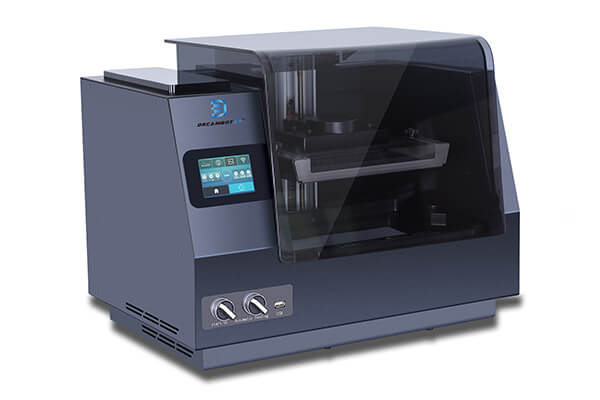

castable resin 3D printer

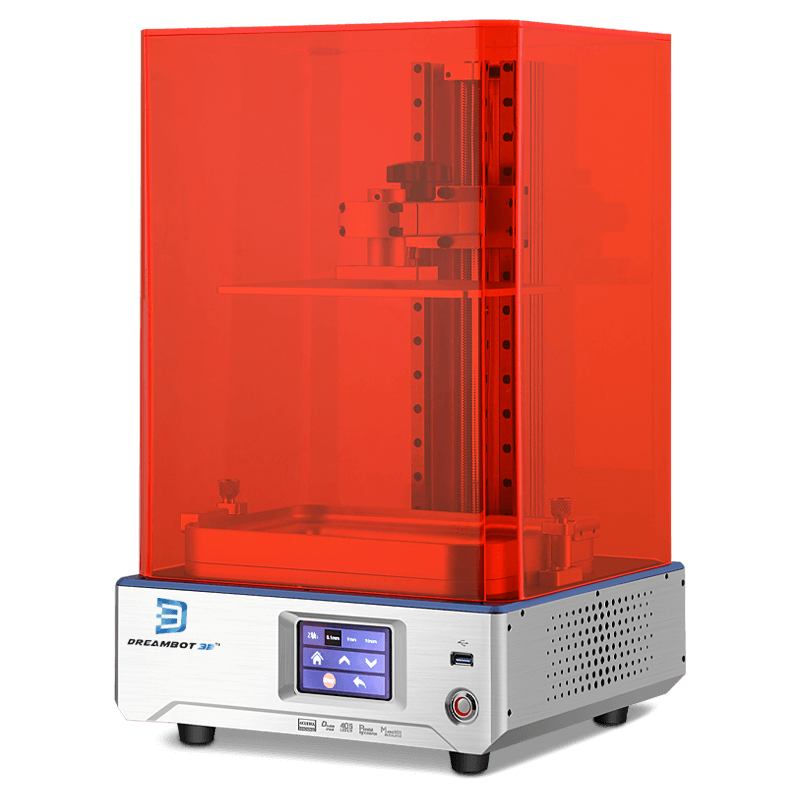

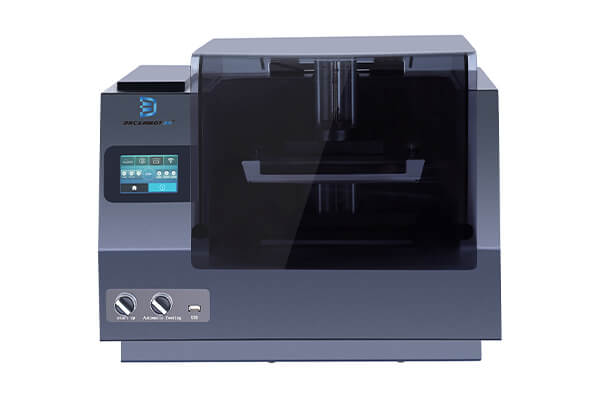

ME-192 LCD 3D Printer

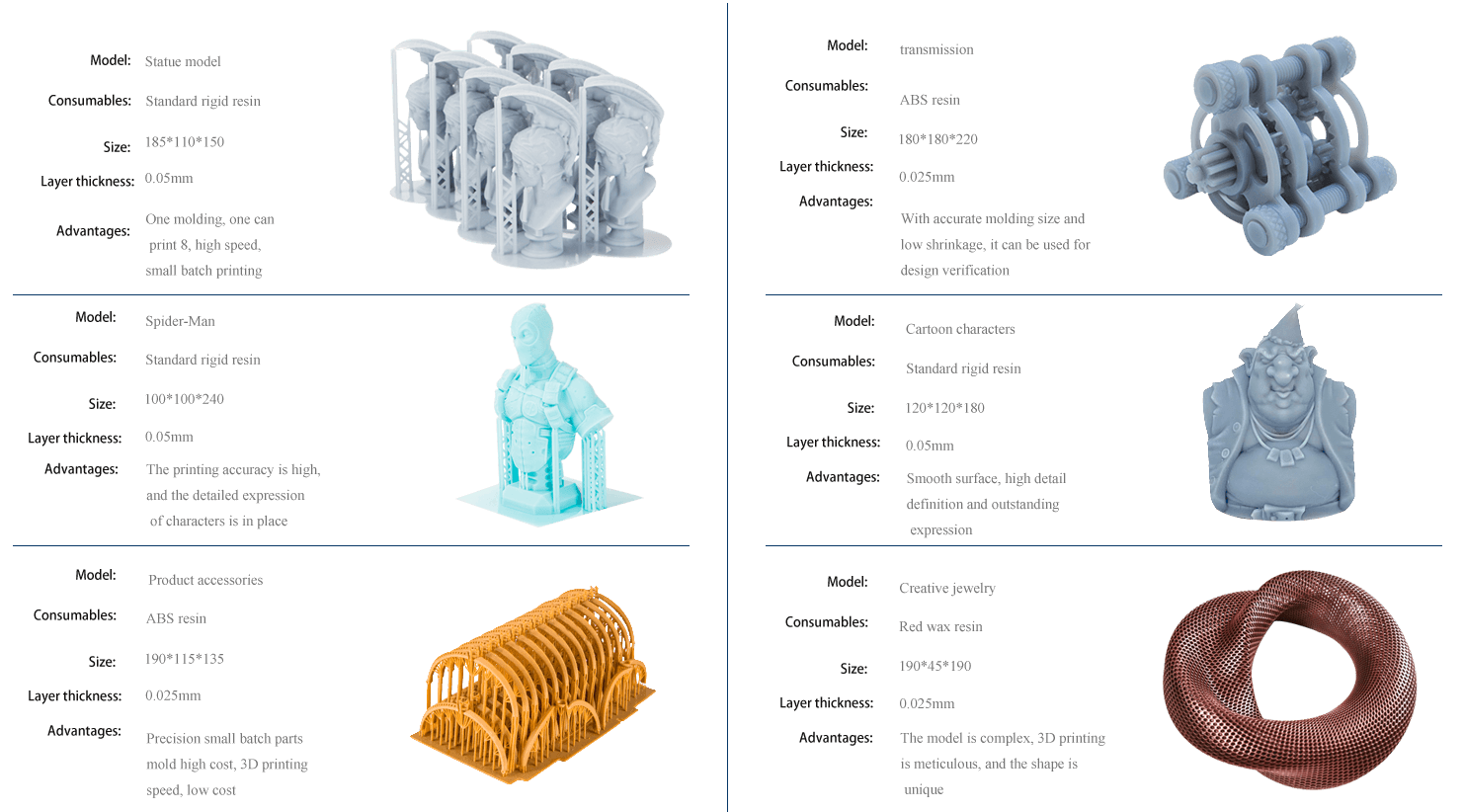

- Stereoscopic light curing 3D printer with LCD technology, high quality of finished products

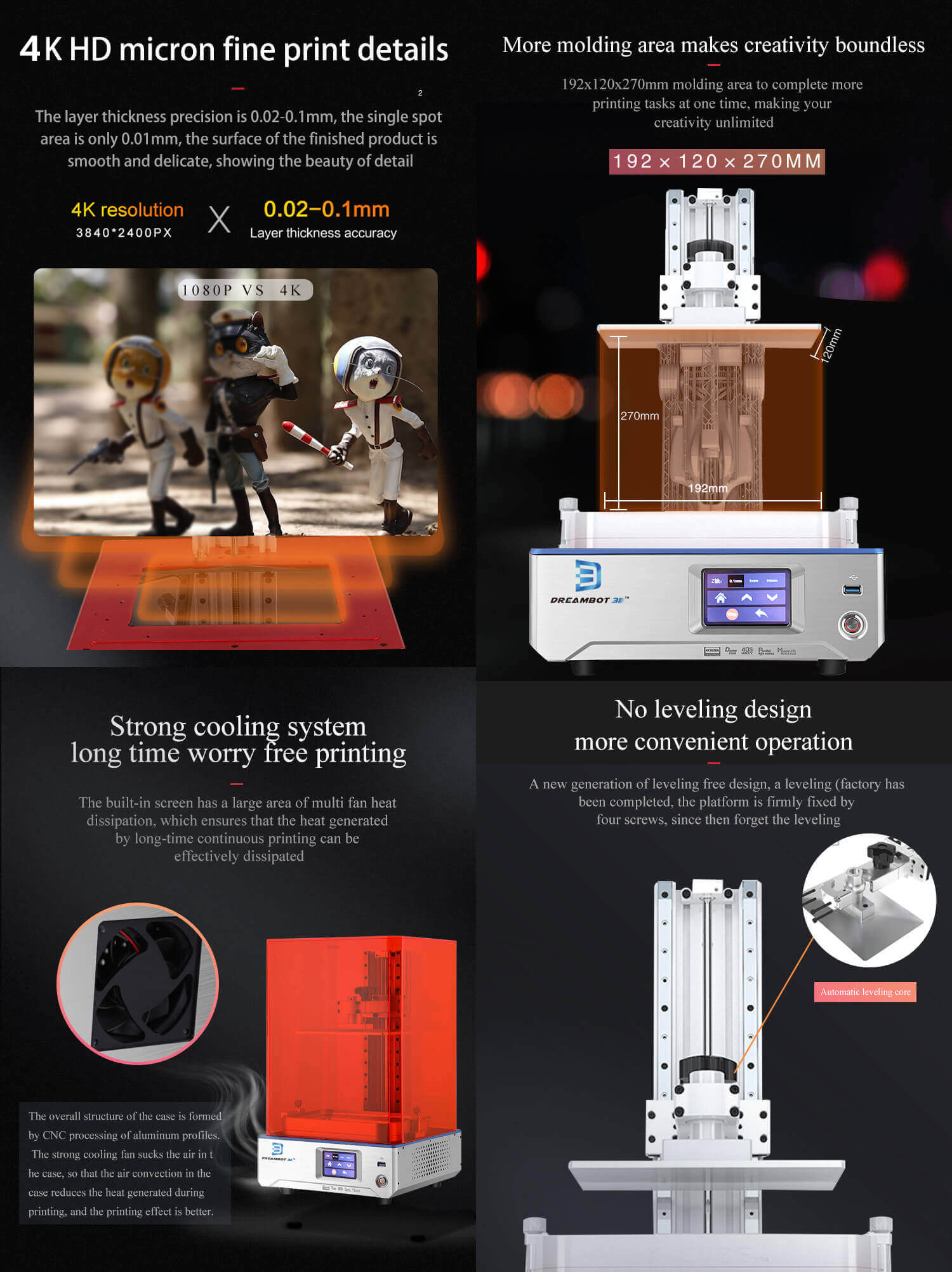

- 4K high-definition pixel printing greatly improves the smoothness of the model surface.

- Dreambot3D LCD resin 3d printer(ME-192) has obtained CE, FCC certification and quality assurance.

Dreambot3D LCD resin 3D printer(ME-192)

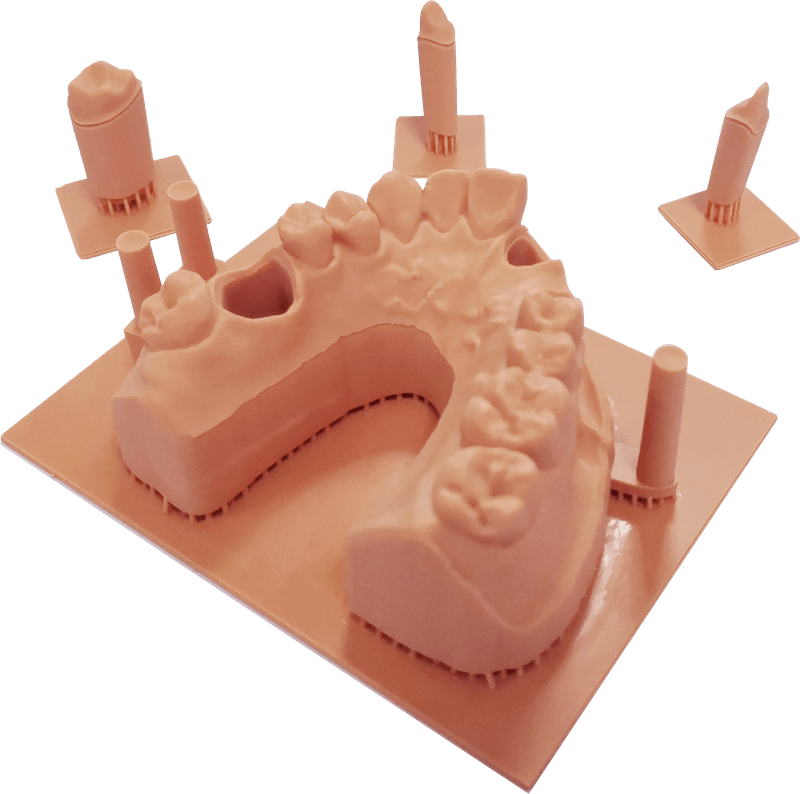

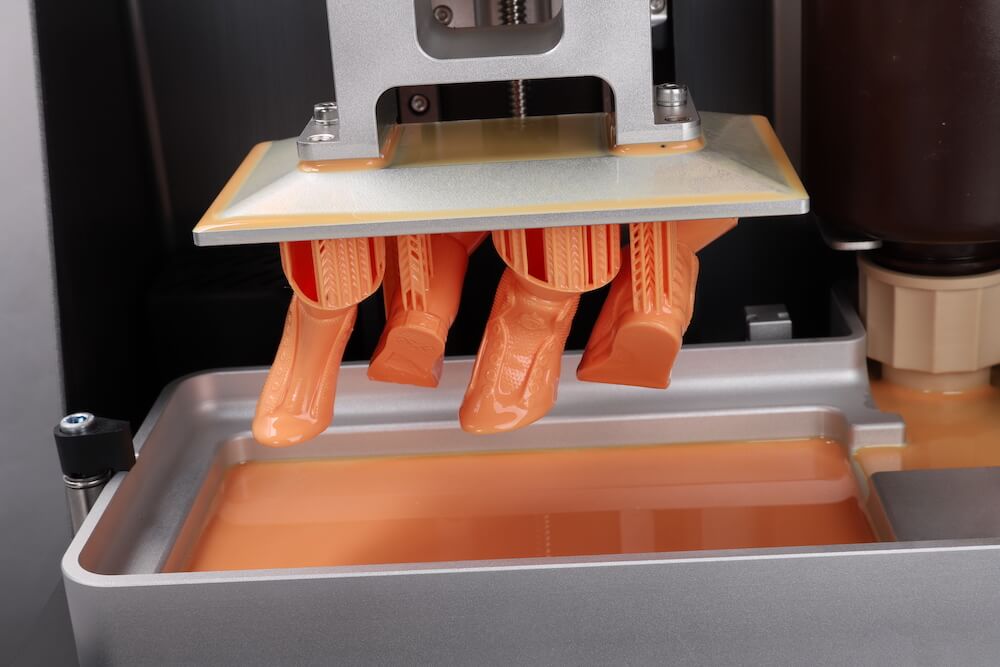

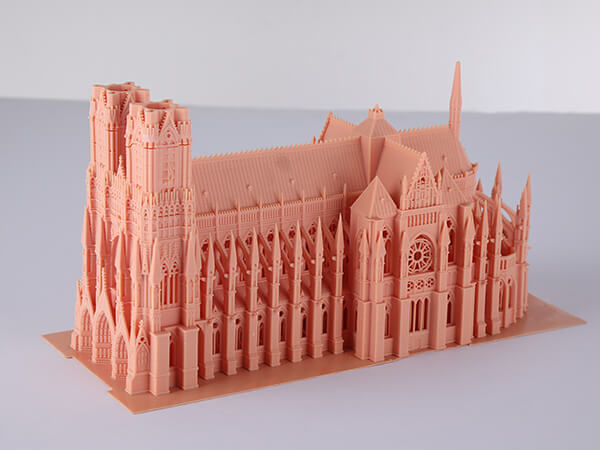

The castable resin 3D printer(ME-192) is used to create high accuracy, isotropic, watertight prototypes and parts in a range of advanced materials with fine features and a smooth surface finish. They are used for printing in these industries: jewelry, dental, engineering and product design, healthcare, etc.

Dreambot3D LCD resin 3d printer(ME-192) makes 3D printing look better because it has a better resolution. The printing process is also faster because it cures a whole layer in a single step.

The curing process of LCD resin 3D printer(ME-192) allows for a stronger layer to layer adhesion in resin-based printing.

| Parameters | ME-192 LCD 3D Printer | |

| Printing Parameters | Printing style | RESIN LCD 3D Printer |

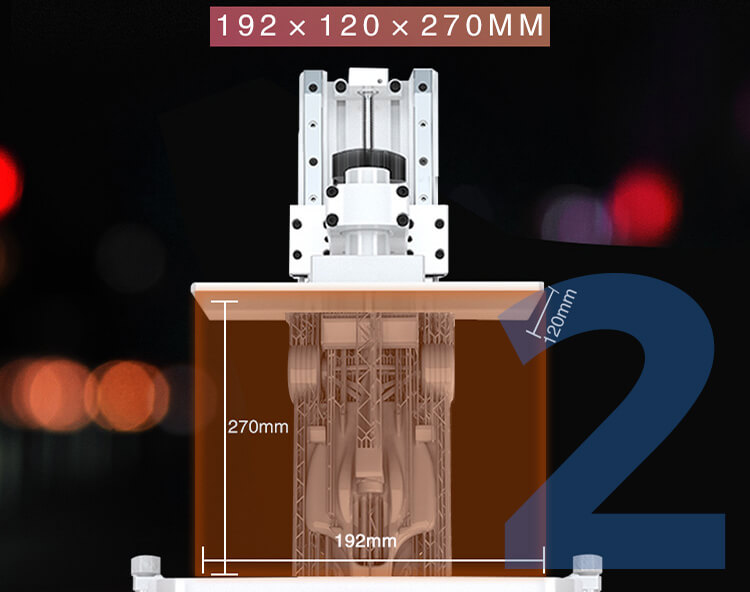

| Max printing volume | 192*120*270mm | |

| LCD size | 8.9 inch | |

| LCD panel | 4K Monochrome LCD Screen | |

| Printing accuracy | X Y axis 0.075mm, Z axis 0.02mm | |

| Printing speed | Max 40nm/h (Z axis) | |

| Resin support | 405nm resin | |

| LED array | Parallel UV LED light source | |

| Z axis | Dual Linear Rail, Ball Screw, 100% Aluminum CNC Structure | |

| Touch screen | 3.5 inch High Resolution Touch Panel | |

| Software Parameters | Operating systems | Windows Linux Mac OS OSX |

| 3D Modeling software | CAD Solidworks 3Dmax UG Maya Rhino Proe 3Done Skatchup ect | |

| 3D Slicing software | Chitu | |

| Input format | STL OBJ AMF ect | |

| Connect mode | USB,Network Connect | |

| Physical Parameters | Printer dimensions | 310*280*490mm |

| Package size | 450*420*610mm | |

| Gross weight | 18kg | |

- Printing accuracy of the LCD resin 3D printer is improved due to the large format light source, thereby making the illumination more uniform, therefore solves the problem of uneven light source.

- The LCD resin printer prints at a speed of 20mm/h, thus printing is done at a fast rate.

- The 4k HD pixel improves the surface smoothness of your printed model at the same time, making it easier to process the model.

- The stereo-light curing of 3D printing provides incredible surface finish that gives all our printing a very smooth and attractive appearance.

- The inbuilt touch screen and the USB plug and play allows you to print all your objects with no requirement for configuring a computer for 3D printing.

- The HD printing pixels makes it acceptable for printing in different fields such as advertising, audiology, jewelry, entertainment, etc.

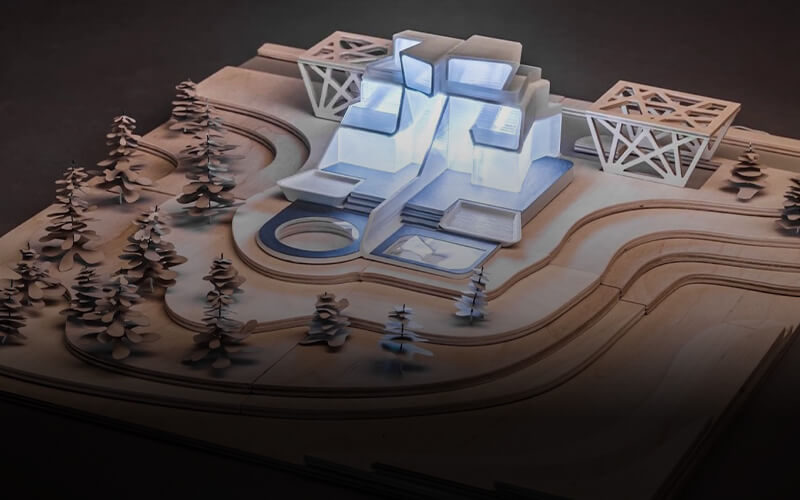

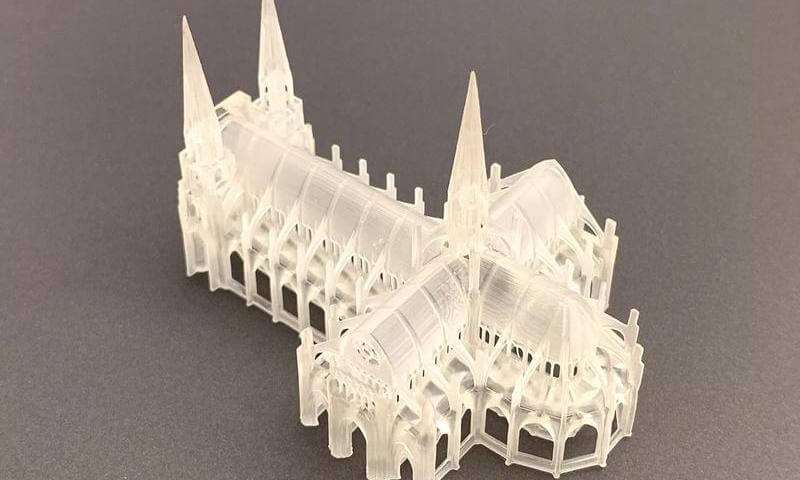

- The 3D printer for wax casting creates high strength and complex objects that makes the architectural industry adopt them for quick printing of structural designs.

- The high definition printing experience also allows every detail of your design printed.

- Your 3D objects can be printed at an accuracy reaching up to 0.025mm that fully reflects the details of your designs.

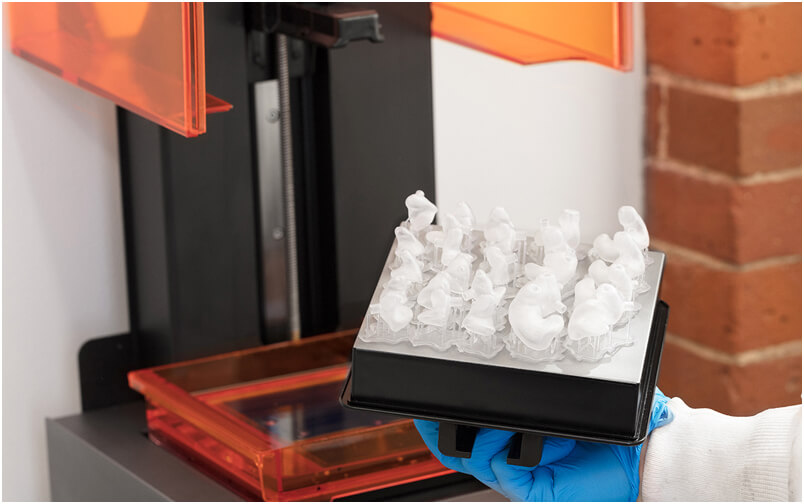

With Resin 3D Printer,you can used in jewelry,medical,dental,Educational,Research,accessories,biomedical,animation, arts and art house ,building,creative DIY,prototype manufacturing and so on.

Application of castable resin 3D printer

Test your part

We provide sample testing service, allowing you to check the working quality of our 3D printer before placing an order

6 points why choose us

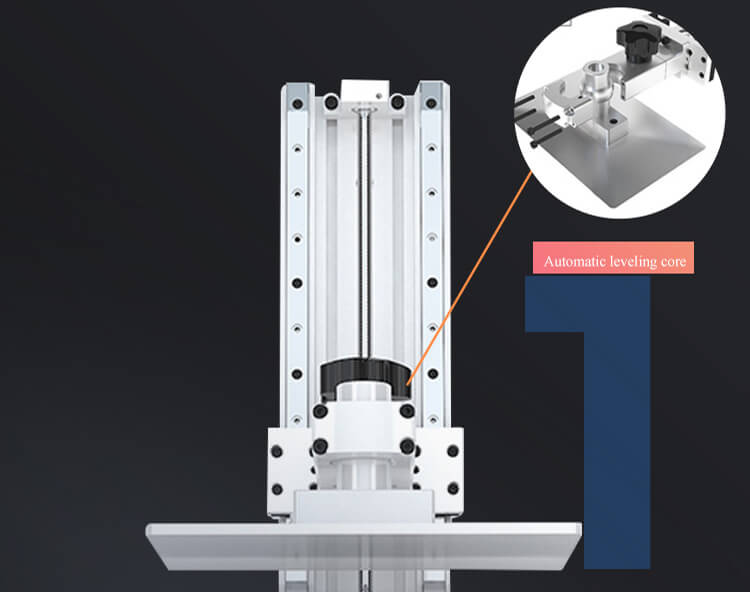

Automatic leveling design

A new generation of leveling free design, a leveling since then no need to set leveling.

Large size printing

Double liner slide rail

Make with thickened aluminum CNC structure with ball screw, high precision and stable balance slide, improve the stability of z axis.

4k mono LCD screen

The layer thickness precision is 0.02-0.1mm, the single spot area is only 0.01mm.

PLC control system

Screen module design

Dreambot 3d resin LCD 3D printer ME-192,screen module design, make your operation more convenient.

More castable resin 3Dd printers

ME-215 LCD 3D Printer

The ME-215 LCD 3D printer is suitable for printing highly accurate 3D wax molds for jewelry production as well as small 3D printing.

DB-293 LCD 3D Printer

The DB-293 LCD 3D printer is used for fast printing of 3D items across different industries, it is also used in jewelry businesses.

ME-345 LCD 3D Printer

The ME-345 3D printer creates high definition 3D objects for all sizes of printing. The speed of printing is highly exceptional.

Castable Resin 3D Printer Buying Guide

Previously 3D printers were considered the only ones utilized in the industry that used to cost tens of thousands, making it a costly machine. However, modern technology has everything.

Nowadays, you can easily find high-quality consumer printers. But there is a twist. These choices come with some luxury, like prices dropping. That means now you can buy a castable resin 3d printer under your budget.

You might think that as the price is low, you can get a new one very quickly. However, it will be quite a challenging task for you to purchase the right one. For example, you need to choose between an LCD 3D printer or an FDM 3D printer.

Speaking about 3D printers, they offer transformative advantages at each stage of production, starting from initial concept design to the final product generation. To get the maximum out of this machine, you need to pick the best one.

Don’t worry about it as here you will get complete information about a castable wax 3d printer, and in the end, you can choose a new resin 3d printer for your project. So, let’s get started with it.

What is an LCD 3D printer?

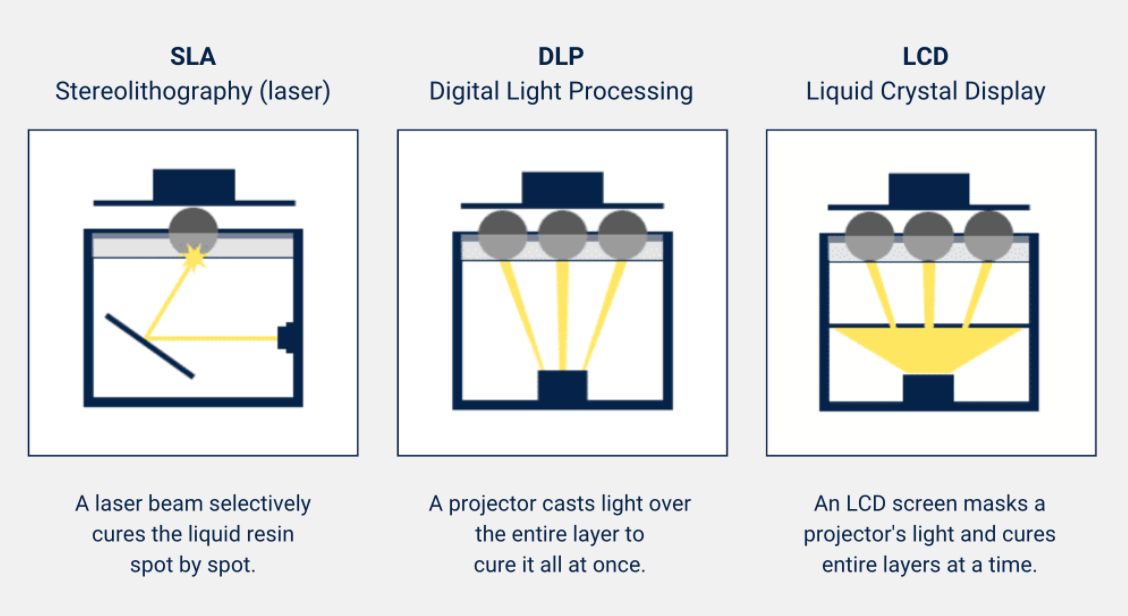

Here, you will know about the significant resin 3D printing methods such as DLP, LCD, and FDM. It also has another printing method called SLA, but it is now outdated.

In this particular chapter, you will learn about LCD D3D printer and how it works. Besides, you will explore the significant differences between LCD, DLP, and SLA.

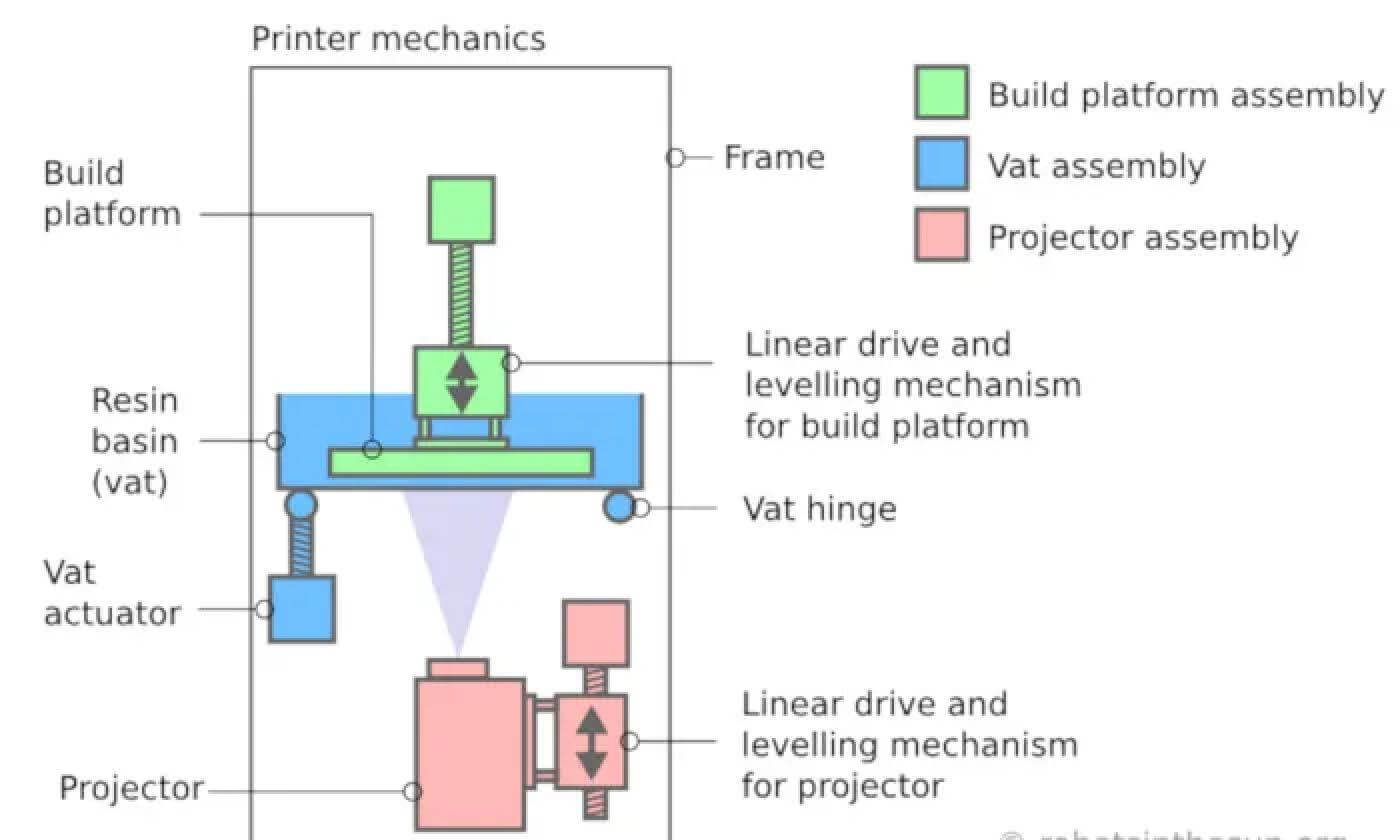

All these printing technologies include a photosensitive resin processed by a light source to create a solid layer and then a whole part. Here the resin is contained within a vat, or you can call a tank, and then the solution is cured against a build platform. This process slowly rises out when the part is formed.

One of the most popular forms of 3D printing is stereolithography or also known as SLA. This technique utilizes a laser operated by the galvanometers. It may be noted that galvanometers can be used as mirrors to guide the laser to a certain point of the build platform through a transparent tank bottom.

On the other hand, DLP- Digital Light Processing utilizes a digital light projected instead of a laser to cure the resin effectively. This procedure flashes images of layers onto the vat’s bottom.

Here, the light is directed selectively by utilizing a DMD-Digital Micromirror Device. The DMD includes thousands of small mirrors. The layers that the DLP printers generate include Voxels.

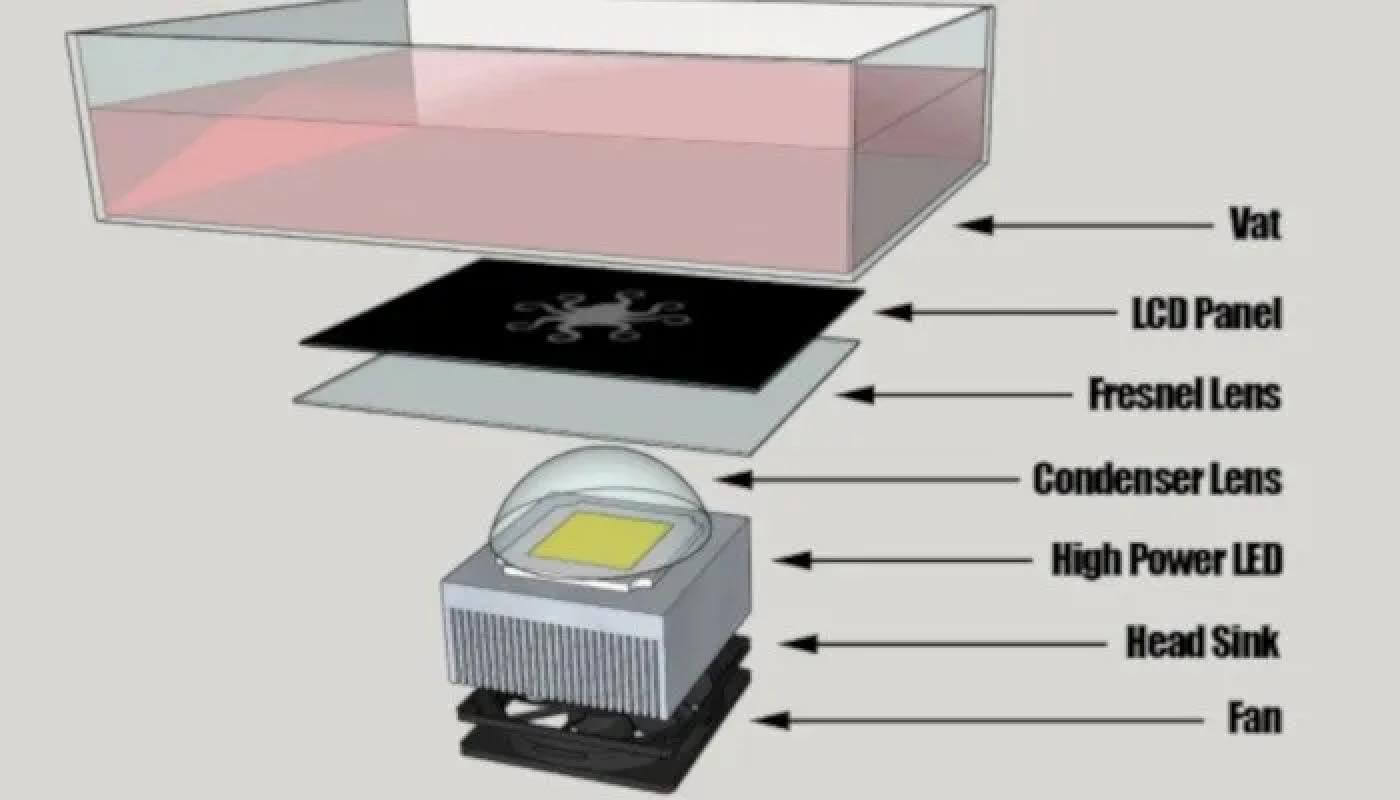

LCD 3D printing is almost the same as DLP. The printer’s flash layers are at the resin tank. However, it utilizes the UV light generated from LEDs shining through the LCD instead of the projector.

There is a skin that will act as a mask and will reveal the pixels that are necessary for the layer. There are no extra devices needed to direct the light. Now, let’s look at what you mean by LCD and how it is constructed.

1.1, What does LCD mean, and where does it come from?

Currently, you will find LCDs- Liquid Crystal Displays everywhere. But LCDs didn’t develop within an hour. It took time to build LCD from liquid crystal creation to a massive number of LCD applications.

The first Liquid Crystals were produced and introduced by Friedrich Reinitzer, a well-known Australian Botanist, in 1888. He dissolved material, such as a cholesteryl benzoate, and found that it converts into a cloudy fluid at the initial stage & when the temperature rose, it clears up.

When it is cooled, the fluid became blue before crystallization. In 1968, the RCA Corporation developed the world’s first experimental Liquid Crystal Display.

With time, the LCD manufacturers gradually developed creative differences by taking this display device into different ranges.

A brief history of LCDs

- 1888- Friedrich Reinitzer discovered liquid crystals while analyzing a chemical called cholesteryl benzoate. The element had two distinct crystal forms, and each of them had its melting point.

- 1962- Richard Williams from RCA began to research the Nematic Liquid Crystal’s optical properties. He filed the groundbreaking LCD patent on 9th November 1962. On 30th May 1967, the panel was legally granted.

- 1960- George Heitmeier started theoretical research to develop the first practical electronic displays to develop LCD TVs.

- 1968- RCA officially reveals the LCD technology at a press conference. While revealing the technology, RCA stated that very soon, one can expect a thin television screen hanging on the living-room wall, and it will look like a painting.

- 1970- After facing a colossal failure to commercialize the LCD technology, RCA sells the technology to Timex. Timex used the LCDs in its digital smart watches.

- 1973- In this year, Sharp introduced the first LCD pocket calculator in the world.

- 1980- STN displays appeared in the market that offered higher resolution images.

- 1988: 100 years after discovering liquid crystals, Sharp founds the death knell for cathode-ray tubes when it produces the first 14-inch color TV with a TFT (thin-film transistor) LCD.

- In the 1990s- Hitachi and NEC emerged as the early producer of active-matrix addressed LCDs. They were made based on IPS technology. In 1996, Samsung introduced the “Optical Patterning Technique,” the helped in developed multi-domain LCDs.

- The 2010s- Toshiba, in October 2011, introduced a 6.1-inch LCD pane having a resolution of 2560 x 1600. In the year 2016, Panasonic introduced IPS LCDs having a contrast ratio of 1,00,000:1.

Formation and other details of LCDs

LCDs include multiple layers that include electrodes and polarized panel filters. This technology is widely used to display images on different electronic devices, such as TV, computers, smartphones, and more.

Light is projected through a lens on a liquid crystal layer. The combination of colored light with crystal’s grayscale image creates the colored images. On the screen, you will see these images.

It may be noted that the LCDs can be made of a passive display grid or an active matrix display grid. For example, most of the smartphones that have LCD panels use active matrix display. However, older models use passive display grid designs.

For their display, almost all the electronic devices depend on the Liquide Crystal Display technology. With this, you will have a unique advantage, like low power consumption than cathode-ray tube or the LEDs.

The screen works by blocking light instead of emitting the light. As they don’t emit any light, they require a backlight. Multiple industries are now using a 3d printer for wax castingas it offers a maximum accuracy level.

1.2, How does an LCD 3D printer work?

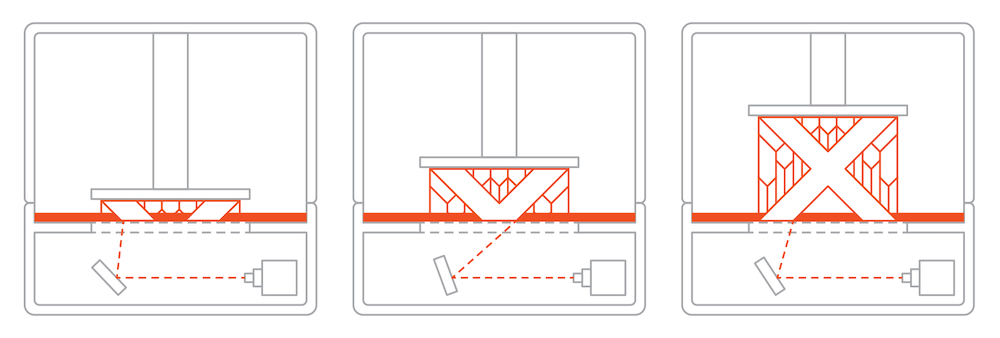

LCD 3D printers conduct the 3D printing through the MSLA process, or Mask Stereolithography process. The machine utilizes a UV light source that adequately shines up into the LCD screen.

The screen is then utilized as a mask to produce an image of every layer. This process hardens the whole layer.

A resin vat sits above an LCD and is separated by a layer of FEP- Fluorinated Ethylene Propylene plastic. The LCD panel shows the shape by shutting down the individual pixels where the resin must be cured. On the other hand, other pixels are illuminated.

Beneath the LCD, the machine has a bright LED. The light can only travel through the LCD through the unilluminated pixels. The light that passes through the FEP and LCD lets the resin squished between the FEP sheet and build platform.

After that, the build platform is lifted to break the surface tension between the FEP sheet and cured resin. The process is going on repeatedly until the whole model is printed.

The LCD printing process is carried out layer by layer using a light source and a digital mask. The process enables a higher level of throughput for its faster turnaround time.

This is quite important for the industry where round-the-clock production plays an important role. For high-quality transparent 3d printing, you can always go for LCD 3D printers.

1.3, LCD vs. DLP vs. SLA: All you need to know

As discussed above, LCD, DLP-Digital Light Processing, and SLA- Stereolithography are three crucial 3D printing technology.

All these printing technologies utilize Photopolymer resins in a tank and then cure the solution to create 3D models. But not all these three technologies are the same.

If you plan to buy a castable resin 3d printer for transparent resin 3d printing, then here are some details about LCD, SLA, and DLP that will help you choose the right one.

SLA 3D Printing

Speaking about stereolithography, it was the first additive manufacturing technology, and during that time, it was used widely for 3D printing. As per the report and historical data, it was commercialized by 3D Systems during the 1980s.

Talking about how it works, SLA printing utilizes a laser beam to solidify resin parts stored in a resin vat or tank. After that, the leaser is shone at the tank’s bottom section and then directed by galvanometers to the cured areas.

The process is repeated for every layer of the design until the model is complete. In the end, the object is cleaned in resin, and the support structures are removed.

DLP 3D Printing

DLP- Digital Light Processing was introduced a few later in 1987 by Larry Hornbeck of Texas Instruments. The exciting part about that was, it was created for movie projection but later used for 3D printing.

This printing technology utilizes a projector instead of the UV laser light that you will get in SLA printing. Here, the projector flashes light into the multiple resin layers at once.

That selectively solidifies the parts utilizing thousands of tiny mirrors named DMD- Digital Micromirror Devices. The DMDs direct the light’s projection.

LCD 3D Printing

When it comes to obtaining an exactresin 3d printing result, you can always go for the LCD 3D printing process. LCD 3D printers are cost-effective and have become quite popular in different industries.

These printers are designed and developed to offer better quality than the FDM 3D printers. They are also known as castable resin 3D printers and use LCD panels and LED lights to cure resin to create 3D models like the DLP 3D printers.

The printing process includes flashing the layers to cure resin stored in the resin vat or tank effectively. However, they don’t use mirrors. The LCD panels shine light through LEDs. The screen lets the light go through the areas that need to be cured into the 3D model. It doesn’t contain the mirrors and galvanometers.

Significant differences between LCD, DLA, and SLA 3D printing

Even though these three printing technologies are relatively similar, they are used to cure resins and work layer by layer. There are some significant differences that you need to know.

If you buy an SLA or DLP printer, you will have to purchase a 3D slicer for resin printing. Speaking about other differences, SLA uses the UV laser technology, LCD uses an LCD screen, and DLP utilizes a projector.

If compared, you will find LCD and DLP printers are much faster than SLA and can craft the whole layers at once. SLA printing method is getting outdated as they require a manual tracing of the dimensions of every layer.

Another key difference is that the DLP printers come with shallower resin tanks. This is a tank that stores resin during the 3D printing process. If you want to save money, then this can be a great advantage for you.

Printing Quality Comparison

Talking about resin 3D printing, this is known as one of the most precise and accurate 3D printing technologies. Besides, you can also go for low-cost LCD printers that can be used to develop complex types of geometries.

Honestly, a castable wax 3d printer’s printing quality compared to SLA or DLP 3D printers dramatically depends on the 3D printers you are using.

For example, LCD 3D printers from Dreambot3d, ME-192, ME-215, ME-345, DB-293, and more will work much better than cheap SLA or DLP 3D printers. The accuracy level will be very high.

If printing speed is the foremost priority, you can always go for an LCD 3D printer to work faster. Besides, if you are looking for 3D printers to make jewelry molds or create 3D models for dentistry, you can use LCD or FDM 3D printers from Dreambot3d.

SLA printing process involves a laser passing on every area of the part that needs to be solidified; the LCD and DLP 3D printers can cure all the layers instantly.

If you are looking for a faster 3D printer, you should go for LCD or DLP. In short, for the best option, you can go for LCD 3D printers. Now, let’s have a look at some benefits of LCD 3D printers.

- They support large printing sizes and higher speed so that you can complete your printing work faster.

- With 4K HD printing details, the mode’s surface smoothness can be improved, and you will be able to process the model faster.

- The modern LCD 3D printing machines come with efficient cooling technology and a better UV heat dissipation channel.

- The stereo-light curing 3D printing offers great details and surface.

- They offer a stable power supply. The machines have obtained FCC and EC Certification

- The modern LCD 3D printers can accurately manufacture different types of complex curved along with special-shaped models, with impressive surface smoothness and fine printing models.

- The cost of LCD is around 1/10-1/5 of the same size SLA/DLP. It greatly reduces the threshold for research and development.

Application fields of LCD 3d printer

LCD 3D printer, also called additive manufacturing, has moved a long way since its introduction in the 1980s. Initially, it was developed as a tool for faster and accurate prototyping; this printing has evolved and improved to cover different technologies.

New 3D printing applications are being continuously formed, but the applications mentioned below have recently got a vast popularity level.

With time, 3D printing technology has developed significantly. This can now significantly carry out roles in different applications. For years, the issue with modern 3D printing was that it had involved a high entry cost. This was a factor that restricts the implementation of this technology. However, the trend is now changing gradually.

The reason behind this can be the simple technologies that are utilized in different applications in various fields. With rapid improvements and variations in the 3D printing technology and its material, the cost has been gone down.

Now the LCD 3D printing applications are more cost-effective and accessible. As possible applications for 3D printing are rising with time, many companies are now trying to find different ways to form new technology opportunities. However, here are some significant applications of LCD 3D printers to consider.

2.1, Used in the jewelry industry

No matter the industry, LCD 3D printing machines are considered a useful and intelligent design tool to craft inexpensive models in the design procedure. With the model created using 3D printers, the designer can now effectively review the concepts. Besides, it provides that manufacturers understand real-time teamwork.

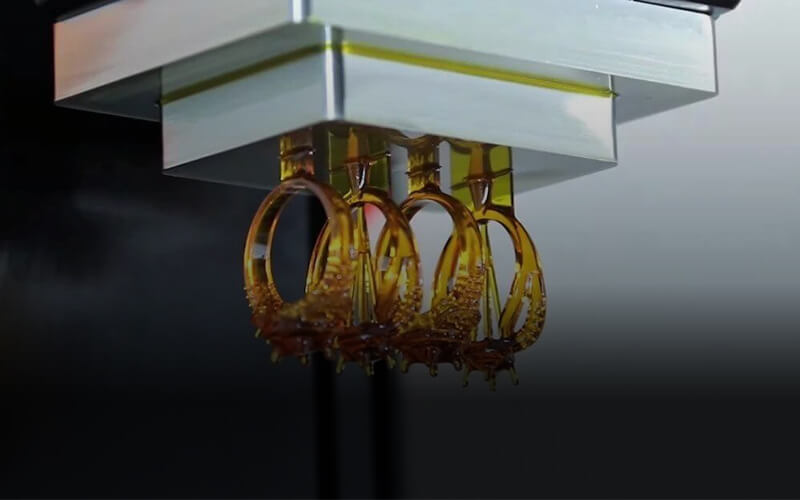

This printing technology has also helped the jewelry industry a lot. In fact, this particular industry was one of the first industries to use 3d printing for investment casting.

Instead of the traditional metal printers, the industry uses wax to print and sculpt jewelry pieces. After that, plaster is poured on the sides, and the liquified metal solution is poured on the wax. Once done, the jewelry piece is polished.

In the global jewelry industry, CAD-Computer Aided Design has brought new eras of creativity. Just because of CAD’s rising advantages, the demand for embracing LCD 3D printing technology has gone up.

By utilizing 3D printers and the 3D printing method, you can realize the transformation from traditional production to the jewelry industry’s digital jewelry creation. Some of the significant applications of this printing technology in this industry are:

- Design communication and demonstration- You can now make multiple and complex models rapidly for assessment and demonstration by using 3D printing equipment or a castable resin 3d printer at the beginning of the design stage. This way, you will save time and lower the chances of defects related to design.

- Assembly test and function test- With 3D models, you can conduct functional tests and assembly tests. This way, you can discover the targets by which the product’s function can be improved while reducing production costs. Your overall product quality will be excellent.

- You can quickly meet tailor-made jewelry’s customization demand- LCD 3D printers offer a higher efficiency level. You will quickly respond to the customer’s demand and offer them the products with the desired design.

- You can develop jewelry parts directly- Since the LCD 3D printing technologies are applied more and more, creative and stunningly looking jewelry products have begun to emerge. You create jewelry parts without any issue and spending a little time.

So, if you plan to start your own jewelry shop, you should use an LCD or FD 3D printing machines to create delicate jewelry pieces.

Remember that LCD 3D printing provides you the fastest and cost-effective approach to design and produce jewelry pieces, and your product development cycle will also get improved with this.

Besides, 3D printing technology can omit the complicated manual steps and speed up wax models’ production by 3d printer for wax casting process.

2.2, Used in the medical industry

It may be noted that the medical industry has emerged as the fastest-growing adaptor of LCD 3D printing. More than 97 percent of medical AM professionals have forecasted that the utilization of 3D printers will increase more in this sector.

This trend will keep continuing for years. From medical devices to bioprinting and even prosthetics, 3D printing plays a significant role in this industry.

Have you ever thought about what is propelling the growth? It is the geometric freedom offered by LCD 3D printing, and using that, the healthcare industry is now offering personalized health care to patients at affordable prices.

When combined with CT scanning, this printing technology can be proven to offer patient-specific solutions very effectively. For example, dental appliances and implants. It can be said that 3D printing has enhanced and revolutionized this industry. Some significant benefits of this for the said field are:

- Enhanced medical devices

It has been proved that 3D printing is the best technology for developing and enhancing the designs for various medical devices. Thanks to the cost-effective, faster prototyping, medical device manufacturers have greater freedom in designing new products, and bringing new devices to the market.

- Tailored healthcare services

The medical industry can now take advantage of advanced 3D printing and a casting resin 3d printer to manufacture patient-specific devices. For instance, implants and prosthetics can now be developed faster and under the budget.

- Simplifying the complex operations

LCD 3D printing plays a significant role in preparing simple operations and providing training to future doctors.

There is no doubt that 2D images are good, but they offer a lower visualization level and don’t look like a real human body part. However, 3D models look very realistic and will make the operational process useful and accurate.

- Intricate care

LCD 3D printers, or you can say resin 3D printers, can be used to create affordable prosthetics for people who don’t have enough money to buy the prosthetics. On the other hand, low-cost medical equipment is also crucial in remote areas and poverty-stricken regions.

- Better customization

Making prosthetics in the older ways is quite expensive as you will have to personalize them based on the individual’s requirements. It offers users the freedom to choose different things, such as different designs, sizes, colors, and prosthetics forms.

The primary application of 3D printing in healthcare

- 3D-printed orthopedic implants

These are used to replace a missing joint and bone surgical. With 3D printing technology, medical experts can now create long-lasting, high-performance, and better-fitting implants.

The first use of 3D printed orthopedic implants were manufactured in 2007. Alder Ortho Group, in 2010 used EBM-Electron Beam Melting metal 3D printing technology.

- Personalized surgery

3D printing technologies are widely used to create patient-specific surgical tools, organs, and medical images. The anatomical models are being created in the medical industry with 3D printers and CAD or CAM software.

You can create a translucent foot model, skull model, arteries model, internal bone structure model, and more. Some 3D printing companies have developed biocompatible materials that can easily withstand sterilization, like PEEK, nylon, thermoplastics, and more.

For example, Endon GmbH, a German medical device company, has developed a surgical tool to remove hip covers using metal 3D printing.

- Medical and dental devices

Different studies have proved that both the dental and medical sector is forecasted to represent around 11 percent of the overall 3D printing market. These machines have brought a great revolution in the field of digital dentistry.

This refers to the design, diagnosis, and treatment tracing, using computer technology and aided equipment, for example, LCD 3D printers. Clear Aligners, the invisible teeth straightening devices, are the most prominent example of 3D printing in the dental sector.

Dental bridges, dental crowns, planning guides, and plaster models also can be developed through 3D scanning.

Some example of 3D printed organs

- Bionic eyes – Some researchers at the University of Minnesota have successfully 3D printed a bionic eye’s prototype. It has some semiconductor photodetectors and is made from polymer resins on a glass hemisphere.

- Antibacterial tooth– Such tooth can kill bacteria, and scientists in Groningen have developed such tooth. They invented this after analyzing the tooth polymer and artificial tooth resins.

- Heart- Scientists have 3D printed a heart from a silicon material that can pump and work as a real heart. However, it can only support 3000 beats, which can last for around 300 to 45 minutes.

2.3, Used in production and R&D

3D printing technology is gradually becoming a crucial element of both the R&D and production industry. First, let’s have a look at how it helps the production or manufacturing sector.

The production or manufacturing industry is looking at innovative and new ways of operating, and for some years, LCD 3D printing has been leading the way.

Rapid advancement in the LCD 3D printing technology, materials, and equipment has resulted in lower cost and better productivity. It has been helping the production industry to satisfy the growing demands. Some significant advantages of LCD 3D printing in production are:

- Significant reduction in the costs

While the traditional production procedures are costly, the 3D printing process has made parts of the products more accessible and cheaper. You can automate the entire process using a tough resin 3d printer. Just upload the design of the product, and the machine will carry out the printing process. You will save in terms of labor costs.

- Lower chances of facing risks

When you can confirm a product’s design before making it to production, it can significantly help you lower the chances of risks related to money, materials, and errors. 3D printing will increase prototyping confidence, and it will make the redesign process a lot easier.

The traditional manufacturing methods depend on mass production efficiency, and LCD 3D printing requires filament material for curing resin prints.

- Faster time to market

With 3D printing, it will be easier to develop ideas faster. It is possible to design and print the products in some cases on the same day. If you are involved in large-scale manufacturing with 3D printing, you will enjoy a faster process and lower manufacturing time.

Now, let’s talk about R&D or Research & Development. This is an essential part of different industries. To enjoy better growth, you will have to make sure that your products are continually evolving and ready to meet the rising demand, competition, customer requirements, and more.

Besides, you need to make sure that your R&D process is cost-efficient. R&D is a forward-looking process that creates a strong foundation for the product innovation lifecycle. The better your R&D, the faster you will able to expand your business. Some significant benefits to consider here are:

- Quicker product development

No matter what the industry is, prototyping has emerged as a crucial part of the development process. A prototype offers you a great way to test and analyze different parts before their manufacturing. Using an LCD 3D printer, you can create a prototype faster, and the team can accelerate the product development cycles.

- Maximum design flexibility

When you can quickly produce the product designs, you will enjoy greater flexibility in testing various designs faster. So, you can quickly change the design based on your requirements within a few minutes.

- A greater level of customization

To the automakers, 3D printing offers a flexible and cost-effective way to manufacture customized parts. Most of the companies dealing with luxurious parts use LCD printing technology to create personalized interior and exterior parts.

- It will be easier to create complex geometries.

Some products’ components require complex geometries, and 3D printing lets you produce those parts that will still be durable and lightweight. You will enjoy the flexibility to work with different design complexities, geometries, colors, and materials.

Using photocurable resin 3d printing through a quality casting resin 3d printer, you can get flawless products that will be accurate replicas of the designs. Keep your production and R&D to the next level with the LCD 3D printing machines.

2.4, Used in the education industry

The classroom study style is now going through a great revolution due to introducing new technologies in the global educational industry, mostly mathematical and engineering learning.

With the changing trend, schools, colleges, and universities are now gradually incorporating 3D printing methods into their syllabus.

The primary benefit of LCD 3D printing is it helps in preparing all the students by letting them create creative and useful prototypes without the requirements for expensive tooling.

It effectively bridges the gap between the images and ideas on a screen or page, allowing them to shape those ideas physically.

3D printers are getting common in public libraries and classrooms. Universities have LCD 3D printers for students to use in projects. For example, there are some companies; MakerBot provides the students with certification courses in 3D printing applications.

The advanced 3D printing tools are now revolutionizing the education system by providing rapid prototyping by students and fabricating high-quality scientific equipment under the budget. Students can learn in a better way by exploring engineering, architectural, and design principles.

By establishing a complete 3D printing center, you can offer your students, different engineering majors, such as model design, mechanical manufacturing, and engineering design with training services.

Besides, you can offer convenience for disciplines construction, research & external cooperation, and vocational education. Some significant results of 3D printing at universities and schools are:

- Better level of motivation

Understanding and utilizing this growing technology can significantly benefit the learning process, especially STEM- Science, Technology, Engineering, and Mathematics. Besides, this is also quite helpful in design technology, geography, history, and biology. Students will learn more through 3D printing projects as it will create that “Wow Factor.”

- It complements the curriculum.

No matter the curriculum, LCD 3D printing can significantly help the teachers and students work better. With 3D printing, students will no longer be passive consumers of information as they can now actively participate through the design, conception, and execution of the projects.

- It opens up new possibilities for learning.

With the help of an LCD 3D printer, students can improve ideas, which help them expand creativity. When they touch and see their projects, they understand the product appropriately. Besides, teachers can present crucial information in an understanding way by using 3D models.

2.5, Used to make various models

When it comes to making the presentation a grand success, most companies are now preferring to use 3D models. It has changed the way engineers design.

3D models help the end-users and the designers visualize the space requirements while improving drawing accuracy and efficiency. 3D models allow the designers to see what they will not see with a 2D model.

When designing the 2D models, you will have to create a separate plan and elevate the view to see the design, which will take longer to do. But with a 3D printer, you can complete the design in just one model.

The designer can go through the 3D models using specialized software. Besides, it lets the designers or manufacturers see if the design conflicts with other elements. The benefits of 3D modeling are not just limited to coordination and productivity.

For the industries that make models of different products, 3D models can be a fantastic tool for both the end-users and designers. Now, let’s have a look at some benefits of 3D models.

- Quick, straightforward, and realistic

From deducing the diagonals’ scores, vertical and horizontal lines of 2D drawing to obtaining a one-shot picture of the product is what 3D models offer.

Your product design will turn out more vivid, and you can offer your clients a comprehensive virtual project. On the other hand, you can check whether some changes are possible or how a change made to the product design will look.

- Better for project approvals and marketing

The experience of sailing through a well-developed 3D model is satisfying and compelling than the 2D models. The vivid scene will linger in the viewers’ minds for a longer time, and you will create a better opportunity to win your customers. Besides, this will increase the chances of project approval.

- Easy to do corrections and re-modeling.

When you have a 3D model, you can finalize your design without spending a lot of money. You will not face those costly post-corrections. Create a 3D model, analyze the design; if you are satisfied with the design, you can go for final production.

- There will be a significant impact on the execution of the project.

When you have a straightforward design, you can complete the projects under your budget. It leads to less cost growth, fewer change orders, less rework, elimination of field interferences, better productivity, and more.

- It helps in getting the necessary licenses.

By using your 3D models, you can quickly get the required permits for your projects. It is crucial to secure necessary permits to ensure that you are all set to execute and complete the projects without dealing with legal issues. The regulators can evaluate the design from the model and make their decision quickly.

3D modeling facilitates designing and planning efficiencies. Buy the best castable resin 3d printer now and get ready to prepare 3D models that will help you in faster product development.

Which resins can be printed on an LCD 3d printer

Are you planning about 3D printing in resin? Do you want to know more about the technology related to 3D printing in resin? Or you want to know what can be printed on an LCD 3D printer?

We have listed down all the options that will help you in getting the desired information. Stereolithography, the oldest form of 3D printing technology, has been in use since the 1990s.

Even though it is getting outdated due to LCD and FDM 3D printing, all the technologies use a liquid resin to create 3D models.

The 3D printed resins’ significant advantages are high-quality, smooth surface, detailed finishing, and better prints. Here are different types of resins that can be printed on 3D printers.

3.1, For transparent resin 3d printing

Speaking about transparent resin 3D printing, it means printing 3D objects of different degrees of transparency. The final result will range from a little translucent to relatively transparent.

Multiple factors can cause such different results, for example, the nature of the 3D model, your castable resin 3D printer settings, type of 3D printer you are suing, materials, and the post-production process.

Remember that getting transparent print can be very challenging, but it can be done quickly with the best material. For example, you can consider epoxy resins, which are generally thermosetting resin. Here you will be using two essential parts, i.e., hardener and resin.

3D modeling for maximum transparency

When it comes to 3D printing of your 3D models, it is crucial to understand that the more complex design tends to refract more light. Besides, it will be less likely to come out very transparent. This is true in the case of curved 3D models as a curve redirects the light.

It is advisable to lower the light refraction level; you should 3D model the objects with the thinnest walls possible. The thicker wall will disperse more light and create an opaquer appearance after completing the 3D print.

Which 3D printing technology is right for your project?

You will have to choose the correct 3D printing technique based on the nature of your project. Do you need to create a final functional product or work on a prototype? Considering the requirement, you need to select the right technology. Here you can consider using FDM or LCD 3D printer for better results. Let’s have a closure look at this technology.

FDM 3D printing

FDM 3D printing technology is a popular and widely used 3D printing technology in the industry. It creates 3D models utilizing a filament.

Under this, the filament is gradually heated up in the nozzle and then slowly squirted through in the object’s shape but layer by layer.

As the FDM printing process is different from others, very tiny gaps can arise between the layers, and that, in turn, contributes to lower light passing by the surface of the object.

The visible layer lines also disperse light. The light refraction interferes with transparency, and lowering it by the design and production methods can optimize the outcome.

While carrying out the process for transparent printing, you need to use optimal settings. You need to set the material extrusion temperature, printing speed, print bed temperature, flow rate, nozzle diameter, and layer height thickness in terms of settings. Some features of transparent resins are:

- Non-yellowing characteristic

- Offers high gloss finishing

- Very low shrinkage level

- Can be Pigmented using the right pigments

- Better UV stability

- Excellent flow properties and low viscosity.

- It offers smoother surface

- You can achieve complex structure that is impossible to attain through traditional printing methods.

Are you ready to carry out your transparent 3D printing model? If yes, with Dreambot3d, you can get high-quality LCD and FDM 3D printers capable of transparent 3D printing. Besides, it will be easier for you to get the best result with our expert’s help.

3.2, For flexible resin 3d printing

The world of designing has gone through a great revolution ever since the introduction of 3D printing. The things that were initially considered impossible tasks can now be done with 3D printing technologies.

For example, you can create flexible 3D models using rubber-like 3D material or flexible resin. Speaking about flexible 3D printer resins, these can twist, bend, and maintain the actual shape.

It’s time to expand your LCD or FDM 3D printing with high-quality 3D printer resins. Using this, you can make products like gaskets, rubber-like products, and phone cases using resins or flexible photopolymers.

Is it possible to 3D print rubber? The answer can be no but using flexible 3D printing resin; you will feel 3D printing rubber.

One of the most common ones is filaments developed from TPEs- Thermoplastic Elastomers. This solution is quite beneficial for different applications, such as shoe soles, flip-flops, and some industrial applications such as sealing rings.

A few years back, designers used to face many challenges when it comes to printing flexible filaments. The reasons were, they were very soft. When processed through the 3D printer, they didn’t come out as expected.

Most of the extruders had the “pushing string effect.” What does that mean? When you push a filament with no rigidity feature towards the printer’s nozzle, the filament will twist as it is very soft. However, the introduction of direct drive extruders has made it possible to 3D print durable and flexible filaments.

The flexible resin can create prints that will look like rubber, not just for flexible filament. Flexible 3D printing is useful when you want to create or prototype flexible parts, for example, wearables, stamps, custom grips, gaskets, and more. For adding ergonomic features to the assemblies, you can also use this.

Some trick and tips for doing flexible 3D printing

There is no doubt that such filaments will significantly help your inflexible 3D printing process. However, using them can be a challenging task if you failed to follow the correct procedures.

Remember that if the material has a more elastic level, it will become more challenging for you to use them. However, to get the desired result, you can consider the below-mentioned tips.

- Always print slowly- Flexible filaments will not perform well at high speeds. Flexible resins need to be printed at a slower speed. Compared to your traditional filaments, flexible filaments will take more hours to print. As per the experts, 20 to 40 mm/s is an ideal starting point for flexible resins. However, this can be improved using a specialized extruder.

- Set the right temperature for printing while doing flexible 3D printing, beginning with the recommended temperature. Once started, you can go up or down till you attain excellent print quality. The too cold and hot situation can lead to poor results.

- The print head should stay inside the model. While 3D printing, you need to make sure that the extruder is inside the model walls and not moving over open air. Most of the slicers have a configuration for this.

- Check the retraction level. When utilizing your rubber-like filaments or flexible resins, the retraction process can bend the filament and create jams. You need to reduce it during the process, or sometimes you can prefer to turn it off.

What can 3D print resin be used for?

- 3D printer snap fits and joints- Sometimes, you may need to 3D print some flexible parts to connect parts. This will help you in reducing the assembly time. Processing high-quality flexible 3D print resins through our FDM and LCD 3D printers, you can come up with flexible yet durable 3D models. Create a snap fits and joints using this material.

- 3D printed shoes and clothes- A durable 3D printing material, such as PEBA, is widely used by the fashion industry. In some cases, designers’ 3D printing clothing is made of flexible materials to create parts that will correctly respond to the body’s movement. For example, have a look at the below dress. This dress is designed by Travis Fitch, an American designer, and has around 30 different sections. The dress is 3D printed, utilizing colorful, flexible material.

- 3D printed sports equipment, and footwear- Advanced and high-performance flexible 3D printing resins can offer you a new perspective on the footwear and sports equipment manufacturing process. You can get the right energy return level and shock absorption properties for creating shoes, helmets, shin guards, and more.

3D printing is an advanced technology, with its high efficiency, all in one molding, easy safety operation, environmental protection, and other such advantages in the global footwear industry. It is rapidly revolutionizing the design, personalized customization of shoes and production. It is widely used for shoe sole mold design and production.

Earlier, sole mold manufacturing normally took a week. If the model is not good, then it needs to be redesigned and mold. For each modification, it takes another two to three days. Besides, a new mold can cost a thousand dollars or more.

But with 3D printing, it can be done within two to three hours. Besides, the accuracy level is also good. You can use 3D printing to create a prototype that can be tumbled sand-cast shoe mold, correctly printed in 360-degree.

You can replace wooden molds. There will be a lesser requirement for material, manpower, and you can give a shape to the intricate patterns.

A well know shoe company, New Balance partnered with Formlabs to developed quality material for 3D printing. They developed Rebound Resin for printing lattice structure that is quite durable.

So, what are you waiting for now? Get the right 3D printing machine now and get ready to create flexible 3D models. A high-quality print using flexible resin with flex resin 3d printer will help you in saving time and money

3.3, For high hardness resin 3d printing

With time, the 3D printing industry is getting more refined and progressing, offering a positive and significant impact on all the sectors, covering medical, design, art, engineering, and more.

With that, 3D printing with FDM and LCD keeps developing, and well-known companies, for example, Dreambot3d, are trying to keep the momentum rolling. Now you can create durable 3D models using a tough resin 3d printer.

While printing with FDM and LCD is getting more popular due to some benefits like batter accuracy and higher resolution, materials concern expense, and reliability. For though 3D printing, you can always go for though resin, which is not fragile.

Speaking more about it, resin offers you the ABS plastic’s mechanical properties. It is developed for various applications that require materials that can easily withstand high stress and strain. Studies have proved that 3D printed parts using resin can offer a tensile strength of 55.7 MPa, and the elasticity level can be around 2.7-GPa modulus.

It creates a perfect balance between compliance and strength. However, the resin is an ideal option for functional and robust prototypes and assemblies that can undergo short periods of strain and stress. So, the resin is ideal for 3D printing gadgets, wearables, and other objects that withstand pressure. Here is a list of characteristics for standard and tough resin.

Tough Resin

- Perfect for functional prototypes along with mechanical assemblies.

- Creates shatter-resistant and sturdy parts.

- Offers better resistance to cyclic loads.

- It can be a little harder to remove from the platform.

- Not ideal for parts that need thin walls.

Standard resin

- Produces high-resolution prints.

- Produces a smooth finish on the surface.

- Colors can affect the properties.

Tough resins can offer some impressive mechanical properties. For example,

- Professionally looking parts

- Lower rate of brittle failure. You will enjoy increased elongation.

- Better level of stiffness and strength. However, the tough resin can increase the flexural modulus and flexural strength by around 15 to 20 percent.

- Impressive performance at the changing temperatures.

Remember that the tough resin prints at around 50 to 100 microns. That needs to be printed using necessary supports, and you should try to avoid the print directly on the platform as it will stick and hard to remove.

So, it is advisable to warm the build platform utilizing heated air to remove the part quickly. If you are printing large parts, increase the support of the touch point’s size to eliminate 3D printing failures.

You should consider its post-curing requirements. To achieve the right mechanical properties of the tough resin, you need to go for post-curing. This process will help you in getting an accurate substantial part with excellent flexural strength and flexural stiffness.

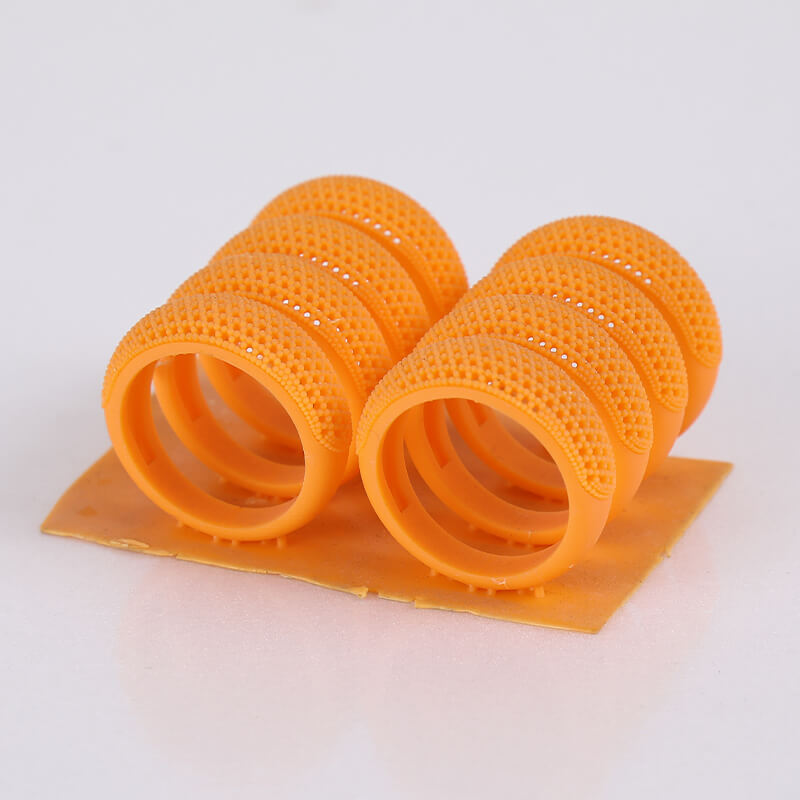

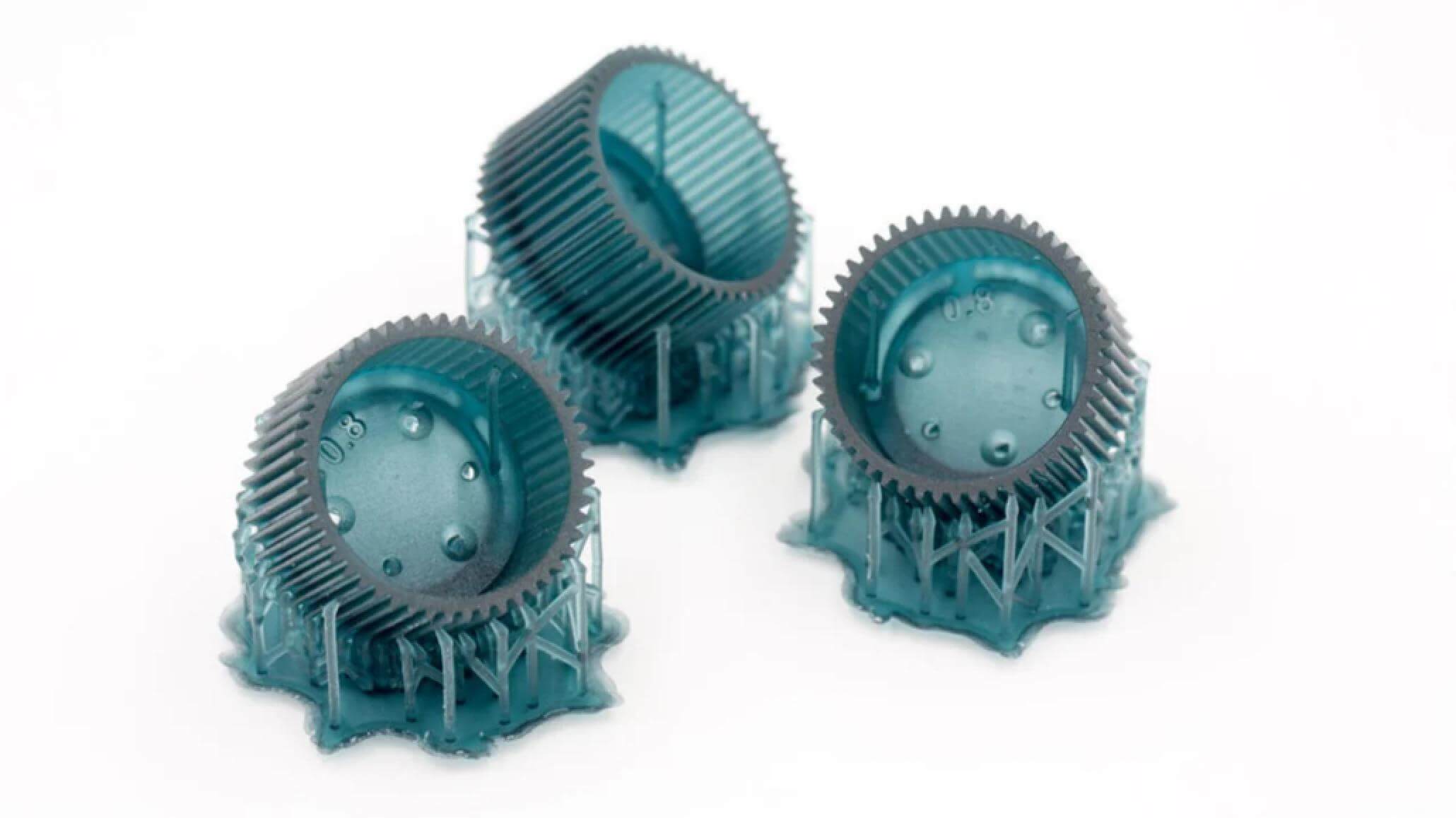

3.4, For castable resin 3d printing

Thanks to the latest technological development in 3D printing, 3d printing wax casting is now possible using castable resin.

Casting is a manufacturing process that consists of pouring liquid material into a mold cavity. When the liquid material cools, it gets harder, and you will get objects in the shape of the resin mold. The object created in 3d printing wax casting process is called casting.

That object can then be used for different manufacturing processes and sold as the final product. However, resin casting is a unique casting process that utilizes synthetic resin.

This is a method where the molds are filled with liquidized synthetic resin, which later hardens. This is generally used for small-scale manufacturing, for example, dentistry or industrial prototypes. Besides, this can be used to produce collectible figures, models, toys, and small-scale jewelry production.

The resin used for the process is a monomer and used for making plastic thermosetting polymer. During the process, the liquidized monomer is polymerized into the polymer solution, and then it gets hardened.

Understanding the basics of the resin casting

Castable resins are synthetic resins and used widely in the casting process. Synthetic resin is converted into a rigid and durable polymer through the curing process. In simple words, it starts in a liquid state but is later converted to a solid-state through curing.

In resin casting, liquidized synthetic resin is appropriately combined with the best curing agent at room temperature. Then the two substances are transferred into a mold cavity. After that, the curing agent turns the castable resin into rigid polymers by hardening. Once done, the hardened casting is removed from the mold.

Some significant advantages of resin casting

Resin casting is effortless and can be carried out utilizing a few tools and materials. It is so simple that some hobbyists use this process to craft small objects. This is the most cost-effective and straightforward way to build small objects.

Besides, using resin casting, you can produce objects having complex shapes. However, the casting shape ultimately depends on the mold cavity’s shape. By utilizing the right type of mold, you can form a casting in the desired shape.

Each day, new 3D printing materials are introduced for different requirements and getting popular in different sectors. Castable resin is time and cost-saving for different works, like dental and jewelry molding. Most of the 3D printed objects appear like traditionally casted products, which is why 3D printed jewelry is on its way to becoming mainstream.

Castable resin is designed to offer smooth surfaces and precise details. The best thing is that it can burn out correctly without leaving any residue, letting the jewelers go straight to the 3D print models from digital design suitable for 3d printing for investment casting. Now let’ have a look at how to use this resin.

How can you use the castable resin?

Going for the traditional method, under this, a model is in wax, and then a plaster mold is developed around the wax model. After that, the mold is fired at a high temperature in a kiln. Then the wax is burned out, allowing the metal parts to be cast. The same method is also used for 3D printed parts.

In the case of LCD or FDM 3D printers, the wax-like resin acts like printing material in these machines. After done with the pattern assembly, the entire section is properly submerged multiple times in slurry. Once done, the coating will be allowed to dry, and it will solidify, creating a ceramic layer.

It is then put inside an oven, and the resin structure is melted. After that, the final casing material is put into the mold and left to solidify. In the end, the outer ceramic molds are removed and processed for the finishing techniques.

Some significant benefits of castable resin?

Such resin is the best and affordable way to craft 3D printed jewelry. This resin is widely used to create a solid and real-looking piece of jewelry having a super smooth surface. Here are some advantages to using castable 3D printing.

- You will be able to craft intricate designs. Typically, the jewelry casting patterns were developed from wax, and generally, CNC machines are used for this. 3D printing can produce parts that were challenging or impossible to make.

- You can easily customize the design. You can easily make changes in your product design. A castable 3D model can be 3D printed as a plastic prototype to check if the design is correct or not. If not, changes can be done using any 3D modeling software, and the final design can be printed using the resin.

- This process is very time-saving. You create multiple patterns within a few hours. This will lower the lead times and costs compared to traditional pattern making methods.

- You will find it cost saving. The reason is, you can 3D print multiple designs in a single print. That means it can be very cost-effective where the production volumes are low.

3.5, For photosensitive resin 3d printing

Is it possible to carryout photosensitive resin 3d printing? Well, everything is possible in the modern world. In 3D printing, you will hear about the material called photosensitive resin with a photopolymer resin 3d printer. Besides, this resin is also used for DLP-Digital Light Processing and Stereolithography 3D printing.

What do you mean by Photosensitive Resin?

Talking about photosensitive resin, this is also called photopolymer, UV curable, and light-activated resin. It is one type of polymer that can change the properties after getting exposed to light, often in the ultraviolet or the electromagnetic spectrum.

Such changes are generally manifested structurally. For instance, material hardening occurs during cross-linking.

In general, the UV curable resin includes monomers, oligomers, co-initiator, photo-polymerization, and some additives like pigments, plasticizers, antioxidants, and stabilizers.

It has been proved that photosynthesis curing offers a lot of advantages over conventional curing, such as less energy consumption, less equipment space and emission, reduced waste, higher productivity, and reduced temperature configuration. These can produce prototypes, dental surgical guides, jewelry models, functional parts, and more.

3.6, For heat resistant resin 3d printing

In some industries, there is a massive requirement of heat resistant resin 3d printing. For this, high-temperature resins are used. Such resins offer the highest HDT- Heat Deflection Temperature and are perfect for 3D printing precise and detailed parts that can offer a higher thermal stability level.

You can choose a heat resistant resin having an HDT of 238 °C @ 0.45 MPa. The 3d printing resin high temperature is perfect for applications that require the parts to withstand a higher temperate without facing excessive loading. Such material doesn’t offer much flexibility, so snap fits cannot print using heat resistant resins.

Such resin comes in 25, 50, and 100-micron layer of heights. For small objects, you can use the 25- micron setting to create a piece of jewelry. The significant difference between printing at 50 microns and 25 microns is a smoother surface finish. However, the print quality will be the same.

Printing in heat resistant resin requires more laser power. While using heat resistant resin for creating parts, you need to use supports. Always try to avoid printing parts on the platform with such resin as you may face adhesion issues between the part and the surface of the build platform.

As per the experts’ advice, always increase the touch point’s size when printing heavy or large objects. If the support touch point size is small, the models can get separated.

3.7, For conductive resin 3d printing

Conductive resin can easily connect different electrical contacts at a single time, and using this; it is possible to develop electrical connections in materials that are not possible to solder.

The electro-conductive resins can be used in conductive resin 3D printer, and resin can be made of a synthetic resin and conductive filler. You can use the material for conduction and different electrical contacts.

Carbon, nickel, silver, and more are used for electro-conductive fillers. For the binder, epoxy resin, silicone resin, urethane resin, synthetic rubber, etc., are used.

On the other hand, conductive resins can be used in sensitive electronics and fuel lines to prevent sparks. This can also be used in external components, wind turbines, and cars painted through electrostatic paint.

Remember that epoxy resin is non-conductive, but you can make it conductive by combining it with silver-filled epoxy resin. It can be thermally conductive and cool the component.

Another benefit is the epoxy can also be thermally conductive, meaning it can also cool the component. Such resin comes with some smart auto-response properties, such as self-repair, self-protection, self-healing, self-curing, and more. This makes it a perfect element for building, aerospace, car, energy supply, technology, and other industries.

How to buy a 3D printer – Question you should ask

There is no doubt that both FDM and LCD 3D printers offer an endless array of possibilities. Whether you are making a smartphone case, a door stops, a piece of jewelry, or a figurine, you can create anything using such machines.

However, choosing the right one will play an important role. How to pick the right one? To help you out in this, we have listed down some questions that you should consider. Have a look at those things.

4.1, Before buying, you should consider your own needs

Here are some questions that you need to consider before making your purchase.

4.1.1 What is the thing to be printed?

Before you buy your 3D printer, you need to understand what exactly you want to print. Remember that there is a massive gap between the 3D printing models or gadgets for industrial-scale production parts and for your desk.

It will also help if you analyze how often you want to print, how much time you can spend on this, and where you will use the 3D printed objects.

4.1.2 What is the size of the print?

This suggests the object’s maximum size that the LCD or FDM 3D printers can print. In this industry, the size is measured by XYZ dimensions; for example, 10 inches wide (X) by 10 inches deep (Y) by 10 inches high (Z). If you go for a smaller build area, this can limit your prints, but you can divide the task into smaller parts and combine them later. However, for decent print, choose a build area of around 5 (X) x 5 (Y) x 5 (Z) inches.

4.1.3 What are the special needs for printing materials?

You can use filaments that are made from different materials like PLA, ABS, and PETG. Some of the most common types of filaments are:

- PLA (Polylactic Acid) is a plant-based plastic and can degrade after years of exposure to the sun. The moisture level can deteriorate the material. However, this can be an excellent option for indoor applications.

- PETG (Polyethylene Terephthalate Glycol)- It is a food-safe plastic. FDM 3D printers create layers that can trap moisture, bacteria, and food. PETG objects need to be appropriately finished applying a food-grade epoxy before using them for food.

- ABS (Acrylonitrile Butadiene Styrene) is a sturdy plastic and works great with an enclosed 3D printer while the ambient temperature is warm. You can use such filament when the printing room can be well ventilated. This can be an excellent option for outdoor purposes.

- Carbon fiber- This resin can provide you the strength of aluminum material and the models will last for years.

- Nylon- When it comes to getting better flexibility and durability, you can always trust nylon resin. The coefficient friction level of this material is low.

- PVA- It dissolves when you put water on it. With this, you don’t have to worry about structure removal issue.

Resin 3D printers, like LCD and FDM 3D printers, utilize liquid resins to form 3D models. Resin comes under different categories. Some of them are:

- Standard resin– It comes in clear, gray, and white colors. It is perfect for developing prototypes or small gadgets. However, this is not sturdy enough to be used for your final products.

- Tough resin– It is generally used in professional settings and for different engineering applications. This resin is physically resistant to other types of resins. If you are building 3D models for higher impact use, you can use tough resins.

- Transparent resin– This is the most robust class of resin and generally used for 3D models that should be smoother to touch and offer a transparent appearance.

- Dental casting resin-Such resin burns instead of melting. The casting process with this resin will be much easier.

- ABS resin-This is tough resin and offer better dimensional stability. The toughness level is also good.

- Jewelry casting-When it comes casting jewelry pieces having complex design, such resin can be used. The result will be accurate.

The FDM 3D printer produced by Dreambot3d supports printing materials like PLA, TPU, 95A, water-soluble materials, carbon, metal filler, woody PLA, customizable ABS, PC, PETG, and more.

4.2, When buying, consider external conditions

4.2.1 Determine your ideal 3D printer style

You need to think about the printer style that is good for you, i.e., FDM or LCD 3D printers. Most of the hobbyists use FDM printers. Such machines can extrude plastic and hot materials, called a filament, to produce 3D-printed models.

On the other hand, LCD 3D printers use resin for this. DLP- Digital Light Processing, SLA- Stereolithography, and SLS- Selective Laser Sintering printers use powder instead of resin.

4.2.2 Resolution requirements of the machine

Speaking about the resolution, it refers to the Z-minimal layer of thickness and X-Y resolution. As the motion systems have been in the industry for years, the X-Y resolution is perfect for FDM and LCD 3D printer.

As the FDM3D printers produce parts with the layering effect, the layer thickness resolution can affect the finished quality of the printed models.

If the layers are thin, the finished part will look smoother. However, it will take time to print. Some 3D printers support a thickness of 50 microns (0.05 mm).

Most of the users prefer to print 3D parts with a thickness of 0.10 mm to 0.30 mm to lower the print time. So, make sure your machine supports the right resolutions.

4.2.3 Choose a reliable brand

When buying a good quality 3D printing machine, you should always go for a reliable brand. With this, you will get suitable 3D printers and better quality after-sales service. This is where you can trust JWSTEC.

4.2.4 Consider whether the price of the machine is acceptable

One of the significant factors that you need to consider when buying a 3D printer is the price. Remember that the price of your printer will depend on its output quality.

If you go for the higher-quality output, it may cost you more than USD 1,000, and most of the professional 3D printers almost cost more than USD 2,000. Besides, make sure that the printer you are buying supports modern and advanced features.

4.2.5 Consider the supplier’s after-sales service capability

Before finalizing the 3D printer purchase, remember to look at the supplier’s customer support or after-sales service feature. Make sure that the company has a professional customer support system. Hence, you can resolve your issues as soon as possible.

4.2.6, Safety configuration of the machine

Most 3D printers come with safety features. For instance, an FDM 3D printer may cool down the nozzle and heat up the bed once your print job is completed. Some printers can move the nozzle away when you stop the printing task. This will prevent heat damage and excess forming of filament.

Conclusion

Challenges indeed arise when you spot a new one. However, after analyzing all the information mentioned above, you can now be able to pick the right 3D printing machine for you.

However, you can always choose LCD 3D printers and FDM 3D printers of Dreambot3d for better 3D prints using different materials.

Besides, for more details about our 3D printers, you can always feel free to get in touch with our experts. If you still have confusion regarding this, have a look at the FAQ section.

FAQ Guide

What is castable resin?

As the name suggests, the castable resin can be cast in a mold to create 3D models. Such resins are durable, and you will get a smoother surface in the finished products.

What is needed to print 3d resin?

You can use standard resin, gray resin, heat resistant resin, photosynthesis resin, and more to print 3D resin models. For more details, you can look at the above-given information.

Is a resin 3d printer better?

Yes, most advanced resin 3D printers are better. In fact, a resin printer will support different printing materials. You can use it as a castable wax 3d printer.

Are Resin prints stronger than FDM?

As per the experts, both resin and FDM prints are more robust, but FDM 3D models will be a little stronger than those of resin 3D models. In the FDM process, thermoplastic filaments are melted and gradually layered on the platform to create the 3D model. Standard resin comes with high-level tensile strength, but it can be quite brittle. So, it is not advisable to create functional parts using resin.

Are resin printers faster than FDM?

Resin printers are faster than FD. However, with FDM 3D printers, you can print thicker layers faster. Besides, resin printing involves more post-processing steps compared to FDM printing.

Can 3d printers print wax?

Yes, it is now possible to 3D print wax using FDM- Fused Deposition Modeling technology. Utilizing our FDM 3D printers, the 3d printing material will let you create wax molds.

How do I do investment casting?

In the process of investment casting, a wax is coated by dipping into slurry. After the coating of refractory material, the dipping process is repeated several times to enhance the coating’s strength and thickness. Once the coating is hardened, the wax is removed, and the molten metal is poured into the cavity; you can use 3d printing for investment casting.

How difficult is it to learn 3d printing?

The fact is it is not all difficult to learn 3D printing as most of the advanced LCD and FDM 3D printing machines will let you do 3D printing very quickly. The machines are effortless to use, and you can get detailed instructions about using them online. With Dreambot3d, you can get online technical guidance and video tutorials.

What is the demand for 3d printing?

As per the report, the global 3D printing market is forecasted to reach USD 51.77 billion by the end of 2026. It is also estimated that the 3D printing market will grow at a Compound Annual Growth Rate of 25.8 percent in the coming years. The primary reason behind the growth is the increasing application of 3D printing in the global healthcare industry.

Is 3d printing the future?

Yes, looking at the current trend and applications, it can be said that 3D printing is the future. Companies are now investing more in this because by using 3D printing, they create products that were earlier complex to develop.

Why is 3d printing becoming so popular?

3D printing is getting popular because of the increasing demand of interested consumers. There is a huge demand for smaller and easy to operate printing machines available at affordable prices. You can even get a 3D printer at the price of a smartphone.

What is the best 3d printer for jewelry?

You can use both FDM and LCD 3D printers for jewelry. For the best product, you can look at the available model of Dreambot3d’s 3D printer. Its ME-192, black and white screen offer better light transmittance level and works 3 to 4 times faster than color display.

How fast is a resin printer?

A resin printer can offer a printing speed of 100+ mm/hour. Well, the maximum speed can reach up to 200mm per hour.

Are resin printers faster?

Most of the resin printers work with DLP or FDM printing technology. So, they work much faster than other 3D printers. Dreambot3d have introduced ME-192 black and white screen that can operate 3 to 4 times faster than the color displays.

How expensive is resin printing?

The 3D printing cost depends on the quality of the material, manufacturer, and type of the material you are suing. The cost of a standard resin can go up to USD 50 per liter. So, to print a 6-inch cube, you may need to spend around USD 300 to 400.

Is resin printing more expensive?

It depends on the object that you want to print. However, if you consider the durability and quality that a resin printing offer, you may not find it very expensive.

Is LCD better than DLP?

The LCD can project the light efficiently and offers a good color saturation. You will get a brighter image than DLP. So, LCD is better than DLP.

Is LCD faster than DLP?

LCD is faster than DLP, and it doesn’t need a nozzle to trace out every layer. LCD 3D printing can cure the whole layer at once. Recently the company has launched its new black and white screen, for example ME-192 which functions 3 to 4 times faster than the color screens. It is forecasted that, in the coming years, other printing machines will also produce black and white screen style.

How do resin 3d printers work?

The resin 3D printers work by creating an object from a digital design by forming resin layers in a particular shape.

What is the best 3d resin printer?

When choosing the best 3D resin printer, you can always go for FDM and LCD 3D printers.

Do LED printers use a toner?

Yes, led printers mostly use toners and a drum unit for printing.

How do liquid 3d printers work?

The liquid 3D printers, using computer-controlled UV lasers, turn the liquid resin into a solid-state. The laser then draws the outlines of the print onto the layer and gradually hardens the parts.