Medical 3D Printer

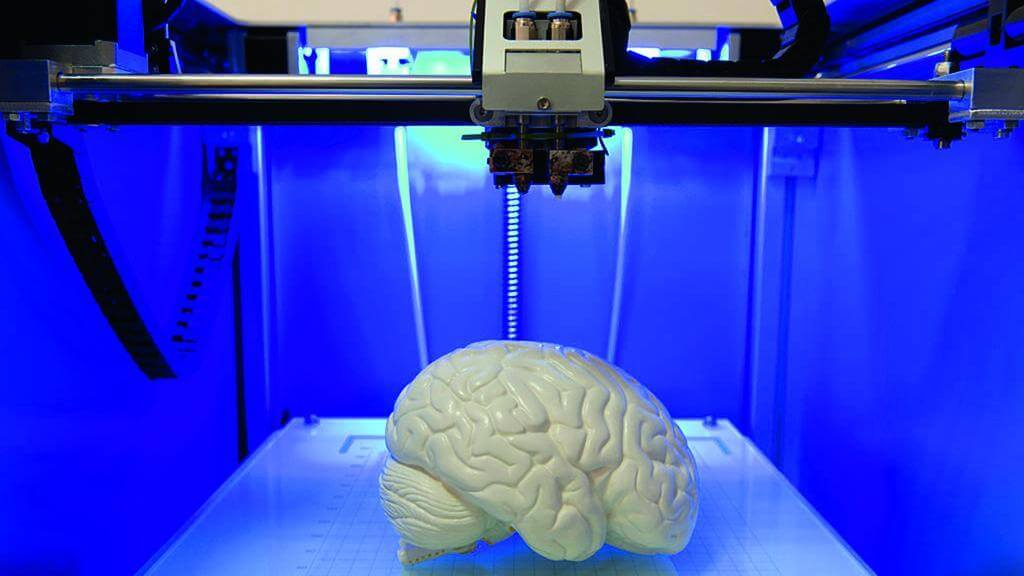

Medical 3D printers are used to print different parts of the human body in 3D form. The medical 3D printer is usable in the medical and dental fields for the purpose of treatment and also training medical students.

How 3D printers work for Medical

3D build

Model

3D printing

model

apply

model

Medical 3D printers are used in the healthcare field because of its potential to improve treatment for certain health conditions.

Doctors can use 3D printing in medical field to make products that specifically match a patient’s anatomy.

3D printing is not limited to planning surgeries or producing customized dental restorations such as crowns, 3D printing in medicine has enabled the production of customized prosthetic limbs, cranial implants or orthopedic implants.

Unlike traditional methods, in which medical parts are created by shaping raw materials into final form through carving or molding, which oftentimes are imperfect.

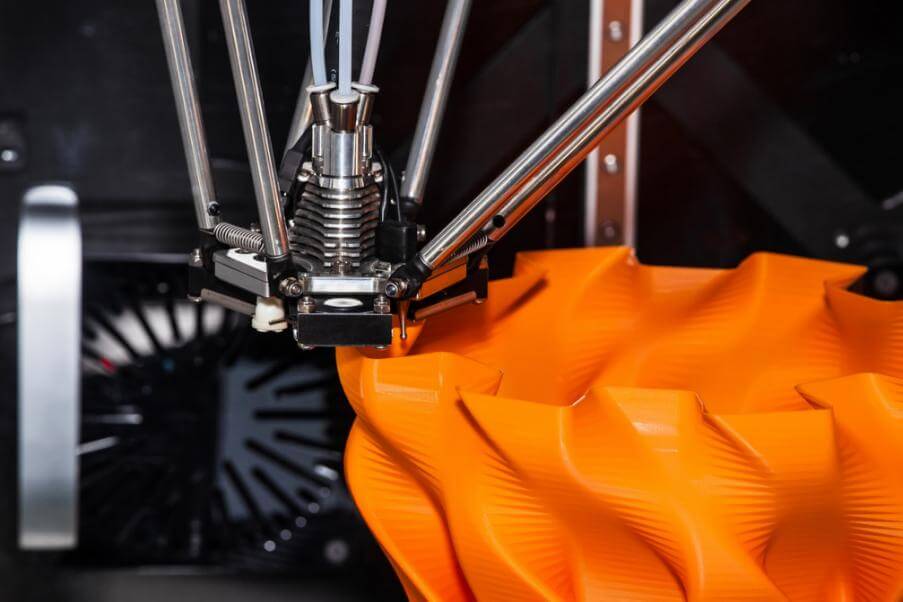

3D printing in medicine is an additive manufacturing technique that creates 3D objects by successive layers.

With the medical 3D printer, you can print parts with complex geometry separately and assemble together or you can print the whole product at once.

Medical 3D printer is really affordable, allows you to print complex parts and performs a noiseless operation.

Medical 3D printers for your Choice

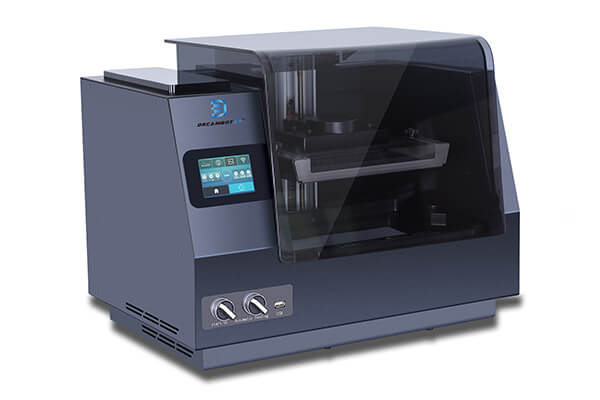

LCD 3D Printers

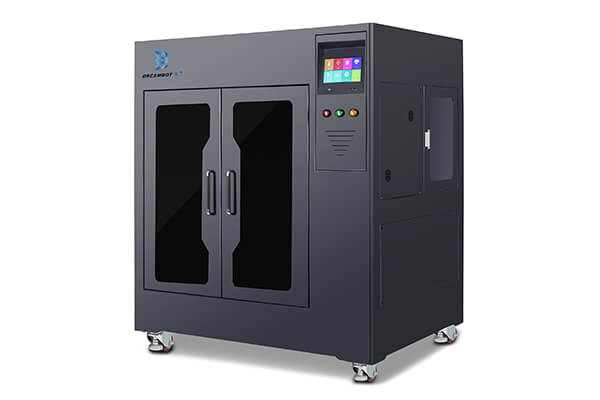

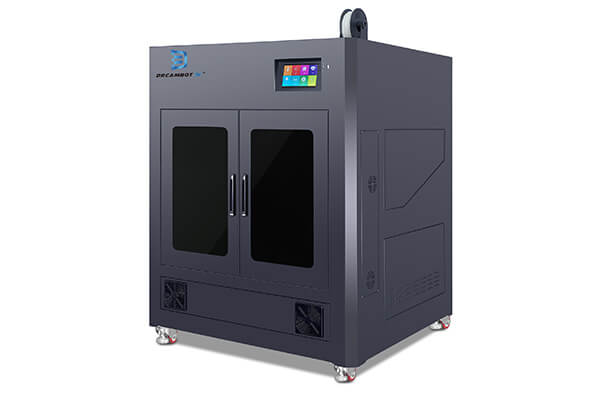

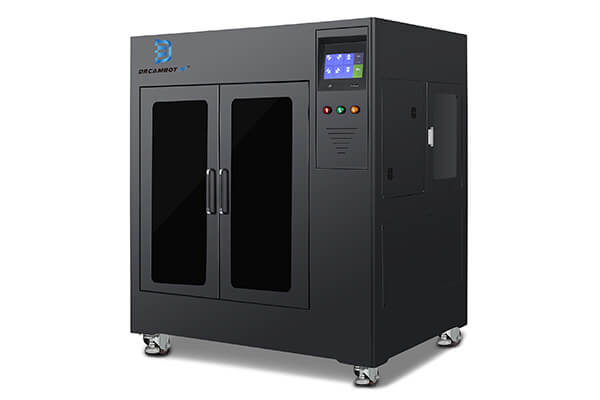

FDM 3D Printers

Don't know how to choose a model?

Are you confused about how to choose the correct model and type of 3d printer? We support 24/7.

4 points why choose us

4K resolution printing

4K black-white industrial screen, 0.01-0.05mm layer thickness accuracy, more accurate printing of details.

PLC control system

All 3d printers are equipped with PLC control system as standard, makes the operation more convenient, and reduces the error.

Extremely speed printing

Large printing size, 20mm/h printing speed, complete your printing tasks faster.

Reinforced structure

The all-metal one-piece shell reduces resonance, makes printing more stable and improves printing accuracy.

What our customers say

How 3D Printers are Used in the Medical Industry

Medical 3D Printer Buying Guide

2.1, What Processes can 3D Printer Replace

2.2, Whats the Changes After the Intervention of 3D Printers

3.1, Introduction to the Working Principle and Development History of 3D Printers

3.2, Analysis of The Advantages of Using 3D Printing to the Industrial R&D

Application of 3D Printer in the Medical Industry

Three-dimensional (3D) printing refers to a number of manufacturing technologies that generate a physical model from digital information. Medical 3D printing was once an ambitious pipe dream.

However, time and investment made it real. Nowadays, 3D printing technology represents a big opportunity to help pharmaceutical and medical companies to create more specific drugs, enabling rapid production of medical implants and changing the way that doctors and surgeons plan procedures.

We compiled this buying guide to help you understand how medical 3D printers are influencing the lives of doctors and patients alike in the medical industry. From this buying guide, you can also obtain detailed insight on the impact and changes 3D printers bring to the industry and the factors to be considered when buying a 3D printer.

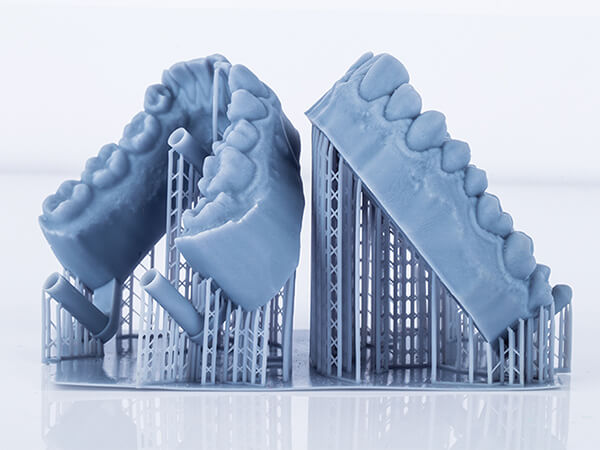

1.1, 3D Printer for Dental

To begin, let’s take a look at the impact medical 3D printers are having in the dental industry. 3D printing is a rapidly growing technology in numerous fields, especially in dental laboratories, all due to the new software, 3D scanners, additive technologies, and post-processing methods that increased efficiency and cost savings, to faster production speeds and improved quality to benefit not only doctors but also patients, to make their experience pleasing through the drop of the price, and save time, which is one of the little advantages that this technology brought with it to this industry.

When it comes to manufacturing dentures, medical 3D printers bring with them a whole host of points of interest. One of the greatest advantages is the improved qualities. Before, With traditional manual workflows, the quality of the finished products is highly dependent on the skills of a given technician.

Achieving consistent and high-quality dental products with so many potential sources of error are incredibly difficult and expensive.

However, now with medical 3D printers, even delicate structures can easily be created as the component is built up layer-by-layer, and the process is controlled by a software program. Compared to a plaster model, a 3D-model is a more stable, durable, and precise alternative. The lines and edges on a bio 3D printed model stay sharp without the dental technician having to worry about wearing them down. Compared to a milled model, a 3D-printed model has a more complex structure with a higher level of detail.

With digital dentistry, the room for error is reduced, and the automation reduces labor, resulting in time and cost savings for labs and practices all around the world, while Manual model-making is time-consuming. Medical 3D printers allow for multiple appliances to be printed at once since the digital copy is received in minutes because it is sent electronically.

The technician can start working as soon as the copy of the scanning arrives. Also, medical printing provides a clean workplace for the technician without having to deal with plaster or inhale grinding dust.

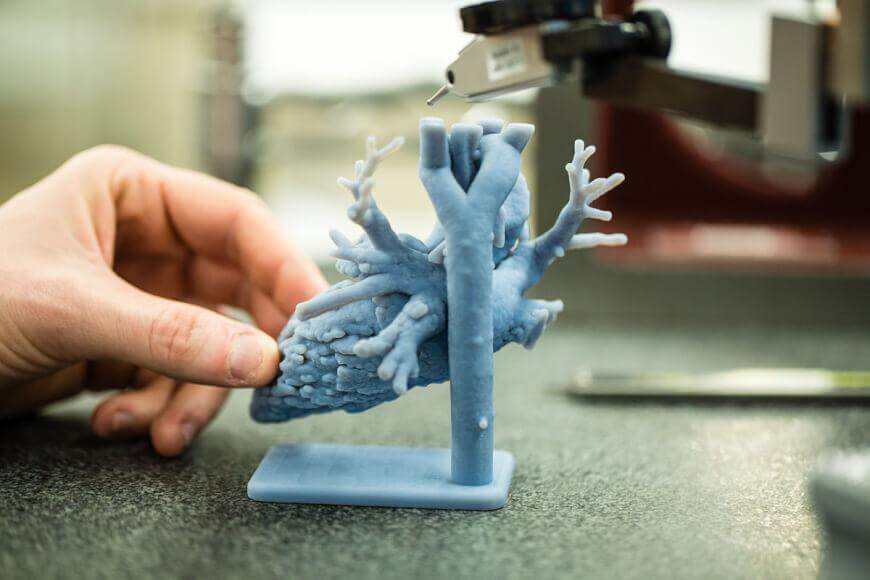

1.2, 3D Printer for Human Organs Model

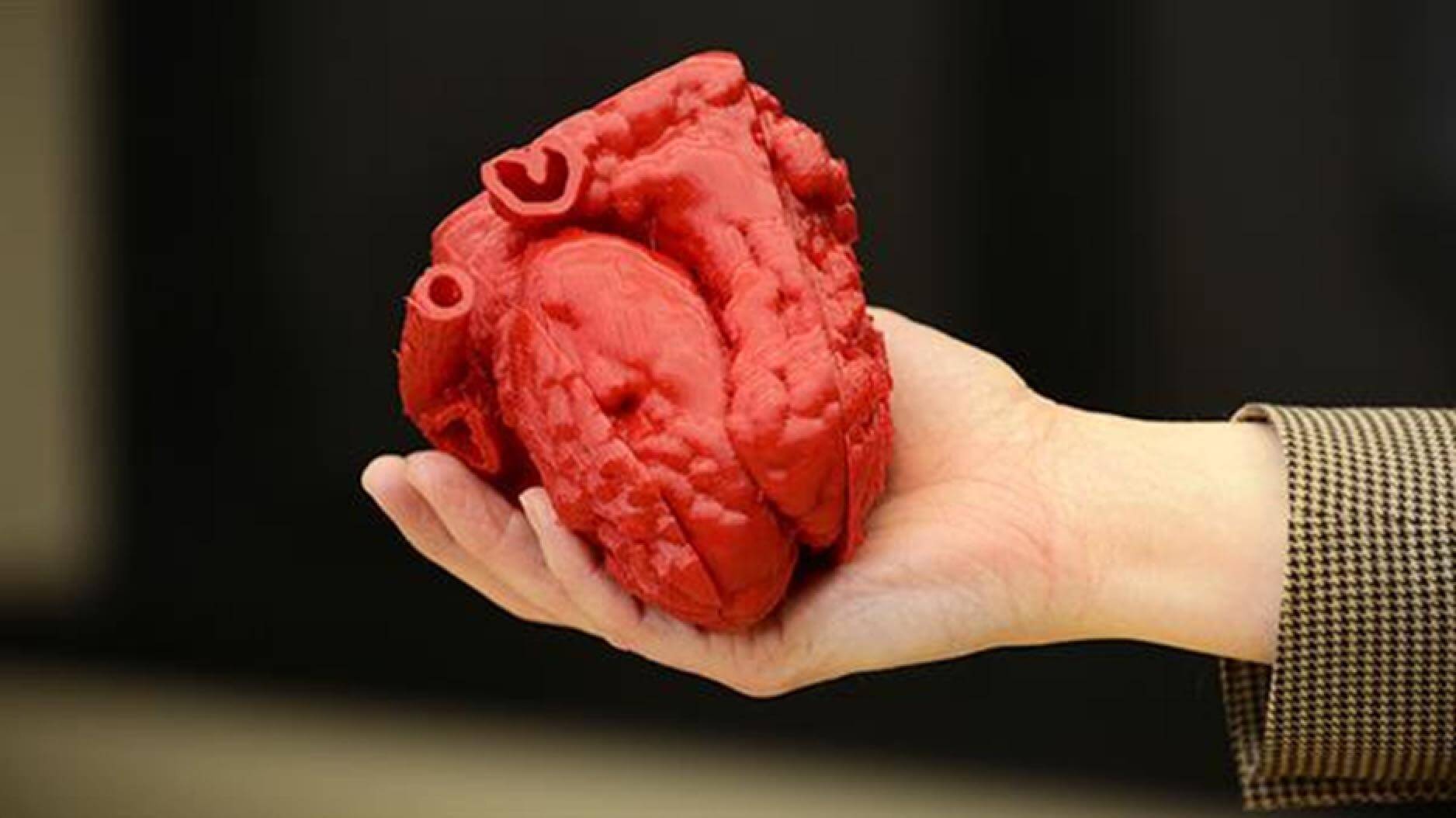

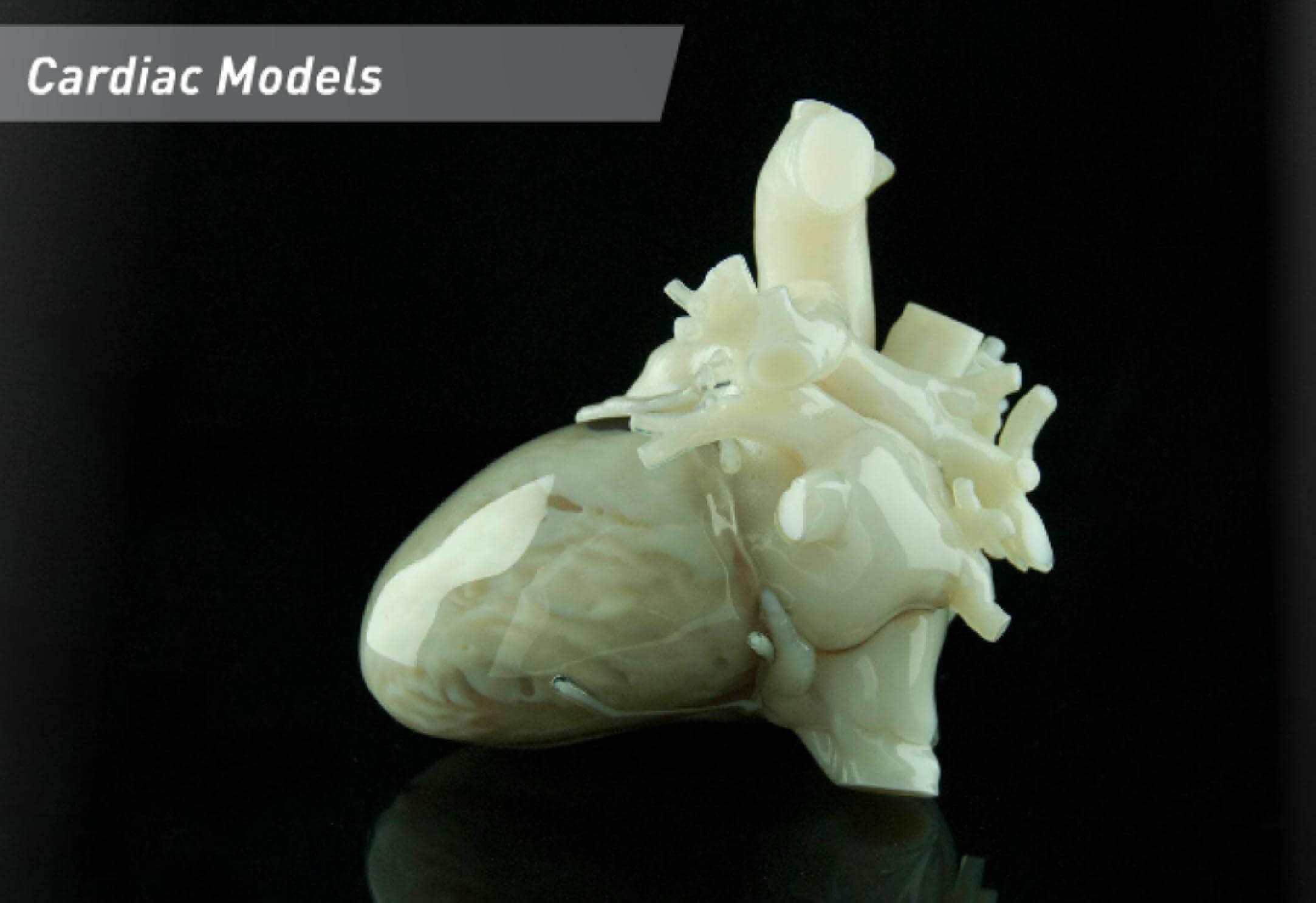

3D printing of human organ models is a rampant trend in the medical industry. Ranging from human heart 3D prints to 3D printed lungs, medical 3D printers leave room for a smooth and more refined medical process. Using a medical 3D printer, doctors and surgeons enjoy a more refined medical process.

However, before we go into detail regarding the human parts, 3D printers leave room to print; it’s important to note that medical 3D printers can only create 3D objects suitable for research and leering. Parts designed using medical 3D printing cannot in any way serve as tangible human parts for transplant. All the information detailed out regarding 3D printing for medical use is mainly focused on research and learning processes.

- 3D Printed Lungs

Creating functional tissue replacements is a high scientific priority because of its potential impact on organ donations. The crisis of organ shortages is a long-lasting one; around 114,000 people are on transplant waiting lists in the United States alone. Even after a successful transplant, patients have to take immune-suppressing drugs to prevent organ rejection for the foreseeable future. 3D Bioprinting organs could play an important role in reducing both problems.

In 3D printing lungs, researchers used specially-designed medical 3D printers to develop an artificial air sac that structurally and functionally mimics similar structures found in the human lung, including the ability to pulsate or “breathe” without bursting. The development represents a step toward the much-anticipated era of 3D-printed human tissues, which holds promise for addressing the critical need for organ transplants.

One of the biggest roadblocks to developing tissue replacements has been an inability to print the complex vascular networks, like airways and blood vessels of the lung or bile ducts and blood vessels in the liver, the researchers said. But the scientists announced they had found a way to overcome this difficult hurdle.

Note that while this medical breakthrough opens up opportunities for individuals in numerous sectors, 3D printed human lungs and tissues are only suitable for research and learning processes. 3D printed parts cannot be used as a replacement for real organs during surgical operations.

- 3D Printed Human Tissue

Progress in drug testing and regenerative medicine could greatly benefit from laboratory-engineered human tissues built of a variety of cell types with precise medical 3D printers. But the production of greater than millimeter-sized human tissues has been limited by a lack of methods for building tissues with embedded life-sustaining vascular networks.

Multidisciplinary research at the Wyss Institute has led to the development of a multi-material 3D bioprinting method that generates vascularized tissues composed of living human cells that are nearly ten-fold thicker than previously engineered tissues, and that can sustain their architecture and function for upwards of six weeks.

The method uses a customizable, printed silicone mold to house and plumbs the printed tissue on a chip. Inside this mold, a grid of larger vascular channels containing living endothelial cells in silicone ink is printed, into which a self-supporting ink containing living mesenchymal stem cells (MSCs) is layered in a separate print job.

After printing, a liquid composed of fibroblasts and an extracellular matrix is used to fill open regions within the construct, adding a connective tissue component that cross-links and further stabilizes the entire structure.

- 3D Printed Human Heart

The FRESH technique of 3D bioprinting was invented in Feinberg’s lab to fill an unfilled demand for 3D printed soft polymers, which lack the rigidity to stand unsupported as in a normal print. FRESH 3D prints human organs using a needle to inject bio-ink into a bath of soft hydrogel, which supports the object as it prints. Once finished, a simple application of heat causes the hydrogel to melt away, leaving only the 3D bio-printed object.

While Feinberg, a professor of biomedical engineering and materials science and engineering, has proven both the versatility and the fidelity of the FRESH technique, the major obstacle to achieving this milestone was printing a human heart at full scale. This necessitated the building of a new medical 3D printer custom made to hold a gel support bath large enough to print at the desired size, as well as minor software changes to maintain the speed and fidelity of the print.

Major hospitals often have medical devices for 3D printing models of a patient’s body to help surgeons educate patients and plan for the actual procedure; however, these tissues and organs can only be modeled in hard plastic or rubber.

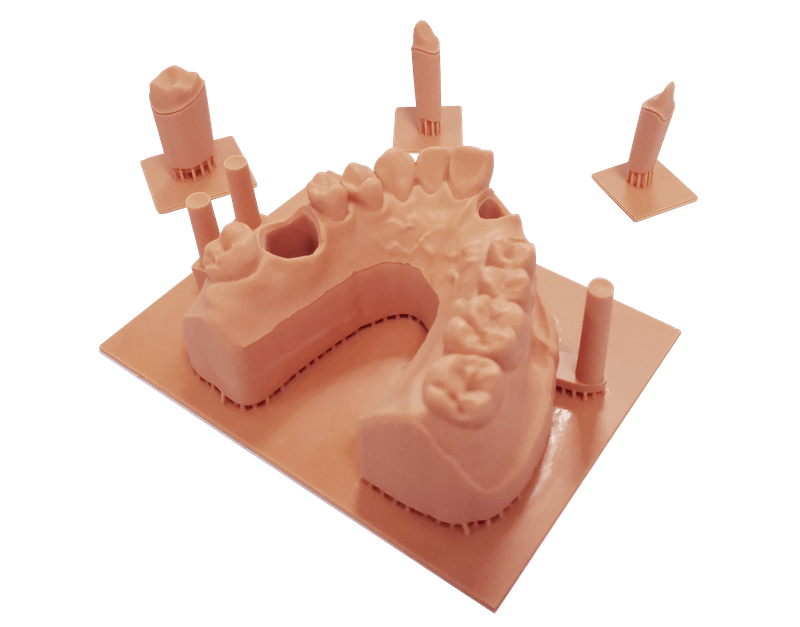

- 3D Printed Hip Replacement

Medical 3D printers are also used for knee realignment. Indeed, in some cases, the cartilage damages are causing pain and make the patient unable to do sports or any physical activity. Then, a surgical operation is required.

Thanks to medical-grade 3D printers, there is actually an operation developed to prevent patients from total knee replacement: knee realignment using additive manufacturing technology. From the CT scans of the patients, doctors can create surgical guides or even joints, totally custom-made using medical 3D printers and perfectly fitting the morphology of the patient.

This way, surgeons can make operations such as osteotomy in order to reduce the discomfort of the patients, using custom-made devices.

3D printed knee implants Companies such as Conformis are also developing the use of additive manufacturing to create implants, using a CT scan of each patient. Conformis knee implants are made possible with medical field 3D printers and are totally making the most of the custom-made aspect. This way, the knee implant entirely respects the morphology and the needs of the patient.

This technology can be used for many different knee problems such as bone spurs, cysts, or flattening of the joint. How does it work? They are using additive manufacturing in order to create custom wax molds, allowing them to make these implants using femoral and tibial components.

- 3D Printed Liver

Researchers say it took 90 days to develop these small, bio-printed livers from patient blood collection to tissue production. The first step is to reprogram the patient’s blood cells into induced pluripotent stem cells. These are then differentiated into liver cells, and their spheroids can then be integrated into the bio-ink. The printing process can now begin. The cultivation of the 3D printed cell structures took 18 days.

To test this method, the scientists explain that they bio-printed three different small livers from the cells of three volunteer patients. They studied the functionalities of the liver as well as the maintenance of cell contact. The spheroids functioned much better than those obtained from single-cell dispersion. As expected, during maturation, the markers of liver function were not reduced. The researchers say this experiment could be done on a larger scale and on other organs. Good news for the medical sector!

- 3D Printed Bladder

The Bladder Assisted Composite Manufacturing (BACM) technique allows the fabrication of complex hollow composite geometries. However, traditional bladder manufacturing methods require multiple steps and a master geometry, which increases the cost and manufacturing time.

Hence, medical 3D printed bladders are presented as an alternative solution to bladders manufactured through traditional methods. The use of 3D printed bladders is demonstrated by consolidating and curing a composite part made out of an aerospace-grade composite prepreg material.

Bladders are additively manufactured using the Fused Deposition Modeling (FDM) technique with Thermoplastic Polyurethane (TPU). Based on the results of a thermomechanical investigation of the TPU, a two-step curing cycle for manufacturing a composite part with IM7/8552 prepreg was designed.

The part consolidation achieved with this method was characterized by measuring void content and comparing it to the void content in a sample cured in a standard autoclave process. The low void content achieved with the BACM method demonstrated the potential of 3D printers in medicine to provide bladders for short production runs or prototyping.

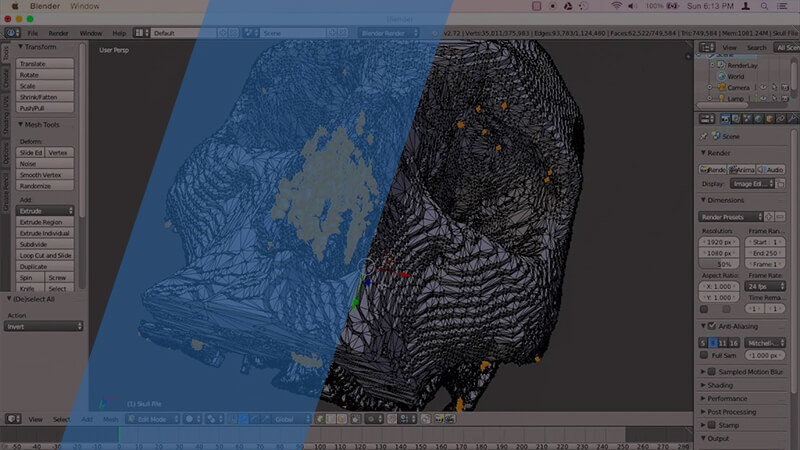

- 3D Printed Human Skull

People have always been fascinated with mortality, from superstitiously fearing the grim unknown to philosophically pondering the meaning of life. From a historical perspective, the skull has always been at the heart of the matter, representing both physical reality and ominous symbolism.

The Anatomical Museum at the University of Edinburgh has started making a variety of highly-detailed printable 3D skulls of a variety of artifacts from their museum, including the skull of a Homo neanderthalensis that lived in Eurasia 400,000 to 40,000 years ago. This is a great option if you want to get your hands on “real” artifacts right in your own home or classroom.

3D printed human skulls have built a reputation for themselves in the DIY and Hollywood industry. A lot of everyday home equipment such as pots and flower vases are designed in the shape of a human skull. 3D printed skulls are also widely used for research and learning purposes in medicine.

- 3D Printed Kidney Transplant

An adult kidney has been transplanted into a child with the help of medical 3D printers, says a report from Guy’s and St Thomas’ in London, UK. According to statistics from the Centers for Disease Control and Prevention (CDC), kidney disease affects around 3.9 million Americans – or 1.7% of the population.

The National Kidney Foundation explains that chronic kidney disease (CKD) includes a number of conditions, and it also has various causes, the most common being diabetes, and high blood pressure. If the kidneys fail, a transplant or regular dialysis is needed to keep the patient alive.

A medical 3D printer was used to create models of Chris’s kidney and Lucy’s abdomen. These enabled surgeons to plan the highly complex operation accurately in order to minimize the risks. The medical-grade 3D printing machine used measurements gathered through CT and MRI scans to produce a liquid plastic model, which was molded under ultraviolet light to reproduce the exact size and density of the body parts.

The 3D medical printer enabled surgeons to check whether the transplant would be feasible and to practice the operation beforehand. The transplant, which took 4 hours to complete, was successful.

- 3D Printed Plastic Surgery

Plastic surgery can help improve quality of life, especially when patients are dealing with craniofacial issues – soft tissues of the face, like the nose and lips, and bones of the craniomaxillofacial (CMF) skeleton.

This field helps improve those things that make us human, such as how we talk, look, and use our hands. Medical 3D printers are often used in conjunction with plastic surgery, and, as a pair of researchers in Missouri explain, it’s an excellent specialty in which to better define how the technology is used in surgery.

Alexander Y. Lin, MD and Lauren M. Yarholar, MD, with the Saint Louis University School of Medicine and SSM Health Cardinal Glennon Children’s Hospital, published a paper, “Plastic Surgery Innovation with 3D Printing for Craniomaxillofacial Operations,” about the four types of 3D printed objects for surgical use, emphasizing plastic surgery and CMF operations, and the technology’s “high clinical relevance to all potential procedures utilizing 3DP assistance.”

“Plastic Surgery restores unique human qualities such as appearance, speech (palate), hands, to improve interaction with others and quality of life,” the two wrote. “3D printing in the medical industry can be applied to Plastic Surgery craniomaxillofacial operations to change the bony skeleton of the skull, face, and jaws.”

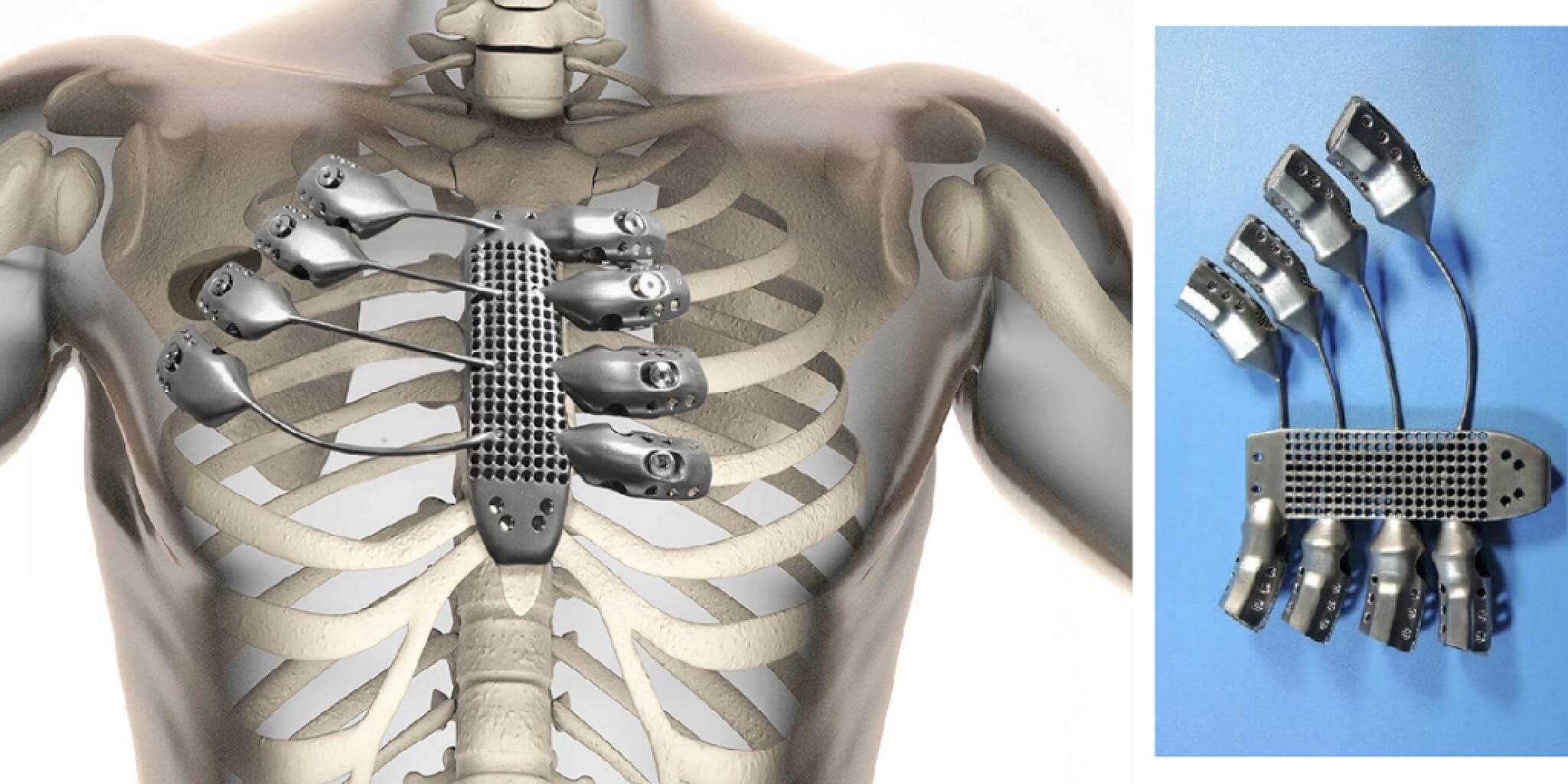

1.3, 3D Printer for Medical Device

Medical 3D printers are used to manufacture a variety of medical devices, including those with complex geometry or features that match a patient’s unique anatomy.

Some 3D printers for medical purposes are printed from a standard design to make multiple identical copies of the same device. Other devices, called patient-matched or patient-specific devices, are created from a specific patient’s imaging data. Commercially available 3D printed medical devices include:

- Instrumentation (e.g., guides to assist with the proper surgical placement of a device),

- Implants (e.g., cranial plates or hip joints), and

- External prostheses (e.g., hands).

Scientists are researching how to use medical 3D printers to manufacture living organs such as a heart or liver, but this research is in the early stages of development.

The 3D printing process can be accomplished using any of several different technologies. The choice of technology can depend on many factors, including how the final product will be used and how easy the printer is to use.

The most common technology used for 3D printing medical devices is called powder bed fusion. Powder bed fusion is commonly used because it works with a variety of materials used in medical devices, such as titanium and nylon.

The powder bed fusion process builds a three-dimensional product from very fine metal or plastic powder, which is poured onto a platform and leveled carefully. A laser or electron beam then moves across the powder layer and melts the material it touches.

Melted material fuses to the layer below it and to the powder around it to create a solid. Once a layer is completed, the platform moves down, and one more layer of carefully leveled powder is placed on top.

1.4, 3D Printer for Surgery Guide

The use of medical 3D printers is gaining considerable success in many medical fields including surgery. Here, the technology was introduced for increasing the level of anatomical understanding thanks to the inherent characteristics of 3D printed models: these are highly accurate and customized reproductions, being obtained from own radiological imaging of patients, and are solid graspable objects allowing for free manipulation on the part of the user.

The resulting tactile feedbacks significantly help the comprehension of anatomical details, especially the spatial relations between structures. In this regard, they proved to be more effective than conventional 2D imaging and 3D virtual models.

To date, an increasing number of applications have been successfully tested in many surgical disciplines, extending the range of possible uses to pre-operative planning, counseling with patients, education of students and residents, surgical training, intraoperative navigation, and others.

In recent years, medical 3D printing was also employed for creating surgical guides and reproducing anatomical parts to be used, respectively, as templates or guides for specific tasks of the surgery and individualized implantable materials in reconstructive procedures.

Future expectations concern on one side is focused on the reduction of bioprinter costs and time to further increase the accessibility of 3D printing in surgery. While on the other, the development of novel techniques and materials suitable for 3D printing of biological structures by which recreating the architecture and functionality of real human organs and tissues is one the rise.

The Impact and Changes of 3D Printers in the Medical Industry

Every year, medical 3D printers offer more and more promise in the healthcare field. And while the ultimate goal of printing whole complex organs for transplants may still be decades away, 3D printing is helping to save and improve lives in ways – and in places – never imagined just a few years ago.

3D printing uses in medicine go beyond its practical benefits. According to The Guardian, the technology is expected to be worth no less than $1.3 billion by 2021 and looks set to disrupt the cost implications of several medical procedures. The typical kidney transplant, for instance, costs an average of $330,000, according to the National Foundation for Transplants.

The conventional 3D bioprinter, on the other hand, retails for just $10,000. In the not too distant future, prices of medical procedures and biomedicines could see a drastic cut in cost if competition increases because of medical 3D printers. In addition to reducing costs, medical 3D printers may also simplify treatment.

Medical 3D printers have successfully recreated body parts as complex as blood vessels, which proves that this technology has a lot of untapped potentials. As of today, organoids (mini-organs) are already being built by medical professionals.

In 2017, a team of biomedical engineers from Pohang University in South Korea, using a medical 3D printer and living tissue, were successful at developing what they called bio-blood-vessels.

In vitro cloning of full-body parts has for a long while been a dream of the 21st-century medical sphere, and while this feat demonstrates the disruptive nature of 3D printers in medicine, it is just a scratch on the surface of the possibilities heralded by 3D printing.

2.1, What Processes can 3D Printer Replace

3D printing technology is going to transform medicine, whether it is patient-specific surgical models, custom-made prosthetics, personalized on-demand medicines, or even 3D printed human tissue. At the moment, 3D printing in the medical field is still at its early stages, but in the future, the technology will be at the cutting edge of medical research. Let’s look at some of the processes medical 3D printers are set to replace.

There are many advantages to using 3D printing in the medical field. Perhaps the most critical is the ability to create custom products and equipment. Personalized implants and tools can decrease the time needed to perform surgery as well as speed up patient recovery time.

In addition, customization can improve the chances of a treatment or procedure’s success. It is also anticipated that 3D printing medical applications will eventually allow drug dosage forms, release profiles, and dispensing to be customized for each patient.

The advent of medical 3D printers stands to decrease health care costs. Medical items can be produced quickly and cheaply, especially for small prosthetics and implants.

This is especially relevant for spinal, dental, and craniofacial disorders. Even printing custom products are relatively inexpensive. Savings during the manufacturing phase can be passed on to patients as well, lowering health care costs across the board.

Finally, 3D printers for medical use is creating a climate of collaboration as materials become more widely available, and costs decrease. This allows more people, including those in medical fields, to use little more than a medical 3D printer and their imaginations to design and produce novel products for personal or commercial use.

Now more than ever, researchers can test promising ideas and share their work with others. Using downloadable open-source files, work can be replicated exactly. This has democratized the research and development process.

2.2, Whats the Changes After the Intervention of 3D Printers

Applications of medical 3D printers can be seen in enterprises ranging from engineering to textiles, but perhaps one of the most exciting uses of 3D printing is in the health care field.

In fact, the use of 3D printers in medicine is expected to transform the medical field, with experts comparing it to the impact of the printing press. There are many uses for 3D printing in the medical world, including tissue fabrication, anatomical models, and pharmaceutical research.

Bionic Ear

As leading researchers become more familiar with the capabilities of 3D printing, they are finding many ways to incorporate the technology. For example, HBR notes that it has been used to create 3D-printed skin for burn victims and airway splints for babies with tracheobronchomalacia, a disease of the central airways. What’s most notable about the latter application is that the splints can be created quickly, cost about $10 per unit, and are designed to grow with the patient.

Scientists at Princeton University have also discovered that 3D medical printers can be used to “create a bionic ear that can hear radio frequencies far beyond the range of normal human capability, in a project to explore the feasibility of combining electronics with tissue. And because these exterior uses are going well, there is a real possibility that 3D printing technology in medicine will be used to replicate internal organs in the future, mitigating the need for donor waiting lists.

Cancer Treatment

3D printing is an exciting prospect for cancer treatment as well. Researchers created facial prostheses for eye cancer patients in 2014, and another research team was able to print “patient-specific, biodegradable implants to more effectively cure bone infections and bone cancer,” according to HBR. Like most additive manufacturing applications, these technologies are inexpensive and efficient to use.

Demystifying Conventional Medical Practise

Scientists are finding other ways to apply additive manufacturing technology, and application medical 3D printers go beyond life-threatening medical conditions into more conventional medical practice. For example, 3D-printed casts and pharmaceuticals have been developed in recent years. “The 3D-printed cast, for example, heals bones 40-80% faster than traditional casts.

3D-printed pills allow for interesting new pill shapes that completely alter the drugs’ release rates,” HBR reports. It is important to note that these technologies are in the early or research stages and aren’t yet available for widespread use.

Research on the Advantages of 3D Printers Compared to Traditional Processes

Different three-dimensional (3D) printing techniques are being increasingly used to produce medical apparatus due to their ability to print intended designs with high dimensional accuracy.

Indeed, the major credit for 3D printing applications in medical fields stems from the ability of this method to prepare patient-matched devices due to the conventional manufacturing methods limitations such as economic inefficiency and multiple steps processing for complex geometries. Let’s take a look at some of the advantages 3D printers provide in comparison with traditional processes.

Practice Before Perfection

Many medical procedures, especially those of a surgical nature, can be tricky, even for highly skilled surgeons. By providing a replica of organs and body parts, medical 3D printers give doctors an insight that cannot be replicated by any form of medical diagnostics.

Unlike organ printing, this practice is already commonplace in the medical setting. A team of surgeons at the Rashid Hospital in the UAE was able to perform an intricate surgical maneuver that required them to safely placate four veins in a 60-year-old, thanks to the prior practice they had had with 3D medical printers.

Design Freedom

Medical 3D printers are changing the economics of the medical design market drastically. Independent designers are now able to bring their designs into the world without having to invest a lot of money first.

Do you have a good idea? Create a CAD file and have it printed directly. Service providers are already hitting the market that provides a full list of related services, ranging from mere production to quality assurance, packaging, branding, sales, and even processing and customer care.

The designer can now cherry-pick what suits his/her talents best – s/he might decide to control the whole process or simply focus on designing great products. Giving the designer a whole new avenue to explore, there are plenty of new objects to be discovered. Medical3D printers enable shapes with undercuts, complex structures, and even directly functional parts.

AM – A disruptive technology

New applications are appearing as new materials, and AM approaches are frequently developing. One of the major drivers for higher accessibility of this technology is due to the expiration of the earlier patents that allows manufacturers to create new 3D printing systems. The cost of medical 3D printers has been reduced by recent developments.

Thus, 3D printing applications have been expanded in homes, schools, laboratories, and libraries. The growing general agreement on the uses of 3D printing in medicine over traditional methods is due to some benefits such as highly precise construction of complex geometry, flexible design, personal customization, and maximal material savings.

Thus, 3D printing applications have been expanded in homes, schools, laboratories, and libraries. The growing general agreement on the uses of 3D printing in medicine over traditional methods is due to some benefits such as highly precise construction of complex geometry, flexible design, personal customization, and maximal material savings.

An extensive range of materials is used in biomedical 3D printing, such as polymers, metals, concrete, and ceramics. Acrylonitrile butadiene styrene (ABS) and Polylactic acid (PLA) are the major polymers that are utilized in the 3D printing of composites.

A New Future for The Medical Industry

Medical grade 3D printing is ushering in a new era of efficiency, cost-effectiveness, and convenience in the medical industry. The use of 3D printing in medicine is leading the path toward the development of a sustainable framework for tackling poorly functioning organs — experts predict a not too distant future where 3D printers for medical purposes can facilitate cheaper organ replacement and better patient prognosis.

Modular 3D printed prosthetics have debuted on the medical scene with the same functionality as conventional models but at as little as half the cost. The slash in cost compared to the traditional base model highlights just how disruptive this tech is; one 3D printing production firm already suggested that 3D printing portends cost savings of up to 70% for its medical clients.

As medical 3D printers evolve into a more practical and efficient system, so also will drug manufacturing, organ transplantation, and other fields of medicine. 3D printing technology in medicine might, at the end of the day, prove to be the kind of disruptive innovation that launches the field of medicine to a new level.

3.1, Introduction to the Working Principle and Development History of 3D Printers

What’s almost 40 years old but looks brand new? Believe it or not, it’s 3D printing. Yep, additive manufacturing technology has been around since the Reagan era. At the time of invention in the 1980s, 3D printers focused on creating scale models using computer-aided design (CAD).

The first patent for a 3D printer was issued to Charles Hull for “Apparatus for Production of Three-dimensional Objects by Stereolithography” in 1986. Hull went on to start the first 3D printing company, 3D Systems Corporation.

With this background in industrial manufacturing, most 3D printing technologies were protected by patents held by companies in the industrial market. As patents expired, 3D printers geared for the consumer began to appear.

3D Printers for industrial R&D have existed since the 1980s; however, it was not until the expiration of Stratasys’ patent in 2009 protecting their ownership of the fused deposition modeling (FDM) process that affordable consumer thermoplastic extrusion printers proliferated.

The expiration of subsequent patents covering alternative additive manufacturing processes has further fuelled this growth.

3.2, Analysis of The Advantages of Using 3D Printing to the Industrial R&D

Research & Development is a very crucial part of many industries as well as markets; it has its own benefits. Manufacturers and firms need to ensure that their products constantly evolve and meet the ongoing trends, changing market demands, challenging competition, varying consumer requirements, and at the same time, be cost-efficient.

R&D is a forward-looking step that forms the foundation for the product innovation lifecycle and is also the precursor for future product development and market expansion. The use of 3D printers in industrial R&D has reshaped the way experts and professionals in multiple industries think about design and prototyping.

From how cars are made to the design sequence in aerospace and the continuous innovation technology brings to the table, 3D printers for industrial R&D plays a crucial role. Here are the major benefit having a custom FDM printer in your production line offers;

- Design iterations – Effortless replication and design modifications.

- Flexibility to work with numerous options in terms of materials, colors, geometries, and design complexities.

- Faster realization of prototypes to test product designs and utility as well as to pitch to investors.

- Flawless products that are true replicas of the designs to the minute detail.

How to Choose Material

3D printing is a new technology in constant evolution. It has rapidly expanded and is now being used in medicine. Patient-specific models with anatomical fidelity created from imaging datasets have the potential to significantly improve the knowledge and skills of a new generation of surgeons.

Various materials can be used to create 3D prints via an FDM, SLA, DLP, or LCD 3D printer. Before we go into detail as to the buying process involved in purchasing a medical 3D printer, let’s take a look at some of the suitable material available and the factors to consider when choosing.

4.1, ABS {Acrylonitrile Butadiene Styrene}

As a thermoplastic polymer, it can melt and cool without altering its chemical properties. That makes it an interesting industrial FDM 3D printer material for medical 3D printing. The filament is known to be strong, tough, and durable. It is also forgiving to scratches, offers good resistance to heat and everyday chemicals.

It can endure heat, pressure, and stress like no other industrial FDM material for medical 3D printing, making it a great choice for wear and tear prints. You can try this out yourself: If you move a strain of ABS filament, it will distort and bend before breaking. PLA breaks much more easily.

ABS is quite forgiving, as long as you print with the right settings and proper temperature management. You can even achieve overhangs of around 45 degrees. If the print succeeds, the results are very convincing.

Most makers like the material because you can process its surfaces with acetone, glue parts, and even file off some material. Lastly, it can be easily painted with acrylic colors.

ABS filament is not toxic when 3D printed. Only at very high temperatures (400 °C), the material decomposes into butadiene (which is carcinogenic to humans), acrylonitrile (possibly carcinogenic to humans), and styrene—nothing you want to inhale under any circumstances.

If you don’t have a medical 3D printer at hand, you can have ABS parts printed by a professional 3D printing service. You can put a call through to our support representative to obtain the best deal on a high-resolution FDM 3D printer for medical 3D printing.

4.2, PLA {Polylactic Acid}

PLA filament is by far the most popular industrial FDM 3D printer material used for 3D printing in medicine, and there’s a good reason for that. It comes in many shades and styles, making it ideal for a wide range of applications. Whether you’re looking for vibrant colors or unique blends, it’s an easy-to-use and aesthetically pleasing material.

PLA is short for Polylactic Acid, a thermoplastic polymer that is derived from renewable resources, more specifically from corn starch or sugar cane. This sets the material apart from other commonly used plastics, which are procured through the distillation and polymerization of non-renewable petroleum reserves.

Since PLA filament is a biodegradable product, it tends to naturally break down in about three to six months. Other thermoplastic materials can take up to a thousand years to decompose, making PLA much more environmentally-friendly.

PLA material has been thrust into the spotlight by the rise of custom industrial FDM printers. PLA filament is available in a wide variety of colors and blends, and innovative PLA-based materials seem to be constantly hitting the market.

Outside of medical 3D printing, PLA is also used to produce things like medical implants, food packaging, and disposable tableware. But inside of the industrial FDM 3D printing sphere, PLA filament is widely thought of as an aesthetic material best used for prototyping.

4.3, Carbon Fiber

Carbon fiber filaments are composite materials formed by infusing fragments of carbon fiber in a polymer base, similar to metal-infused filaments but with tiny fibers instead. The polymer base can be of different 3D printing materials, such as PLA, ABS, PETG, or nylon, among others.

While true carbon fiber materials have long continuous fiber strands that improve mechanical resistance, these FDM 3D printer materials contain short particles of around 0.01 mm in diameter. Although this is enough for improving the strength of printed parts, keep in mind that such filaments cannot compare to the actual material.

For those seeking tougher FDM 3D printer materials for the medical industry, carbon fiber filament presents a relatively easy alternative to the more expensive and demanding materials, such as polycarbonate (PC) or PEEK. Moreover, the increased strength provided by the carbon fiber particles contributes to greater dimensional stability, helping to avoid warping and shrinking.

However, using a medical 3D printer to 3D print these materials does present some issues. The infused carbon fiber particles aren’t melted by the nozzle during extrusion, which may lead to frequent clogging.

In addition, these particles work as abrasive agents during extrusion, which over time will wear down a brass nozzles’ internal bore. This is why special nozzles like hardened steel are strongly suggested for printing with composite materials.

4.4, PETG

PET (polyethylene terephthalate) is a thermoplastic polymer used for drink bottles or sailcloth. Mixed with glycol (hence the “G”) exhibits good 3D printing features. PETG FDM 3D printer material is resistant to high temperatures and water, presents stable dimensions, no shrinkage, and good electrical properties.

PETG combines ABS durability and PLA printability, and it comes as no surprise that it’s frequently chosen by professionals seeking a reliable filament for their projects. PETG gained a lot of recognition during the coronavirus pandemic because it can be easily sanitized and therefore is useful for medical applications such as face shields.

Note that You may encounter two options — PETG (sometimes written as PET-G) and PET. The “G” stands for glycol — a substance added to prevent corrosion and crystallization effects. Glycol modified PET is easier to 3D print. PET without glycol is more fragile and prone to breaking.

On the other hand, PETG is characterized by a delicate outline that’s easy to scratch. That being said, the chemical properties of PETG are far better for medical 3D printing despite some minor disadvantages. PETG is suitable for use on any medical 3D printer.

However, if you are interested in created 3D prints with PETG and you are yet to find a suitable high-resolution 3D printer for the task, don’t hesitate to put a call through to our support team.

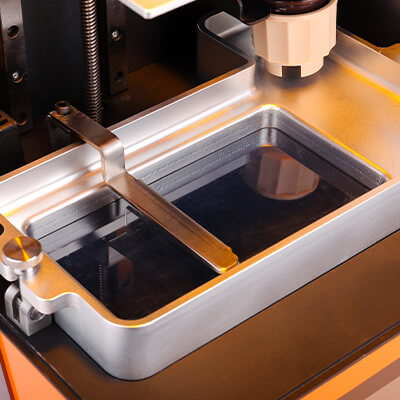

4.5, Resin

While FDM 3D printing technology uses traditional industrial plastics like ABS and Polycarbonate (PC), SLA, DLP, and LCD 3D printers require special photopolymer resins that harden (cure) once UV light is directed at it. Most 3D printing resins are either epoxy-based or acrylate-based, the latter being used more often in desktop printers.

A lot of people think of resin 3D printed parts as fragile and most suitable for ornamental and prototyping applications rather than functional and load-bearing components. But this is only true if the resin isn’t properly selected. That being said, if you’re buying a generic resin for a tough job, it won’t give you the strength that you’re looking for.

Examples of super-strong resin can be found in a wide variety of industries. There are castable resins for making jewelry and 3D printing in the field of dentistry to produce mouth guards, crowns, and surgical guides. There’s also high-temperature resins that are suitable for 3D printing in aerospace and even resins that can produce rubber-like parts.

As the definition suggests, tensile strength values are usually measured by a pull test that follows strict international procedures, so the results can be used worldwide. The higher the tensile strength, the stronger the material is considered to be because of how much stress it can withstand.

Just because the resin is tough, it doesn’t mean that a 3D printed medical part made from these resins will be twice as strong as if printed with a standard resin. Other factors, like model design and print settings, play important roles in the final print’s strength, which we’ll discuss in more detail later.

Nonetheless, comparing tensile strength is a straightforward way to determine which material is stronger, and from the numbers supplied by the manufacturers, it’s clear that these resins are much tougher than the standard.

How to Choose 3D Printer for Medical Industry

This buying guide won’t be complete if we don’t provide a detailed overview of the processes involved in choosing a medical 3D printer. There are lots of 3D printers available in the global market;

Choosing the best medical 3D printer requires insights into the processes involved. Below are major factors you need to keep in mind when buying a 3D medical printer.

5.1, What is the size of the Print?

The size of the print says a lot about the type of medical 3D printer to buy. While most LCD medical 3D printers can create CAD designs suitable for every printing task, you might want to keep in mind that you can sometimes come across machines with size, dimension, or weight constraints.

Determining the size of a print requires in-depth knowledge of the customer base or audience you create 3D models for on a regular. If your day-to-day workload revolves around providing CAD designs and models of large print size to experts in numerous other industries, we recommend you thoroughly scout for a machine palatable enough to handle the dynamic needs of your customer base before finalizing the purchase.

Print size is one factor most individuals take for granted when purchasing a medical 3D printer. If you don’t carefully consider the dimension, weight, or size of the model your medical 3D printer would be able to print before making payment, then keep in mind that the need to purchase another printer wouldn’t be far off.

If it seems impossible for you to accurately pinpoint the size of the 3D models or patterns you would be subjected to creating on a regular; please put a call through to our support team; they are fully equipped to guide you through every step of the decision-making process.

5.2, Chose a Reliable Brand

Every smartphone or gadget lover would easily relate to how frustrating buying a device from an unverified or unreliable brand can be. Starting up a medical 3D printing company might not require a million-dollar investment—it’s amongst the few lucrative businesses that individuals from all walks of life can easily use to make earns meet.

Before we dive deep into what choosing a reliable brand entails, note that your printing line is only as viable or as functional as the type of 3D medical printers available.

If your 3D printers are by-products of companies or manufacturers with little to no track record of providing sustainable medical 3D printers, it’s advisable you revisit the market as soon as possible and arm your production line with printers created by reputable brands.

While it’s important you choose the right brand for your medical 3D printing need, the process involved can sometimes get confusing. To know if a 3D wax printer of choice is an ideal end product for individuals and manufacturers who would go the extra mile to ensure you enjoy the best printing experience possible, explore the following factors;

- For how long has the manufacturer you are about to purchase a 3D printer from been in business?

- What sort of customer feedback is backing up their brand’s identity?

- Are they regarded as a top brand by professionals and experts in the industry?

- How often do they provide medical 3D printers with a price tag in line with the productivity, efficiency, and durability you require from the device?

5.3, Safety Configuration of the Machine

When purchasing or using a medical 3D printer, you must keep in mind that safety is paramount. And this is not just because you wouldn’t want to expose yourself to the toxic fumes most 3D printers emit during the design and creation process, but also because your ability to build a lucrative 3D printing business is largely dependent on how safe and ready-to-use your 3D printers are.

If this is the first time you are tasked with handling all the challenges that come with purchasing a medical printer, the safety configuration of the machine might seem alien to you. Don’t neglect the durability effect that comes with purchasing a medical 3D printer with safety configurations that does not reflect the productive ability of the machine.

When making your 3d printing machine buying decision, you need to be on the safe edge. The only way to achieve this feat is by putting due diligence into every step involved in the process. Note that the safety configuration of most medical 3D printers is quite complex and bulky. To demystify this tiring yet important process, consult with a support service representative before finalizing your buying decision.

5.4, Resolution Requirement of the Machine

How important is the resolution of a 3D printer to the end processor finish product? The answer to this question depends on the industry, client, and customer base you are serving. Having a high-resolution medical 3D printer is quite essential for professionals who design complex prototypes. A hobbyist can easily make do with medical printers of any type rest assured, the finished product and design are guaranteed.

There is no ideal benchmark or resolution requirement for doctors or surgeons looking to provide their clients with the best models and designs possible. However, having a medical 3D printer with high definition can help you attract, build, and grow a formidable client base.

Before making a purchase, explore the resolution of the 3D printer. Try to be as detailed as possible. You can seek advice from experts and professionals with a reputable track record in the medical industry. Endeavor to have a basic idea or information on the 3D printer resolution requirements that would keep your production line running at an optimal level before actualizing your medical 3D printer purchase.

5.5, Consider Weather the Price of the Machine is Acceptable

It’s never a fun experience to have explored all the remarkable features and benefits a medical 3D printer is offering, weighed it with your production line, and obtained satisfactory results just to find out during checkout that the medical 3D printer you want to purchase is far above your budget.

Medical 3D printers are quite expensive. They require a sizable investment, especially if you are looking for industrial-grade printers. As a doctor or surgeon looking to help individuals from different walks of life obtain the prototypes or finish product they desire, having the best medical 3D printer is essential.

Before exploring all the features and benefits of a medical 3D printer, weigh its price range with your budget. Note that the price of a medical 3D printer does not determine efficiency. There are a lot of medical 3D printers with a high price but not as durable and efficient as counterparts with low price tags.

To hasten your 3D printer buying process in terms of price, it’s advisable you put a call through to a support representative backing up the activities of a brand of choice stating your estimated budget and the type of 3D printing activities you would like to carry out using the machine.

5.6, Consider the Suppliers After-sales Service Capability

While most of the decision-making process involved in buying a medical 3D printer we have listed thus far revolves around upfront features, benefits, and price tags, you might want to bear in mind that there is more.

What’s the after-sales service of the brand you are purchasing a medical 3D printer from like? Is their support service trained to assist you during and after the sales? Do they take up complaints even after the deal is finalized? Is there room for free shipment or a money-back guarantee if the medical 3D printer shipped to you does not meet the required specification?

The after-sales service of your vendor or manufacturer goes a long way to determining how long your medical 3D printer would last. Many 3D printer manufacturers do not provide their users with sustainable after-sales service. Most brands tend to neglect complaints and don’t take into consideration customers feedback not in line with their sales and marketing goals.

Since its impossible to accurately determine how reliable a brand or supplier’s after-sales service is by asking the customer representative, the most viable method you can use to ascertain the quality of the brand’s after-sales service is by contacting individuals who have previously purchased medical 3D printers from your chosen manufacturer.

5.7, Consider the Service Life of the Machine

Every medical 3D printer comes with a designated service life. Most manufacturers state how long a machine would last base on the equipment and products that went into the design and development phase. To authenticate this claim, most medical3D suppliers attribute a warrantee on their machine based on the service life.

Most medical 3D printers come with a one-year warranty. While this is the normal service life for most medical 3D printers, it shouldn’t come as a surprise if printers with six months’ warranty are thrown your way. In most cases, such printers are relatively cheaper and come with limited benefits and features.

It’s best you ask your supplier’s support representative about the warrantee policy backing up the machine you are about to purchase. Try as much as possible to weigh in on the same scale as your production line and the price tag attached. If the service life of the medical 3D printer doesn’t seem to one that can yield profitable returns within the estimated time, it’s best you abort the purchase.

5.8, Consider the Maintenance Cost of the Machine

It’s no news that without maintenance, even the strongest of machines would at some point fail. Maintenance isn’t a factor that’s to be considered after you must have finalized the buy; it’s a factor that should be considered as so as you come across a medical 3D printer capable of handling the dynamic printing task at hand.

Maintenance can become an expensive venture when proper consideration is not given to it during the buying process. You don’t have to weigh how much every part of the machine would cost or the effect print fail would have on the machine in the long run. The basic maintenance culture needed to keep the medical 3D printer running effectively is all that’s needed.

Consider how much catering to the day-to-day needs of the machine would cost, weigh it against your budget, and, if possible, allocate a stipulated amount into maintenance. Note that creating a healthy maintenance culture during the buying process can help you heighten your medical 3D printer service life for a far longer time than your manufacturer or supplier proffered.

Conclusion

We have said all there is to say about the use of 3D printers in the medical industry. From how doctors and surgeons can benefit from additive manufacturing to the countless advantages medical 3D printers bring to health care workers and the bourgeois folk alike, we have covered it all.

Chapter 5 focused on the buying process involved in purchasing a medical 3D printer. We purposely hinted at all the vital features you need to put into consideration because a lot of 3D printer manufacturers provide machines that are far below standard. And we wouldn’t want you falling prey to such manufacturers.

Dreambot3D is a medical 3D printer manufacturer dedicated to providing doctors and surgeons with the best 3D printers for medical applications. Whether you are looking for a medical 3D printer to help students understand the intricate parts of a human heart or a 3D printer to develop a prototype for a kidney transplant, Dreambot3D got you covered—we provide one stop 3D printing solutions for the medical industry—get in touch today.

FAQ Guide

How are 3D printers used in the medical field?

3D printing in healthcare makes it possible for medical professionals to provide patients with a new form of treatment in a number of ways. 3D printing is used for the development of new surgical cutting and drill guides, prosthetics as well as the creation of patient-specific replicas of bones, organs, and blood vessels. Recent advances of 3D printing in healthcare have led to lighter, stronger, and safer products, reduced lead times, and lower costs. Custom parts can be tailored to each individual. This improves the understanding of patients by medical professionals and improves patient comfort level by allowing interaction with products that are designed especially for their anatomy. Due to the individualized nature of healthcare, 3D printing is a perfect solution for this industry. As opposed to fabricating a large number of identical parts, 3D printing empowers the creation of prosthetic and orthotic devices custom-fitted to a patient’s particular anatomy – thereby enhancing their adequacy.

Do hospitals use 3D printers?

Yes, hospitals use medical 3D printers. 3D printing has been used to print organs from a patient’s own cells. This means that patients may no longer have to wait a long time for donors in the future. In the past, hospitals implanted structures into patients made by hands. 3D printing has drastically improved this process.

Why is 3D printing important in medicine?

3D printing is important in medicine because it plays an important role in training future doctors and preparing for actual operations. 2D images are useful; however, they provide little visualization and do not represent an actual human part. 3D printing, on the other hand, provides models that look realistic and mimic actual human parts. This makes the operational process more accurate and effective. Future doctors can practice on 3D printed organs. This is much more accurate than, for example training on animal organs. Training on human-like, 3D printed parts increases the quality of skills doctors obtain during training and the medical treatment of patients. 3D printers create low-cost prosthetics where people need them, for example, in war-torn countries. They are an affordable solution for people who cannot afford to buy a prosthetic. Low-cost medical equipment is also important in poverty-stricken countries and remote areas. There are areas where road infrastructure is too bad to deliver medical equipment. 3D printing makes it easier to print the necessary equipment in those villages without having to transport them regularly.

How does 3D printing affect the medical field?

Making prosthetics the traditional way is very expensive because they have to be personalized to the individual. 3D printers give users the freedom to choose, e.g., different designs, forms, sizes, and colors of their prostheses. This makes every 3D printed piece personalized. 3D printers also allow prosthetics to be more widely available at a lower price. 3D printing allows to 3D print medical and lab equipment. It is possible to 3D print plastic parts of the equipment. This drastically reduces costs and time spent waiting to receive a new medical device from external suppliers. Furthermore, the manufacturing process and further applications are also easier. This makes the equipment more readily available and allows low-income or hard to access areas to get 3D printed medical equipment more easily.

What body parts can be 3D printed?

Just a few years ago, the idea of ‘printing’ a body part seemed like the stuff of science fiction. It’s now becoming a reality, and not just for high-tech research laboratories. Some amazing creations are being made using readily available, standard 3D printers. Some body parts that can be 3D printed include bionic eye, antibacterial tooth, heart, skin, bionic ear, elastic bone, and ovary.

How can 3D printing help humans?

To highlight some of the positive impacts that 3D printing is having on humans, here is a list of some of the top ways that the technology is making a difference for the environment, health, culture, and more.

- Disaster Relief

- Affordable Housing

- Affordable, Stylish, and Children Prosthetic

- Saving the Coral Reef

Can 3D printing save lives?

The specialized 3D printers can be used to jet living cells along with support material known as scaffolding. These bioprinters are excessively used for printing skin, bones, and joints. Recently a new technology is used for creating the pelvis of man. Moreover, organ printing systems is no less than a revolutionary change as the number of people waiting for organ transplant increase every day, and a lot of them die while waiting for the transplant. Therefore, printing bones, muscle structures, and other organs can incredibly save human lives.

What is 3D printing in a medical application?

Three-dimensional (3D) printing in medical applications refers to a number of manufacturing technologies that generate a physical model from digital information. Medical 3D printing was once an ambitious pipe dream. However, time and investment made it real. Nowadays, 3D printing technology represents a big opportunity to help pharmaceutical and medical companies to create more specific drugs, enabling rapid production of medical implants and changing the way that doctors and surgeons plan procedures. Patient-specific 3D-printed anatomical models are becoming increasingly useful tools in today’s practice of precision medicine and for personalized treatments. In the future, 3D-printed implantable organs will probably be available, reducing the waiting lists and increasing the number of lives saved.

What is medical 3D printing?

Medical 3-D printing is an emerging area of technology that explores how 3-D printing can be used to replace or support an existing biological structure. Medical practitioners have now begun using 3-D printers to produce medical devices.

How is 3D printing used in medicine?

3D printing is revolutionizing how surgeons prepare for surgery. The technology is used for replicating patient-specific organs from scan data that allow the surgeon to practice and prepare before the actual complicated operation takes place. 3D printing in medicine has – just as it has done in other fields – enabled customization, prototyping, manufacturing, and research. The areas of application for 3D printing are broad, going beyond general medical practice and research.

What examples are there of other 3D printing medical products?

Medical devices that are produced using 3D printing technology include orthopedic and cranial implants, surgical instruments, dental restorations such as crowns, and external prosthetics. Medical imaging has been playing an important role in the medical industry; X-ray scanning, laser scanning, CT scan, and MRI has become an essential part of medical treatment. Modern technology has increased the capability of using these foolproof images to create 3D objects.

Why is 3D printing a significant innovation?

Simply put, it has the ability to transform consumerism. By empowering people to build their goods, unprecedented customization, and a significant shift in manufacturing power is possible. The technology is here to stay and will only become more commonplace as it continues to be refined.

What can 3D printing be used for in the medical field?

3D printing in the medical field can be used to produce prosthetic limbs that are customized to suit and fit the wearer. It is common for amputees to wait weeks or months to receive prosthetics through the traditional route; however, 3D printing significantly speeds up the process, as well as creating much cheaper products that offer patients the same functionality as traditionally manufactured prosthetics.

How do doctors use 3D printing?

Doctors are currently using models produced by 3D printing from patient scan data to enhance the diagnosis of illnesses, clarify treatment decisions, plan, and, in some cases, even practice chosen surgical interventions in advance of the actual treatments. The models enable doctors to understand patient anatomy that is difficult to visualize, especially when using minimally invasive techniques. Models also assist in precisely sizing medical devices. Doctors can also utilize the models to explain an upcoming medical procedure to patients and their families and to communicate the surgical steps to their colleagues.

What material is used for 3D printing organs?

3D printing organ utilizes the techniques used in conventional 3D printing where a computer model is fed into a printer and produces layers of filament-like plastics or wax until it completes a 3D object, in this case, organs like ear, heart, or kidney. The process is also called 3D bioprinting because it combines 3D printing like-techniques, cells, and biomaterials to create living tissues. Its goal is to develop functional human organs that are ready to be transplanted.

How does 3D printing affect the medical industry?

3D printing allows to 3D print medical and lab equipment. It is possible to 3D print plastic parts of the equipment. This drastically reduces costs and time spent waiting to receive a new medical device from external suppliers. Furthermore, the manufacturing process and further applications are also easier.

When did 3D printing in medicine start?

3D Printing was first used for medical purposes as dental implants and custom prosthetics in the 1990s.

How does 3D printing advance construction?

In the construction industry, 3D printing is often used to create construction components or to ‘print’ entire buildings. Development is appropriate for 3D printing. 3D Printing in the construction industry means greatly reduced production time. That’s because the machines themselves are very fast; some of them are capable of manufacturing 600 to 800-square-foot (55 to 75-square-meter) home in just 24 hours. Sounds amazing, doesn’t it? 3D printers are also fully automated, which eliminates human error. The machine just needs to be monitored, but most of the production process doesn’t involve any human help.