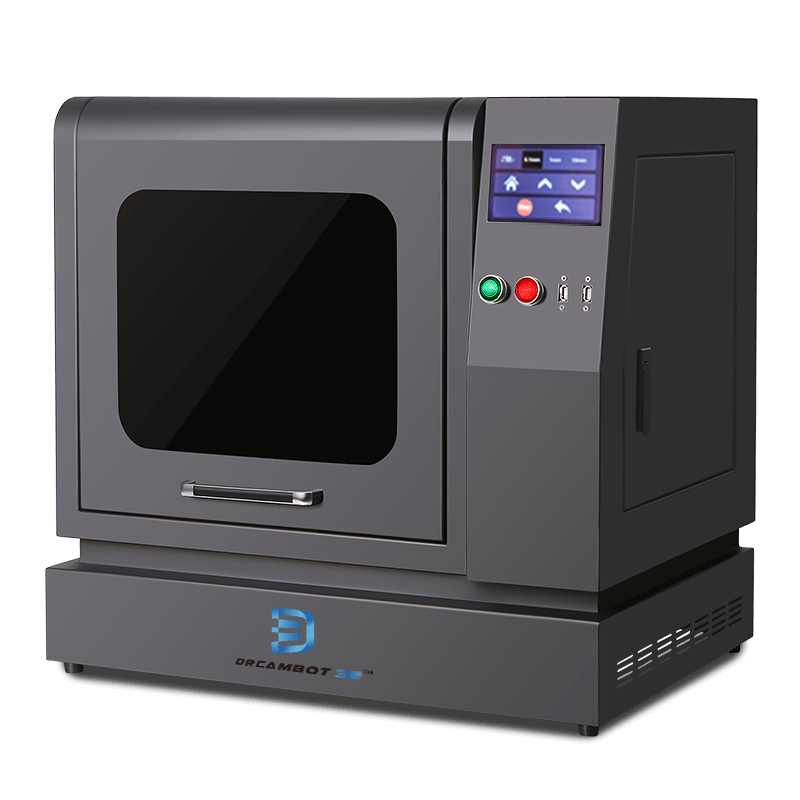

4K LCD 3D printer

DB-345 LCD 3D Printer

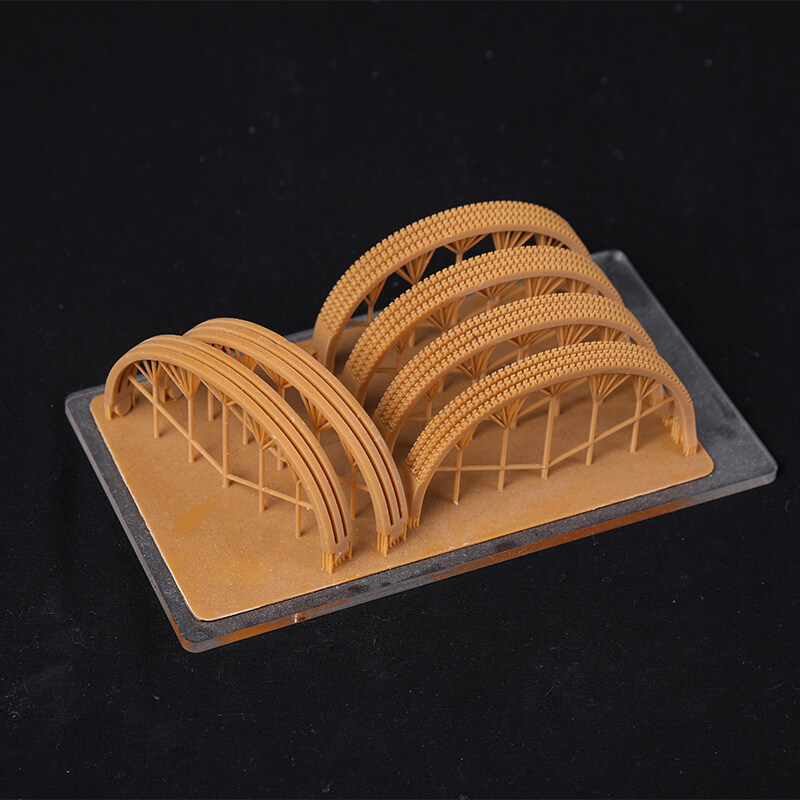

- Stereoscopic light curing 3D printer with LCD technology, high quality of finished products

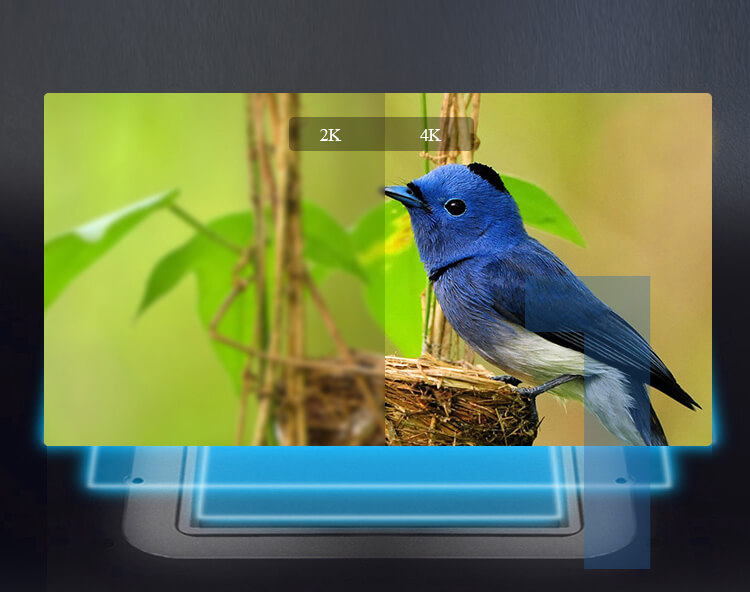

- 4K high-definition pixel printing greatly improves the smoothness of the model surface.

- Dreambot3D 4K LCD 3d printer(DB-345) has obtained CE, FCC certification and quality assurance.

Dreambot3D 4K LCD 3D printer(DB-345)

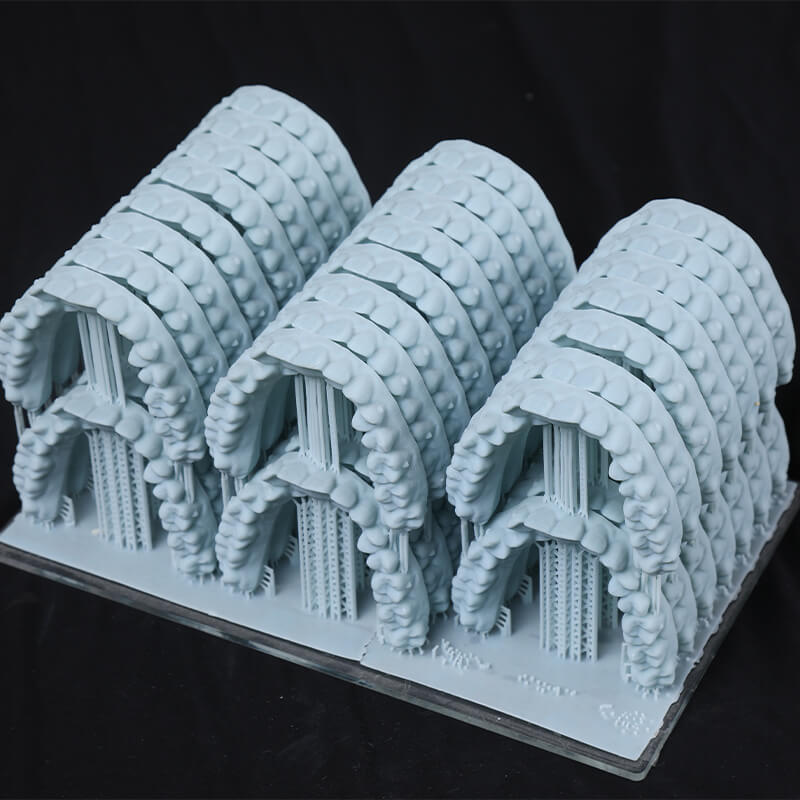

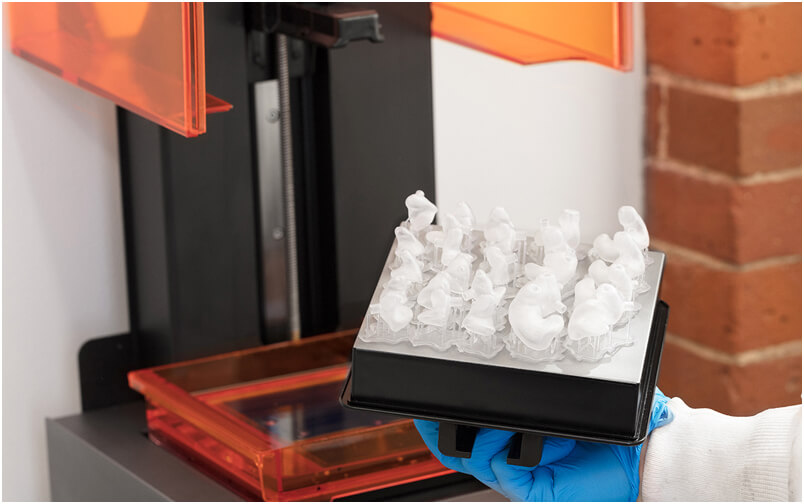

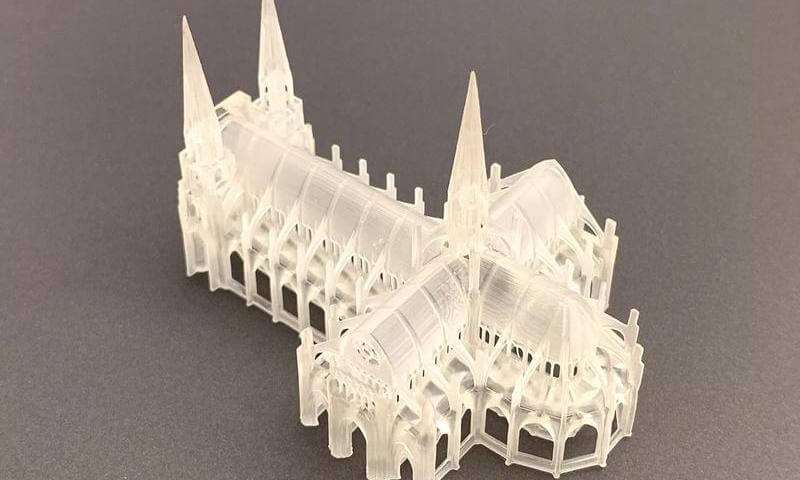

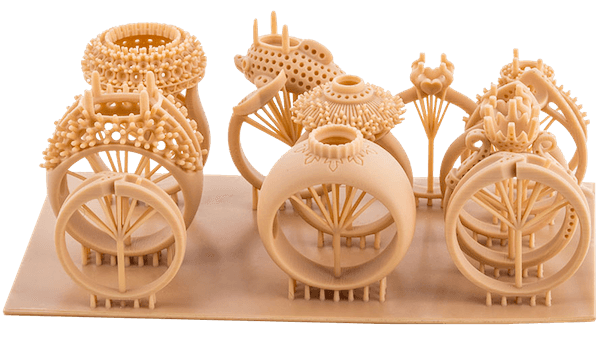

The Dreambot3D 4K LCD 3d printer(DB-345) is used for printing high definition 3D objects. It is commonly used in fields such as jewelry, character and item model, dentistry, home and garden, toys, prosthetics, building model, etc. It is suitable for different categories of 3D printing.

Printing with a 4k LCD printer gives consistent 3D printing throughout the printing process. When you print with Dreambot3D 4K LCD 3d printer(DB-345), you spend less on printer maintenance. The 4k resin 3D printer is all together affordable to purchase, fast in printing and easy to use.

| Parameters | DB-345 LCD 3D Printer | |

| Printing Parameters | Printing style | RESIN LCD 3D Printer |

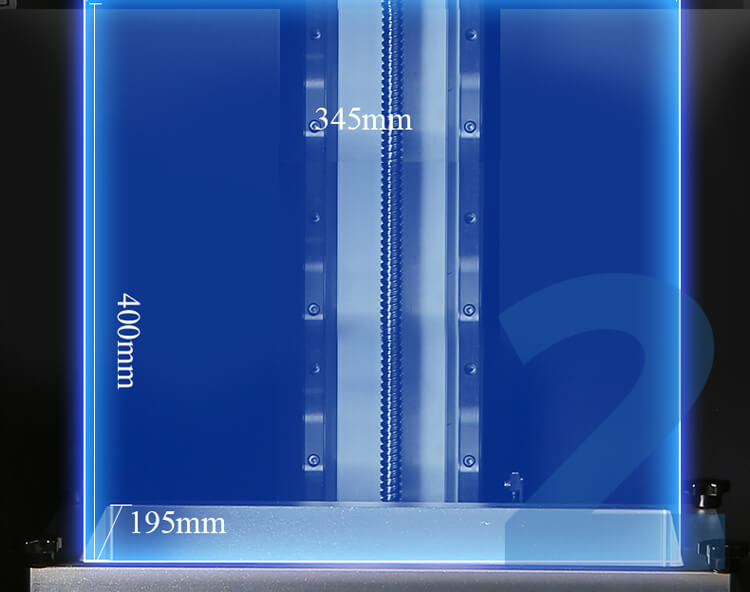

| Max printing volume | 345x195x400mm | |

| LCD size | 15.6 inch | |

| LCD panel | 4K LCD screen panel | |

| Printing accuracy | X Y axis 0.075mm, Z axis 0.02mm | |

| Printing speed | max 20nm/h (Z axis) | |

| Resin support | 405nm resin | |

| LED array | Parallel UV LED light source | |

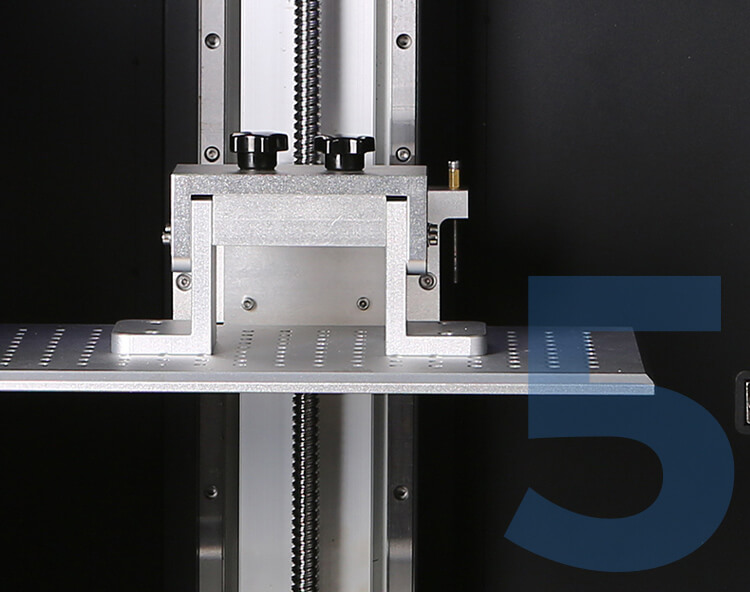

| Z axis | Dual Linear Rail, Ball Screw, 100% Aluminum CNC Structure | |

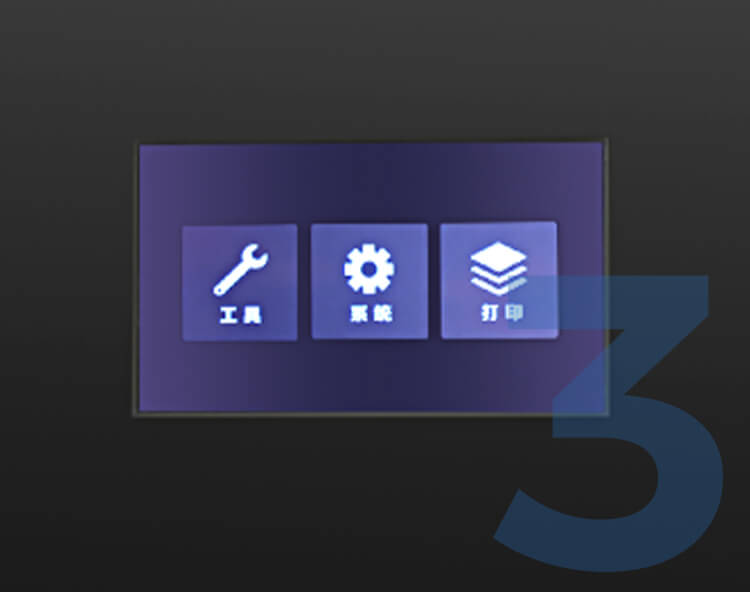

| Touch screen | 5 inch High Resolution Touch Panel | |

| Software Parameters | Operating systems | Windows Linux Mac OS OSX |

| 3D Modeling software | CAD Solidworks 3Dmax UG Maya Rhino Proe 3Done Skatchup ect | |

| 3D Slicing software | Chitu | |

| Input format | STL OBJ AMF ect | |

| Connect mode | USB,Network Connect | |

| Physical Parameters | Printer dimensions | 670x430x640mm |

| Package size | 730x520x870mm | |

| Net weight/Gross weight | 48kg / 55kg | |

| Structure | CNC Sheet Metal (full enclosed style) | |

- The Dreambot3D 4K LCD 3d printer(DB-345) has a 4k resolution that makes it possible to reach 31.5 micro resolution that gives all printed 3D objects detailed finishing.

- The 4K resin 3D printer has a ball linear slide rail that makes balance sliding more stable. This helps you to achieve a smooth and quiet printing operation.

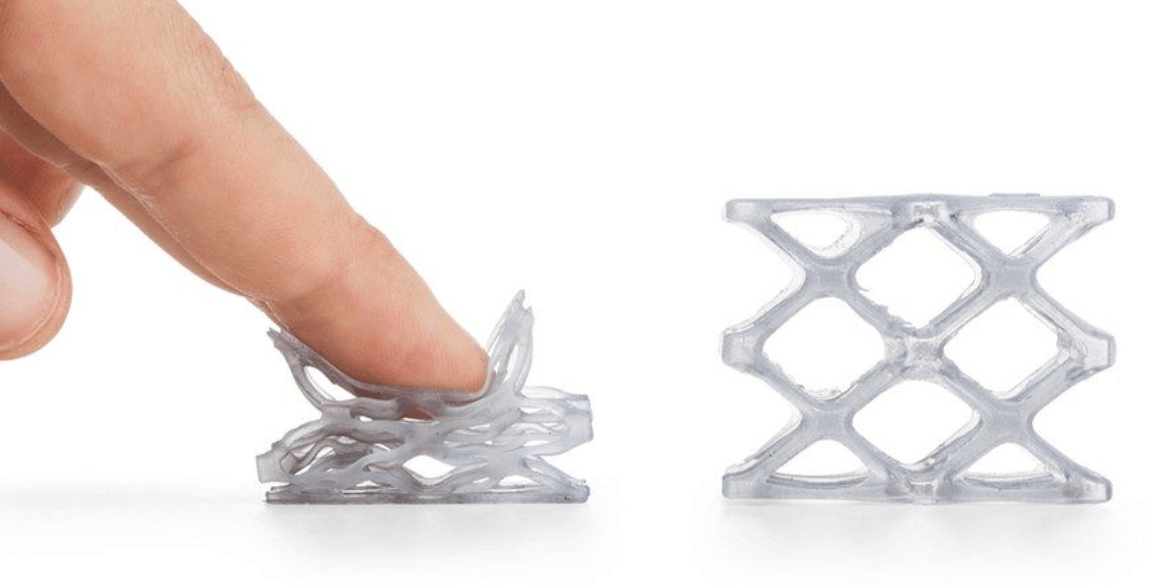

- The Dreambot3D 4K LCD 3d printer(DB-345) has 4 to 8 times anti-aliased edges which gives smooth edges and colours to your 3D objects. Therefore, all objects with complex shapes or edges appear less jagged and help blend colours in a natural looking way.

- The print size has horizontal lines that are 8.9 inches.

- The speed of printing is 30mm/h. 3D printing takes very little of your time.

- There is no need for leveling, this feature is particularly suitable for new users of the 4K LCD 3D printer.

- The Dreambot3D 4K LCD 3d printer(DB-345) has a resolution of 4K pixels while the thickness of each printing is 0.02 to 0.1mm.

- The printer applies the cooling system to adjust the temperature of the ultraviolet lamp and the internal temperature of the printer, which allows for continuous printing.

- You can achieve a large printing size of 345x195x335 mm with no shrinkage or wrapping.

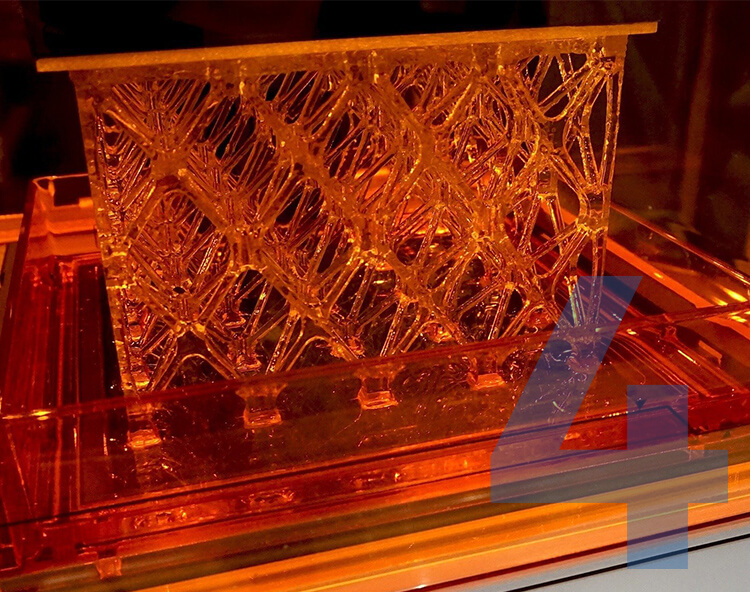

Application of 4K LCD 3D printer

Test your part

We provide sample testing service, allowing you to check the working quality of our 3D printer before placing an order

6 points why choose us

4K resolution printing

Large size printing

PLC control system

Extremely speed printing

Industrial grade ball screw guide

Reinforced structure

More 4K LCD 3D printer

ME-345 LCD 3D Printer

The ME-345 is a high powered 3D printer that makes small and large scale printing seamless. It can be used across different industries.

ME-192 LCD 3D Printer

The ME-192 is used for high precision printing for all sizes of printing. It adopts high definition pixels for printing.

DB-550 LCD 3D Printer

The DB-550 is used for printing large 3D objects. It is used by industries that require printing large complex objects like prosthetics.

4K LCD 3D printer buying guide

2.1, Used in the jewelry industry

2.2, Used in the medical industry

2.3, Used in production and R&D

3.1, For transparent resin 3d printing

3.2, For flexible resin 3d printing

3.3, For high hardness resin 3d printing

3.4, For castable resin 3d printing

3.5, For photosensitive resin 3d printing

When Gutenberg invented the world’s first-ever printing press, the ability to enjoy printing was only available for a few people. The private printing facility was relatively inaccessible until the introduction of the typewriter. The same thing goes for 3D printing.

Once the bastion of scientific universities, architectural firms, and art houses, LCD 3D printing or transparent 3d printing have changed the printing processes with a 4k LCD 3d printer for the hobbyist and professionals.

The introduction of LCD 3D printers has brought a great revolution that has allowed students to manufacture their dreams in unique 3D models or objects.

The global manufacturing industries are now building robust 3D prototypes utilizing state-of-the-art equipment. Such printers have enabled them to enjoy rapid prototyping. They design the product with a CAD-Computer Aided Design software and produce the final products using a tough resin 3d printer.

The introduction of a rough resin material that can easily withstand a higher-level of pressure has dramatically advanced it. On the other hand, the introduction of thermoplastics and the development of efficient and smaller machinery having faster printing speed have enabled 4K 3D printers to move out from the factory to the office desktops.

These printers utilize resin or filament to produce a high level of detail and super smooth surfaces. You can find them in jewelry workshops, clinics, and dental labs. However, with time their popularity also increasing among makes and hobbyists.

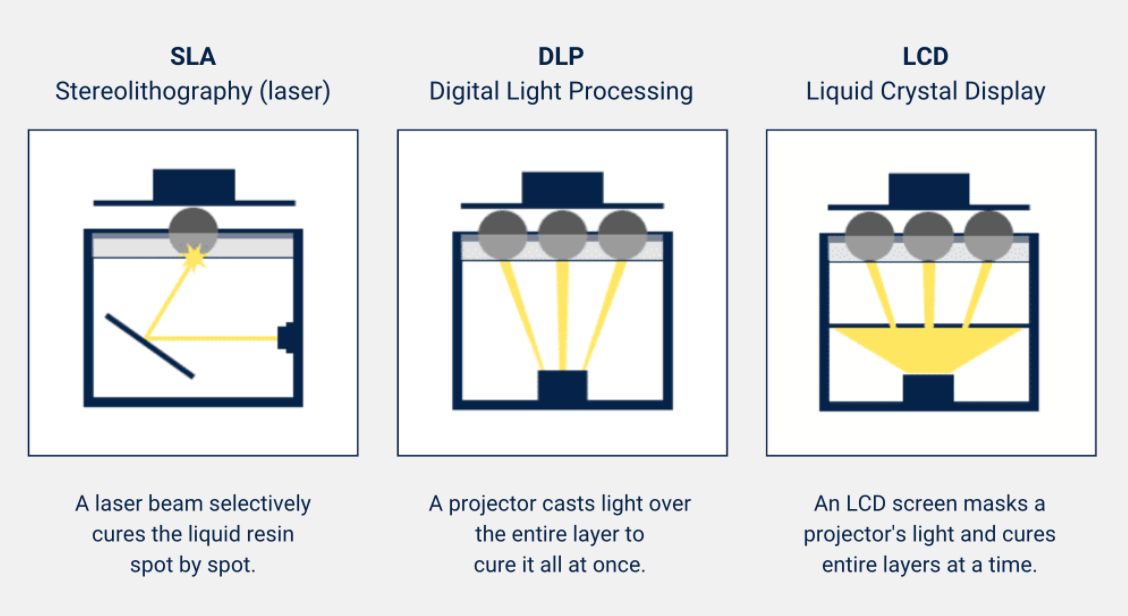

The way a 4k resin 3d printer works depends on the printing technology, for example, SLA- Stereolithography, DLP- Digital Light Processing, FDM- Fused Deposition Modeling, or LCD (an LCD screen is used to mask the projected light).

The work process of LCD 3D printers is the same. However, they may require different post-processing steps, for example, post-curing or resin removal. These 3D printers are computer-controlled devices. Using this, different types of objects can be designed and defined within the software, and you can give them a three-dimensional shape from polymers and plastic materials.

A 4k resin printer is designed to facilitate flexible and rapid production of models, spare parts, prototypes, and other items covering the industrial, commercial, and domestic spheres. The available range of 3D models can range from robust or tough designs for factory use to small and affordable models for home use.

So, if you have not tried out this fantastic machine yet, it is the right time to go for it. With this, you can give your production or 3D printing business a perfect boost. However, when choosing the best new resin 3d printer, you may face some challenges. So, how to buy the best one based on your requirements? This is where this buying guide will help you out. This comprehensive guide will get all the information to select the best budget resin 3D printer with LCD technology. Let’s get started with it.

What is an LCD 3D printer?

Before understanding an LCD 3D printer, it will be better for you to know about 3D printing. This is called additive manufacturing, where different physical objects are produced utilizing materials in layers based on your digital models. The process requires hardware, software, and different printing materials to get the job done.

This printing can be utilized to craft anything from the high-end technical final product, simple parts to prototypes. Some examples are life-saving medical implants, airplane parts, eco-friendly buildings, artificial organs, and more.

In the world of 3D printing, you might have come across the word DLP-Digital Light Processing printing technology. This printing technology utilizes a digital light projector to cure resin material and produce highly-accurate 3D models. Such a process doesn’t use the laser light that you will find with SLA- Stereolithography. In a DLP printer- the light is projected by the DMD- Digital Micromirror Device.

The LCD 3d printer 4k just works like DLP 3D printers. In such a printer. Here the machine produces UV lights that generate from LEDs and projected onto the LCD panel. The LCD screen works like a mask, and it only shows the pixels required for the printing. When it comes to getting high-resolution 3D models, you can always trust a 4K LCD 3D printer. Now let’s have a look at some benefits of 3D printers.

Advantages of 3D printers

- One of the significant advantages of 3D printers is rapid prototyping. You will be able to design, produce, and test different customized parts quickly.

- The cost related to 3D printers and 3D printing is very cost-effective. If you want to produce a prototype within a few days, 3D printing will be a cost-effective technique.

- Another most significant advantage is you can 3D print almost anything. Just feed the design into the slicer software, add required supports, and the printer will carry out the task.

- With this, you will be able to conduct a physical demonstration of new products to investors and customers.

- The machines are designed to produce robust heat dissipation.

- They don’t require any type of leveling. The level of precision is right, and the details will come out quite accurately.

- Made of advanced technology, the power supply during the printing process will remain stable.

- As they offer a higher quality and consistency level, a 3D printer will let your business mitigate the risk involved in your manufacturing process.

The significant advantages of a 4K LCD 3D printer or the best affordable resin printer are realized in its cost benefits, speed, and flexibility. So, don’t think much and get one now for your business.

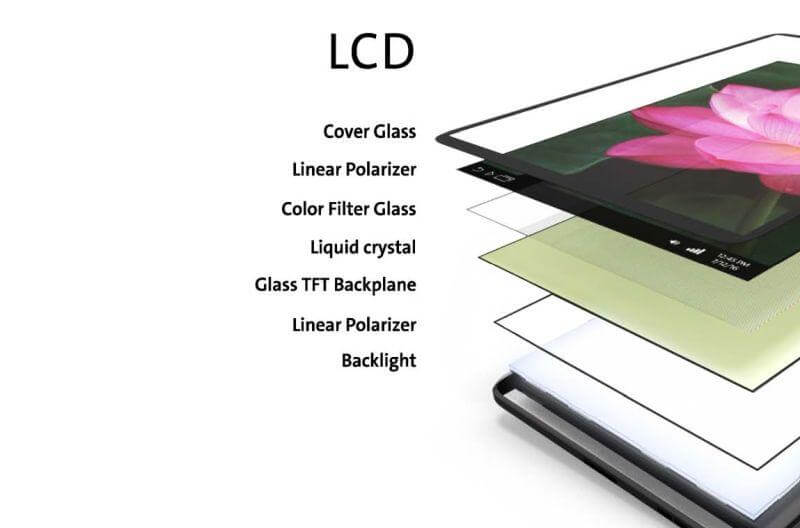

1.1, What does LCD mean and where does it come from?

LCD- Liquid Crystal Display is a flat panel display technology widely used in monitors, TVs, laptops, smartphones, and other electrical products. Speaking more about it, these were a significant lead in terms of the types of technology they replace, including LED- Light-Emitting Diode along with gas-plasma displays. LCD technology allows the displays to be relatively thinner than CRT- Cathode Ray Tube technology.

Such display panels utilize less power than LED as they work on the principle of blocking light. They don’t emit the lights. An LED panel emits light, but LCD’s liquid crystals produce the images by utilizing a backlight. Even though LCDs are gradually replacing outdated display technologies, they have replaced other advanced display technologies, such as OLEDs.

Have a look at the history of Liquid Crystal Displays

As per the report, the Liquid Crystals were first invented in 1888 by Friedrich Reinitizer, an Austrian botanist and chemist. He discovered them in cholesterol extracted from carrots.

Later in 1962, RCA, Richard Williams developed stripe patterns in a thin layer of liquid crystal material using voltage. That effect was based on the electrohydrodynamic instability, which is now known as “Williams Domains.”

According to different papers, between 1964 to 1968, a team of scientists and engineers at the RCA David Sarnoff Research Center in Princeton, New Jersey, led by George Heilmeier, Louis Zanoni, and Lucian Barton, developed a method to control the light reflected from the liquid crystals. That way, they successfully demonstrated the first-ever liquid crystal display.

The LCDs of Heilmeier utilized crystal display that he named DSM-Dynamic Scattering Method. In this, an electric charge is sent that rearranges the molecules to scatter the light.

However, the DSM technology not appropriately worked and consumed more power. Later, the DSM design was replaced by a better version that utilized liquid crystal’s twisted nematic field effect. It was discovered in 1969 by James Fergason.

It may be noted that James Fergason, a well-known inventor holds some crucial patents related to Liquid Crystal Displays that are filed during the 1970s, including a patent for “Display Device Utilizing Liquid Crystal Light Modulation.”

The ILIXCO- International Liquid Crystal Company, in 1972, manufactured the world’s first modern LCD watch based on the patent of James Fergason.

Different types of LCDs

- TN- Twisted Nematic- These LCDs are inexpensive but offer high response times. On the other hand, these displays produce low contrast ratios, viewing angles, and low color contrasts.

- IPS- In Panel Switching- These displays offer better contrast ratios, color contrast, and better viewing angles compared to TN LCDs.

- VA panels- Vertical Alignment panels-Such panels come between IPS and TN display and offer medium-level features.

- AFFS-Advanced Fringe Field Switching- This is a top performer compared to the IPS displays in color reproduction.

Such displays have brought a great revolution in the display industry, and all most all the products use LCDs. The best resin printer also comes with LCDs. Now, let’s have a look at how LCD 3D printers work?

1.2, How does an LCD 3D printer work?

Before exploring this, let’s know about the history of 3D printing. This is also known as Additive Manufacturing. A French engineer team made the first attempt, but the project was abandoned due to a lack of business opportunities. During the 1990s, significant technologies were developed, for example, FDM- Fused Deposition Modeling technology. This made 3D printing much faster and gave it new hope. Now, let’s talk about how the best resin 3d printer works?

In simple words, the best resin for 3d printer is a computer-operated fabrication device. Different design types and objects can be crafted in 3D format within a printing device from various plastics and polymers. Here the objects are developed through the rapid addition of layers of materials, and each layer covers the previous layer. The printing material, such as resin, is applied through the extruder. When heat is applied, it becomes soft, and when they have cooled, they become solid.

Designs planned for printing are generally created in 3D printing software, for example, CAD- Computer-Aided Design and AMI- Amazon Machine Image files. These define the object’s dimensions to be created. Before printing, the AMI and CAD files describing the 3D objects need to be converted into a programming language that the printer can read. Such conversion can be done by a software called “Slicer.”

The process

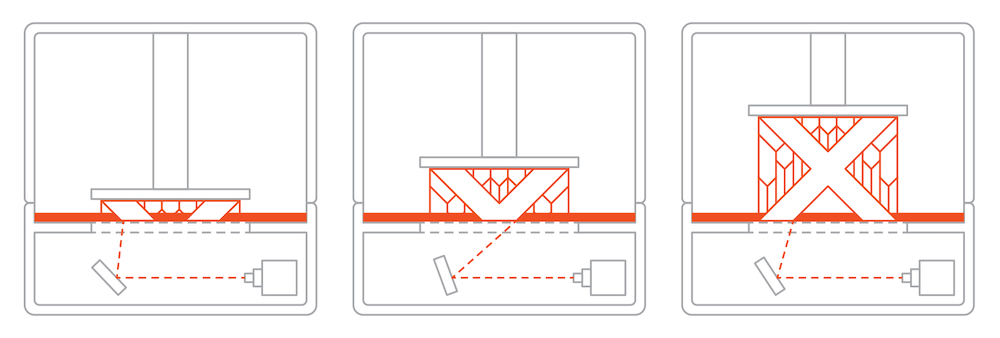

The printing process with a 4k LCD 3d printer starts with your designs or images. It starts as a 2D design and then structured as a 3D design using some software, or you can use a 3D scanner for this. When the design is digitally mastered, it is sent to the printer through Ethernet, USB, or wirelessly.

The design is carefully sliced in the modeling program into different thin layers that correspond to the cross-section of the 3D model. These are the guide of the 3D printer and decide how many layers are required to print.

The printing process begins after the 3D printer reads the digital design files and releases a flexible material, like resin, through the heated nozzle or extruder, creating hot beads that will melt onto a flat plate cooled; the material will get harden.

The nozzle is attached to a powerful mechanical motor, creating the 3D model in layers by layers, horizontally, side to side, and front to back.

Once done, the model is removed from the build platform and sent for post-processing to remove excess parts. Under this process, you may need to follow some steps, like UV-Curving, washing, sanding, support removal, and more.

Using 3D printers, you will not take much time for rapid prototyping. With time the machines are getting very powerful. For example, you can consider the LCD and FDM 3D printers of Dreambot3D, such as ME-192, ME-345, DB-293, L5-300, L5-400, L8-500, and more. Such machines can use different printing materials, such as PLA, TPU, 95A, wood PLA, nylon, PETG, ABS, metal filler, and more.

1.3, LCD vs. DLP vs. SLA: All you need to know

The scenario of 3D printing has to get a little confusing with the introduction of LCD printing technology. Previously the term was very clear as at that time 3D printers were using DLP and SLA technology. However, the primary question is, what is DLP, SLA, and LCD 3D printers? Why are they different from each other?

In terms of 3D printing, most people know that 3D printers use the SLA molding technique, a photo curing technique. But what about the DLP and LCD? Let’s know about them in datils.

About the SLA technology

SLA 3D printing or Stereolithography is one of the widely used and extensive strategies for additive manufacturing. This technology is worked using laser light to solidify liquid resin stored in a tank to produce the desired 3D models. In general, this printing process converts photosensitive fluid into 3D concrete forms in a layer-by-layer production process utilizing a laser along with a photo polymerization. After forming the resin prototype, it is treated and then polished, repainted, and tinted to get the desired product.

About the DLP technology

Texas Instruments introduce DLP-Digital Light Processing, and first, it was applied on projectors to get higher efficiency, better speed, and accurate spital light modulation. Here, a digital projector projects a single image of the layer. It uses UV light to cure the resin. However, some commercial DLP machines don’t use pure UV, and instead that they use resins or UV photopolymers. The best thing about a DLP 3D printer is it can offer a better accuracy level than an SLA printer.

About LCD technology

It is also called MSLA – Masked Stereolithography, as the LCD screen will work as a mask to block the UV light sources. LCDs are made of tiny pixels that being inactive and active. It is a red and blue color fluid crystal panel, which is transferred with lens magnification. The light source in the machine is UHP.

LCD and DLP technologies are faster than SLA as they can effectively project one top layer simultaneously. No matter how complex and significant the object is, its z resolutions and height will significantly affect the printing time. The resolution on the XY axis much depends on the pixel size of the LCD screen. If the screen resolution is high, you will get a higher XY resolution of the 3D model.

Some advantages and limitations of SLA

- SLA printers can create parts having very high dimensional accuracy, and the level of detail will be quite useful.

- You will get 3D models with a smooth surface. So, for a good-looking visual prototype, you can go for such a printing process.

- This can be used for specialty SLA materials, for example, castable, transparent and flexible resins.

- It may be noted that SLA parts are brittle, and you cannot use them to produce functional 3D models.

- If the model is exposed to sunlight, it will lose its natural visual appearance and mechanical properties.

DLP vs. LCD printing quality

When compared to SLA printing, the advantage that both LCD and DLP share is construct rate. It is a fact that the whole layer is blinked at the same time, instead of a single factor. So, they can create 3D models quiet faster than SLA. Both these printers are used in the design, jewelry, oral, and fashion industry. The DLP and LCD printers can accomplish a fast print rate while offering great details, but in terms of price, the DLP 3D printers start to outdo their LCD counterparts.

As per the experts, if you are professional and looking for a device that can offer more important details with a faster printing rate, you should go for specialist DLP printers. However, if you are using 3D printers for the first time and are a beginner, then a cheap resin 3d printer with LCD technology will work great for you. Keep this thing in mind while buying one.

When it comes to getting a robust 3D printer with advanced features under your budget, you can always trust the brand Dreambot3D. The company has introduced some top-class products like ME-192, ME-215, DB-550, L5-400, DB-293, and more. With these printers, you don’t have to worry about the printing materials as they support all types of 3D printing materials.

Application fields of LCD 3d printer

3D printing, or additive manufacturing, has emerged as a perfect alternative to the traditional product manufacturing methods. Using 3D printers, highly-quality injection molding, casting, and CNC machines are the most reliable manufacturing methods and offer different advantages. While offering countless benefits, the LCD 3D printers have opened new possibilities.

This process has enabled different industries to produce parts having complex geometries that are quite impossible to manufacture through the traditional product development process. This method offers an extraordinary level of geometric flexibility. On the other hand, they have made mass customization a lot easier. That means you can quickly change your 3D file and print a new one.

The industries dealing with small volume production, 3D printing can be a low-cost and most-efficient solution. On the other hand, such type of 3D printing has helped in avoiding material waste. So, a more significant number of industries are now using 3D printers. The market experts have predicted that the 3D printer market will reach USD 41 billion marks by the end of 2026. It can be said that the possibilities that you will enjoy with the best affordable resin printer are awe-inspiring.

Now, let’s explore the application of a 4k LCD 3d printer in different industries. You will also know who such printers are helping different industries for faster business growth.

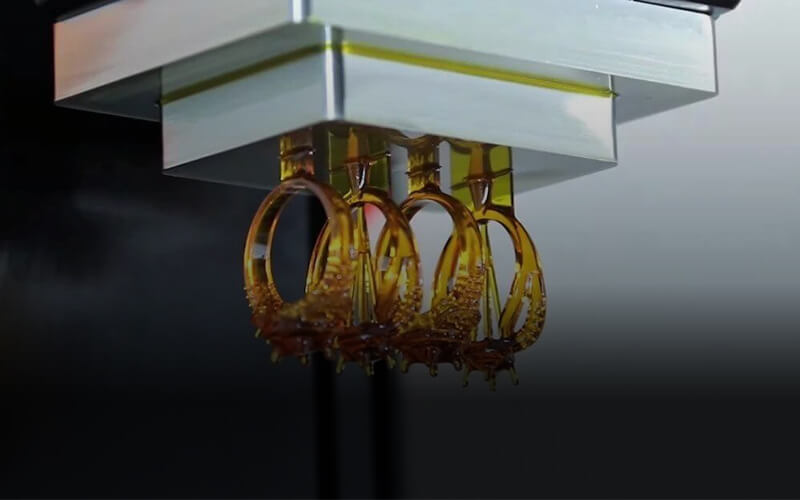

2.1, Used in the jewelry industry

3D printers were introduced to produce rapid prototypes. However, it is the greater versatility of advanced 3D printing that has opened up many possibilities. An area that is immensely enjoying its excellent benefits is the Jewelry industry. The potential for 3D jewelry printing across the world is very high.

For creating jewelry in bronze, copper, brass, and gold, jewelers use casting and lost-wax printing. All these methods are based on modern 3D printing and traditional metal casting.

Here, the process begins with 3D printing the 3D model using wax. The budget resin 3d printer will use wax-like resin. After that, multiple wax sprues are attached to the model. Now, the model will be fixed to the wax tree using the sprue. The tree, covered in a fine plaster, will be placed in a flask. The plaster, while solidifying, will create a mold for metal casting. The mold will be put in the oven and heated to burn the wax. In the jewelry industry, 3D printing is used for investment casting and to produce jewelry pieces.

Is it possible to 3D print jewelry pieces using gold?

3D printers are used in the jewelry making process to optimize your casting process. However, you should not consider this as a total replacement for traditional jewelry making. The jewelry-making process through 3D printing is different from direct 3D printing using metals, for example, DMLS- Direct Metal Laser Sintering. The object is created using metal powder. The use of gold can be a very costly affair.

On the other hand, the minimum size of the product for direct 3D printing needs to be more than 1-2mm, however, 3D printing with precious metals like gold still practices. Lionel Theodore Dean, a well-known designer, made some pieces of gold ornaments using a 3D printer.

The Future of the Jewelry Industry

Owing to the high cost of large-scale 3D printing along with the perceived barrier to digital jewelry designs, 3D printed jewelry pieces represent a small fraction of the market. However, with increasingly easy access and use of3D printing technologies, the market of 3D printed jewelry is poised for fantastic growth. There are some easy-to-use materials; for example, castable reins are now offering opportunities to learn new things.

3D printing techniques in the jewelry industry

In this industry, 3D printing is used to make jewelry in two significant ways, i.e., direct printing and investment casting. Let’s know about investment casting.

Investment Casting

This method of jewelry making through 3D printing involves the following steps.

- Formation of patterns-Previously, this was done by applying casting wax into a mold made of metal. Now, 3D printing lets the patterns directly be 3D printed from castable resin. You can give any shape you want.

- Assembly of mold-The advanced 3D printing method has significantly disrupted this process by 3D printing patterns of the prat and the casting tree in a single step.

- Building the shell-After pattern assembly, it is submerged in the slurry, and then it is left to dry. Once cooled, it will create a ceramic outer layer.

- Burnout-The jewelry structure is placed inside a furnace to melt the resin structure.

- Pouring-After removing the materials, the casting material is poured into the structure and left to solidify.

- Knock off and cut off-The outer mold is removed by vibrating the mold, and individual casted items are cut off from the tree.

- Finishing-The jewelers use traditional finishing techniques.

Jewelers using advanced 3D printing technology, for example, DLP and SLA, can gain a significant competitive advantage over their competitors who are still using traditional jewelry manufacturing techniques. Within just a few hours, you can create a perfect master model.

2.2, Used in the medical industry

Now, advanced 3D printers are widely used to produce different medical devices, covering complex features and geometry. The parts that are 3D printed match correctly with the unique anatomy of the patients. Some devices are 3D printed from the standard designs to produce identical copies. Some other devices, like patient-specific medical devices, are produced using imaging data. Some of the major 3D printer medical equipment that commercially available are-

- External prostheses, like a hand.

- Instrumentation, like a guide to help with the surgical placement of a medical device.

- Implants, like hip joints or cranial plates.

The 3D printing process in the medical industry can be achieved using multiple technologies. The most common technique is “Powder Bed Fusion.” This works perfectly with other materials used for medical devices, such as nylon and titanium.

One of the major sections that are taking maximum advantage of 3D printing in the dental industry. The current worth of 3D printing in the dental market is USD 780, and this is a move toward achieving the USD 3.1 billion mark. It is also predicted that this will contribute to above 60 % of all dental production requirements by the end of 2025.

To understand how this can improve prosthetists, dentists, and orthodontists’ daily activities, let’s cover some examples.

- 3D printed braces that have LED lights

Some researchers from Saudi Arabia’s King Abdullah University of Science and Technology have developed “Smart 3D Printed Braces”. This is developed to faster the teeth alignment and straightening process. The braces are made of semi-translucent 3D print material and put better teeth. The energy will help the teeth move faster. Don’t worry at all, as the naked eyes will not see the light.

- Antimicrobial teeth

Dentists across the world are now planning to use 3D printed antimicrobial teeth. The teeth are 3D printed and can replace the extracted teeth. Compared to the natural tooth, this will offer better decay-resistant.

- Bridges and crowns

These 3D printed items are used to correct missing and damaged teeth. These are created from ceramic and metal alloys. The scanner scans the mouth, and the 3D printer print the 3D model for testing the fit.

- Surgical guides

After done with the scanning for the mouth, surgical guide models are produced. They are used while doing complicated dental surgeries where the dentists need help to prevent drilling into patient nerves.

The common application of 3D printing in the medical industry

- Surgical learning tools

There is no doubt that a lot of focus for 3D printing has been around medical devices and implants. But one of the crucial areas of 3D printing application is also concentrated on anatomical replicas. Previously, medical education, training, and equipment testing relied on human cadavers, mannequins, and animal models. However, these also have some limitations, like limited supply, inconsistencies, inaccurate representation of tissue, and more. However, 3D printing has helped physicians to produce an accurate 3D model of different body parts. They use FDM, SLS, SLA, LCD, and material jetting methods for this.

- Surgical tools and guides

By using 3D printers, physicians and doctors are now creating guides that match patients’ anatomy. They can now easily use drills and other medical devices accurately. These are used to place restorative treatments like plates, implants, and screws more precisely, and the patients will enjoy better postoperative results.

- Implants

Surgical implants made through 3D printing can offer a better level of osseointegration while lowering the rejection rate. Some biocompatible materials, such as cobalt-chrome titanium, can be used in jaw and face surgery.

- Hearing aids

More than 10,000,000 patients are now using 3D printed hearing aids. Hearing aids are the greatest success stories of 3D printing technology in the medical industry.

- Bionic ear

At Princeton University, scientists have successfully 3D printed a working bionic ear that combines cartilage and a tiny coil antenna. This bionic ear can capture radio frequencies far beyond the reach of human capability.

These are some of the examples of 3D printing in the medical industry. This technology is still offering new opportunities for this industry to facilitate better health care.

2.3, Used in production and R&D

When it comes to growing in this competitive world, it is important to introduce new products. You will have to keep your customer satisfied with unique products, and this is where you need a robust R&D process. For every company, R&D helps improve the company’s product innovation cycle, and 3D printing can help in this. Let’s take the example of the shoe industry.

3D printing helps the shoe manufacturer customize shoes by utilizing this for shoe sole mold design and mass production. Earlier, the shoe sole mold manufacturing process takes a few weeks. If the model is not right, that must be redesigned, and every change takes two to three days. However, things have changed a lot. Using a flex resin 3d printer, you can now directly craft a 3D prototype. This has replaced wooden molds. Besides, with this, you can enjoy less manpower, shorter time, more complex patterns, less material usage, efficient process, and more.

Currently, from the overall global footwear market revenues, 3D printing revenues cover around 0.3 percent. However, by the end of 2029, this will cross 1.5 percent.

3D printing technology offers a perfect alternative by enabling footwear manufacturers to streamline certain shoe parts, for example, molds.

What types of 3D printing technology is used for this?

The most popular 3D printing technology used in this sector is photopolymerization. It includes resin-based printing material and used Digital Light Processing, Stereolithography, and DLS- Digital Light Synthesis. The light source is applied to the resin layer by layer to make it hard. Faster printing speed, high-level accuracy, flexible printing materials, such as silicone and TPU, along with polyurethane for sports shoes, have made the photopolymer resin 3d printer and 3D printing a perfect production solution.

A running shoe can be created using 3D printing technology. Running shoes are perfect for 3D printing. Like New Balance, Under Armor, Nike, and Adidas, well-known shoe manufacturers use additive manufacturing to create printed sneakers. For example, Adidas has produced a limited edition of FutureCraft using this technology. Partnered with Carbo 3D, the brand has introduced FutureCraft 4D made through the DLS process.

Another manufacturing industry that is widely using 3D printing is the mold industry. In general, molds are produced in small quantities and come with complex shapes that cannot be achieved through traditional processes. However, using flexible resin 3d printing, this can be done. 3D printing can be applied in the following fields of the mold industry:

- Machining, assembly, and testing of moving fixtures, fixing fixtures, and modular fixtures.

- Molding covers soluble mold core, LSR, RTV, blow molding, EPS, pulp mold, FRP mold, and more.

- Casting for metal hydroforming, sand mold, thermoforming, spinning, and more

- Effector and robot

2.4, Used in the education industry

3D printing technology has emerged as a rising technology in high schools, universities, and colleges. This has drastically changed the learning and teaching process. While facilitating a perfect medium of learning new things, the 3D models easily understand the concepts.

- Chemistry:To make 3D Structures, 3D models of organic bonding and molecules, and for elements construction

- Mathematics:This is used to create accurate geometrical objects and shapes for better presentation.

- Marketing:In marketing, it is used to create sample display products, charts, and 3D graphs, taking the marketing data to understand the subject.

- Sports Education:In the field of sports education, this helps in creating a blueprint of sports, games plans,and sport equipment samples.

- Fashion Technology:3D printing is quite useful for dress material design.

- Pre-Schools:Used to create3D model training objects and teaching aids.

- Networking:To better understand the network structure, you can use 3D printing to create 3D models of network component design and network topology design.

- History:To make the students understand the subject in a better way, 3D printing is used to create 3 models of monuments, fossils, and historical objects.

Some significant advantages of 3D printers in this industry

- 3D models can offer the participants extensive practical exposure.

- When you have a perfect 3D blueprint of the objects, it will help you understand the object correctly.

- Students of fine arts, biomedicine, and fine arts can significantly benefit from this advanced printing technology.

- Students can convert their digital data into a 3d shape with this technology.

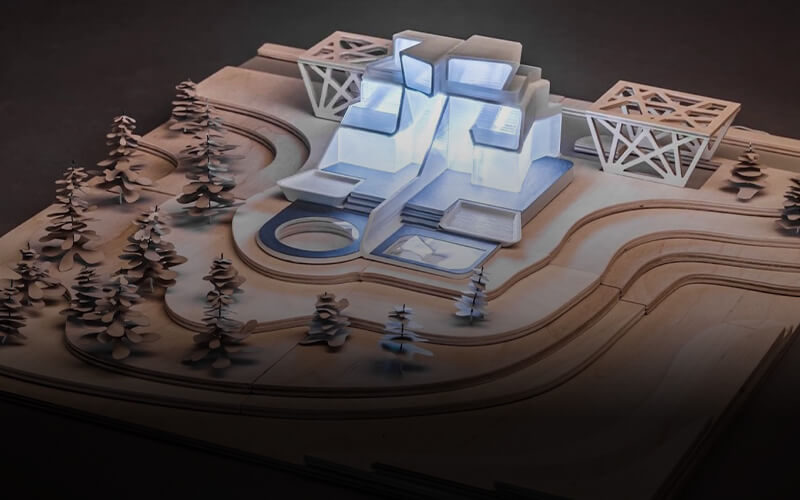

2.5, Used to make various models

While making models, be it a product or house model, you need to make them look realistic and vivid. This is only possible through 3D printing technology. Speaking about model making, this is one type of scale model, a three-dimensional representation of any structure created to study different aspects of the design or elaborate the customers’ design ideas.

This allows you to create clear and colorful 3D models from your digital idea. When it comes to achieving more essential details and maximum accuracy, you can always trust 3D printing.

To make 3D models, you can choose different types of materials. For example:

- ABS-These are quite common and affordable, and the durability level is also right.

- Polyamide-Also known as Nylon Plastic, models created from this have a granular look and sandy surface.

- Transparent resin-The 3D models are fabricated from a hardened resin. With this, you can 3D print parts having a better level of durability.

Are you looking for the best low-cost resin 3d printer to produce high-quality 3D models using different materials? Have a look that the 3D printers available at Dreambot3D. The machines are quite powerful and can offer a printing speed of 20 to 150 MM. They can cover a layer thickness of 0.05 to 0.3MM.

Which resins can be printed on an LCD 3d printer

The resins used for 3D printing through an affordable resin 3d printer are liquid material. They are generally liquid, unprocessed, often smell chemical and belong to the family of the synthetic resins. In the process of 3D printing, the polymerization of resin is done by a UV light source in the LCD 3D printers. After this, the liquid resin gets harden and change the shape from liquid to hard plastic. After curing, the final material belongs to the thermosetting plastic group. In nature, liquid resin is produced from plants and trees.

However, for 3D printing purpose, scientists have developed artificial resins. It combines liquid polymers along with other additives, making it durable for 3D model production. It represents a reactive intermediate stage in the process of thermosetting plastic manufacturing. This has been used for years in prototype and model construction. Besides, it is used for model making.

When it comes to 3D printing, most of the users prefer to use resins as they offer excellent results. Some other significant features are easily paintable, large sizes, transparency and focus on essential details. For resin printing, the printing technologies used are SLA and DLP.

Based on the characteristics, resins can be divided into thermosets and thermoplastic. Some common examples of thermoset resins are vinyl ester, epoxy, polyester and polyurethane. Examples of thermoplastic resins are polystyrene, polyethene and polycarbonate. However, if you are here in the industry for the first time, you will hear about some other types of resins. Based on their properties, they are used for different purposes. Let’s have a look at those resins in details.

3.1, For transparent resin 3d printing

Transparent resin 3D printing is cost-effective, and the 3D models are produced from clear resins using the laser. Such material offers high translucent level, better smoothness and easy to paint. On the other hand, with this printing, you can achieve better details than other 3D printings.

Besides, this painting doesn’t involve any complicated processes. If you are looking for excellent quality 3D printing at the best prices, you can always go for it. The printing process will create supports, but you can easily remove the support structure once done with the model creation.

There are some essential things that you need to keep in your mind when it comes to clear resin 3d printing. There are some types of transparent resins which can change when exposed to UV light. In fact, your indoor fluorescent light can also change the material. The most noticeable change is in the aspect of the colour of the material. UV light can degrade the polymer that can lead to ambering. You will see a yellow discoloration. The crystal-clear resin will start to turn yellow. However, this can be prevented by using a UV stabilizer.

Besides, for a better result, you need to consider some factors like temperature of the print platform, layers thickness, height of the layers, flow rate, printing speed, the temperature of extrusion, the diameter of the nozzle and more.

Amazing features of transparent resins

- Combined with a UV stabilizer, such resin can offer better UV stability level.

- You will enjoy a lower level of shrinkage in models or objects.

- The 3D models will come with a transparent and super smooth surface. The quality will also be useful.

- You won’t face the yellowing issue.

- If you are looking for high-gloss finishing, you can always go for this resin.

- Are you finding it challenging to create a complex structure? Try out transparent resin for better result.

Are you looking for an advance 3D printer that can help you in transparent 3D printing? Have a look at the printers of Dreambot3D. We manufacture FDM and LCD 3D printers capable of producing transparent 3D models. If you think it is challenging for you to learn the process, don’t worry at all. We can also offer a video tutorial on this.

3.2, For flexible resin 3d printing

Flexible resins are rubber-like material and offer excellent elastomeric properties. There is one thing that you should keep in mind. The products produced through flexible resin 3D printing may have a low level of elongation. You can bend and compress the products, but they will not support a higher level of stretch.

Due to the compression feature, flexible resin 3D printing is used to create models for high-impact application. You can also create ergonomic prototypes and functional models. Some companies use this to create end-use parts.

Moreover, using this, you can create custom holds, cushioning, grips, gaskets, shoe insoles, wearable prototypes and more. Even though they don’t offer better details, the possibilities that you will enjoy will be endless.

3.3, For high hardness resin 3d printing

The standard resins utilized for 3D printing are fragile, and they produce smaller details that will make the product susceptible to crack. That’s why there are used for artistic models and visual prototypes. To deal with such issues, some companies have introduced more rigid and durable 3D print resin that can offer mechanical properties of durable ABS. The objects developed through though resin 3D printing can easily withstand high stress and strain.

Different experiments have proved that 3D model developed by a tough resin, for example, carrier gear, can sustain high impact forces and other mechanical pressures. Some are tested using electric drills, but the users don’t find any breakage on the models after multiple drills. For some application, the material needs to support the extremely high level of stress along with strain performance. This is where tough resin comes to play.

These resins are perfect for LCD 3D printers. With around 2.8 GPa modulus of elasticity, such material can offer 56 MPa of tensile strength. Some of the features are:

- This printing process is best for mechanical assemblies and functional prototypes.

- Using this, you can create shatter-resistant and sturdy parts.

- It offers a sufficient level of resistant to the cyclic loads.

- This is not ideal for 3D model parts having thin walls.

- They support higher shock resistance than standard resin.

3.4, For castable resin 3d printing

Castable resin 3D printing is widely used in dental and jewelry industries to create 3D parts which can be cast as metal. You can use LCD and FDM 3D printers for castable 3D printing. Under this process, molds are filled with liquid resin and let them get cool. Once done, you will find the rigid structure. When it comes to creating models, small-scale manufacturing, collectable figures, dental models, jeweler productions and more, you can always choose castable resin 3D printing process.

Such resins are 100 percent ash-free burnout and will offer you quality casting using the burnout cycle. The support fast curing properties to offer your fastest printing process.

Benefits of using this printing method

- This type of printing is time-saving and cost-saving because it lets you do print the model in a single print.

- Castable printing offers maximum facilities in changing the designs. You can change the design as long as you want.

- With this, it is now possible to craft a highly intricate or complex design which is impossible to process through the traditional methods.

3.5, For photosensitive resin 3d printing

Photosensitive resin 3d printing uses resins that are also called as UV curable, light-activated and photopolymer resins. The specialty of this resin is it can change its properties when exposed to the light or UV rays.

Changes happen structurally. The resin combines some resins and additives, for example, co-initiator, oligomers, monomers, photopolymerization, plasticizers, stabilizers and more. some of the significant features of photosensitive resin 3D printing are:

- The 3D model will start setting when you apply the light. So, you will get enough time to work

- The parts will come combinedly, so there is no need to worry about the mixing process.

- Such resins support faster drying.

Whit this photocurable resin 3d printing, you will enjoy lower energy usage, reduced waste, enhanced productivity and more. Want to know more about this printing method? You can feel free to take the help of Dreambot3D.

3.6, For heat resistant resin 3d printing

Some brands are now offering resins that can easily sustain high-level temperature. Products made through heat resistant resin 3d printingcan support around 290 to 300-degree C of HDT- Heat Deflection Temperature. This is perfect for both LCD and FDM 3D printers.

You can use this printing method for different applications, such as creating testing channels for fluids, injection molding tools and thermoforming tools.

It may be noted that to carry out heat resistant 3D printing; you may need to create the stupor structures. Besides, make sure that the touchpoint size is big.

Applications of heat resistant 3D printing

This method is best for prototyping kitchen appliances, milli-fluidic devices and cosmetics encapsulation. Moreover, you can use this to create mount sensors and prototype components used under the hood. Besides, in the electronic industry, this is used to create the protective mask for soldering, injection moulds and test moulds. In the jewelry industry, this is used to create vulcanized moulds.

3.7, For conductive resin 3d printing

Using this printing, it is now possible to create an electrical connection in the material that is impossible to solder. Conductive resins are made of synthetic resins combined with conductive fillers. You can use this for different applications where there is the risk of mechanical and thermal cracking. As the curing temperature is a little low, it will not damage the heat-sensitive components.

For the binder, materials like epoxy resin, synthetic rubber, silicone resin, and urethane resin are used as the binder and the for electro-conductive fillers; carbon, silver, nickel material is used.

As they are thermally conductive, they will keep the electrical components cool. Some resins also feature self-healing, self-curing, self-protection and self-repair properties. If you are looking for a best conductive resin 3d printer, you can contact Dreambot3D.

How to Buy a 3D Printer – Question you should ask

4.1, Before buying, you should consider your own needs

4.1.1 What is the thing to be printed?

Understand what you want to print using 3D printing. You will have to buy the 4k LCD 3d printer based on your printing needs. You can’t use a standard printer for industrial production. Furthermore, understand the printer usage frequency.

4.1.2 What is the size of the print?

This means the size of the product a 3D printer can print. In the case of 3D printing, size is measured by XYZ. For example, 3-inches Wide (X) by 15-inches Deep (Y) by 30-inches High (Z). Choose a printer that supports different sizes.

4.1.3 What are the unique needs for printing materials

You need to choose a 4k resin 3d printer based on the printing materials that you want to use. You can use filaments and resin. In the case of the filaments, you can go for options like ABS, PETG, Carbon fiber, PLA, nylon, PVA and more. Coming to the resins, the options are tough resins, transparent resins, ABS resins, standard resins, dental casting and jewelry casting resins.

4.2, Used in production and R&D

4.2.1 Determine your ideal 3D printer style

While buying a 4k resin printer, you need to choose the printer based on the printing style that you will use. You can go for FDM or LCD printing technology based on the 3D models that you want to print. As per the experts, if you are a hobbyist and working for the first time, you can go for FDM 3D printers as they are priced lower. For professional printing, LCD printers are suitable.

4.2.2, Resolution requirements of the machine

In this work, the resolution of the printer is measured by microns. A resin 3D printer can offer you a resolution of 100 microns. However, in case of an FDM printer, the resolution will be little lower, i.e., around 25 microns. Such printers let you adjust the printing resolutions. It is suggested to buy a printer that can support resolution of around 50 microns.

4.2.3,Choose a reliable brand

When it comes to buying a quality printer, the brand will play an important role. A good brand can offer you high-quality 3D printers that can support all types of printing materials. This is where you can trust Dreambot3D. It has a good track record of offering world-class 3D printers. For example, it’s latest ME-192 black and while screen-printer. With better quality light transmission, it works 3 to 4 time faster than the color options.

4.2.4 Consider whether the price of the machine is acceptable

You can easily find a printer between USD 500 to USD 1500, but you need to make sure that the printers support all the latest features, like faster printing speed and printing material support.

4.2.5 Consider the supplier’s after-sales service capability

You need to choose a printing manufacturer who can offer 24×7 after-sale service as the problem can arise anytime and you should resolve them as soon as possible to keep the 3D printer running smoothly.

4.2.6, Safety configuration of the machine

Consider safety features such printer’s interface, filament support, heated glass beds, and design of the printer. Besides, choose a machine that can prevent gas leak and heat-related damages.

FAQ Guide

What is castable resin?

Speaking about castable resin, such resin is specially developed to offer high-quality and high-detailed jewelry moulds. Such resin will not leave any ash when burnt and produce gas when the temperature increases. This will not create any pressure within the casting. It will effectively capture every single detail with the dry surface to offer the perfect finish to the investment mould. When a jeweler wants to move to cast jewelry to 3D printing from the traditional methods, the most crucial characteristics in the workflow will be castable resin. With this resin, every time you will get excellent quality.

What is needed to print 3d resin?

The most important thing that you need to print 3D resin is a professional resin 3D printer. Professional level resin 3D printing is widely used to create all most all types of things, starting from tools and prototypes to medical implants and sports equipment. If you are looking for best quality resin 3D printers, you can always check out the 3D printers available at Dreambot3D. It offers entry-level to professional 3D printers that support different printing materials, including the resin.

Is a resin 3d printer better?

As per the experts, if you want to produce large-size 3D printer products and want to complete your prints, then you can go for the filament printers. On the other hand, if you are looking for quality and deals with printing small models having a great level of details, you can go for the resin printers. A crucial consideration in 3D printing is the object quality that you want to print. If compared to finish products, a resin 3D printer will yield best results. The resolution level of the best budget resin printer is fantastic.

Are Resin prints stronger than FDM?

Yes, resin printing can be stronger than FDM printing. In the market, you will find different types of resin, including tough resins which are used to produce industrial-grade 3D models or parts. 3D models developed using tough or rigid resin can produce a tensile strength of around 56 MPa. On the other hand, the elasticity modulus level can be around 2.7 GPa. It is more robust than FDM printing materials, like ABS or ASA. But remember that, such printing material is not durable like PLA and PETG. However, you can trust budget resin printer printing for durability and create shatter-resistant parts.

Can 3d printers print wax?

3D printing or also known as additive manufacturing includes different 3D printing technologies, for example, Stereolithography, material jetting, Fused Deposition Modeling and selective laser sintering. Some of these processes can efficiently perform wax 3D printing. You can 3D print wax models utilizing different 3D printing technologies. While professional 3D printing service use material jetting, but wax-like 3D models can be made using FDM 3D printer. Wax also comes in resin format.

How do I do investment casting?

These are the steps that are followed to craft parts with intricate details and complex geometries.

- Creating wax pattern- A pattern that will replicate the finished part geometry is developed using 3D printing or a wax injection die. CAD software is used to send the design to the printer.

- Wax assembly- All the wax patterns are carefully assembled onto runners and then into a pattern tree which will be dipped.

- Slurry coating-The pattern tree is dipped into the ceramic slurry that will create a ceramic shell around the dree.

- Stuccoing- After done with slurry coating, sand particles are dropped onto the tree’s surface. This will strengthen and thicken the walls.

- Dewaxing- Once dried, the wax is removed. It is carried out using a furnace or a steam-dewaxing autoclave.

- Casting- The molten metal is applied to the mould cavity.

- Cooling- The mold then allowed to cool, and this will solidify the metal for final casting.

- Removal of shell- The shell is removed using steel grit blasting or vibration.

- Cut off and finishing- The finished parts are cut off from the runner system, and finishing techniques are used to get the desired surface. You can use sandblasting and grinding.

What is the demand for 3d printing?

In the year 2019, the global 3D printing market size was $11.58 billion, and the experts have projected that during the year 2020 to 2027, this market will grow at 14 percent of Compound Annual Growth Rate. The primary reason behind this can be increasing demand for quality prototyping applications in different industries such as defence, aerospace, automotive and healthcare. On the other hand, 3D printing is also much-helping manufacturers in terms of structural designing, prototyping, modelling and has lowered the time to market.

Is 3d printing the future?

Yes, looking at the current trend in the field of 3D printing, it can be said that 3D printing is the future. It has been predicted that 3D printing will have emerged as the mainstream technology for serial production. From consumer goods to automotive, companies are now getting aware of the advantages of 3D printing. On the other hand, focusing on global education industry will enable a considerable number of 3D printing adoption and applications. Experts have also predicted that this technology will become a significant production method for dental devices and restoration. With time 3D printers are also getting smarter and faster. So, there is no doubt that 3D printing will be the future.

Why is 3d printing becoming so popular?

Three-dimensional printing offers different uses along with limitless possibilities. This printing technology is more affordable, easy to understand and extremely versatile. Anyone wanted to buy a quality 3D printer can get it from well-known manufacturers, like Dreambot3D. Apart from the specific applications, 3D printers provide users with faster turnaround times when it comes to considering digital technology and come up with a physical result. Besides, it offers unlimited opportunities for better product customization and investment casting. More such things have made 3D printing popular.

What is the best 3d printer for jewelry?

3D printers for jewelry production need to very reliable and precise. For this, the 3D printers used for such tasks support all types of resin-based technologies, as SLS- Selective Laser Sintering and FDM- Fused Deposition Modeling. You need to look for a 3D printer that can offer a higher level of resolution, broad compatibility, smooth exposure and better price-performance ratio. This is where you can go for LCD and FDM 3D printers manufactured by Dreambot3D. The support better speed and all types of printing materials. You can go for ME-192 black and white screen printer that offers better light transmission and functions 3 to 4 time faster than colour display printers.

How fast is a resin printer?

Before speaking about the speed of a resin 3D printer, remember that speed of the printer can be influenced by different factors such as printing technology, light source and more. Besides, it will also depend on the types of 3D models that you want to get. However, such printers can offer 1000+mm/hour printing speed, and the maximum printing speed can be around 200mm per hour.

Are resin printers faster?

Yes, resin printers are faster. The reason behind this is most of the modern resin 3D printers utilize FDM and DLP printing technology. You can take the example of Dreambot3D’s ME-192 black and white screen resin 3D printer. This will offer you 3 to 4 times faster-printing speed than the colour displays. Even though the printers are faster, you will not face any issue in the printing quality.

How expensive is resin printing?

The cost of 3D printing depends on different elements, such as manufacturer, material quality, material types and more. The standard resin can cost you around USD 50 per liter. At such a price, to print a 6-inch cube, you will have to spend around USD 300 to 400.

How do resin 3d printers work?

The primary 3D printing technology used by a resin 3D printer is Stereolithography. Coming to the printing process, a thin layer of liquid polymer is spread through the build platform, and the thickness level is also right. After that, the polymer is appropriately struck by a light source, like a UV laser. The light source will convert the liquid resin into a solid form. You need to follow the steps until the final product is complete. After that, the printed item is removed from the platform and sent for post-processing.

What is the best 3d resin printer?

If you are looking for best 3D printers, you need to choose a resin 3D printer that supports DLP technology as that works much faster than SLA. You can save time with this. With DLP, you can also adjust the UV light’s intensity. Besides, you can also go for FDM and LCD 3D printers.

Do LED printers use a toner?

Yes, most of the modern LED printers utilize a drum and toner to create prints.

What is LCD 3d printing?

Here, the 3D printing is done through the MSLA process, also called as Mask Stereolithography. The 3D printer uses UV light that shines up into the LCD panel. The screen produces the image of the layer. It is carried out layer by layer using a UV light source and a digital mask. This offer faster turnaround time. For better result, you can use 3D printers or a best cheap resin printer of Dreambot3D.

Is it illegal to 3d print a 3d printer?

3D printing offers a wealth of innovation and opportunity, but at the same time as with so many technological advancements, the law is unprepared for its effects in its current format. So, 3D printing itself is not illegal, but some of its consequences might be especially in terms of intellectual property law. Yes, it’s possible to 3D print a 3D printer! Some self-replicating 3D printers have been created, and there are already several versions of them. Though, these types of 3D printers can’t do the whole job themselves. You have to 3D print each part of the 3D printer individually, and then assemble them yourself.

Are resin 3d printers better?

One of the crucial considerations in 3D printing is the object’s quality that you want to print. Even though FDM 3D printers are suitable, they depend on different factors, for example, nozzle size, extruder precision, layer adhesion and more. Shifting, shrinkage and warping are not uncommon. However, resin printers offer high-level quality as it is the laser light that will determine the details of the object. As a result, you will get extremely precise, high-quality print jobs. If you compare the finished product, a best cheap resin 3d printer will produce better results.

How do LCD 3d printers work?

One of the modern developments in the field of 3D printing is LCD. It flashes complete layers at the tank of resin. However, the UV light coming from the LEDs shines through an LCD. There is no projector which you will find in DLP technology. The LCD panel works as a mask and masks the redundant pixels. This only reveals the pixels that are necessary for the layer. There is no need to use any special device to direct lights so you can eliminate the cost of DMD devices. The liquid resin them turns into a hard plastic on the areas where the UV light hits.

Is LCD stronger than DLP?

Even if the printing speed is a little similar, LCD can run faster than DLP. On the other hand, the print size that you will get with LCD will be larger than DLP. While DLP is around 6-inches, LCD can be around 8.9 inches, 10.1 inches, 13.3 inches, 15.6 inches, and can even go up to 24-inch printers.

What should I know before buying a 3d printer?

Before buying a 3D printer, there are some crucial factors that you need to consider. These are cos of the printer, printing technology used by the printer, material used to print, safety feature available in the printer, pixel size, printing speed and customer support facility.

How strong are resin 3d prints?

Resin 3D prints are quite strong and are widely used for industrial part manufacturing. For more robust 3D print, you can use tough resin. 3D models printed from the tough resin can offer a tensile strength of around 56 MPa, and you can get 2.7GPa of modulus elasticity level. Tough resin is used to produce functional prototypes, shatter-resistant and sturdy part.

Can you 3d print liquid?

Yes, the advancement in the sector of 3D print has made it possible to 3D print liquid. The traditional 3D printing process adds layers on top of another layer, but the new liquid 3D printing technology can print uninterrupted. It uses an advanced innovative technology called CLIP- Continuous Liquid Interface Production that processes liquid medium to create hard objects. The 3D printer, in the lower part, has a membrane that allows UV Light and oxygen to pass. The oxygen blocks the solidification process and createsa zone that doesn’t harden. When the UV light hits the resin, it starts producing layer by layer and solidify the oxygen-free areas.

What is an LCD printer?

Speaking about LCD printers, they are like laser printers. They don’t use a laser for image creation, instead of that they shine a light through a liquid crystal panel. The individual pixels, based on the product design, pass the light or block it, to create the images composed of Dotson. LCD printers offer print quality that is equivalent to the laser printers.