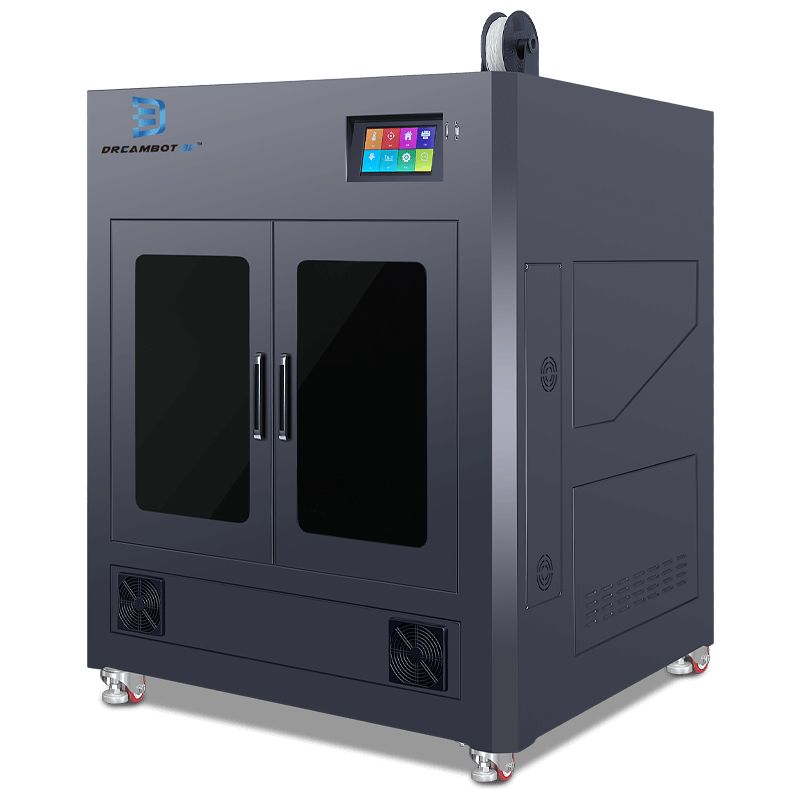

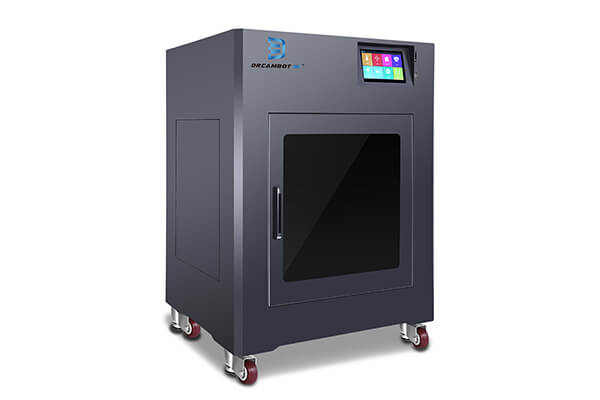

800x800x800mm 3D printer

L-800 FDM 3D Printer

- Using FDM process principle, it can support industrial-grade printing size up to 800x800x800mm. Its high precision can reach 0.05mm

- Industrial-grade FDM 3D printers are used in a variety of materials: PLA, ABS, PC, Nylon, Carbon Fiber, etc.

- Adopts PLC intelligent control and can print offline. Can continue printing after power failure

Dreambot3D 800x800x800mm 3D printer

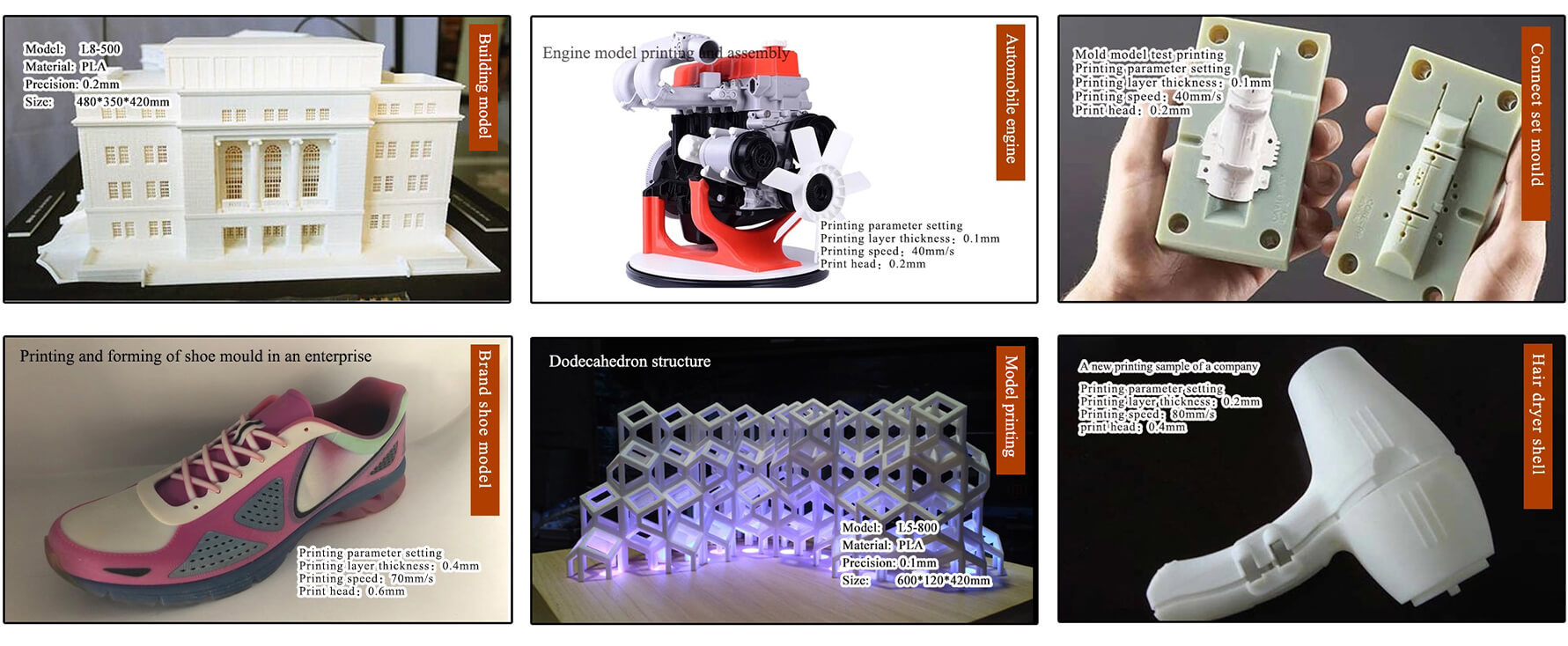

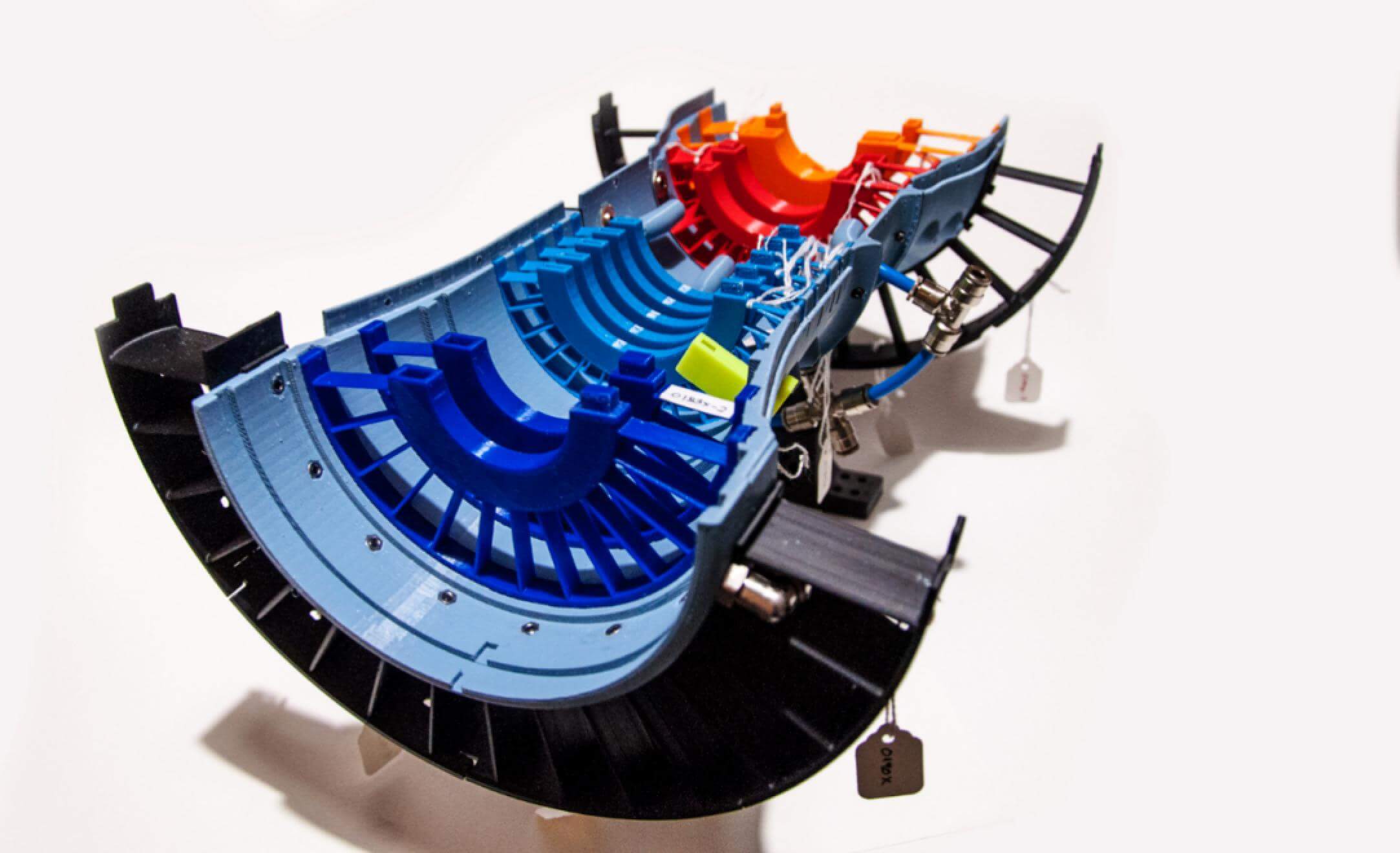

The Dreambot3D L-800 800x800x800mm 3D printer allows for prototyping of 3D products in these industries, automotive, architectural, medical,aerospace and some other industries that print heavy 3D objects.

With the large industrial L-800 800x800x800mm 3D printer, there are essentially no setup steps so large prototypes are significantly faster to print than making them in any other way.

The printing material that the Dreambot3D L-800 800x800x800mm 3D printers make use of such as the ABS, PLA, etc are easily obtainable.

Big 3D printers help you bring your large creations into original 3D objects. They are reliable for continuous business growth because they save time and cost of 3D printing.

| Technical parameters | Model | L5-800 |

| Max printing volume | 800x800x800MM | |

| Printing platform | The platform moves down when printing | |

| Technical principle | FDM fuse manufacturing technology | |

| Print head | High-precision extrusion system (double nozzles can be customized) | |

| Nozzle diameter | 0.2, 0.3, 0.4, 0.6, 0.8MM | |

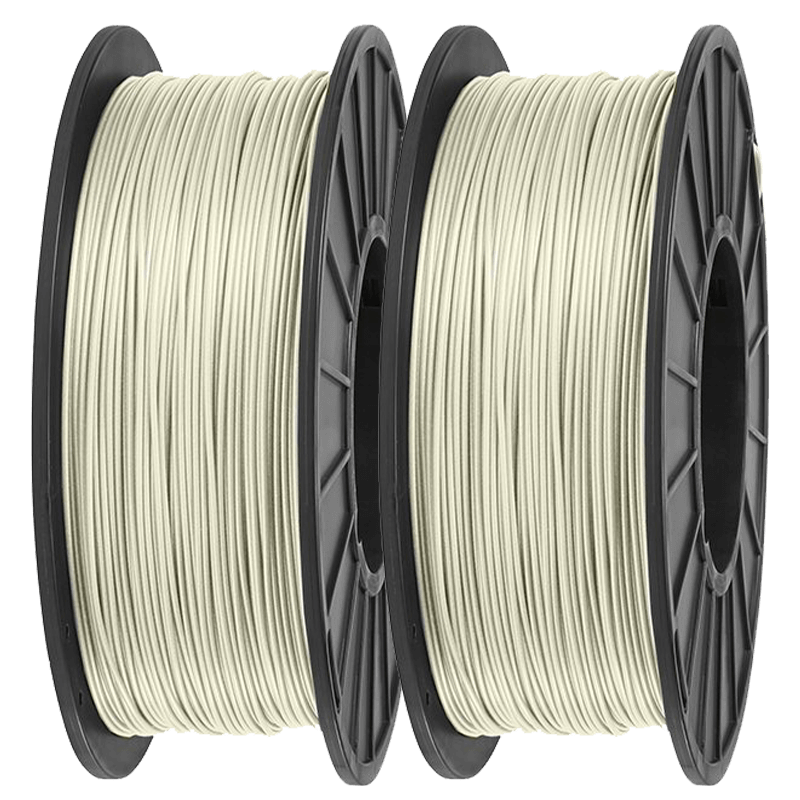

| Consumable diameter | 1.75MM | |

| Printing materials | PLA, TPU, 95A, water-soluble materials, wooden PLA; customizable ABS, PC, PETG, nylon, carbon fiber, metal filling materials, glass fiber addition materials, etc. (not available for 300 size machines) | |

| Positioning accuracy | X axis 0.0011, Y axis 0.0011, Z axis 0.00125MM | |

| Printing layer thickness | 0.05-0.3MM | |

| Printing speed | 20-150MM | |

| Printing platform | Heating aluminum substrate + black crystal glass platform | |

| Platform temperature | 30-50℃ (30-120℃ optional) | |

| Platform calibration | Automatic pre-calibration leveling | |

| Nozzle temperature | 75-280℃ | |

| Movement noise | 50 dB | |

| Connection method | U disk, SD card (both as a gift) | |

| Screen control | 7 inch full color touch screen (support all languages) | |

| Chassis structure | 3MM thick sheet metal, fully sealed chassis | |

| Filter function | 2 air filter devices | |

| Lighting | LED lighting | |

| Mechanical transmission | Double linkage gantry type machine tool linear navigation | |

| Physical parameters | Dimension | 118x109x132CM |

| Package Size | 123x115x147CM | |

| Net weight | 190KG | |

| Gross weight | 230KG |

- Dreambot3D L-800 800x800x800mm 3D printers boast of proper wire management, the control box sits under the machine to add stability and decrease its footprint, it makes it easier to put the printer together.

- The build volume of the large industrial 3D printer has a large print capacity of 400x400x400mm with a maximum of 1000x1000x1000mm. The large industrial 3D printer can be placed either on a desk or on an industrial grade.

- Our large 800x800x800mm 3D printer Ultimaker Cura software has been tested severally with different printing functionalities and materials. These softwares and materials ensure excellent printing results for large scale printing.

- Dreambot3D L-800 800x800x800mm 3D printer has an air filtration system that filters the odour that may be emitted during printing. The air filtration system ensures that the air is odourless and hygienic for you.

- The large industrial 3D printer has a glass door that helps to control airflow within the printer for better printing quality. It also allows you to observe the printing process.

- The big FDM printer prints 3D prototypes with multiple materials such as PLA, ABS, nylon, PC, TPU, PVA, etc. These materials can be easily gotten from 3D printer accessory stores.

Test your part

We provide sample testing service, allowing you to check the working quality of our 3D printer before placing an order

6 points why choose us

Automatic resume printing

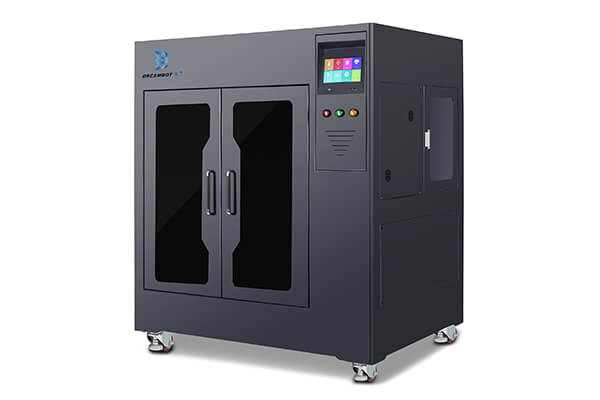

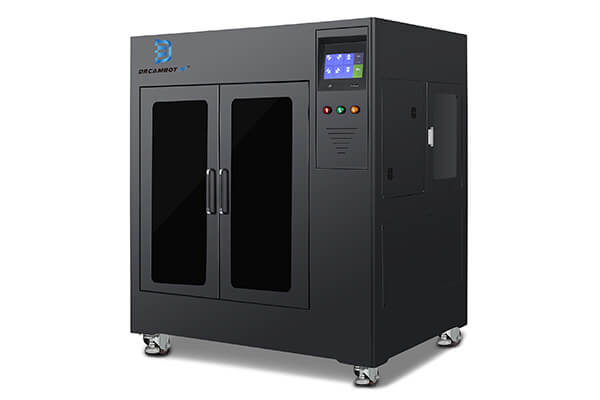

Full enclose stable frame

The whole machine case is thickened by CNC cutting, with accurate hole position, better assembly stability, and higher positioning accuracy of printer operation.

Allow offline printing

Use U disk or SD card to print without connecting to a computer to print. After starting to print, the data is automatically saved and the U disk or SD card can be removed.

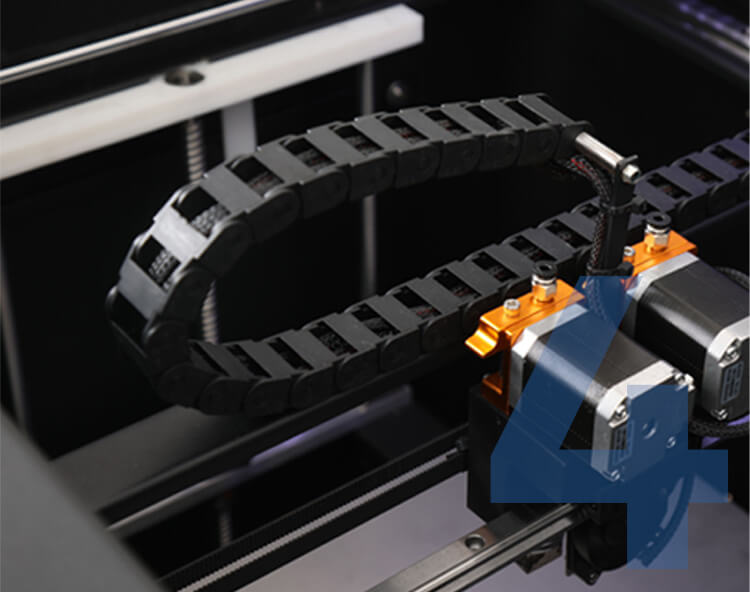

Drag chain wiring design

The wire is installed in the inner casing of the drag chain to effectively ensure that the wire will not be damaged for a long time when the printer moves at high speed.

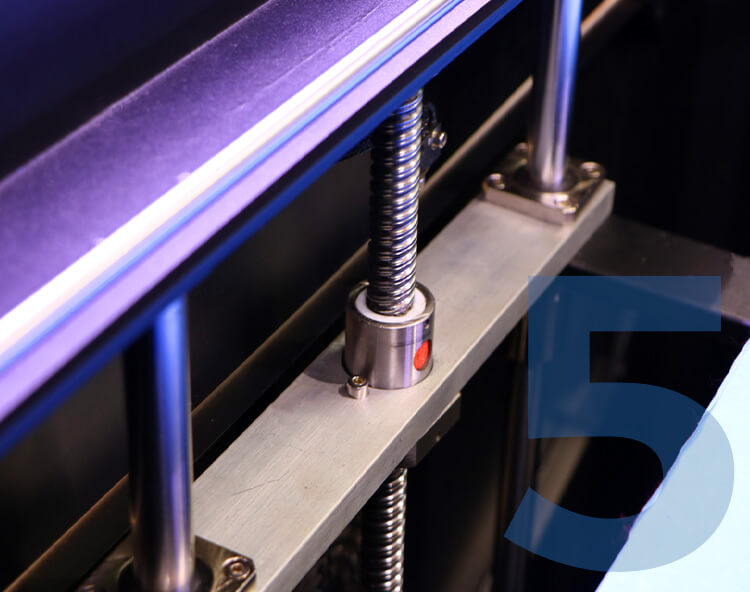

Precision ball screw

Using the latest Taiwan ball screw, it has higher straightness, lower friction coefficient, better smoothness, higher positioning accuracy and more stability during printing.

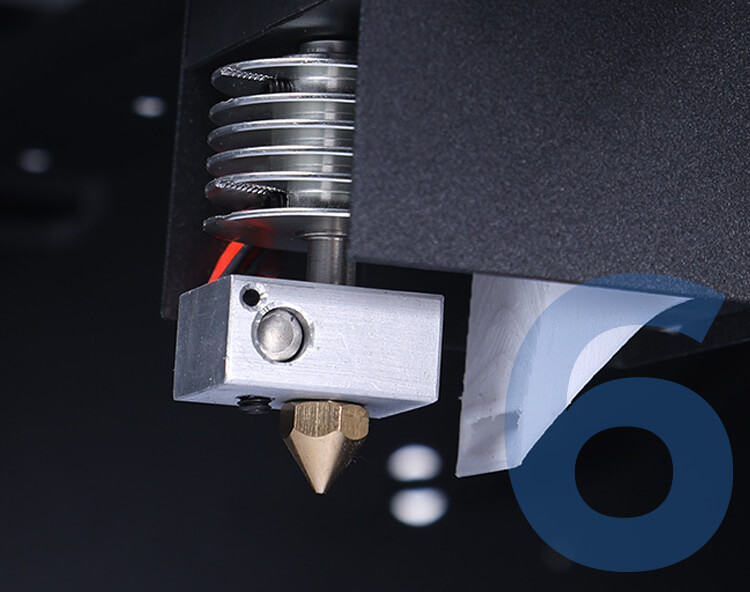

Alloy nozzle

Independently developed a unique bullet nozzle with uniform heating and a patented head assembly, so that it can work smoothly without interruption.

More FDM 3D printers

L-300 FDM 3D Printer

L-300 3D printer prints highly accurate 3D prototypes for all small businesses or new businesses that require 3D printing.

L-600 FDM 3D Printer

The L-600 3D printer is largely acceptable for both small and large scale printing. They can be used to particularly print 600x600x600mm size.

L-1000 FDM 3D Printer

The L-1000 is often used for large scale printing and requires printing larger 3D objects. This 3D printer can as well be used to print multiple prototypes.

Industrial FDM 3D Printer Buying Guide

FDM 3D Printer Introduction

There are multiple 3D printers in the market. Some optimised for industrial purposes while others are suitable for handling day to day task. In this buying guide, we would like to highlight all there is to know about the 800x800x800 3d printer.

Amongst all the other 3D printers in the market, the 800x800x800 3d printer is widely used for industrial manufacturing purposes. The unique printing style, speed and efficiency the machine possesses makes it a perfect fit for experts and professionals in multiple industries.

This buying guide is dedicated to helping you understand the buying process behind the 800x800x800 3d printer. Ranging from the printing principles behind the FDM 3D printer to the industries where its widely used, the advantages it brings to the production line and factors to keep in mind before buying, this buying cover it all.

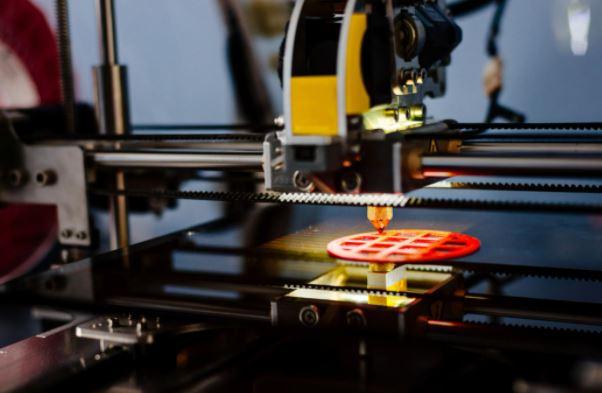

1.1, Principle of FDM 3D Printer

FDM 3D printers are machines with strips that keep the plate from moving while in transit. Most FDM 3D printers come with a small interactive screen that’s flexible to touch and bold enough to read. Before we formally dive into FDM 3D printers’ working principles, let’s look at some of its basic parts.

The Printer platform: an FDM 3D printer platform is made of either metal, ceramic or hard plastic, depending on the manufacturer and product purchased. This platform serves as a base for each successive layer.

Raw Material: while detailed info on the types of materials that can be printed on using an FMD 3D printer is detailed in the next section, it important you keep in mind that the raw material commonly used for FMD 3D printing is production-grade thermoplastics. Note that metals can also be used.

Printer Head: the FMD 3D printer head, also referred to as nozzle, is attached to a mechanical chassis. The nozzle is commonly controlled via a belt or leads screw system. The Printer head melts and extrude filament material and deposit an object layer-by-layer according to a CAD design.

Working Principle of FMD 3D Printers

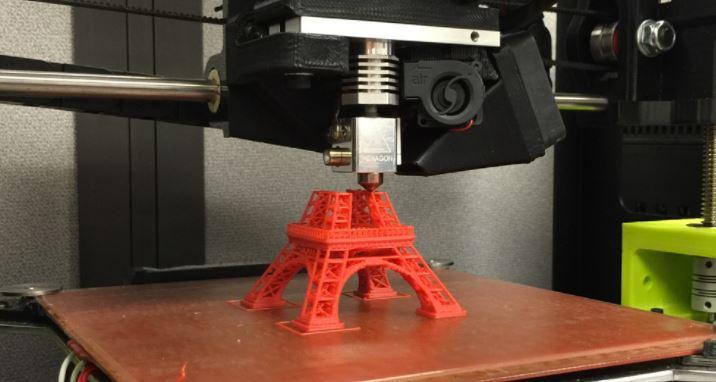

For an FDM machine to function properly, it requires a heated nozzle, a build platform, and raw material to build upon. The printing process begins after the modeling software slices the 3D CAD file creating an extrusion path for the nozzle to follow. All necessary support needed by the object is factored into the extrusion path, and the nozzle movement is controlled via the interactive interface found on the machine.

When the software successfully determines a suitable path for the nozzle, the filament is let loosed and fed through the heated nozzle. As soon as the raw material gets to the nozzle, it dissolves to a semi-liquid state and is forced out of the nozzle in the form of super fine beads. Immediately after the material leaves the nozzle, it hardens and bonds to the layer under it.

Using the FMD machine’s mechanical interface, you can lower the platform holding the material to about one-sixteenth of an inch, giving room for the nozzle to start working on the next layer. Note that to remove the object or model created from the platform, you have to either break them off or use a solution of detergent and water.

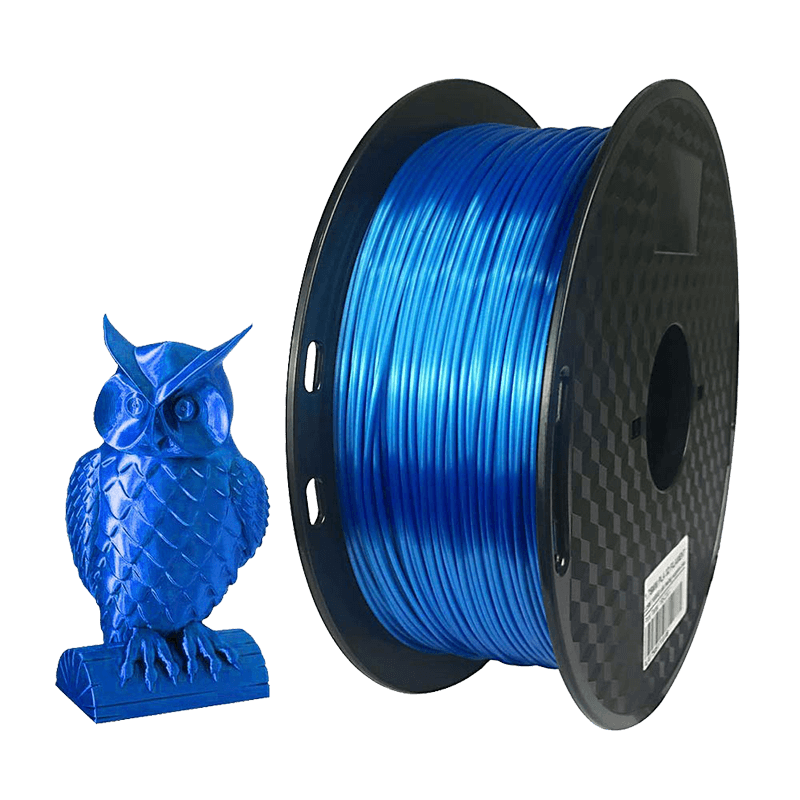

1.2, What Materials can be Printed by FDM 3D Printer

An FDM 3D printer can print several materials for industrial purposes, with each of them coming with unique strengths, weaknesses, and features. Because of that, each of these materials is great for printing different types of industrial additives. This chapter introduces you to some of the best materials for a professional 800x800x800 3d printer.

Nylon (Polyamide): Nylon is a synthetic, durable, flexible, corrosion-resistant, and low-friction thermoplastic used for making 3D printing filament. Nylon is suitable for creating objects with delicate and complex geometrical representations. It is one of the primary filament materials for FDM 3D printing because it’s easy to dye. However, nylon is hygroscopic and has a short shelf-life of 12 months. It also shrinks when cooling, resulting in less precise prints.

ABS (Acrylonitrile Butadiene Styrene): ABS is another popular thermoplastic for making 3D printer filament. It is excellent for manufacturer and engineering 3D printing and is suitable for using any 800x800x800 3d printer. The popularity of ABS emanates from its wide availability, mechanical strength, relatively long lifespan, and a wide variety of colors. However, ABS require heating of the printer bed, experiences warping due to its high melting point, and is non-biodegradable.

PLA (Polylactic Acid): PLA is a bioactive and biodegradable thermoplastic polyester made from corn starch and other natural, environmentally friendly materials. It is excellent for printing additive parts, prototypes, and other products. PLA filament makes it possible for a 3D printer to deposit materials more accurately, resulting in a fine surface.

It is available in many colors, is biodegradable, and allows improvement of strength through baking. Besides, the material works well with the fastest 800x800x800 3d printer with a lower printing temperature and minimal or no shrinkage. However, additive parts printed using PLA aren’t durable and can be affected with exposure to UV light. In addition, at 140°C, PLA tends to get warped or “cooked.”

PET (Polyethylene Terephthalate): PET is a thermoplastic polymer produced by combining two monomers for making various products, including clothes, bottles, and prototypes. It is mainly food-safe, flexible, moisture-resistant, tough, shock-resistant, paintable, recyclable, and capable of producing excellent, smooth layers. Unfortunately, even though PET is easy to use, it makes objects whose details are hard to notice. It also has medium heat resistance, limiting the number of application in which you can use it.

PETG (Polyethylene Terephthalate Glycol): PETG is slightly different from PET because of the addition of glycol, which is the “G” in its name. It is a modified material that’s inherently more durable and stronger than PET, making it great for use during large-format 3D printing.

It produces nice-looking, smooth layers while making food-safe, moisture-resistant objects. Since PETG has good stress and heat resistance, it is suitable for use in printing mechanical additives. Even though it shrinks less, the material can break down with exposure to UV rays and softens at only 170°F (80°C). It also tends to change color from the original translucent to semi-transparent during the printing process.

TPU (Thermoplastic Polyurethane): TPU is a rubber-like material for producing semi-flexible parts using some of the top industrial 3D printers. It is technically a block copolymer and polyurethane plastic with a structure featuring chain or soft and hard segments, giving it characteristic flexibility. TPU is flexible, abrasion-resistant, robust, semi-transparent, and wear-resistant. However, it can be challenging to use during printing, hard to glue together, and hard to use for 3D printing.

PC (Polycarbonate): PC is an ABS alternative with a carbonate-filled structure that makes it strong enough for use with a 800x800x800 3d printer in construction, aircraft, and medical applications. It is also a preferred material for fabricating electronic covers, glasses, and bottles. PC filaments use an FDM 3D printer relatively quickly and can be retardant, transparent, and sterilized. However, it is sensitive to UV light, requires high temperatures to print, and absorbs moisture.

ASA (Acrylonitrile Styrene Acrylate): The original purpose of creating ASA was to serve as an ABS alternative for making high-quality parts and additives. It is a strong, UV-resistant, and heat-resistant material, making it suitable for use with an Industrial FDM 3D printer for objects meant for outdoor use. ASA is a strong, UV-resistant, weather-resistant, stress-resistant, durable material that can be smoothened using acetone. A significant disadvantage of ASA is its propensity to yellowing when used outdoors. It is also mildly hygroscopic and requires high printing temperatures.

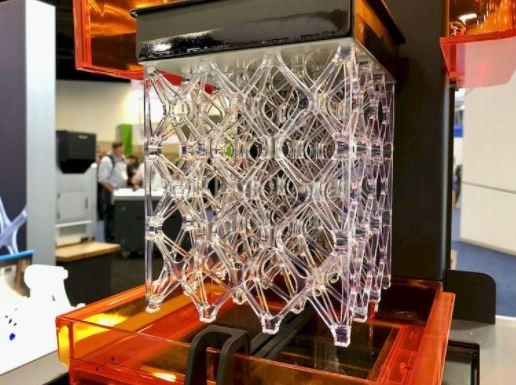

1.3, How Does FDM 3D Printer Develop from Desktop to Industrial Level

Most desktop 3D printers use the Fused Deposition Model, and they are similar to their industrial-level printers. They all use the extrusion technique, printing objects layer by layer, but their capabilities differ. FDM 3D desktop printers are cheap and easy to use by almost everyone for little prototypes. 800x800x800 3d printer, on the other hand, are huge 3d printers used for industries like R&D for the production of bigger and stronger prototypes.

Although 3d desktop printers can produce low-quality prototypes like the design for architecture classes, they are not suitable to handle high-grade materials, large format 3d Printing, and high precision requirements. To produce precise and quality parts for industries like aeronautics and automotive industries, you need industrial 3d printers, ranging from 400x400x400mm 3d printers to 1000x1000x1000mm 3d printers.

3D desktop printers use materials such as PLA and ABS because the printer head can comfortably extrude these materials at temperatures of about 220 to 280 degrees Celsius. However, if you are dealing with tougher materials like carbon, PC, and Nylon, it is advisable to use an Industrial 3d printer to handle the high extruding temperatures.

Also, a large industrial 3d printer has a greater production capability when compared to 3d desktop printers. This is because the industrial-grade 3d printer helps you complete your task faster, and they have a larger printing area which means the production of larger parts.

Application Field of FDM 3D Printer

FDM 3D printers are built to tackle different needs such as prototyping, design, and creating complex geometries. Before buying an Industrial 3d printer, it is essential first of all to know where and how it will be used; this will guide you in your decision.

Although all FDM printers work with the same principle, they differ when used in different industrial applications. However, FDM 3d printing is a fast and cost-effective remedy in all fields it is used in. Therefore, the application of these FDM 3d printing is increasing in different industries. The following are the different fields where FDM 3D printing technology is being utilized.

2.1, For Industrial R&D

FDM 3D printing technology has earned its respect for not only being used to produce gifts and toy prototypes or used just for a hobby. This technology has established itself as a strong force in producing strong, durable, functional products employed in end-use applications.

Research and development are essential aspects of any field, be it medicine, automotive, or aerospace. However, before any final product is produced, many prototypes are produced to understand and demystify the whole idea and concept. Hence prototypes help to move innovative products from ideas to marketable merchandise. Industrial 3D printing machines have helped lower the cost of making prototypes and speed up early-stage prototypes.

This FDM 3d printed prototypes can help you de-risk the possibilities of designs before a company commits considerable resources to these products. In addition, FDM 3D printers are fast, and they produce complex models that will be expensive or impossible when you are using the traditional subtractive methods.

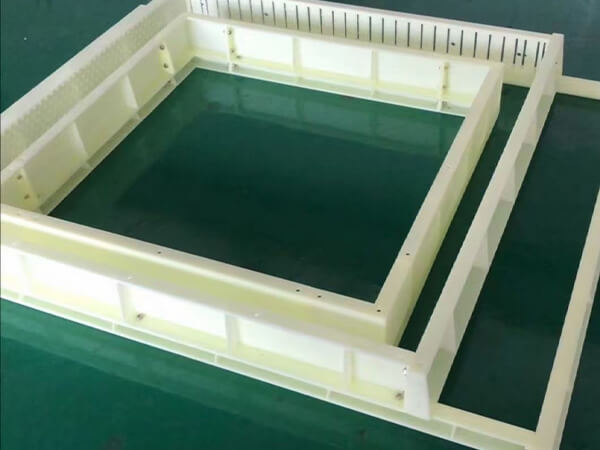

2.2, For Molds Making

Injection molding is an essential aspect of the manufacturing world of plastic products. Although the injection molding method was the most used before the emergence of FDM 3d printing, this method is time-consuming and expensive, especially when dealing with complex molding features.

The emergence of 3D Printing has made the process of mold making less expensive and time-consuming. Here are some of the benefits of using 800x800x800 3d printer for your mold making.

Not Limited By Mold Size: when using the traditional mold-making process, it is difficult to make changes once you have arrived at the final version. But with FDM 3d printers, you can make changes immediately you notice defects with the first batch of your printed mold.

All you need to do is make changes to your CAD, and your next mold will come out just the way you need it. You do not have to wait for weeks and months for adjustments or pay more money for changes to be done. You will get what you need without extra expenses that you did not budget for.

Manufacturing Cost Reduction: 3d Printing offers you the opportunity of manufacturing accurate molds, thereby reducing your expenses with regards to mistakes. Also, this method is cost-effective regarding materials, unlike the traditional means of production that produce a lot of scrap materials. Therefore, if you are using expensive materials, they will be utilized without waste.

3d Printing offers you a lot of flexibility regarding designs that have to change after production has begun. Therefore, you can easily change and adapt to the new designs without wasting time and resources.

Shorten Mold Production Cycle: if you are working with time and deadline, you need a machine that helps you deliver within the deadline. 3d Printing reduces the set-up time for mold making and quickly updates the existing design tools. The 800x800x800 3d printer is an example of a printer that prints faster, hence helping you reach your deadline.

This means that your business can frequently update and improve its mold design and outcome. This brings about more innovation at a faster rate, keeping in touch with the needs of the market and industry.

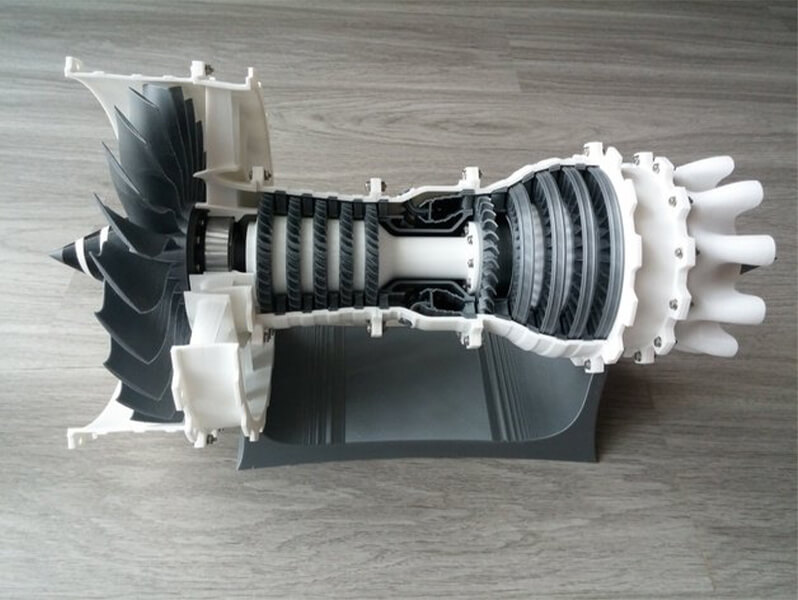

2.3, For Aerospace Printing

FDM 3D printing is a blessing to the aerospace industry because of its ability to manufacture intricate parts that are more lightweight and resilient than traditional techniques. 3d Printing helps to reduce the cost of buying metal parts for the production of titanium aircraft.

With the traditional method of producing aircraft, you might have to buy metal raw materials of between 12 to 25kg raw materials to produce a part of just 1kg. this means that a lot of the expensive raw material bought is wasted. With 3d Printing, you only use the necessary materials, thereby significantly reducing the waste of raw materials.

Making use of 3D-printed parts can reduce the operational costs of airlines. The production of lighter airplane parts has been made possible using 3d printing technology, and these parts are durable and strong. Reducing the overall weight of the plane leads to less fuel consumption, reducing the expenses of airline companies.

Large industrial 3D printers have made it possible to manufacture parts quickly; this means that airplane parts can be produced at the point of need. This solution takes away the difficulty of predicting the demand for spare parts. Printing parts at the point of need also eliminates the problem of having a physical inventory of parts.

With the variety and reliability of 3d printed materials, aircraft structural and complex engine components can be manufactured with ease. This means that these products are not only used for prototypes and design display; they are manufactured for end-use.

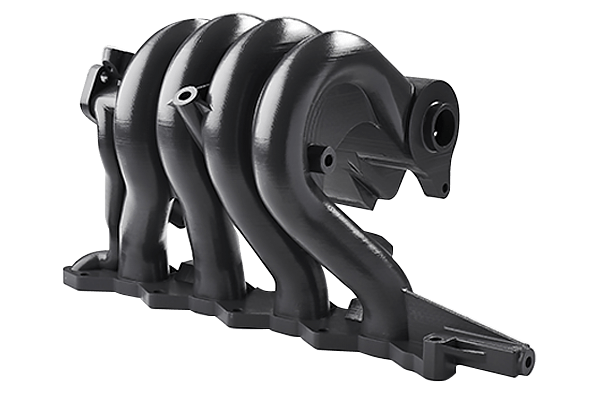

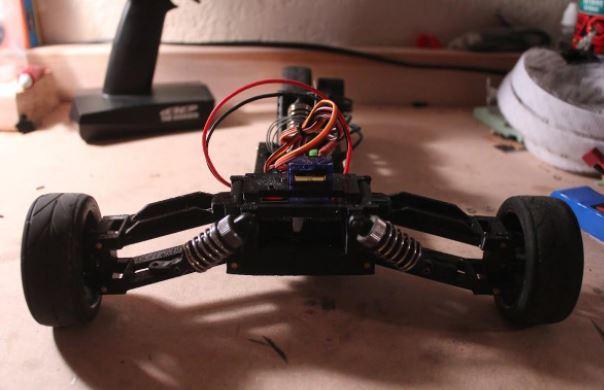

2.4, For Car Parts Printing

The automotive industry is one industry that has greatly benefited from the 3d printing industry. With the help of a professional FDM printer, many car parts have been designed, manufactured, re-designed according to various needs and requirements. This has helped in creating aesthetically appealing final car products.

The ability to print car parts on demand could save the automotive industry a reduction in production and storage costs. Furthermore, manufacturing complex internal structures can now be easily produced with industrial FDM 3D printers like 800x800x800 3d printer. This is proving to be more economical and less time-consuming.

Many complex car parts were time-consuming to fix and assemble; this has been made easier by single or two-part assemblies. In addition, 3d Printing produces lighter car parts and components; this reduction in the weight of the car enhances lower energy consumption and better performance.

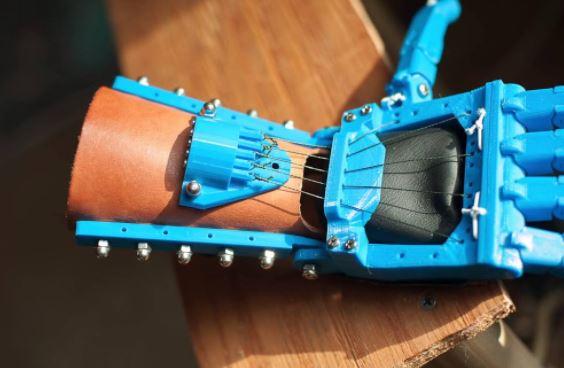

2.5, For Medical

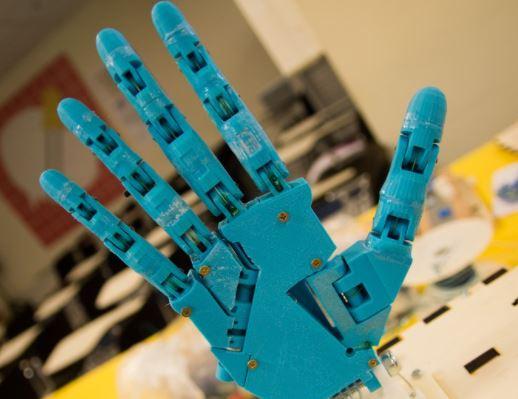

FDM 3d printing plays an essential role in the medical field and has aided medical research, tools, and processes. For example, 3d Printing has helped save lives in the medical field by developing medical devices and helping surgeons better understand health conditions through physical modeling of the internal organs. These are the following areas that 3d Printing is being used in the medical field.

Research And Learning: with 3d Printing, medical researchers are advancing the manufacturing of medical devices and implants. Surgeons are looking for better ways to repair broken bones by using custom-sized screws made from 3d technology. The materials used for these 3d products are biocompatible, which means that they naturally bind with the human cells.

Amputees who need prosthetic limbs do not have to wait for weeks and months to be attended to. 3d printing technology has sped up creating effective, comfortable, and cheaper prosthetic limbs for amputees. 3D Printing also helps to train medical students for actual future operations.

They provide visualization and models for the complex internal system and organs of the body. Therefore, medical students can easily practice with these printed organs, increasing their knowledge and skills for actual future occurrences.

Medical Equipment: lab and medical equipment can now be printed faster, easier, and cheaper with the help of FDM 3d printer technology. This means that hospitals do not have to wait for weeks and months to receive medical equipment and devices.

The high precision of industrial 3d printers like Dreambot3D3D 800x800x800 3d printer makes it easy to manufacture efficient medical tools that make the surgical process easier and more comfortable for surgeons.

2.6, For Various Models Making

FDM 3d printers can be used to produce concept models, display designs, and prototypes for many industries. The following are areas that rely on FDM 3d printing for making detailed and perfect outcomes.

2.6.1, Anime Figure

Anime figures are things we love, be it cartoons or movies. And our love for these figures springs from the distinctness and details of anime characters. So while the finished product might look enticing and exciting, creating anime figures requires a lot of precision, details, and flexibility.

Imagine if you have to produce the design, prototype manually, and the end product; it will surely be time-consuming, hectic, and expensive. FDM 3d printer makes this task less stressful and makes you yield a better result at a faster rate.

Creating anime figures requires you to develop creative ideas that you might want to apply as your work goes on. With 3d printers, you can change your initial design and prototype quickly without wasting resources and wasting time. In addition, with FDM 3d printing, you can work on the character details of each anime figure perfectly.

Also, with the variety of 3d machines and materials, you can create quality anime figures for your movies and cartoon at a minimal cost. You can produce your anime figures at a cheaper rate, faster, and with more quality materials. With the 800x800x800 3d printer, you can print in hours rather than days and weeks.

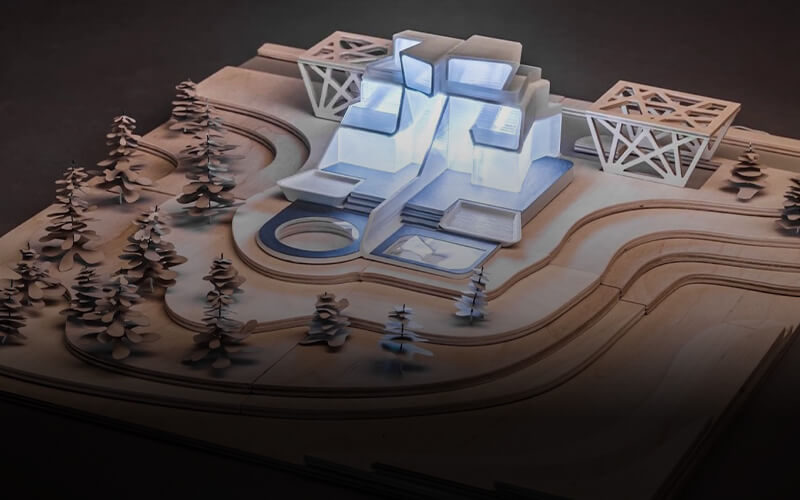

2.6.2, Architectural Models 3d Printer

Architecture is one field where satisfaction is gotten from what one can see and touch. If you are an architect working on a project, you can satisfy and impress your client by physically showing them what you intend to build. So, this is one field that uses a lot of prototypes to display designs before the end product is produced.

With 3d Printing, you can plan, create, and win more clients for yourself. The FDM 3D technology helps you create a scale model of the desired project, impress your client, and help you achieve your goal. There are two applications of 3d printing technology when it comes to architecture.

3d printers can help you create a low-cost architectural model, which can help as a study model during your creation process. Secondly, you can create detailed and realistic architectural models which you can use to promote a project by showing the final and expected outcome. This second use creates a striking model for your clients and the audience you wish to reach.

3d Printing enables you to produce architectural models that are low cost yet with high precision. A 800x800x800 3d printer can help you pay attention to details and achieve precision for an architectural model that is essential in convincing your clients.

The clarity and efficiency of 3d printed objects can help you notice any flaws in your architectural model, which you can easily make adjustments to. If you are looking for the right FDM 3d printer, you can check our catalog for any 3d printing machine price.

2.6.3, Mannequin

Mannequins are very important in the fashion world, helping designers to produce fashion pieces, and also advertising these fashion materials. Our top industrial 3d printer can produce both small and large mannequin models.

3d printers help you produce mannequins with precision, and this makes your mannequins represent your product the way you want rather than purchasing random mannequins in the market. Also, using the traditional production methods can take a lot of time because of the unavailability of printing materials.

With the availability of 3d printing machines and materials at a low cost, you can print as many mannequins as you want within a shorter time. Our mannequin FDM 3d printer is one of the fastest FDM 3d printers in the market. You can check out our catalog for the 800x800x800 3d printer or a specific printer that matches your need.

2.6.4, Gun

Printing guns with your 3d printer can raise legal and moral concerns, which is not allowed in some countries. In addition, while it is possible to print some gun parts, you still need some non-3d printed parts to complete the gun set-up. This makes it a little tricky if you aim to print and possess an unregistered firearm.

The FDM 3d printer does not create a complex functional gun in one piece. Instead, each component of the gun is printed separately and assembled. This process is complicated and can be time-consuming. But with the technological advancement of industrial 3d printing machines like 800x800x800 3d printer, this is changing.

Many 3d printing machine manufacturers are beginning to make FDM 3d printers that can manufacture gun parts like AK receivers, Glock frames, and pistols like a songbird, which were difficult to print in the past. However, printing these gun parts is expensive, and it cannot be achieved with cheap 3D printers.

Although the aim is to enable people to print these guns with cheaper FDM 3d printers and filaments, one will still need metal parts to complete guns like Glock frames and AK receivers.

2.6.5, Ship Models

Ships and their working mechanisms can sometimes appear complex to us. With 3d Printing, these complexities can be broken down to us through the Printing of ship models. Also, it has helped engineers come up with better and innovative technologies for the marine world.

We have witnessed simple boats, ships, and water vessels; the FDM 3d printing can help us come with models for the simplest boats to more complex ships and water vessels. In addition, you can 3d print ships as artifacts for your collection.

Engineers also use 3D ship printing to produce prototypes for research and development. Again, it is cost-effective, and it is an easy way to print complex ship designs faster.

2.7, For Cosplay Props Making

One of the advantages of 3d Printing is the helps it gives to detailing. With 3d Printing, you can easily print detailed models than if you were using the traditional methods. And one of the essential things in cosplay is the details attached to each character. So 3d printing has made it easier for cosplay fans to recreate and produce popular items from their favorite movies, shows, games, and more.

Most of these cosplay items involve making costumes to recreate specific characters. This means that your build volume will be significant because you are printing big pieces. To effectively print these large pieces, you will need an industrial printer because your small home printer might not accomplish this task perfectly.

While it is possible to make your props and costumes by hand, it is tasking and time-consuming, especially if you need to get the details right. Using an FDM 3d printer will reduce the time, energy and give you a detailed product that meets your desires. If you are interested in getting a 3d printer, you can check our catalog for an FDM printer price. Our 800x800x800 3d printer is one of those industrial printers which might help you easily print large volume costumes and cosplay products.

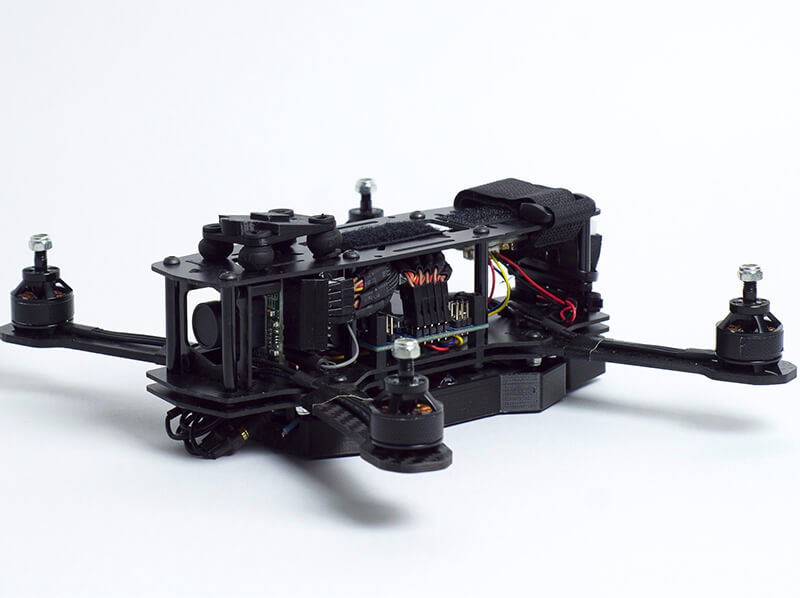

2.8, For Drone Manufacturing

Drones are a very fashionable tech item these days, and many people are getting more access to these items. Thanks to 3d Printing, getting a drone is a lot easier than it used to be. Also, if you have used a drone, we all know the accidents that we frequently make during our first attempts to fly these machines.

It is easy to lose parts from these accidents, and ordering new parts can be difficult and can take a lot of time and resources. With FDM 3d printing, you can print the different parts that you need for your drones. So apart from printing spare parts, you can design custom-made drones.

This means that you can add your design and concept and watch your imagination come to reality. The parts of the drone that you might not be able to print are the electronic, motor, and battery. You might have to purchase these parts. But you can print other parts and assemble them by yourself. The 800x800x800 3d printer creates lighter and effective parts at a faster rate.

Factors Affecting Efficiency of FDM 3D Printer in Manufacturing Industries

FDM 3D printers have been heavily adopted into various manufacturing because of their high efficiency. The materials used in industrial-grade 3D printers are easily available and are cheaper than conventional materials, making it easier to test new products or even develop finished products quicker.

Top industrial 3D printers are equipped with cooling fans to regulate the temperature from exceeding the set limit and use ventilators to contain the material in case it oozes, ensuring optimal safety during the manufacturing process. This has allowed its massive adoption into the manufacturing sector, especially for small-scale production factories.

Most 3D printing machine manufacturers place a 250x250x250 mm working area for large format 3d printing. Still, Dreambot3D3D L-800 FDM 3D printer is among one of the few large industrial printers capable of a printing size of up to 800x800x800 3d printer that have come to take over the manufacturing industry, and here are the main factors pushing the change.

Cost Reduction

Though traditional manufacturing machines cost a lot of money to design and install, they are capable of handling large volumes of products. Still, maintenance, repair, and overhaul can be pretty expensive for these machines. Making matters worse, if they experienced any sort of failure, it could hold up the manufacturing process resulting in unprecedented losses.

This is where industrial FDM printers step in. They are cheap to buy with the capability to handle metal powder and engineering-grade thermoplastics, so there is no excuse for the product’s quality. For traditional manufacturing properties, different workers were needed to operate different machines, or a production line was required to assemble the product.

800x800x800 3d printer require only one operator who initiates the printing process, and everything else is done by the computer and the printer. This has reduced the costs associated with labor either for the direct use of the machine or the design and building of the device.

Part consolidation

This is the best benefit of using a 3D printer. Part consolidation is the ability to integrate multiple parts into a single component. It reduces the number of parts needed simplifying both the maintenance and assembly process by reducing the time required. Complex products such as engines contain very many features that have to be interlocked for them to work; FDM 3D printers excel at such designs as long as everything is symmetrical.

Shorter lead time

According to a study report conducted by Sculpteo in 2018, 52% of manufacturers within the industrial goods sector are in favor of using 3D printing. FDM 3D printing does not require any tools. Once a manufacturer is done designing the product, they go directly to production, saving the time-consuming process of moving from design to finished product.

ArianeGroup, which produces rocket components, claims that they used a 3D printed injector head for the Ariane 6 launcher. Ariane designers say they reduced the injector head from 285 different parts that needed to be machined and welded together to a one-piece component that could be printed as a whole.

The process of creating an injector head would take up to three months, casting and machining the product but now it takes only 35 hours using an EOS M 400-4, which is short of 100 mm to reach the exclusive 800x800x800 3d printer club. Ariane Group also reported a 50% reduction in costs.

No limitation in geometrics

One of the most significant advantages of a 800x800x800 3d printer is its ability to print complex geometric shapes challenging for traditional machines without using expensive tooling equipment. Complex aeronautical components require precision to produce products of the same geometry as the design and are still durable and lightweight at the same time.

This allows aerospace component suppliers and manufacturers a cost-effective way of producing small batches of parts at a friendly cost.

Enhanced product development

Quality assurance is something that is vital for all manufacturing industries, which means before a product reaches the market, the design must be validated, tested, and approved. This happens during the product development stage, and the design is called a prototype or a model, and they are crucial in the research and development of new concepts.

FDM 3D printers have significantly increased the speed of producing prototypes by enabling the rapid production of components. By using 3D printing technology, product engineers and designers are capable of developing and testing multiple product iterations in a shorter time frame. The fastest FDM 3D printer should have a printing capacity of 800x800x800 3d printer should reduce the development time.

Mass customization

In the medical area and, to some extent, the automotive industry, the customer usually requires a personalized product tailored to specific requirements. Conventional machines produce components in huge volumes, making it difficult or expensive to get a customized product. Commercial FDM 3D printers are changing that too.

For example, in the dentistry sector, every patient requires personalized molds or braces for their teeth. With digital technologies finding themselves inside a dentist’s place, traditional processes are slowly being phased out. Dentists are combining intraoral scanning with 3D printing to produce products that match perfectly with a patient’s anatomy.

Faster-time-to-market

The ability to accelerate product development has directly affected the speed products reach consumers with. When products are available on time, everybody in the cycle is satisfied, from the consumer to the producer, and how 3D printers affect the speed of delivery of finished products.

Given the short time a 800x800x800 3d printer takes from designing a product to its finished state where they have passed the quality assurance test, manufacturers can definitely speed up their time to market. In 2015, PepsiCo produced several prototypes into the market to determine which product consumers mostly liked.

There are mostly positive factors affecting the use of FDM 3D printers in the manufacturing sector. The only limitation to using FDM 3D printers could be that they can’t handle large-scale designs. The bigger the design is, the higher the chance that the product will not print correctly because the printing material is too hot or solidifies quickly.

Main Components and Parts of FDM 3D Printer

Understanding FDM 3D printer components and parts ultimately result in printing objects of the highest quality. Undoubtedly, an FDM 3D printer has different parts that work together to give you better quality prints at the desired speed. In-depth knowledge of these parts is necessary for maintaining the 3D printer and giving it a longer life. It is also essential when it comes to upgrading and modifying the elements as required. This chapter discusses the different parts and components of an FDM 3D printer in greater detail.

Build Area/Volume

The build area/volume is the space occupied by the objects as the 3D printer prints them. Therefore, its description is volume, indicating the maximum printable size of a 3D object for that particular printer. For example, the Dreambot3D3D has a build area of 800x800x800mm, meaning that the main printable additive parts for this specific printer measure 800x800x800mm. The build area is measured in the x-y-z dimensions.

Motherboard/Mainboard/Control Board

The motherboard is the component responsible for maintaining the machine’s smooth operation. It is the 3Dprinter’s brain, directing the motion components based on the instructions it receives from a computer.

It also interprets sensor signals and translates them into the necessary actions. As such, an industrial-grade 3D printer would require a high-quality controller board to achieve the highest possible performance. A machine with the best parts but a flimsy motherboard wouldn’t function as well as expected.

Frame

The frame is essential for holding together all the other components of a 3D printer and maintaining the machine’s stability. It is, therefore, the primary determinant of a 3D printer’s durability. A good 800x800x800 3d printer requires a strong metal frame to hold its many components together. However, some 3D printing machine manufacturers use wood, acrylic, and other materials to make their printers. Therefore, choosing a machine with a stable metal frame is a must for anyone looking for a durable 3D printer.

Even so, a metal frame may significantly increase the FDM 3D printer price, putting it outside the affordable range. 3D printer frames can be open or closed, with the latter offering better results by maintaining a consistent temperature in the print space. However, there is a compromise, especially when it comes to printers with a semi-closed frame.

Print Filament

Every 800x800x800 3d printer requires a suitable filament, in the form of a spool with a string wound around it, to produce the object in question. Printing can only happen by slotting the spool into the machine. An FDM 3D printer heats and melts the material before depositing it onto the print bed or the object being printed. The printer deposits the material layer-by-layer as the object forms progressively. 3D printer filaments come in various material types like PLA, ABS, PETG, and nylon, with each having its advantages and disadvantages. That’s why it is essential to check that a commercial 3D printing machine is compatible with the types of material you intend to use.

Motion Controllers

They are called 3D printers because they work along the x, y, and z axes. After receiving instructions from the motherboard, the motion controllers make movements as they print the object in question. The following 3D printer components play an essential role in the activities any machine makes:

Belts: The motor has straps connected to it for making x-axis and y-axis movements from side to side. Since the belt movements affect the precision and print speed, they determine the quality of results one can get from an FDM 3D printer. When the belts sit tightly, they ensure the best possible results.

Stepper Motors: The purpose of the stepper motors is to enable all movements happening in the printer. A stepper driver controls their activities along the x, y, and z axes, and they drive the print bed, print head, and the lead screws while making rotations in steps. That’s the reason for the name”stepper motors.”

Threaded Rods: Connected to the stepper motors are threaded rods to enable the print head to move upward or downward. Several top industrial 3D printers may have the movements of their prints beds relying on the threaded rods. Therefore, most movements along the z-axis depend on the threaded rods. In some printers, movements along the x-axis and y-axis also depend on these rods. However, since they are too expensive, a majority of 3D printers use belts.

End Stops: End stops make it possible to mark endpoints along the three axes while the various components move. Their work is to identify each component’s range of movement.

Print Bed

A print bed is a flat surface on which objects sit while they are created. The extruder nozzle deposits the molten filament onto the print bed layer-by-layer until it finishes building the entire additive part. It is one of the most significant 3D printer parts, determining the surface finish and quality of the final object.

Depending on the preferred filament material, a 3D printer might have a heated or non-heated printer bed. For example, PLA filament works best on a non-heated bed, while other materials need a heated one. Heating is essential for maintaining the stability and adhesion of the first layer of the object being printed.

Prints beds might feature different materials depending on the needs of the 3D printing machine manufacturers. The most common materials are aluminum and glass. While an aluminum printer bed would heat up faster, one made from glass is flatter, providing a better finish and is easy to maintain. With an aluminum print bed, the industrial 3D printer cost can be way too high. Some printer beds have automatic calibration, while others require manual manipulation to work correctly.

Power Supply Unit (PSU)

The power supply unit (from its name) supplies power to all parts of a 800x800x800 3d printer to ensure the smoothest possible operation. It could be attached to the frame or sit separately together with the controller box. In the best 3D printer for industrial design, the power supply is so compact that it doesn’t interfere with the machine’s overall design. The strength of a PSU determines just how much heat a 3D printer can produce and, therefore, the material it can use. To print using high-end materials, one must select a printer with the highest temperature range.

Extruder/Print Head

The extruder is the 3D printer that extrudes molten filament, depositing it on the print bed. A print head is made up of the cold end and the hot end. The cold end locks the filament and gradually pushes it towards the hot end. In turn, the hot end has a nozzle that heats the filament by maintaining a temperature higher than the material’s melting point. After melting the filament, the hot end deposits it on the print bed layer-by-layer until the object is formed. The following are the different parts that combine to make up the print head:

Filament Drive Gear/Extruder Drive Gear: This part pushes the filament from the cold end to the hot end.

Heat Sink: The heat sink works with the heat sink fan to keep the material solid until it gets into the nozzle.

Thermocouple: The thermocouple is a temperature sensor that makes it possible for the extruder to maintain the temperature at the right level. It is situated in the hot end part of the printer head.

Heater Cartridge: This is the part of the extruder that heats the filament, melting it.

Nozzle: The tip of the extruder that releases the melted filament to the print bed. Every 800x800x800 3d printer comes with its nozzle size, even though the most common is 0.4mm. The size determines the quality of the printed object you get from a 3D printer. While a smaller nozzle produces finer details, the larger ones print quickly but with relatively poor results.

Cooling Fan: The deposited melted filament needs cooling down for setting before another layer is deposited. Thus, the cooling fan kicks in to ensure that happens and fast.

A typical 800x800x800 3d printer has one extruder, even though some come with two of them. The advantage of a dual extruder is how it enables simultaneously printing using two different filaments. For example, dual extruders might be attached to one print head or work using two distinct print heads.

Feeder System

The top industrial 3D printers use two major feeder systems – the Bowden and direct feeder systems. With the Bowden feeder system, the cold end and hot end are located in two different locations. Therefore, it has a filament tube that directs the filament to the hot end, increasing the print speed more dramatically because it makes the extruder lighter. On the other hand, the direct feeder system has the cold and hot-ends connected directly. That is common in printers that rely on flexible filaments.

Connectivity

Every professional FDM printer provides several connectivity options, including a USB port, Wi-Fi, and so on. Thus, it can connect to a computer via a simple USB cable, Ethernet, or through a Wi-Fi network. In addition, with Wi-Fi, it is possible to connect the printer to a laptop, tablet, or smartphone. The purpose of all of these connectivity options is to transfer the 3D design file to the printer for eventual printing. Besides, some printers have slots for SD cards to transfer files without using any other device.

User Interface

It is hard to find a large industrial 3D printer that doesn’t have an LCD user interface. The LCD screen controls the printer settings without the need for an additional device (such as a computer). That’s what enables a 800x800x800 3d printer to work independently using files from a simple SD card. In addition, one can use the interface to check the printer parameters and initiate the filament loading and unloading. The small screen is also valuable for initializing the auto-leveling system before and during the printing process.

How to Choose a Suitable FDM 3D Printer for Your Industry

We have stated earlier on how FDM 3d printing machines can be used in different industries and the many benefits they possess. Therefore, before buying any machine, it is advisable to consider what you intend to do and which 3d printer will be best to help you achieve your aim.

Some FDM 3d printing machines are best suited for some tasks than others, and before you invest your resources, there are many things you need to consider before you purchase a 3D printer. We will look at some of the essential things to watch out for when selecting a 3d printer for your industry.

5.1, Your Application Industry

Your application field is an essential element to consider before buying any FDM 3d printer. It could be a professional field, or it could be for hobby purposes. Your application industry will determine the size of the printer, the speed, and the type of filament materials to purchase. For example, the 800x800x800 3d printer is an industrial-grade printer that helps you print your industrial objects.

If you aim to use FDM 3d printing to produce little objects like toys, little models for things like planes, ships, and cars, you will go for the machines that suit your need. If, on the other hand, you hope to produce large objects like parts for automotive, ships, airplanes, and medical equipment, you will go for large industrial FDM 3d printers that will best suit your needs.

You are using FDM 3d printing to achieve your aim in both cases, but you are reaching out to different audiences and expectations. You can take a look at our catalog to help you pick the best 3d printer, and if you are not sure of your choice, you can reach out to us through our contact.

5.2, Print Size Requirements

An FDM 3d printing machine for toys would differ in size from the printer for industrial products like medical equipment parts and spare parts for the automotive and aerospace industry. If you are printing bigger objects, you need a bigger 3d printer to help you print easily. A machine like Dreambot3D’s 800x800x800 3d printer will be best for printing large and industrial-grade objects.

If you use a smaller machine to print more significant objects, you might need to print them in parts and then assemble them, which might take more time and energy. For effective FDM 3d printing, it is necessary to be aware of the unit of measure for your CAD file. This file will determine how small or big your print size is going to be.

Also, the weight and size of your printed object will determine which FDM 3d printer to use. Different filament materials will produce different results on the size, weight, and dimension of the object printed, regardless of whether you used the same CAD file for both filament materials.

5.3, Printing Material Requirements

If you have been paying attention, you will know that your industry will determine the type of filament material you need. We use FDM 3d printing because of its efficiency, attention to detail, and the ability to recreate designs and models with metal and thermoplastic materials.

This is not a case where one shoe fits all. The different filament materials are best suited for different industries. You can use PLA for toys, display designs, and models, and it will be perfect. But you cannot use the same material for printing automotive parts and things like glass shields. Some filaments are more durable and stronger than others, so to get the best result, it would be essential to know what materials best suit the object you wish to manufacture. The 800x800x800 3d printer is compatible with many filament materials.

FDM 3D Printer Buying Guide

Your first printer will be determined by the type of projects you intend to use it for; of course, no one is ever satisfied with less, and you want the best printer on the market that will offer you as many functions and unique possibilities as possible. Still, such a printer doesn’t come cheap. Choosing the right FDM 3D printer isn’t easy if you have no prior knowledge, but through this guide, we will help you become a pro in no time, even when using an all-purpose industrial 800x800x800 3d printer.

And that is why you’ll have to be very selective when choosing a printer. Do you want a vast 3D printer or a small one? Is it for personal use, educational, hobby, or professional use? Everything will be a lot easier once you narrow down your choices. Let’s go through a few factors that will help you when buying your first 3D printer.

6.1 Check the Brand Reputation

Are you looking to buy the fastest FDM 3D printer? Why not buy the best there is? The best advice we can offer is: First narrow down your choices and make a shortlist of the printers that you find to suit your needs, then read up about them online, you’ll find this information to be of great importance when it’s time to shop.

Once you’re familiar with the models, you can visit the shop to see the live demos for yourself and get expert advice from people who understand 3D printers inside out. Like Dreambot3D’s 800x800x800 3d printer technology is among the best, having passed several quality assurance tests.

6.2 Safety Configurations of the Machine

Proper and frequent maintenance of every manufacturing equipment is very vital to keep the machine running smoothly. Still, sad to say, people tend to ignore these instructions, and that is why most appliances do not last long before troubleshooting.

Before you get going, it’s best to always have a tool kit at arm’s reach, spare some time to check your machine and its prime components, check all the electrical cables and connectors for any damage, and make sure they are firmly connected. Simple polishing, dusting, and lubricating your linear rods can go a long way.

6.3 Resolution Requirements of the Machine

3D printer owners and designers all want one thing: to achieve the top-most results. To get quality printed parts, you’ll need to understand 3D printing resolution, or else it will affect your printed part or model. So, how do you know if a 3D printer has a high resolution? There’s more than one answer to this question. 3D printers generate parts in 3 dimensions, so you’ll have to consider at least two factors: the XY plane feature and the Z-axis resolution (layer diameter and height).

Most importantly, you’ll have to consider the XY resolution; the Z-axis resolution can be easily determined. More or less, you should pick a printer that doesn’t favor one side but performs well on both sides. A 800x800x800 3d printer is guaranteed to print out models with the highest resolution given their high precision margins.

6.4 Consider whether the Price of the Machine is acceptable

FDM Printer price will depend on your needs. Is it for professional use, industrial use, or just a hobby? There are tons of printers, and all vary depending on size, quality, performance, or durability, and the printer should fit your requirements. What is the printer for? How often will you be using the printer, and who can use it? You will want to ask yourself these questions before you go shopping.

Most hobbyist 3D printers are cheap and can buy one for as little as $200 – $500. While some, like the professional 3D printers, are a little more expensive and range between $1,500 and $6000. Lastly, the industrial 3D printer costs more than the hobbyist and professional 3D printers and is not easy to operate without the required knowledge, and they range anywhere from $20,000 to $100,000. With that said, if you want the printer for industrial use, go for the super large L-800 FDM 800x800x800 3d printer.

6.5 Consider the Supplier’s After-Sales Service Capability

Checking out potential 3D printer manufacturers in advance can be a smart move to make. It would be best if you approached it strategically to make the right move. Ask around for testimonials from previous clients and read the reviews. In addition, you may ask friends for their honest opinion and thoughts about a specific 3D printer supplier.

With hundreds of companies offering 3D printing services, it can be hard to find the right service provider to fit your needs, whether you’re buying it for the first or the tenth time. You’ll still have to consider their customer service before and after you’ve purchased your printer.

6.6 Go for Flexibility

Every day more good 3D printers are manufactured, making it less easy to choose. Think of your level of skills, and if you’re a beginner, you will need a 3D printer that is flexible, easy to adapt regardless of the size of the printer. A user-friendly 3D printer will allow you to begin production sooner.

Look for a manufacturer that will assist you with a program, training, or video-assisted guide to make your training short. For example, the L-800 800x800x800 3d printer manufactured by Dreambot3D has a great support feature and comes with a detailed user manual that covers the most frequently asked questions.

6.7 Pay Attention to Details

So, you’ve finally decided to buy a 3D printer after learning about the unique possibilities it has to offer. In this segment, we will highlight a few details you should pay attention to when buying a 3D printer of your own. Before purchasing your first printer, think of the most significant object you would want to print and buy one with a large build volume. It will determine the maximum size of the height, width, and length.

Getting the right building platform is very crucial, quickly explained; it is the base where your print begins setting up. There are many heating beds on the market but what mainly differentiates them is whether they are heated or not. A heated bed improves the quality.

The printer software is beneficial, but fewer people pay attention, which is very wrong to think you’ll do fine without. You can buy a device with plug & play versions; everything else will make more sense from the beginning. The smallest of details do matter.

6.8 Put Safety First

Is 3D printing safe? Just like many machines, it’s safe using one as long as you take precautions. If you’re buying a 3D printer either for your home or just business, always ensure you have installed proper internal and external ventilation in your house or shop, and understand all the risks first. External ventilation is as vital as internal ventilation; external ventilation sucks out all the emissions from the heated filaments out (hazardous air), replacing the air inside with fresh and cool air.

The fact that there are hazards related when using a printer means you need to read up on 3D printers before you buy one, and don’t use the printer anywhere in your house, set aside a specific room for 3D printing use. The L-800 800x800x800 3d printer looks like a safe enclosing the printed process and protecting you from toxic fumes emitted during the printing process.

6.9 Select the most Cost-effective

The cost of 3D printed models is often determined by the material used in printing and manufacturing time. First, consider your budget because 3D printers are readily available from $200, do not go for an industrial printer if it’s for home use.

Which material you want to print with is also an essential factor to consider. Often these materials will cost more due to their physical, chemical, and mechanical properties. Suppose you’re looking for the easiest and less expensive printer. In that case, I’d suggest FDM printers because of their plastic filaments, which are easy to process and cheaper when compared to other materials.

6.10 Why is Dreambot3D’s FDM 3D Printer So Prominent?

Dreambot3D is a 3D technology company which is specialized in the production of high-quality 3D printers like the L-800 3d printer for all different applications. There are several reasons why our FDM 3D printer stands out from many printers:

- In the event of unforeseen power failure while still printing, Dreambot3D’s printer is designed with a memory module that saves all the printing data so you can continue printing once power is restored.

- The printer allows offline printing with the use of an SD card; if you don’t want to connect to your PC, all your data will be automatically saved even after you’ve removed your SD card.

- The whole 3D printer is fully enclosed by CNC cutting, with precise hole settings and top positioning precision of printer operation.

With over 12 years of experience in the 3D printing industry, we can assure you prints produced by our 3D printers are highly accurate. Not to forget affordable printing materials, either for medical use, architecture, or aerospace, etc.

FAQ Guide

How do FDM 3d printers work?

Fused deposition Modelling {FDM} printers or Fused Filament Fabrication {FFF} printers {as they were formally known till the FDM term was trademarked by Stratasys in 1991; the company behinds its first design} are machines built to deposit melted material in a pre-determined path layer-by-layer selectively.

Fused Deposition Modelling {FDM} printers are 3D printing machines that create images one at a time. FDM printing process revolves around a three-dimensional output. Each layer of the material you are printing is placed on top of another again and again till a finished product is acquired.

The printing process begins after the modeling software slices the 3D CAD file creating an extrusion path for the nozzle to follow. All necessary support needed by the object is factored into the extrusion path, and the nozzle movement is controlled via the interactive interface found on the machine.

What are the benefits of additive manufacturing?

Additive manufacturing simplifies the printing process to an extent where even the average joey can enjoy an out of the box printing experience. Additive manufacturing aids users in printing assemblies as a single piece. That’s you get to save money from every printing process.

Additive manufacturing also gives users the opportunity of printing multiple movable parts as a single piece. Compared to other conventional manufacturing processes, additive manufacturing helps you enjoy a simplified yet highly accurate printing process.

How can 3d printing be used in manufacturing?

The manufacturing industry revolves around product prototyping and design. With an FDM 3D printer, experts in the manufacturing industry can simplify the complex syntax and operations attributed to the process.

By using a 3D printer and adding material layer by layers, such as plastics and metals, complex objects can be produced both rapidly and at low cost, in short runs, or as one-of-a-kind parts.

What does FDM printer mean?

FDM means Fused deposition modeling. FDM is regarded as a 3D printing technology often used to print 3D models and patterns. FDM machines can be found in almost every industry. The 3D printers are renowned for their ability to create 3D models of high quality with high accuracy and durability at cost-efficient rates.

What is the largest 3d printer available?

The largest 3D printer available is the 1000x1000x1000 3D printer. However, due to the durability and efficiency it provides its quite expensive. if you are looking for a cost efficient option for you production line, we recommend you check out Dreambot3Ds 800x800x800 3D printer.

How big can a 3d printer print?

The actual build area of the largest 3D printers is 1000 millimeters long by 1000 millimeters deep by 1000 millimeters high. On the 800x800x800 3D printer, the specified maximum print size is 800 millimeters long by 800 millimeters deep by 800 millimeters high for a single extruder

What is the standard for 3d printing units?

On Dreambot3Ds 3D printers, the default measure unit set is the millimeters, but you can choose, before you upload your file, between Millimeters, Centimeters and Inches as unit of measure for your 3D print.

Be careful however because if you designed your model in centimeters in your CAD software, when you’ll upload it on Dreambot3D and choose millimeters, your object’s unit of measure will be changed.

Can 3d printers be used for mass production?

Yes, 3D printers can be used for mass production. The 800x800x800 3D printers are already making wave in multiple industries due to its ability to help create accurate designs within a short period of time.

What is the strongest plastic for 3d printing?

Polycarbonate is the undisputed king of materials for desktop 3D printing. Even we were surprised at polycarbonate’s strength. In comparison to nylon at 7,000 psi, polycarbonate’s tensile strength of 9,800 psi makes it the ideal choice for high-strength, functional components.

How much does it cost to 3d print a car?

The price of 3D printing a car varies based on the the type of 3D printer you are making use of, the material and the expert professional carrying out the printing task. However, the LSEV. An electric car was 3D printed for about $7,500 back in 2017.

What is 3d printing examples?

3D printers can be used to print anything and everything. Some of the items that area regularly 3D printed include Prosthetic Limbs & Body Parts, Homes and Buildings, Firearms & Military equipment, Musical Instruments etc.

Is 3d printing going to change the world?

Yes, from how doctors attend to patients to how manufactures design and create a product, 3D printers are revolutionising everything. It’s okay to say 3D printers are already changing the world.

Is PLA cancerous?

Nope, PLA is not cancerous. However, the potent mix of chemicals and heat used when printing and processing PLA pose a health danger. In addition, the coloring in PLA signifies the presence of an additive that is not food safe. Another concern is that PLA 3D printed materials have tiny holes and cracks that can accommodate harmful germs and bacteria

Does 3d printing have a future?

3D printing is already dominating most production lines. With the huge number of experts and professionals relying on the efficiency of the machine, it’s safe to say that 3D printers are no more machines of the future, they are instead, machines of the now.

Conclusion: Why our FDM 3D Printer is the Best Choices

Finally, we are at the point where you have to make the big decision. As we said earlier, we’ve highlighted all there is to know about 800x800x800 3D printers, now it’s up to you to make up your mind regarding your buying decision.

But before we say the final goodbyes, it’s important we introduce our catalog. Dreambot3D is a 3D printer manufacturer catering to the individual and industrial needs of hobbyist and experts making use of 3D printers in their production line.