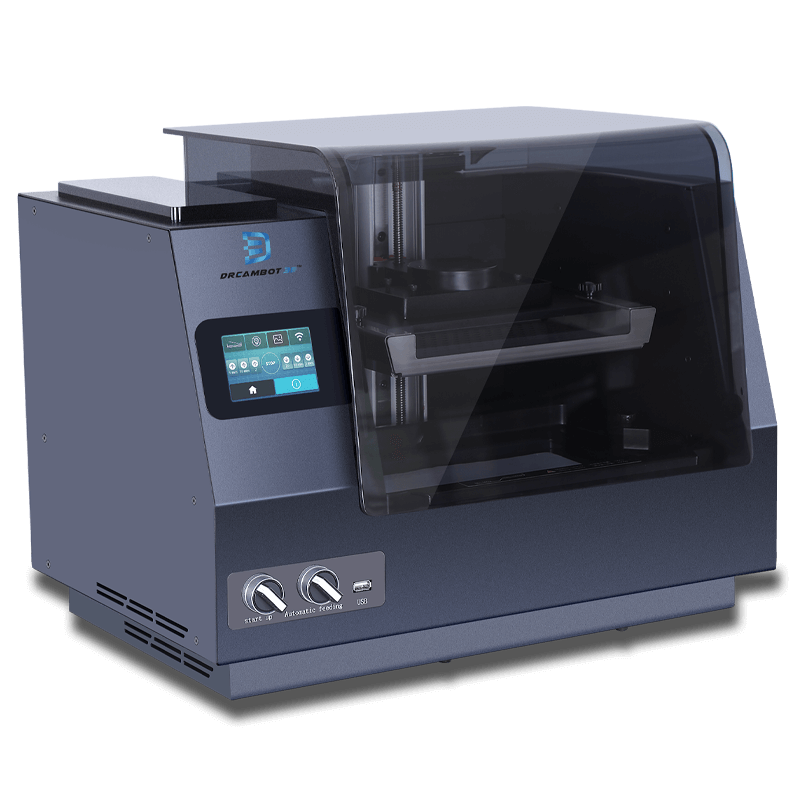

lcd resin 3D printer

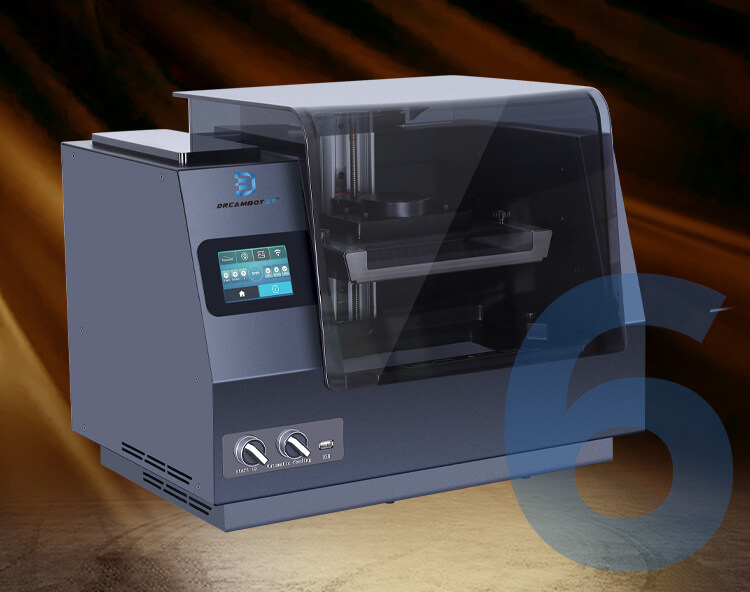

ME-215 LCD 3D Printer

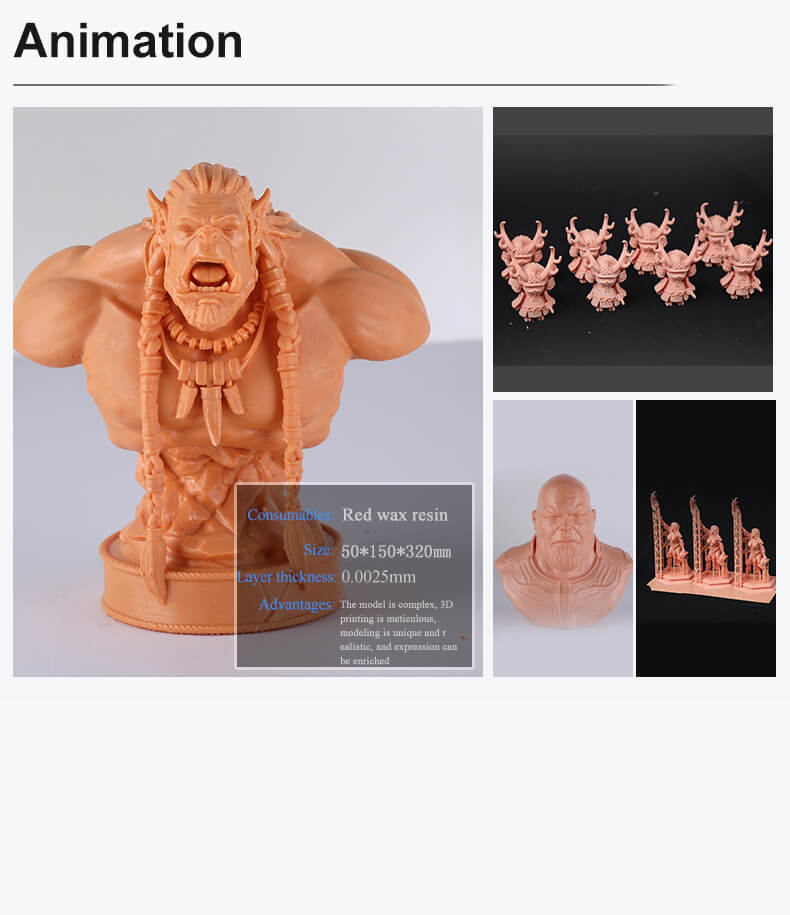

- Stereoscopic light curing 3D printer with LCD technology, high quality of finished products

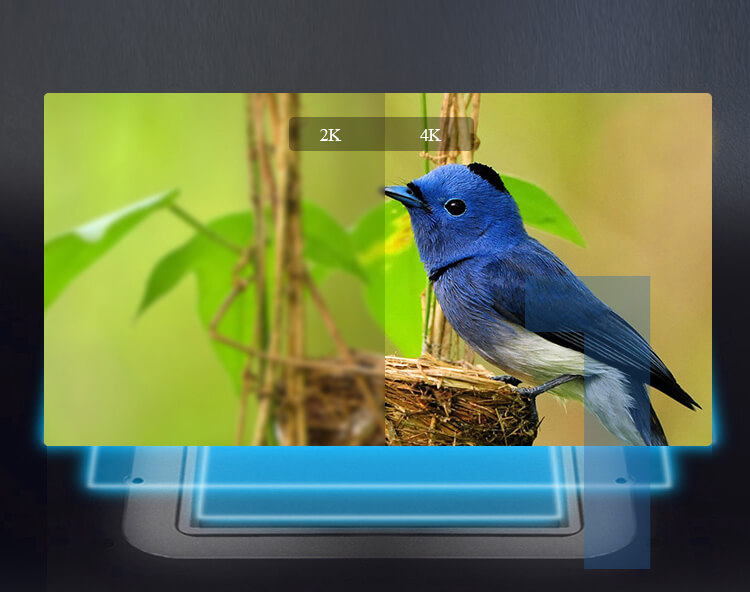

- 4K high-definition pixel printing greatly improves the smoothness of the model surface.

- Dreambot3D LCD resin 3D printer(ME-215) has obtained CE, FCC certification and quality assurance.

Dreambot3D LCD resin 3D printer(ME-215)

The Dreambot3D LCD resin 3D printer (ME-215) produces incredibly accurate prints using resin within a short time. Hobbyists, professionals and businesses make use of the LCD 3D printer to meet various printing needs.

The LCD resin printer is used in jewelry making, dental, engineering industries. The LCD resin 3D printer is relied upon to create only accurate and highly detailed 3D objects.

The Dreambot3D LCD resin 3D printer (ME-215) is quite affordable, allowing you to print high definition objects at a high speed. Printed objects have a smooth and detailed surface and they are as thick as 0.025mm.

| Parameters | ME-215 LCD 3D Printer | |

| Printing Parameters | Printing style | RESIN LCD 3D Printer |

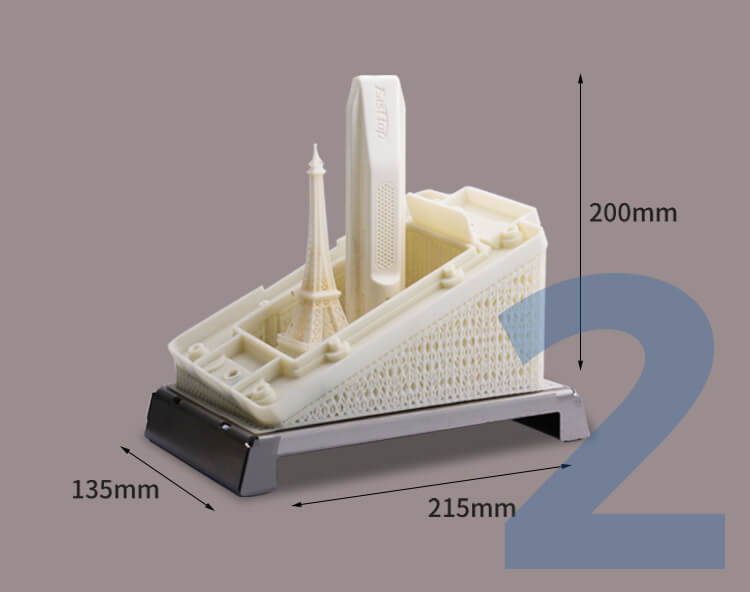

| Max printing volume | 215*135*200mm | |

| LCD size | 10.1 inch | |

| LCD panel | 2K LCD screen panel | |

| Printing accuracy | X Y axis 0.075mm, Z axis 0.02mm | |

| Printing speed | max 20nm/h (Z axis) | |

| Resin support | 405nm resin | |

| LED array | Parallel UV LED light source | |

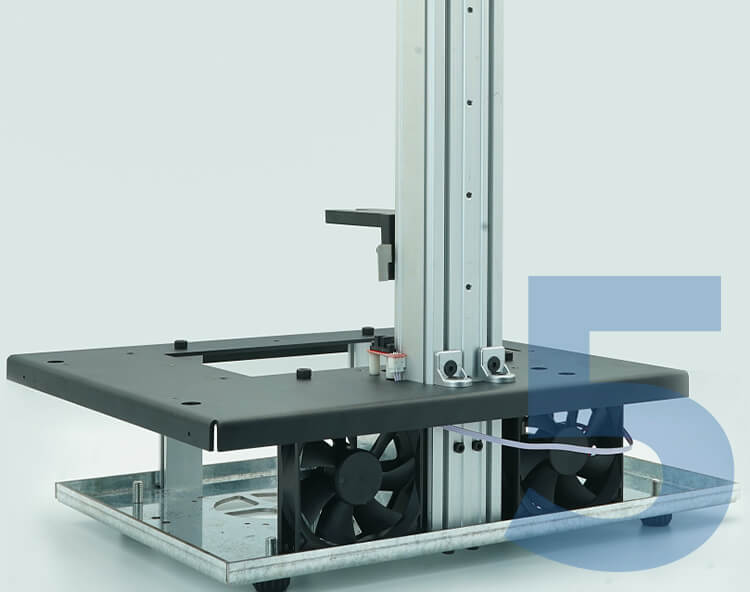

| Z axis | Dual Linear Rail, Ball Screw, 100% Aluminum CNC Structure | |

| Touch screen | 5 inch High Resolution Touch Panel | |

| Software Parameters | Operating systems | Windows Linux Mac OS OSX |

| 3D Modeling software | CAD Solidworks 3Dmax UG Maya Rhino Proe 3Done Skatchup ect | |

| 3D Slicing software | Linux | |

| Input format | STL OBJ AMF ect | |

| Connect mode | USB,Network Connect | |

| Physical Parameters | Printer dimensions | 510*345*405mm |

| Package size | 620*450*500mm | |

| Gross weight | 28kg | |

| Structure | CNC Sheet Metal (full enclosed style) | |

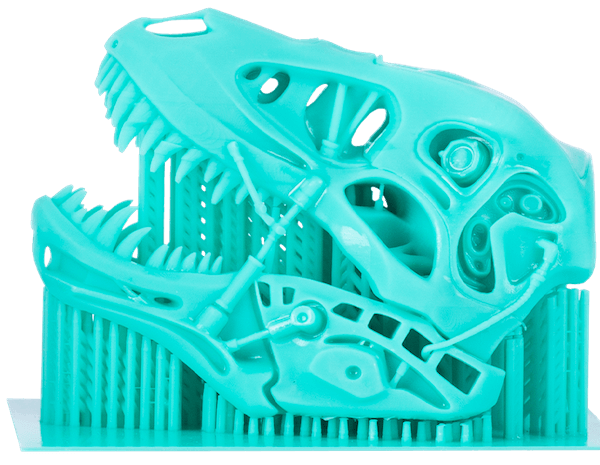

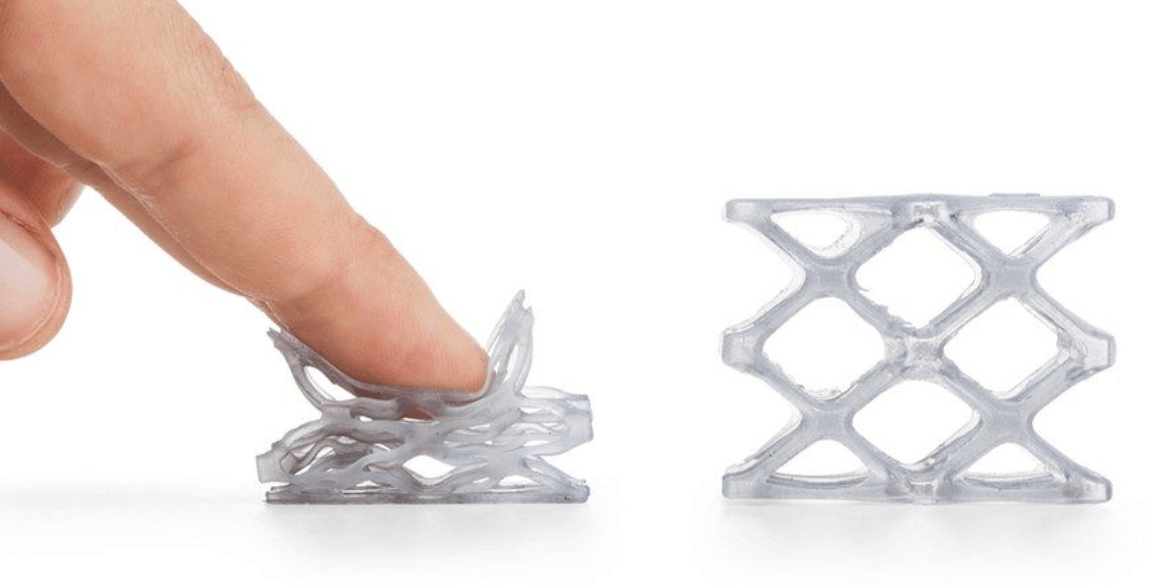

- Dreambot3D LCD resin 3D printer (ME-215) is able to accurately print a variety of complex items as well as items with complex shapes which will be totally impossible with other means. This means that you are able to print exactly what you design.

- You can print large size objects that meet your needs for creating larger applications.

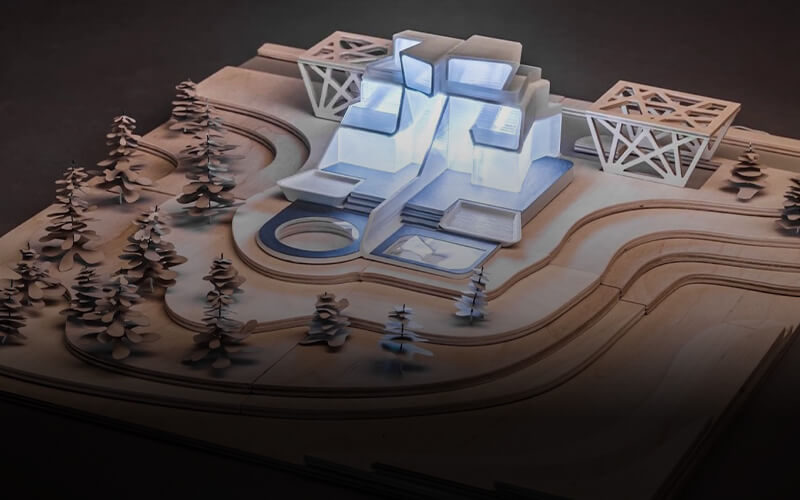

- Printing with the LCD resin printer makes all printing highly accurate which makes the machine suitable for use in architectural, handicrafts, animation companies.

- The stability of the 3D printer contributes to accuracy of printing. The precise z-axis linear guide ensures that every minute movement of the z-axis is accurate under the strict requirements of the x and y axis. The stability of the structures makes your creations more refined.

- The LCD resin 3D printer uses a 4k high image display technology with an increased lifespan of 200% and increased efficiency of 30%.

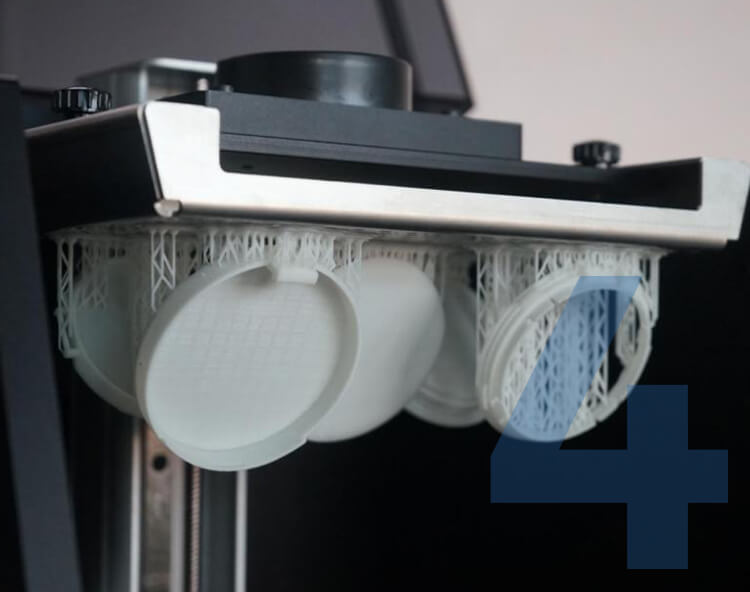

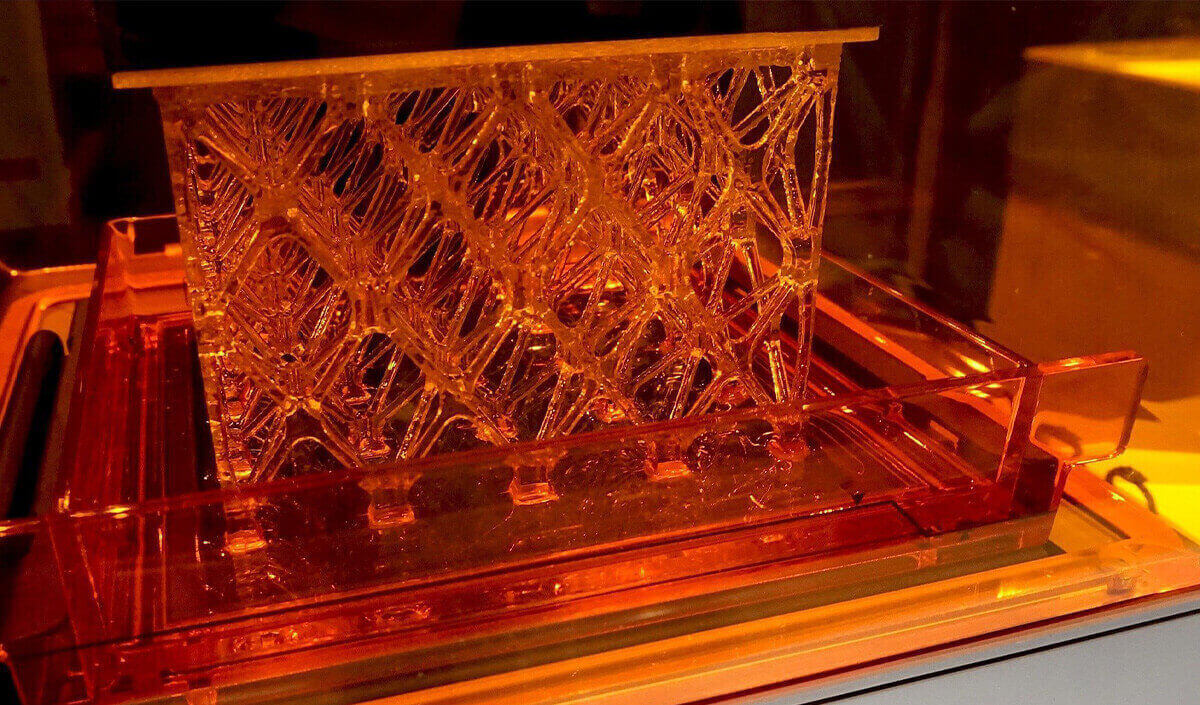

- The resin material is cured layer by layer under the ultraviolet light, each layer is cooled efficiently to provide high printing quality.

- Large printing is done at the rate of 20mm/h, which completes your simple and complex designs faster. Therefore, you can print more within less time.

- Dreambot3D LCD resin 3D printer (ME-215) has the EC and FCC certification, which means all our printers are of high quality and very safe for use.

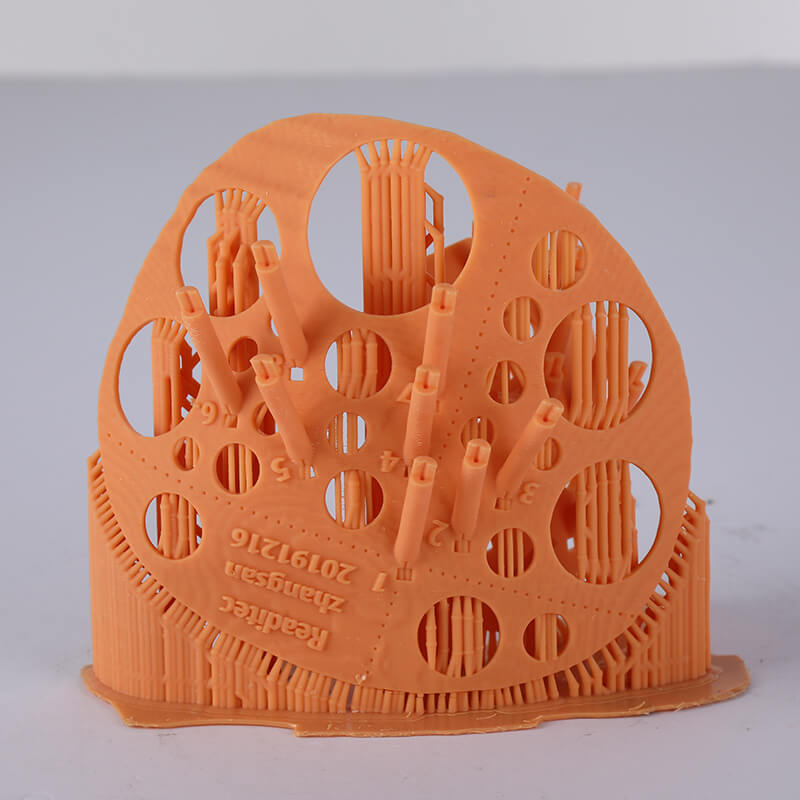

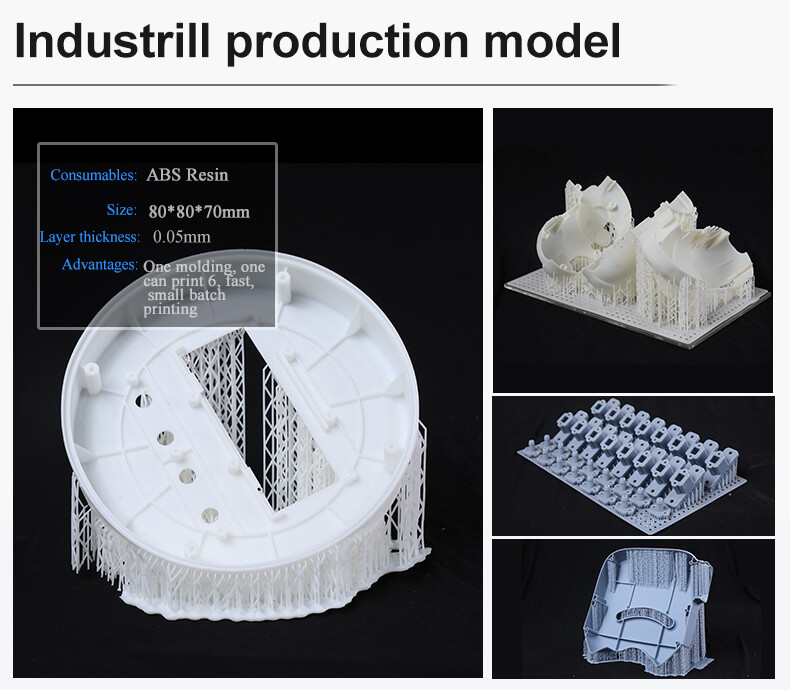

Application of lCD resin 3D printer

Test your part

We provide sample testing service, allowing you to check the working quality of our 3D printer before placing an order

6 points why choose us

4K resolution printing

Large size printing

Our newly developed industrial-grade LCD 3D printer can support print sizes up to 215x135x200mm

PLC control system

Extremely speed printing

Industrial grade ball screw guide

Reinforced structure

More LCD resin 3D printers

ME-192 LCD 3D Printer

The ME-192 3D printer provides a highly accurate 0.01-0.05mm layer of accuracy for you. It has a simple leveling that makes it suitable for new users.

DB-293 LCD 3D Printer

The DB-293 3D printer is used for printing high definition and professional 3D objects. It is best used for jewelry molds, building models, etc.

DB-550 LCD 3D Printer

The DB-550 3D printer is used to print complex objects with many angles. They are also used for large commercial printing.

LCD resin 3D printer buying guide

What is an LCD resin 3D printer?

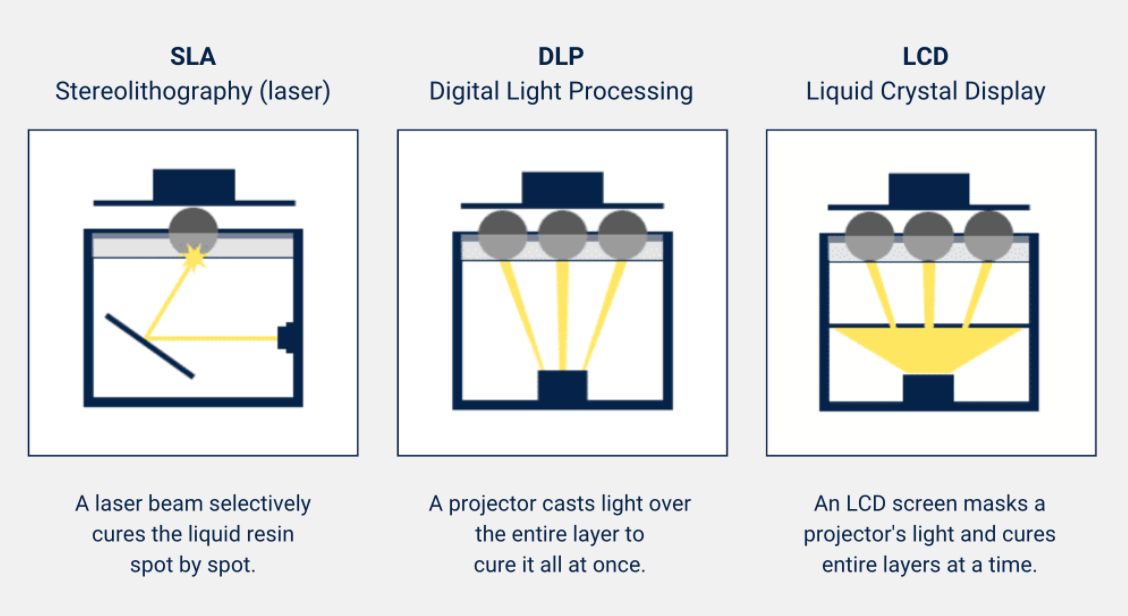

An LCD resin printer is used to transfer words and images onto various flat surfaces. This resin 3D printer is commonly mistaken for a laser printer.

They are both used for almost the same purpose, printing, but they differ in structure and functionality. The laser printer, just like the name suggests, uses a laser beam as its source of light to imprint patterns.

LCD resin printer uses UV LCDs as their light source to imprint via a liquid crystal panel.

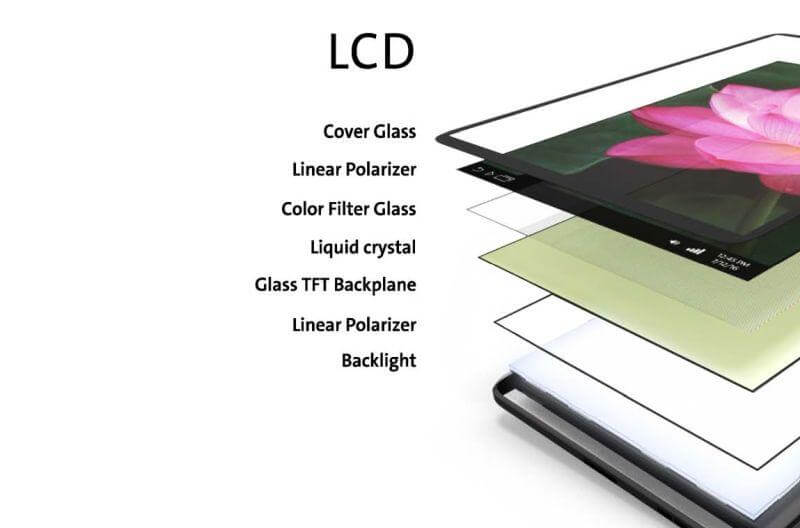

This resin-based printer creates its patterns in the form of dots. You might be wondering how it can achieve dots. LCD 3D printer is composed of panels that contain pixels.

The various pixels are responsible for allowing light or blocking light from penetrating these panels to form the dotted patterns. The more pixels, the better the quality of the imprinted patterns.

1.1, What does LCD mean, and where does it come from?

LCD stands for Liquid Crystal Display. At this stage in life, most people are only familiar with the three famous states: solid, liquid, or gas.

Well, there is another rare state, liquid-crystal. This state might sound contradicting as we all know that a crystal can’t exist as a liquid.

It turns out that crystals can be turned to liquid faster as compared to solid. Liquid-crystal exists both as solid and liquid. The molecules in this state can maintain their orientation like solid and can change position just like liquids.

LCD 3D printing is amongst the latest development in the 3D printing industry. While it has been in existence for over a century, its innumerable growth has helped it rise above its counterpart to become one of the cheapest and fastest resin 3D printers.

LCD 3D printer’s efficiency and spontaneous growth are backed by its operational sequence. The machine uses an affordable LCD screen to create the mask, eliminating expensive DMD chips used in DLP techniques. This technique works by an array of LEDs illuminating the LCD.

1.2, How does an LCD 3D printer work?

An LCD resin 3D printer consists of a metal-halide lamp that houses the UV LCDs; these UV LCDs are used as the source of light by the 3D resin printer. It works when the light from the UV LCDs is shown on a prism. The prism then divides this light into three polycrystalline silicon panels, also known as polysilicon.

The light in the 3D LCD printer panels then travels to the print areas, which has pixels. The pixels respond by opening up to allow the light to penetrate or close to block the light from penetrating.

This opening and closing process carried out by the 3D resin printer’s pixels allows the liquid polymer to create various effects on the image, such as multiple colors and shades.

LCD 3D printers are designed in a way that all the emitted light from the UV LCD stays focused on the projected image. Interference such as de-pixelation won’t affect you when printing as the light is carefully regulated to stop it from expanding. Unlike other printers, an LCD resin printer’s image quality varies based on the LCD density.

LCD vs. DLP vs. SLA: all you need to know

Every professional or hobbyist is familiar with the unpleasant syntax attached to the R&D phase. From designing and prototyping to manufacturing and distribution, the workload, zeal, patience, and tenacity required is second to none.

The creation of 3D printers brought about a simplified design and creation process. However, the number of individuals enjoying the cheap and affordable 3D modeling process 3D printers offer is quite limited.

And why is that? Many experts, hobbyists, and professionals find it hard to pinpoint the right 3D resin printer for a particular task. This section will highlight the basic features of the multiple variants of resin 3D printers available, allowing you the opportunity to navigate and pinpoint which would suit your dynamic business needs.

Keep in mind that if you plan to buy any resin 3D printer, it’s important you conduct thorough research on each. Taking out time to conduct such research will help you make a more informed decision by giving you insights on how they work, their similarities, and how they differ.

However, if you are new to the printing business and in search of directions as to the 3D resin printer to buy for specific needs, we recommend you stick with this piece for a while.

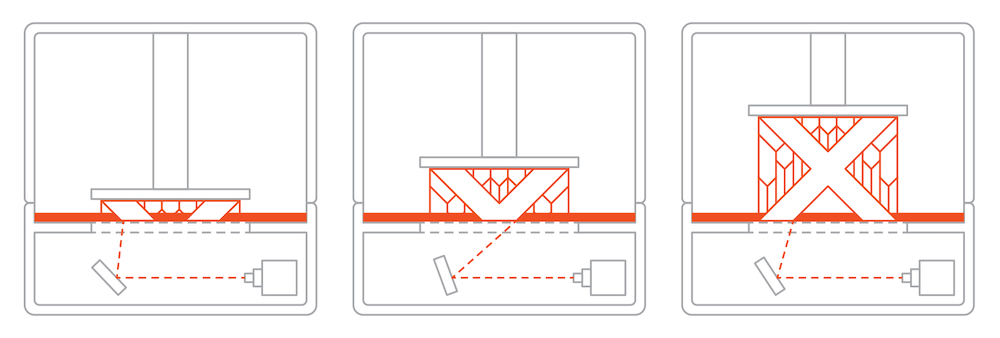

There are three major printers strong and flexible enough to handle your 3D resin printing needs; SLA 3D printer, DLP 3D printer, and LCD 3D printers; as to which ranks best, you will soon find out.

SLA 3D Printer

SLA, meaning stereo-lithography, is the oldest resin 3D printer. Its framework was used to create the modern 3D printers. SLA printers use laser beams as a source of light. The laser beam is used in solidifying resins in some parts of the resin tanks.

The laser beams’ reflection commences at the bottom of the tank before being redirected by galvanometers (mirrors) towards the focal point. The SLA 3D printers are built to undergo a repeated modeling process until the image’s desired pattern is achieved. Note that SLA printers are no more as reliable nor as rampant as they use to be due to the more advanced printing process DLP and LCD 3D printers provide.

DLP 3D Printer

Digital Light Processing (DLP) 3D printers were founded in 1987 by Larry Hornbeck. Hornbeck designed this purely for movie projection. The DLP printing sequence built a reputation for itself due to its smooth and highly efficient printing process.

DLP 3D printers are famous for projectors. This resin printer uses projectors to shine a light on the resin layer. Digital micro-mirror devices that are made up of many printing mirrors are used to solidify particular areas of the resin by directing the light’s projection towards the pixels. Note that the DLP 3D printer projector makes use of pixels that contain voxels.

LCD 3D printers

Liquid crystal display (LCD) 3D printer is a cheap resin printer that uses LCD light to transfer patterns onto flat surfaces. Imprints from this printer are of high resolution. This 3D printer is better than most in its category; it can print the internal material without interruptions from outer objects.

LCD 3D printer utilizes almost the same technology as that of a laser beam. The difference is that LCD resin printer uses UV LCDs as its source of light, and the image produced is better than that of the laser printers. LCD 3D printers are regarded as the most reputable resin 3D printers globally.

The unique surface finish, accuracy, and precision they bring to the 3D modeling and designing printing process are seconded to none.

Basic similarities and differences between SLA, DLP, and LCD printers in terms of cost, efficiency, tank size, and print quality.

All three 3D technology printers have quite a reputation. Their quality is not yet unmatched. They make up the backbone of 3D history. However, they all have their pros and cons.

SLA

Even though it’s the oldest among the three, it’s still one of the top resin 3D printers. Its quality is still remarkable, and the technology used in building it is outstanding.

However, SLA 3D printer operations are extremely tedious and time-consuming. Most of its operations, such as tracing, are done manually, and it’s quite expensive. In a fast-paced world backed by constant advancement in technology, hobbyists and professionals regard the DLP and LCD 3D printing process as higher and more sophisticated than SLA.

DLP

DLP 3D printers provide a surface finish similar to that of LCD. Just like LCD, its operations are automated. This resin 3D printer produces one of the best resin coating 3D prints. However, this 3D resin printer is not in any way budget-friendly in comparison to LCD printers. If you seek a highly specialized printing service, it’s recommended you opt for LCD 3D printers.

LCD

LCD 3D Resin printer is one of the most preferred 3D printing technology in the 21st century. This high-resolution resin 3D printer is globally accepted for its high print quality. It’s one of the fastest resin 3D printers as all its operations are hands-free.

If you are looking for a portable best budget resin printer, then an LCD resin printer should be your preferred choice. LCD resin 3D printers are cost-efficient. It won’t waste your time like the SLA as its operation are automated. Its portability gives it an upper hand. Not to mention the fact that its print quality is unmatched.

Application Field of LCD Printers

LCD 3D printing is an innovative technology that helps businesses cut costs and develop new methods of productions.

Though 3D printers have been in use for more than 25 years now, they have gained prominence only recently. The simplicity of use and almost unlimited customization has resulted in 3D printers becoming more popular as design tools.

3D resin printers allow rapid printing and testing of objects for form and function. Initially, 3D printers were used as a rapid prototyping solution to make one or two quick physical samples giving the designers a chance to correct the flaws and modify the product.

While resin 3D printers are still widely used for prototyping, technology developments have made it possible for hobbyists and professionals to use LCD 3D printers beyond research and development stages and even incorporate them into the manufacturing phase.

LCD resin 3D printers come in diverse shapes and sizes and are being used in various industries. Resin 3D printers are yet to obtain usage in numerous industries;

The printer has already originated numerous innovations set to lead the party-ideology for the coming generation in shoe-molding, jewelry casting, dentistry, and medical industry. Let’s highlight the basic effect of 3D resin printers in a few renowned industries.

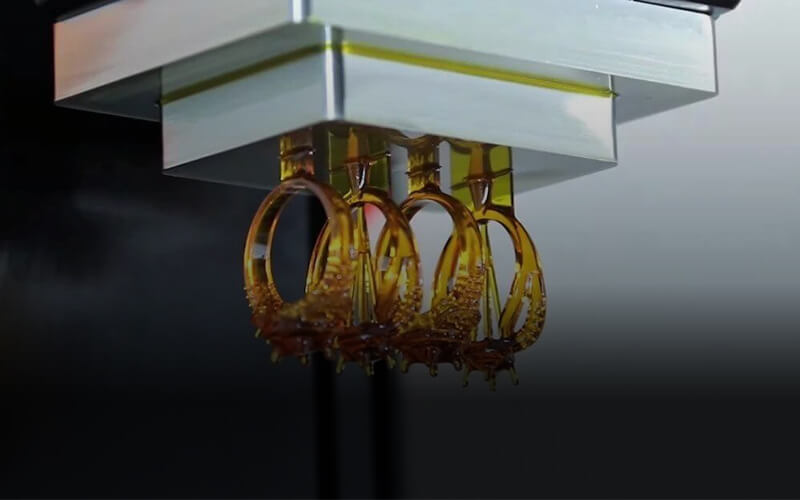

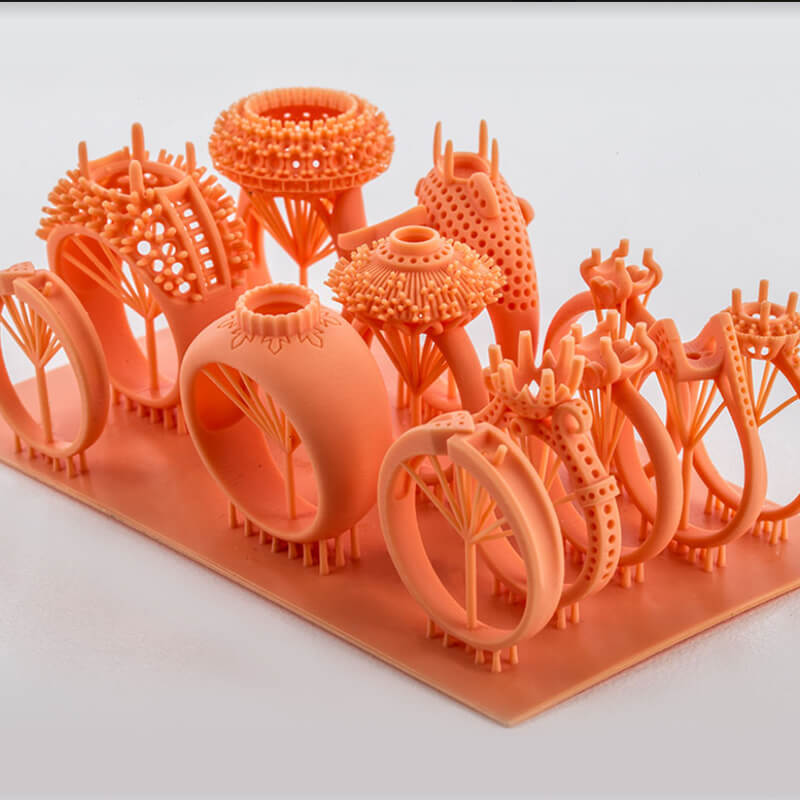

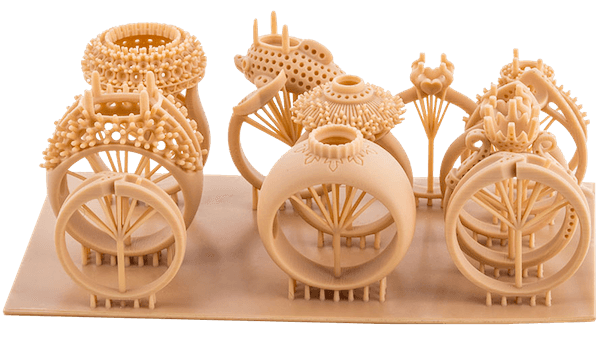

2.1, Used in the Jewelry Industry

The production of jewelry is one industry that has embraced LCD 3D resin Printing. Many jewelers now use the technology to disrupt the way things were done for hundreds of years. 3D printing is now used to create the patterns for investment casting and to print jewelry directly.

There are several advantages to using 3D printing to produce jewelry. These include:

Very complex designs can be created. Historically, jewelry casting patterns were carved from wax using CNC machines. 3D printing is not restricted by the limitations of CNC machining and can produce parts that were impossible to make in the past. Designs can also easily be customized.

With 3D printing, multiple patterns can be made at once and within a concise time frame. This has significantly reduced lead times and cost compared to traditional pattern-making techniques (wax CNC, aluminum molds for casting, etc).

LCD 3D resin printers also allow multiple designs to be produced in a single print. This means it is very cost-competitive for low production volumes (an important issue for jewelry where customers typically want a one-off piece).

2.2, Used in the Medical Industry

Medicine, as we know it now, has evolved from a series of discoveries and inventions. New advancements have enabled newer and more sophisticated techniques in medicine, surgery, and healthcare, in general.

Wondering how? Well, LCD 3D resin printing in medicine has already caused quite the revolution by aiding the 3D printing of implants and helping the surgeons with as detailed mock surgeries as possible.

Bioprinting is the next level of 3D printing in healthcare, and the repercussions are mind-blowing! Bioprinting uses bio-inks and proteins, and other constituents to build tissue or an organ layer by layer. With the advent of LCD resin 3D printers, we have now come to a point where it is possible to fabricate a living tissue, and consequently, an organ.

A lot of limits have already been pushed in the field of healthcare and 3D printing. Right from the perfect prosthetics, accurate pre-op models for academic purposes, practicing surgical procedures, and even something as complex as fabricating human tissue. 3D printers are not only great for creating prototypes but also small-scale production units.

There are some obvious uses and benefits of LCD resin 3D printers in the field of healthcare.

Customizable: Considering human anatomy is as different as every individual on the planet, customizing your output is a huge asset and is key to understanding anatomy on a deeper level. This is true for prosthetics based on the characteristics of the patient, fabrication of different types of tissues,

For recreating difficult bone disorders such as craniofacial disfigurement (where one can decide the thickness of the bone!), and even equipment and medicine. Each patient can get the customized solution they need, thus revolutionizing the healthcare industry.

Cost-Effective: While large scale productions are still quite cheap, smaller production runs and prototyping are now affordable with the LCD 3D resin printers in the picture. Smaller procedures can now be tested and developed as per the end consumer’s parameters. The first output will be as inexpensive as the last, as human resources’ cost is eliminated.

Efficient: Making a prosthetic or an implant or even developing a prototype involves long hours and delivery time. If the process is completely automated with the readings already in place, accurate to the decimals, the output is fast and reliable. It is also replicable and scalable, making the whole process a lot more streamlined and efficient, with high productivity.

Collaboration: With the process easier and cost-effective, more researchers and professionals can develop designs and innovate. By facilitating simpler solutions to bring your imagination to life is so easy, our vision is to bring about more innovation and revolution in medicine – both research and applications wise.

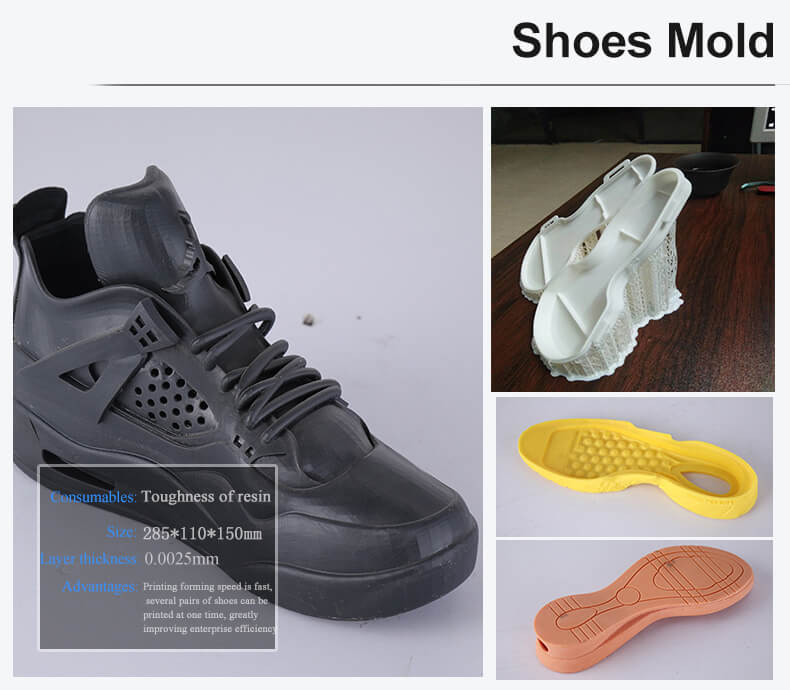

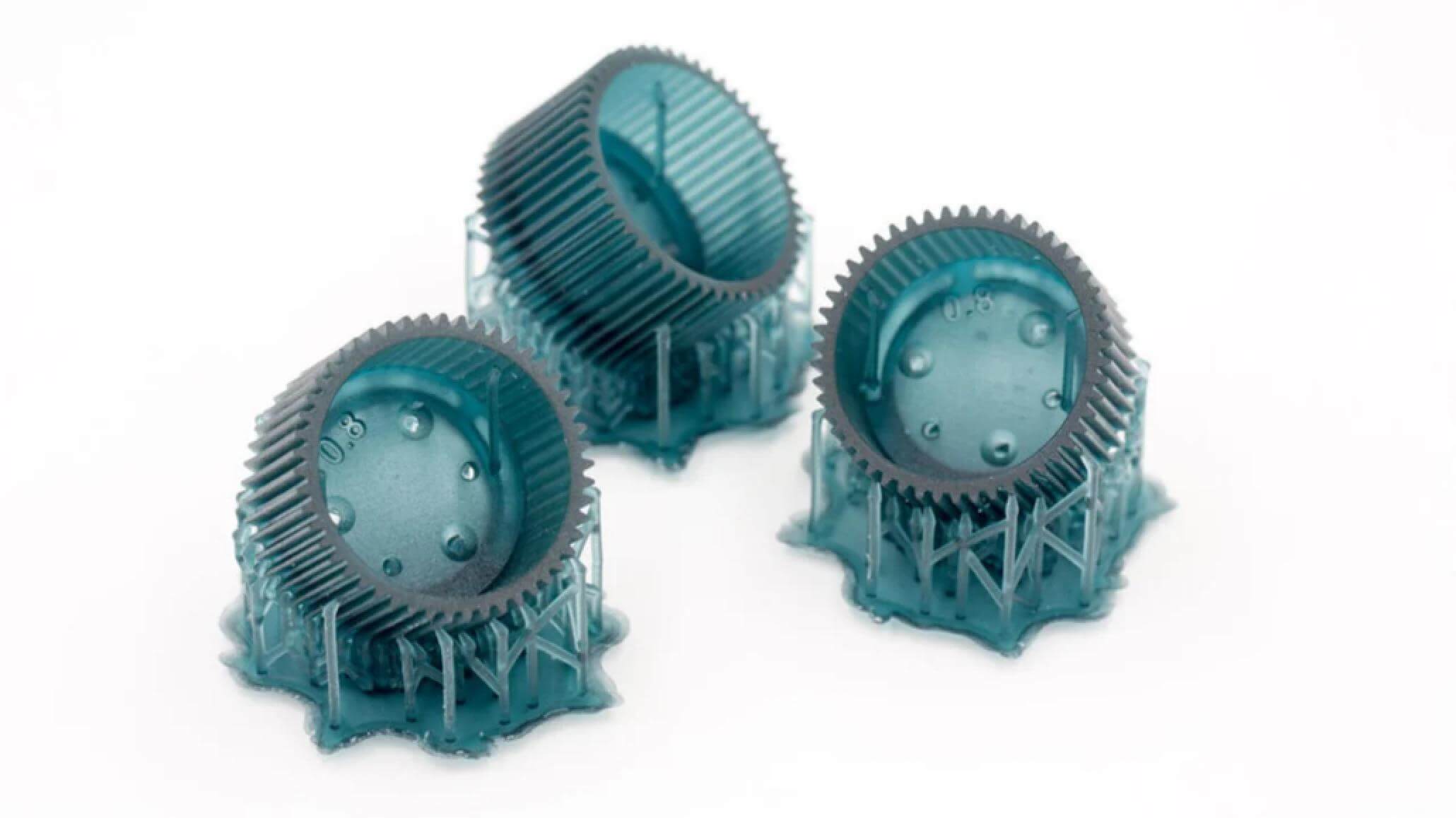

2.3, Used in Production and R&D

3D printers help brings ideas to life. It helps experts in the R&D industry understand the object they are trying to create and help design prototypes using 3D models to streamline a smooth and efficient production process.

Every manufacturing industry has an R&D team powering their innovations, so it’s okay to say that wax 3D printing machines are essential in almost every industry worldwide.

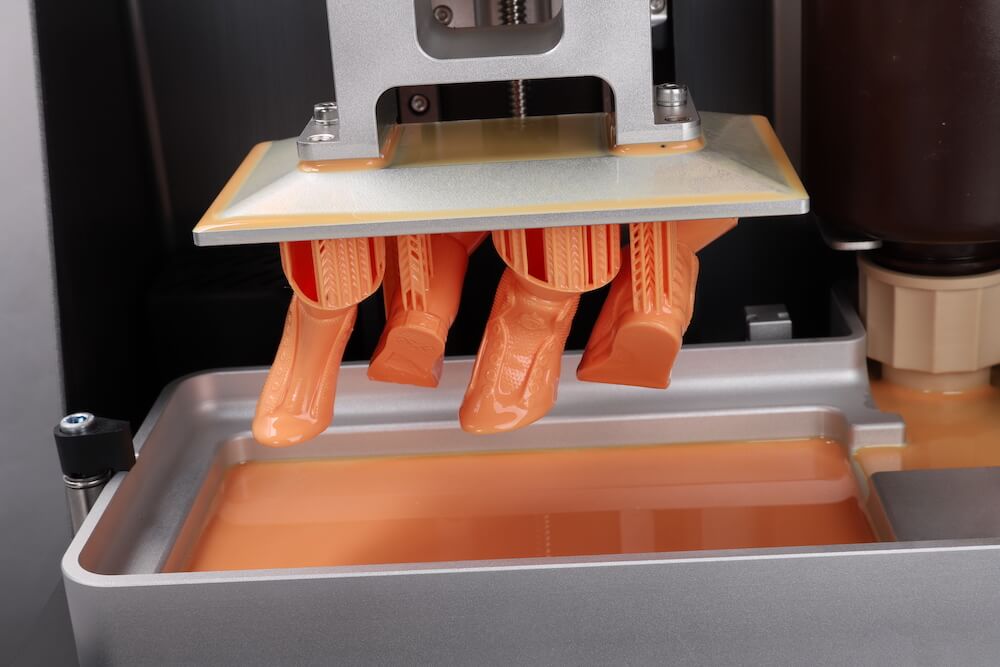

While the R&D industry is vast, shoe soles’ design and production hardly come to mind each time the term is used. LCD resin 3D printers play a substantial role in the design and creation of shoe molds.

With multiple variations of the liquid 3D printing machine available, small and large shoe companies enhance productivity and growth via the simple and fast mold creation process LCD 3D printers offer.

Ranging from shoe models, shoe molds to finished shoe soles, LCD 3D printers’ introduction influenced the production cycle.

Using an LCD resin 3D printer, hobbyists and professionals in the shoe-making industry get to enjoy a 360-degree prototyping process, shorter labor time, accurate finish to complex shoe patterns, and higher efficiency when printing multiple models of different specifications at a time.

The digital sector is also a major benefactor of the remarkable opportunities LCD resin 3D printers provide. Most of the innovation the digital sector brings to the world on a day to day basis underwent critical research and development procedures. From prototyping to modeling, production to manufacturing, numerous 3D models were created along the way.

2.4, Used in Education Industry

3D printers are receiving a lot of interest in the educational space and are frequently cited as a new catalyst for learning. Certainly, this revolutionary technology helps teachers reach a level of student engagement that is almost impossible to recreate from a textbook.

But it’s not just about engagement. In fact, a report from the Department for Education (DfE) found that 3D printing in schools offers several compelling benefits for teachers and students.

3D printers help inspire a new generation of STEM learners by combining problem-solving skills with creativity and innovation. But this nifty tech also has the potential to support pedagogy across all disciplines.

Make learning active

Pupils learn best through interaction and application. By doing rather than by reading a book or listening to a lecture. As such, 3D printers are an excellent way to deploy experiential learning and give pupils more hands-on experiences.

With 3D printers, teachers can create activities that take academic concepts from the theoretical to the practical. For example, in biology lessons, students could create an anatomical heart. Such active learning also ensures that pupils retain information with greater ease.

Fire imaginations

3D printers and design software inspires creativity and ignites young imaginations. In fact, the possibilities of what students can create through 3D printing are infinite; and it’s remarkable how creative children can be when empowered with the ability to turn their 3D designs into real physical objects!

Instill spatial intelligence

Spatial intelligence involves analyzing and interpreting the size, shape, movement, and relationships between objects; it’s the ability to draw correct conclusions from observing three-dimensional environments.

According to studies, using 3D printers in lessons enhances a student’s spatial intelligence, with such intelligence an important predictor of achievement in STEM subjects.

Boost digital engagement

3D printing is a hands-on, fun activity. By incorporating this technology into lessons, teachers can uncover fresh ways to keep pupils engaged, adding extra value and relevance to lessons in a mentally stimulating and enjoyable way. What’s more, 3D printers are applicable across education levels, making them a natural starting point for early years of digital engagement.

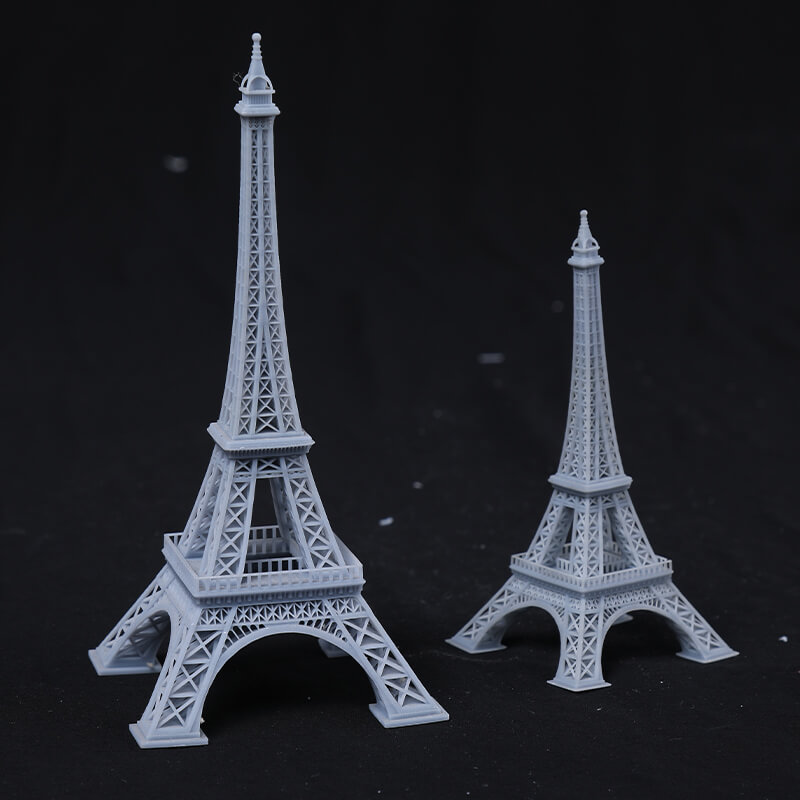

2.5, Used to Make Various Models

With a wax 3D printer, you can create a 3D print of anything and everything. While many folks feel 3D printers are quite expensive and their usage is associated mainly with individuals in the R&D or jewelry industry, this is a myth—and we beg to differ.

3D printers are machines suitable for use by anyone and everyone under the sun. Below are some of the advantages you enjoy from inculcating LCD resin 3D printers into your production line.

Design Iteration: the production sequence in most industries require a repetitive process. Although with the continuous change in customer requirements and the endless modification that comes with constantly evolving industry trends, effortless replication is essential.

LCD resin 3D printers help streamline an iterative process that keeps the production line on a constantly evolving front to meet its customers’ dynamic needs.

Fast and Efficient: designing and testing prototypes is a necessary task in R&D. To create viable products, due precautions must be applied during the design and testing phase. LCD resin 3D printers play an important role in this phase. With a 3D model to direct the workflow, individuals in the R&D team can enjoy a fast and efficient prototyping process.

Flawless Production: with a 3D resin model directing the flow of affairs in a production line, the mode of operation and workflow becomes easy, and durability of the end product is guaranteed. The use of LCD resin 3D printers in the production industry creates room for a flawless production line and helps keep R&D experts operating.

Which Resin Can be Printed on LCD 3D Printer

Since we are done exploring the different industries LCD 3D resin printers can be used, we think it high time we looked at the type of printer you can use in printing a resin material of choice. Subsequent sections focus on the different types of resin 3D printers available in our store, their durability, and usage.

3.1 For Transparent Resin Printing

If you have encountered issues with the quality of print or smoothness of the finish product while trying to create patterns on semi-transparent materials during the resin printing process, you don’t have to settle for the notion that it’s unavoidable.

With our DB-345 LCD 3D printer, you get to enjoy an efficient cooling process free of bubbles. Our DB-345 LCD 3D printer comes with a 15.6-inch 4K high-precision screen and possesses a printing speed of 20mm/h—that’s you get to enjoy HD pixel printing and complete complex task within a short period.

The DB-345 LCD 3D printer is optimized to provide its model with a surface smoothness that eliminates bubbles. It’s important to note that while most of the information we have detailed thus far about the DB-345 LCD 3D printer is focused on its ability to keep your transparent resin printing free of bubbles, its functionality goes above such spectrum; here are some of the notable features you get to enjoy when using an DB-345 LCD 3D printer to cater to your transparent resin printing needs.

Exclusive UV Heat Dissipation Chanel: LCD printers, as you already know, make use of UV light to imprint patterns. Using an LCD printer for an extended period can result to overheating or malfunctioning.

At Dreambot3D, one of our primary goals is to help our customers enjoy an impeccable printing process for long hours. We built our DB-345 LCD 3D printer with an exclusive heat dissipation channel that helps regulate our liquid printing machine’s temperature, enhance print quality, and keep the LCD machine operating far longer than its warranty certifies.

4K High-precision Screen Exposure Imaging Display Technology: no one likes a complex machine. No matter how proficient a device is, complexity in its controls can hinder functionality.

We are well aware of this fact, and to ensure our customers are enjoying the all-round proficiency our DB-345 LCD 3D printer offers, the machine comes with an interactive panel that supports real-time human interaction. That’s you get to communicate with the DB-345 LCD 3D printer at an intelligent and humane level.

High Precision, Smooth and Delicate Surface Finish: Precision in design and finish is of utmost importance not just to the day to day hobbyist but also to the final consumer. A machine that doesn’t guarantee a finished product of high accuracy doesn’t only hinder sales;

It can chase away existing customers. At Dreambot3D, we love it when our customers provide feedback with a subtle yet priceless smile on their faces. The DB-345 LCD 3D printer is optimized to provide high precision with a smooth and delicate surface finish to all prints.

3.2 For Flexible Resin 3D Printing

You can use flexible resins in creating coatings, adhesives, and high-performance composites. This resin is dynamic and is widely used in numerous industries. The shoe mold industry is amongst the few enjoying qualitative usage of the resin. Printing on flexible resins isn’t as complex or complicated as printing on transparent resins.

However, the importance of having the right 3D printing machine should not be in any way undermined. SLD 3D printers are quite outdated; you hardly find their dominance in any industry. DLP 3D printers, currently enjoying widespread usage, are quite expensive for day-to-day hobbyists looking to design a simple 3D model for jewelry casting or shoe molds.

When it comes to flexible resin 3D printing, the most viable option is LCD 3D printers. There are numerous models and variants of LCD printers available in the market. We know you wouldn’t fancy scouring multiple catalogs to find the right liquid 3D printer for flexible resins.

To hasten the process, we recommend trying out our DB-345 LCD 3D printer. The DB-345 is suitable for transparent as well as flexible resin 3D printing. its widely used by hobbyist and professionals in the shoe mold and jewelry industry. Here are some of the perks you get to enjoy from using our DB-345 LCD 3D printer.

USB plug-and-play stand-alone offline printing: many printing companies shy away from LCD printers because of their reliance on computer plug-ins. Not anymore; the DB-345 LCD 3D printer is built to stand alone.

Whether you are offline and need to create a 3D model using flexible resins or are always finding it hard to configure your LCD printer to easy printing, the DB-345 got you covered. The machine is built to operate in offline mode with a transparent cover that allows you to observe your prints first-hand.

More Uniform Illumination: the DB-345 LCD 3D printer relies on light-activated resins to build objects. This LCD printer uses a large-format light source and directs the UV light into areas layer by layer to solidify them.

That’s you get to design 3D models or imprint patterns on materials systematically and uniformly. The Stereo-light curing 3D printing also provides an incredible surface finish with fine adhesion to details.

Reduced Resonance: having a noisy machine doesn’t just attract lousy neighbors; it also limits your workflow. At Dreambot3D, we know how important time is to productivity and wouldn’t for any reason create machines that hinder workflow.

The DB-345 LCD 3D printer comes with an all-metal integrated shell built to make printing more stable and improve accuracy. Our DB-345 LCD 3D printer is also built with a touch-screen interface that supports man to machine interaction. You can interact with the machine via Chinese or English.

3.3 For High Hardness Resin 3D Printing

There is a wide variety of high hardness Resin 3D printers currently available online. Google has made it easy to view 3D resin-based printers of different makes, sizes, and even resolution.

However, Google or other search engines you prefer don’t assure reliability or longevity. You have to find out that through research. We all know how tiring and time consuming that search can get.

We, Dreambot3D, will save you all that hassle. We recommend LCD resin 3D printers as our products are of the same criteria. Our LCD resin printer models are characterized by the distinctive smooth finish of their print models.

We ensure that our clients get the most suitable LCD model with the highest probability of generating the desired outcome while protecting their pocket.

At Dreambot3D, we have a line of various LCD 3D printers designed to serve all your printing needs. For high hardness Resin-based 3D printing, we have ME-345; a superb LCD resin 3D printer.

This incredible high-resolution resin 3D printer model is built on advanced photo-polymerization technology. This technology entails picking light-sensitive resin and placing it in the printing area.

The UV light shines particularly on some parts of the resin. While the UV light shines, the material gets cured layer by layer to generate a solid product. ME-345 resin-based 3D printer has many characteristics. Here are some:

- It has a considerable printing size.

- It’s fast

- It has an even surface.

- It has universal engineering designs.

- It’s substantial

- Its operations are affordable.

ME-345 LCD 3D resin printer also has other incredible features that will interest you. We will mention a few.

Humanised Operation Interface

ME-345 is one of the immense sizes of top resin printers. Big size machines are known for their confusing sequences. You might find it challenging to operate, but we have all that covered.

Our Dreambot3D Research and development engineers designed a human interactive UI interface that comes with ME-345. This interface directs you on operating the machine through a communication sequence available in two languages; English and Chinese.

Uninterrupted Workflow

If you run a resin-based 3D printing business, you understand how tedious your day can get. You move from place to place, attending to different printing needs.

Owning a ME-345 LCD resin printer is not a guarantee that you won’t have such days, but it will significantly simplify the work.

This model is engineered to keep running even if you change the 3D models. ME-345 LCD 3D printer has an extraordinary ability to work for many hours without alteration of the performance.

Automatic Detection and Feeding

ME-345 resin-based printer is built with an automatic detection 2*1 material box. It detects all activities and signals you for smooth operations. Its smooth operation is based on several factors: the level of stability, how clean the flows are, and even the amount of material required.

This resin 3D printer will not only reduce your wastage rate, but it will also ensure that quality productions are achieved within the set period.

3.4 For Castable Resin 3D printing

Castable resin is a monomers free resin that’s mostly used by jewelers and dentists. This resin is inexpensive, has high stability, mouldable with low shrinkage rates. All the 3D resin printers can also use it, but LCD 3D and DLP 3D printers are more suitable. At Dreambot3D, we find LCD 3D resin printers work best with castable resin. We created an LCD 3D model specifically for this resin, ME-192.

ME-192 LCD resin printer uses casting resin to produce incredibly detailed quality print model designs. It has been trending for its outstanding features earning it the hashtag “born to be extraordinary and create the future.”

If you want the most delicate, detailed, smooth finish and quality output, then ME-192 is for you. It’s a photo-polymerized LCD 3D printer that uses smart technology with nine advanced configurations.

Let’s look at some benefits of using a ME-192 LCD 3D printer.

Powerful Cooling System

Machines, especially printers, are famous for producing a lot of heat when in session. 3D printers can’t function efficiently when overheated. They need time to cool off, which slows down the production.

ME-192 LCD resin 3D printer works effectively for many hours with no breaks required for cooling. Unlike other resin 3D printers, the ME-192 LCD resin printer has an inbuilt automated series of fans. These fans detect overheating during production and automatically releases the heat. The heat release ensures the safety and durability of the printer.

Higher Printing Accuracy

Every expert of hobbyist in the jewelry or shoe molding industry know how important a fast 3D printing machine is to the production line. The ME-192 LCD resin printer is backed by a 4K black and white high definition screen that allows users enjoy a flexible operating sequence.

With the ME-192, you get to enjoy a printing process backed way faster than that of the average industrial LCD 3D printer. The ME-192 printer can print as fast as 40mm/h without affecting print output, quality or accuracy.

CNC Machining

Jewelers can describe to you how creating impeccable design manually can be exhausting and time-consuming. Well, now they have a reason to smile. ME-192 3D automated printer comes equipped with a pre-programmed series of models. You select the model you prefer, and voila, you have it.

Larger Moulding Area

Most top-down resin printers are naturally big, but their molding areas are questionable. You can only use a small casting resin to avoid imbalances. With the ME-192 LCD resin 3D printer, you will have enough room to use whichever amount of resin you prefer, with no worries about quality or imbalances. It’s customized for mass production. A series of various productions happen simultaneously.

One Time Printing and Direct Use

ME-192 LCD printer uses casting resin, which highly mouldable and cheap. It makes the production cost very affordable. With ME-192, you can produce just about any model without having to worry about the cost. Unlike other printers of its kind, it’s exact. A small cost of Research and Development is required even when designing the most complicated models.

High Definition Display Screen

High-end printers are tough to operate. They are made with assumptions that the user is knowledgeable. This assumption discourages newbies. Some companies will purchase them then only use the basics. They are afraid to explore the printer due to its complex nature.

ME-192 comes with a humanized user interface. It instructs you on how a particular feature works using a common language. Enjoy a conformable and highly efficient visual experience.

3.5 For Photosensitive Resin 3D Printing

Photosensitive resins are a mixture of photo-initiator, monomer polymer, and prepolymer; this material can be cured under ultraviolet light focusing on specific wavelengths. The model printed with photosensitive resin material has a smooth surface, high printing accuracy, and high molding quality. Photosensitive resin 3D printing is compatible with the SLA, DLP, and LCD 3D printers.

Focused on LCD 3D printers known to handle all the challenges of photosensitive resin 3D printing proactively, we present the ME-345 LCD 3D printer. ME-345 has a larger printing space, high-volume product mold, low costs, and a short production cycle.

The finished product can be printed directly through 3D printing to realize small-batch production. Some of the benefits of using the ME-345 LCD 3D printer for photosensitive resin 3D printing include

High-Resolution Surface Effect: Purchasing the ME-345 LCD 3D printer grants you access to materials such as ABS resin material tray, spare film kit, and post-processing cleaning box.

With such a supporting list backing up the Tiny XY spot (0.008mm²) and fine layer thickness selection (0.02mm), the ME-345 printer is optimized to provide a printed product with clear details smooth surface finish is guaranteed.

Feel the Fun of Printing: are you tired of a boring printing process? Use this Dreambot3D 3D printer to step up your game. ME-345 uses cutting-edge light-curing 3D printing technology, which places liquid photosensitive resin in the printing area and selectively irradiates it with ultraviolet light.

The material is cured layer by layer under the action of ultraviolet light to form a three-dimensional product. The printing size is large and can design multiple 3D models at high speed.

3.6 For Heat Resistant Resin 3D Printing

Heat resistant resins are common in almost every industry. This low-cost resin does not require a dynamic printing process. Heat resistant resins are suitable for most LCD / DLP UV cured 3D printers with a wavelength of 405mm.

Heat resistant resins possess high strength with 2% low shrinkage capacity. Its ability to ensure the strength of the molded component instead of shrinkage improves printing speed, reduces hardening time, and maximizes LCD machines’ printing efficiency.

While most of the machines available in our store can serve as durable options for heat resistant resin 3D printing, we recommend the ME-192 LCD 3D printer. The ME-192 is built with a layer thickness accuracy is 0.02-0.1mm optional, and the single spot area is only 0.01mm².

Our ME-192 LCD resin 3D printer uses a black-white screen with better light transmittance, exposure time is 3-4 times faster than the original color screen, the overall printing speed is higher, and the accuracy is higher. The surface of the finished product produced by the 3D printer is smooth and delicate, showing the beauty of details.

Support Wireless Transmission Printing: with the ME-192 3D printer, you can enjoy a wireless transmission printing process. While a computer’s presence in designing and creating a CAD model is still essential, the machine can function perfectly via wireless transmission of the design. That’s you don’t have to always connect the 3D printer to a computer each time you want to finalize a heat resistant resin printing task.

No need for Levelling Design: the ME-192 is not only popular for the unique surface finish it provides, but it’s also regarded as a more convenient option. The machine leaves room for you to access a new generation of leveling-free designs and enjoy one-time leveling. The machine is firmly fixed by 4 screws operating via a self-leveling core.

Shortens Production Cycle: when using a heat resistant resin material for printing, and the molding accuracy is high, and the processing of accessories with complex structures is difficult. 3D prints can be molded at once, and the molding strength of the accessories, which is high, can be directly applied to the product. That’s with a ME-192 LCD 3D printer at your disposal; you get to finalize hefty printing tasks within a short period of time.

3.7 For Conductive Resin 3D Printing

LCD 3D printers are popular amongst most experts specialized in Conductive resin 3D printing. Unlike the DLP 3D printer, which is widely known for the smooth and efficient surface finish it provides, LCD 3D printers are cheaper and can finish bulk work within a limited period of time.

Conductive resin 3D printing is not as complicated as the transparent 3D resin printing process. However, it’s recommended you take special precautions when picking a 3D printer for conductive resin printing.

LCD 3D printers come in different variants. Each variant possessing unique features suitable for a specific task. When it comes to conductive resin 3D printing, any LCD 3D printer can efficiently handle the task. In order not to keep you second-guessing yourself each time you come across a durable 3D printer for the job, we recommend checking out our DB-345 printer.

Our DB-345 LCD 3D printer comes with standard version configurations. That’s if you have ever used any LCD 3D printer before, you wouldn’t have a hard time navigating your way around the control sequence. With the DB-345, you are guaranteed a printing thickness accuracy that fully reflects the products’ details. Some of the bonus you get from purchasing our DB-345 printer include

High-definition printing: the DB-345 LCD 3D printer leaves room for every bit of the printing process to be shown in detail. The machine is built to accurately reflect the model’s subtle structural changes and add a qualified delicate texture till the physical model is created.

Life-Time Technical Support: at Dreambot3D, it’s not just about producing an innovative machine at low cost; it’s about satisfying an individual’s needs. Purchasing our DB-345 machine grants you automatic access to lifetime technical support—that’s you can contact our support team on a 24 hours basis, 365 days a year rest assured someone would be active to tend to your every need.

1 Years Warranty Policy: While all our machines are tested multiple times during the research and development phase, we are well aware that issues can arise at any time during or after shipping. Regardless of when and how such problems occur, we got you covered. Using our DB-345 machine to cater to your conductive resin printing needs entitles you to a 1-year warranty policy.

How To Buy a 3D Printer: Questions You Should Ask

At this point, we believe that you now know the essential details of an LCD 3D resin printer. You know the meaning of the word LCD, its brief history, and why it is called LCD 3D printer.

By now, you should be able to differentiate between LCD, DLP, and SLA. You have an idea of what each is, their similarities, differences, pros, and cons. The type of printer recommended for each resin and options are available in our store.

This chapter will help you understand the things you should look at before purchasing an LCD resin printer. The initial chapters were the foundation of knowledge on various printers, their features, and their function.

You will find the information you are about to read easy to grasp, if only you were keen to understand previous chapters.

Below are elaborated factors you need to consider before you buy an LCD resin-based printer.

4.1, Before Buying, You Should Consider Your Own Needs

When you go to buy something, there’s either a need or a want to be met. A need is a necessity; you can’t do without it. A want, on the other hand, is an elevated need, luxury.

You have options you can consider. For example, if you go to a shopping mall to buy an ordinary bag, then that’s a need. But if you go to buy a designer bag, then that’s a want.

When it comes to LCD resin printers, the same analogy applies. You have to know what needs of resin-based 3D printing you want to satisfy. However, to satisfy those needs, you have to be familiar with the top resin 3D printer features; features to suit your need.

Familiarising yourself with the features required for a particular need will help you avoid getting duped. People won’t push you into buying anything. You will have sufficient reasons for a particular commodity.

Take your time to figure out what is vital as a business owner at that particular time. Do you need a printer that saves time or power? Are you looking for a unique print model? All these questions should help you identify your needs.

4.1.1 What is The Thing to Be Printed?

After equipping yourself with the features you see fit for your LCD resin 3D printer, you move to the type of things to be printed. Do you often print on fabric, paper, or even nylon bags? The type of thing to be printed will influence your choice of the Resin-based printer.

The type of surface you are printing on will also determine the Resin to be used. LCD resin printer is famous for being compatible with almost all types of Resin. However, Resin differs. Read on different types of palatable resins in chapter 3.

Resins can be confusing, and even experts still have a hard time picking the best. So we don’t blame you if you are still confused. Fret not, contact our reliable support, and they will be of great help. While at it, make sure you give detailed information on the things you print on and your customers’ printing needs.

4.1.2 What is The Size of The Print?

Knowing the features and the type of things to be printed on is essential, but the prints’ size is too. These low-cost resin 3D printers are made for various functions. Some are made to serve purely smaller businesses while others more businesses.

Can you term your business as small scale or large scale? Do you know all your customer needs? Which customers come in regularly? Which type of resin-based 3D printing assignment is common? What is the size of their print? If you can comfortably answer all these questions, you know what model of LCD resin printer you need.

Here at DREAMBOT3D, we have LCDs printers that are in line with your preference. Our experts will advise you on what suits you best. They are just a call away. Call today!

4.1.3 What Are the Special Needs for Printing Material?

Most appliances in our homes come with special needs. It’s important to look at important aspects of a printer like how smooth the print finish is; you also have to look at some smaller details such as Automatic detection.

According to Matt Bevin, “while it may seem small, the ripple effect of small things is extraordinary.”

It’s paramount to meet your special needs, too, even if they are the last on your list. Go for a printer that can offer you an extra service such as feeding features; this will benefit you immensely.

The listed factors above should have given you an idea of what LCD 3D resin printer to go for. If you are still in doubt, don’t hesitate to call our customer support helpline. They have all the details you might require.

4.2, When Buying Consider External Conditions

In comparison to DLP and SLA, the LCD resin printer is the best budget resin printer. Nevertheless, it will still cost you a good buck. A good quality LCD 3D printer might be expensive, but it’s worth the investment. Giving your client quality resin coating 3D prints will keep them coming back for more.

Questions to consider for keeping customers satisfied

4.2.1 Determine Your Ideal 3D Printer Style

LCD 3D printers are created uniquely. Each with specialized features that make it different from the other. Some printers are wireless and portable others have unmatched speed, etc. All these are great features for a printer. Nonetheless, if you own a printing business, you should keep your customers’ preferences in mind.

What type of customers are your dailies? Which type of printing needs do they come with? Are they satisfied with your current models, or they want advanced models?

For you to have all the questions figured out, you have to understand your own needs. It would be best if you based your needs on the business needs. If you know what you prefer, then understanding your client base shouldn’t be hard.

4.2.2 Resolution Requirement of the Machine.

LCD resin printer consists of an axis (XY and Z). The distance covered by the axis determines the quality of the print.

Resolution is the measure of the quality of a model print. So now you get the picture of how the axis comes in. The axis movements determine the level of the resolution. Mostly smaller movements are preferred for best quality prints.

A resin bath 3D printer with a high resolution will produce quality models. Invest in a resin 3D printer that will leave your customers with reasons for more. Avoid resin 3D printers with a low resolution at all costs. Best Resin-based printers have a resolution of either 20microns or 50microns.

Be careful when buying a 3D printer. Its resolution goes hand in hand with your regular Resin. If you are not knowledgeable about the type of resolution that will satisfy your client, seek expert help.

4.2.3 Choose a Reliable Brand

When purchasing an LCD resin 3D printer, it’s important to get it from a reliable brand; it has built its name purely on quality and durability. There are many printing brands in the market currently, and very few are reputable.

LCD resin printers are quite an investment for you to buy just from any brand. Make sure to check the brand records, reviews, and testimonials of the previous clients.

In this era, there are so many big names in the printing industry that have poor commodities. Most of these brands established their reputation in the 90s. The technological changes are so rapid that keeping up has become a problem.

Although researching a brand name is important, don’t do this before you are sure of the machine you’ve chosen. Counter-check if all the features listed are compatible with your requirements. You can use the reviews from other clients to know if the features listed are present on the actual thing.

4.2.4 Consider Whether the Price of The Machine is Acceptable

Anything available for purchase has a price. It’s up to you to decide if the price is within your means. Top resin 3D Printers, too, have a price range.

The prices vary with needs and want. If you want a luxurious printer, it will cost you accordingly. Checking the price of the printer model before heading to the counter will save you heartache.

LCD 3D resin printer is a low-cost resin 3D printer, the price of an LCD printer is 1/5 or sometimes 1/10 of the same size DLP/SLA 3D printer. Checking the cost of a printer should be considered even if it comes last on your list. Don’t wait for those cashier embarrassment; go for a Resin-based printer that will fit in your budget.

You can avoid going beyond your budget by calling our customer sales representative to give detailed specifics of your needs and budget. They will save you the hassle.

4.2.5 Consider The Supplier’s After-sale Capability

Many times you have majored in key features and your budget. You forget about the guaranty, also known as warranty. If you purchase any machine, check for the warranty. Any machine purchased without a warranty might result in a loss.

Most 3D printers, especially the LCD 3D printer, are entitled to a minimum 1year warranty. Don’t purchase any printer that doesn’t offer a warranty. Insist on getting at least 1year guaranty; anything less than that is unacceptable.

Remember to check the brand’s technical support and if it’s functional. You don’t want to purchase an LCD high-resolution resin 3D printer from a brand that won’t be available when you need help. Some brands claim to offer round the clock support, yet they are available for just a couple of hours. You can find out a brand’s true functional hours by checking client reviews on technical support.

4.2.6 Safety Configuration of the Machine

Safety comes first. Be cautious not to buy something that might bring your business trampling to the floor. Most people don’t bother to check the safety measures when using a particular machine.

Don’t make that mistake. Make sure you understand the safety configuration of that machine. If you are new to that top resin printer, follow all the instructions given in the guide. Machines differ.

You now ready to purchase an LCD 3D resin printer of your choice. Remember to follow the steps provided above:

- Know your needs and your clients’ as well

- Check the print size and the thing to be printed.

- Research on the brand and its technical support,

- Purchase within your budget and check the configuration of the machine

Conclusion

We have come to the end of the journey. By now, we believe you are well equipped with everything you need to pick the right LCD 3D resin printer for your production line. If such is the case, then we ask that you visit our store.

At Dreambot3D, all our products are optimized to provide users with an exceptional printing experience. Whether you are searching for an LCD 3D printer with excellent tolerance for creating fun and useful things or an industrial-grade LCD 3D printer that ensures consistent temperature throughout the building process—we got you covered.

All you need to is to put a call through to our support representative, and we guarantee a machine of choice would be delivered to your doorstep within 3 to 5 business days.

FAQ Guide

Are resin prints stronger than FDM?

There is no resin on the market today comparable in strength and mechanical performance to filaments. Resin and FDM both have their benefits and can be used for completely different purposes. If you are looking to create a fine feature design prototype, then resin is the better option. Otherwise, FDM will be more versatile for parts across the production process, from designing, to manufacturing, to maintainable.

How much does a resin 3D printer cost?

Depending on the specific need and features, 3D printers vary in cost. The price of our LCD 3D printer is around US$800 to US$10,000, depending on the size and configuration selected by the customer, you can contact us for details.

How do liquid 3D printers work?

Liquid 3D printers use ultraviolet lights to create a 3D design out of resin. These printers use an array of UV LEDs as the source of light. It creates images or patterns by either allowing or blocking light from passing through individual pixels in the panel. The light from the flat LEDs shines directly in a parallel fashion onto the build area. Because the light is expanded, pixel distortion is less of an issue with LCD printing. The print quality of the printer is dependent on the density of pixels in the panel.

What does LCD stand for?

LCD stands for Liquid crystal display. LCD resin 3D printers are a low-cost resin 3D printer using LED lights to imprint patterns on flat surfaces. These 3D printers provide high precision with a smooth and delicate surface finish. Unlike most other resin printers available, the liquid 3D printing process involves flashing entire layers at once to imprint patterns on the material housed in the resin tank without the interference of an external object or material. The LCD 3D printers involve a simplified process similar to that of laser beams {note that LCD 3D printers use an array of UV LCD as its light source} but provide a more thorough finish.

Is it illegal to 3D print a 3D printer?

No, it is perfectly legal to 3D print a 3D printer. However, it is essential to note that there are few items that it is illegal to create a 3D representation of. For instance, a federal law called ‘The Undetectable Firearms Act’ makes illegal any gun that doesn’t go off in pass-through metal detectors. Such guns could, theoretically, include plastic 3D-printed guns. So it is important to check out the legal regulations of the region before 3D printing any material.

Is resin printing better?

This is dependent on the size and quality of the print you are looking to make a d on the amount of time you have got. If you are looking to print a large piece, then filament printing is the best choice. However, if you want to create a high-quality print or print a small piece with great detail, resin printing should be used.

What is LCD 3D printing?

LCD 3D printing is the action or process of creating a physical object from a three-dimension model using an array of LEDs exposing the UV light through an LCP. Unlike other types of 3D printing like the SLA and DLP, LCD does not require any specialized device to direct the light source.

What is the best resin 3D printer?

LCD resin 3D printers are the best resin printers available. Some of the features that distinguish it from other resin printers include exclusive heat dissipation, reduced resonance, automatic detection, feeding, etc.

Is SLA better than DLP?

It is hard to say which is better between SLA and DLP. It is mostly dependent on the size and model of the print you are looking to make. The major difference between them is the light source. The SLA uses a UV laser beam, while the DLP uses UV light from a projector. SLA is more suitable for printing several intricate parts in one go, and since the curing of resin is done from point to point, SLA 3D printing produces better quality prints compared to DLP 3D printing. On the other hand, DLP is useful in printing large parts without many details as it works faster and cuts down 3D printing time significantly.

How long does a resin 3D printer take?

3D printing can take anywhere from 30 minutes to 7 days or more. This is dependent on many factors. Note that one of the major factors determining how long a 3D printer takes to print is the type of printer being used. Other factors include the print, type of resin, design, etc.

How strong are resin 3D prints?

Resin produces highly detailed and accurate parts with very nice surface finishes. Still, when tough and functional parts are required, resin printing is usually the go-to technology. The most standard resins are relatively brittle compared to other 3D materials, and they are not recommended for stressed or outdoor use.

Are resin printers faster?

Deciding resin printers are faster when compared to FDM is a matter of use case, rather than speed alone. There are many factors to consider when deciding which is faster. Some of the factors include the type of material, size of the print, setting, etc. When designing small 3D models with quality and accuracy, resin printers are the viable option. On the other hand, filaments can be regarded as the best option when creating a massive 3D model within a limited time.

Can you reuse 3D printer resin?

You can reuse uncured resin just fine, but you’ll need to filter it out properly to ensure the larger pigments of cured resin aren’t put back into the bottle. If you do this, you might be pouring back hardened resin back into the vat, which isn’t good for future prints. Once the resin is slightly cured, you can’t practically reuse it for your 3D printer. Note that you can leave uncured resin in your 3D printer vat/tank for several weeks if you keep it in a cool, dark area. Giving your 3D printer extra can prolong how long you can leave uncured resin in the vat for, though when it comes time to 3D print, you should gently stir the resin so it is fluid.

Can I leave my resin in my 3D printer?

You can leave the tray in the printer; make sure to use the scraper that comes with the printer to stir the resin well before the next time you print; also endeavor to take out the cartridge and shake it. The resin has some pigment that will settle out of the resin over time, so it needs to be mixed between prints if you take a break.

What happens if you touch an uncured resin?

Resins are not as toxic as acid, but they can create a surface rash that could develop into an allergy if you expose yourself to resin for long periods of time. Resins also give off fumes, and molecules from the fumes can get into the lungs and create irritations. You can also encounter issues with an uncured resin if your workplace is not well ventilated.

How do LCD 3D printers work?

Wax 3d printing essentially means melting the thermoplastic plastics, then spraying the finer ‘threads’ at the nozzle, then spraying them up layer by layer, and layering up layer. In essence, 3d printing is just a combination of layer by layer ‘planes’ to make it three-dimensional. LCD 3D printers display images by sending light from a metal-halide lamp through a prism or dichroic filter series. This dichroic filter separates light into three polysilicon panels. In simple terms, a liquid 3D printer uses an array of UV LCD as its light source. The printer shines light directly from the flat LCD panel in a parallel fashion onto the build area. As the light travels through the light source, the individual pixels open up to allow light to pass or close to block the light. This combination of open and closed pixels creates room for the liquid polymer 3D printer to produce multiple colors and shades on the projected image. The light emitted from an LCD 3D printer isn’t expanded—that’s, it doesn’t spread beyond its projected frame. Using these 3D printers, you can design patterns and images of multiple variations; rest assured you wouldn’t experience pixel distortion halfway. Note that unlike most other resin printers, the LCD 3D printer print quality depends on its LCD density.

How long can a Resin 3D printer last?

The standard photosensitive 3D printer resin can last several days in the vat in the printer. However, some resins need to be agitated to remain usable. You may also need to clean the bottom of the vat so that things don’t stick to the bottom of the vat. For unopened 3D photosensitive resin, it can last for months or even years if sitting on a cool, dry shelf and kept out of the light. You can leave the liquid resin in the standard printer tray for a day or two if you cover it with the standard orange cover.

How do resin 3D printers work?

An LCD resin 3D printer consists of a metal-halide lamp that houses the UV LCDs; these UV LCDs are used as the source of light by the 3D resin printer. It works when the light from the UV LCDs is shown on a prism. The prism then divides this light into three polycrystalline silicon panels, also known as polysilicon. The light in the 3D LCD printer panels then travels to the print areas, which has pixels. The pixels respond by opening up to allow the light to penetrate or close to block the light from penetrating. This opening and closing process carried out by the 3D resin printer’s pixels allows the liquid polymer to create various effects on the image, such as multiple colors and shades. LCD 3D printers are designed in such a way that all the emitted light from the UV LCD stays focused on the projected image. Interference such as de-pixelation won’t affect you when printing as the light is carefully regulated to stop it from expanding. Unlike other printers, an LCD resin printer’s quality of images varies based on the LCD density.

How dangerous is resin 3D printing?

If you’re wondering what might happen to you if you don’t adhere to safety recommendations when working with resin – it depends on the resin you use, what safety advice you aren’t following and how fast you act to remedy an accident. Generally, not wearing gloves while working with resin, for example, can cause mild skin irritation. Washing your skin with plenty of soap and water usually solves it. You may not experience a reaction the first few times resin comes into contact with your skin at all. Still, in some cases, the skin’s resistance to resin exposure decreases over time, leading to more severe reactions such as skin burns and blisters.

What should I know before buying a 3D printer?

There are a lot of factors to put into consideration when buying a 3D printer. First things first, you might want to take note of what you need the 3D printer for. Are you into commercial 3D printing, or are you a hobbyist looking to design personalized models? If you are looking for a 3D printer to satisfy your personalized 3D printing needs, you need not worry much about your buying decision; detailing out the features and specifications you require from the machine would do the job. But if you are looking to fill a market need and need a 3D printer for the job, put the following factors into consideration; who is my target audience? Do I need a filament or resin 3D printer to fulfill my customer’s needs? What specification and features do I need from a preferred 3D printer? What’s my budget like? To get detailed info on all the factors you need to consider when buying a 3D printer, please refer back to chapter 4 of Dreambot3D’s LCD 3D printer buying guide.

What is an LCD printer?

Liquid crystal display {LCD} 3D printers are a low-cost resin 3D printer using LED lights to imprint patterns on flat surfaces. Unlike DLP printers, LCD printers don’t use mirrors to direct flashes across layers that cure resins. The LCD panels shine light via LEDs at the model, which the LCD panel blocks off in the areas that are not to be solidified. LCD printers are known for the incredible surface finish and fine details they provide.