: The 2.02 million points per second maximum point capture rate of Dreambot3D 3D laser scanners enables quick and precise scans.

- High-resolution scans: The scanners take detailed high-resolution scans that are important for measuring precisely and performing reverse engineering.

- Versatile: 3D laser scanners under the Dreambot3D brand may be used to scan a range of things, including complicated shapes, and can collect data without actually touching the object.

- Non-destructive: Since the scanners are non-contact devices, the item being scanned is not harmed, making them suitable for fragile or sensitive items.

- Dreambot3D 3D laser scanners may be used in a variety of settings and locales due to their portability and ease of transfer.

- Customizable: Dreambot3D provides customers with the opportunity to personalize their scanners to meet their own demands and specifications.

- Cost-effective: Because the Dreambot3D brand 3D laser scanners are reasonably priced, a larger range of consumers and industries can use them.

3D Laser Profile Scanner

We provide sample testing service, allowing you to check the working quality of our 3D scanner before placing an order

3D Laser Scarner Accurracy

A 3D laser scanner’s accuracy is influenced by a number of variables, such as the scanner’s type and quality, its proximity to the object being scanned, its size and complexity, and the environment in which the scan is being conducted.

High-end 3D laser scanners are typically able to record details with an accuracy of less than a millimeter, or “submillimeter” accuracy. However, accuracy may suffer as the object’s complexity or the distance between the scanner and the object grows.

It is significant to remember that the software utilized to handle the scan data can also have an impact on how accurate a 3D laser scanner is.

This 3D laser scanner has a small body but is equipped with strong capabilities. It is lightweight and portable. With its sophisticated anti-shake algorithms, even prolonged handheld operation is not taxing. The scanner can be directly powered by a power cord, in terms of power supply.

Data output during scanning is made possible by the real-time visualization function, and the scanning effect can be seen in real-time on a computer screen. Data that has been scanned is accurate and reliable, and it can instantly fill in any gaps.

Physical things can be converted into models by simply scanning them, simplifying the time-consuming modeling procedure and making it simple to collect 3D data of physical models.

The scanner includes a variety of scanning modes and functions, including single line laser mode, fine mode, and standard mode (which uses crossed blue laser lines in sets of seven) (suitable for scanning deep holes and dead ends). With the use of this scanner, measurement precision may be as high as 0.01mm, volume accuracy can be as high as 0.01-0.35mm/m, and a high-quality reproduction of the object’s geometry and surface features is possible. Repeated measurements of the same workpiece produce reliable, consistent data throughout time.

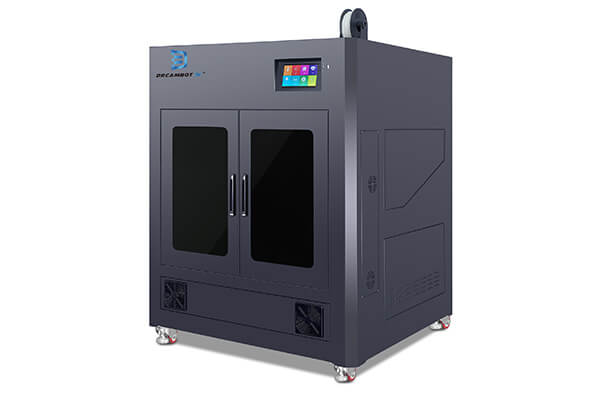

Dreambot3D 3D printers for your choice

L-800 FDM 3D Printer

The L-800 3D printer has a printing volume of 800*800*800mm suitable for industrial printing applications that involve heavy printing like aerospace, construction, etc.

DB-345 LCD 3D Printer

The 3D-345 3D printer has a printing volume of 345*195*335mm suitable for small printing applications like jewelry making, handicraft, personalized printing, etc.

DB-550 LCD 3D Printer

The DB-550 3D printer has a maximum printing volume of 527*296*550mm suitable for commercial and industrial printing options, like construction, advertising, robotics, etc.

3d laser scanner FAQ Guide

- Install any essential software on your computer or device before setting up the scanner. Also, make sure the scanner is properly charged. Verify the scanner’s accuracy and readiness for usage.

- Get ready the thing: Make sure the item you want to scan is clean and clear of any impediments or debris. If required, fix the item firmly in place to prevent it from moving while being scanned.

- Place the scanner in the proper position by holding it at the proper angle and distance from the object. For the ideal distance and angle, adhere to the manufacturer’s recommendations.

- Start your search: Once the scanner is on, move it around the object to get images from all directions. Make sure you adhere to the scanner’s scanning instructions. Examine the scan: After the scanning procedure is complete, you can examine the resultant 3D model on your computer or other device. Using editing software could be necessary to fix any errors or holes in the model. Scan is saved and exported: Export the 3D model in the selected file format, such as STL, OBJ, or PLY, and save it to your computer or other device. The model can subsequently be applied to a range of tasks, including 3D printing and visualization.

- The price of a 3D laser scanner can vary depending on several factors such as the brand, model, features, accuracy, speed, and versatility. Generally, 3D laser scanners can range from a few hundred dollars to tens of thousands of dollars.

- Handheld 3D laser scanners are generally less expensive than stationary 3D laser scanners. Handheld scanners can cost anywhere from a few hundred dollars to several thousand dollars, while stationary scanners can cost anywhere from several thousand dollars to tens of thousands of dollars.

- Some factors that can affect the price of a 3D laser scanner include the resolution of the scanner, the speed of scanning, the software that comes with it, the type of scanner (portable or stationary), and the level of accuracy needed for the specific application.

- It is important to research and compare different options to determine the best 3D laser scanner for your specific needs and budget.

A modern company called DreamBot3D sells inexpensive, high-quality 3D printers. The brand has expanded its capabilities with the acquisition of a reasonably priced 3D laser scanner, enabling users to easily produce precise and complex 3D models. Anybody wishing to advance their 3D printing should consider purchasing this scanner because of its amazing accuracy. You can easily and affordably bring your ideas to life with DreamBot3D.

- Laser beam emission: The scanner emits a laser beam that is directed towards the item to be scanned.

- Reflection detection: A sensor in the scanner detects the laser beam as it reflects off the object’s surface. It is timed how long it takes the laser beam to get from the scanner to the object and back.

- Triangulation: To calculate the distance between the scanner and the item, the scanner makes use of triangulation. This is accomplished by measuring the distance traveled by the laser beam to reach the target and return as well as the angle at which it intersected the sensor.

- Making a 3D model: The scanner builds a 3D representation of the item using the distance and angle readings. As it advances across the item, the scanner continues this process, gathering information that is utilized to create a more accurate 3D model.

- Data processing: The scanned information is transformed into a digital format for usage in a variety of applications, including 3D printing, virtual reality, and manufacturing quality control.

- Generate 3D models: A 3D laser scanner can take precise measurements of real-world things and locations, which may subsequently be used to produce 3D digital representations of such objects and environments. These models may be applied in a variety of contexts, including engineering, virtual reality, and product design.

- Reverse engineering: By taking precise measurements of the dimensions and forms of real-world things, a 3D laser scanner may be used to reverse engineer them. With this data, digital models of the things may be made, which can subsequently be edited or duplicated using 3D printing or other manufacturing techniques.

- Quality control: Throughout the production process, 3D laser scanners may be used to measure the characteristics and dimensions of items to make sure they adhere to the necessary requirements and quality standards.Preservation: For the goal of preservation and documentation, 3D laser scanners may be used to make digital models of historic or cultural relics, buildings, and other structures.

- Inspection and analysis: Defects, deviations, and other abnormalities in goods, constructions, and other structures can be found with 3D laser scanners. For inspection and analytical reasons, such as locating structural flaws or places in need of repair, this might be helpful.