3D printed ship model

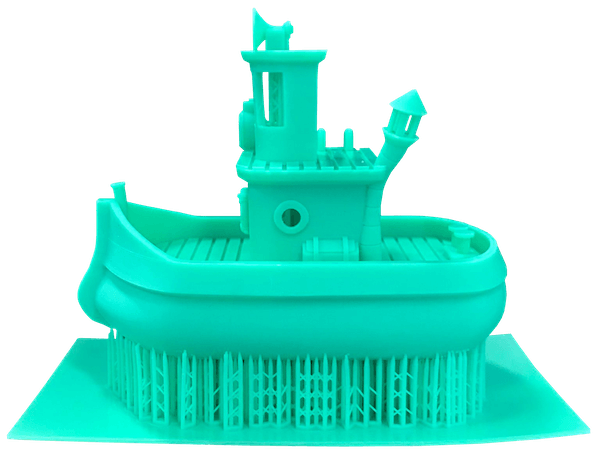

3D printed model ships are made with the 3D printer. The 3D printed model ships are used in the maritime industry to create prototypes for building ships. It is also used by engineers and students for personal projects.

How 3D printers work for ship models

3D design

Model

3D printing

model

Painting

model

3D printing ship models with the 3D printer is without restrictions associated with conventional production methods. The 3D printer can create complex structures to cut weight, gain strength and reduce costs at the same time.

3D printing model ships enable you to test various versions, even if they are quite similar for a reasonable cost.

With the boat 3D printer you can print your spare parts and print model pieces for very large boat models at a reduced cost.

The 3D printer allows you to print promotional 3D printed model ships to allow potential customers to see and feel your creations.

Large industries like the maritime industry use the 3D printed models ships before they begin the construction of actual ships, this helps to save cost and time of ship building. 3D printed ships are also created by students for personal projects.

ship models 3D printers for your Choice

LCD 3D Printers

FDM 3D Printers

Don't know how to choose a model?

Are you confused about how to choose the correct model and type of 3d printer? We support 24/7.

4 points why choose us

4K resolution printing

4K black-white industrial screen, 0.01-0.05mm layer thickness accuracy, more accurate printing of details.

PLC control system

All 3d printers are equipped with PLC control system as standard, makes the operation more convenient, and reduces the error.

Extremely speed printing

Large printing size, 20mm/h printing speed, complete your printing tasks faster.

Reinforced structure

The all-metal one-piece shell reduces resonance, makes printing more stable and improves printing accuracy.

What our customers say

How 3D Printers are used in Ship Model Production Industry

Ship Models 3D Printer Buying Guide

The shipbuilding industry stands amongst the biggest sectors worldwide simply because it fulfills a basic need; Transportation.

From the dawn of civilization till date, humans have showcased their flair for business beyond continental dwellings, and with multiple oceans and seas standing as an influential barrier. And while compass and other navigational instruments are playing crucial roles in movement and transportation between borders, their reliability is only as important as the design and structure of your ship.

Shipbuilding lies at the apex of the transportation sector. They serve as the foundation or bedrock on which most of the opportunities sailors and other sea navigators enjoy on a daily stand. To keep it simple, the need for profound and highly customized ships remains on the rise, and as a shipwright, staying updated on all the latest tools and technology that can easily streamline the process is quite important.

Our focus for this piece is on 3D printed model ships. The 21st-century market has made it impossible for creatives, designers, and architects in any industry to effectively carry out his or her day to day activities without reliance on the flexibility and durability 3D printers offer.

In line with that trend, we optimized the content to help you understand the opportunities 3D printers are offering shipbuilders, their potential as a shipbuilding tool, and the many advantages and factors you need to take note of when buying a 3D printer.

Types of Ships Models – The Significance of Ships Models on the Market

Shipbuilders {shipwrights} are well aware of the intricacies and complexity of building a ship. Be it a simple ship optimized for fishing or carrying small cargo across borders or a gigantic tycoon, and a Naval force would be needed to pilot war affairs, state of the art design is essential.

And with the increasing need for more flexible and highly sophisticated ship models, it’s important we highlight the basic types of ship models. So before we go into the impact and changes 3D printers are having in the ship model industry, let’s take a look at the types of ship models available and the journey so far.

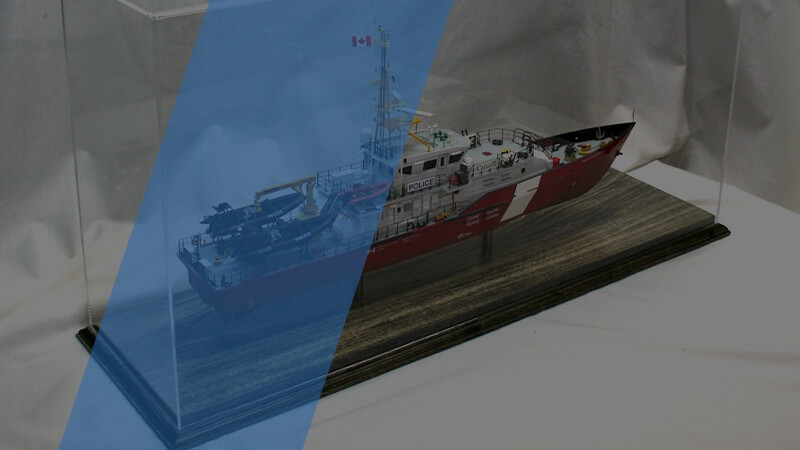

1.1, Static Model for Collection and Display

We’ve all seen a static ship designed for collection and display. And you haven’t seen, then it’s high time you get acquitted with the sailor down the street—his birthday might earn you an opportunity to not just see one, but all also take out your card and make a purchase.

Static model ships for collection and display have little to no relationship with the open sea. These models are designed mainly as gift items or museum artifacts in commemoration of an event. You can buy a static 3D printed match for your kids to enjoy the extravagant flair and beauty of the ocean from home, or you can make a static ship model design yourself in reference to an event.

However, while the static model for collection and display might seem all inexpensive and less of a hassle to design and create, this notion doesn’t always stand true. Yeah, you can purchase a static ship model for collection and display without breaking the bank or putting your house on lease, but the same can’t be said in terms of design.

The art of designing a static ship model for collection and display is quite complex, especially if you are not skilled in the art or don’t have the tools needed for design and structuring. The simplest way to design a static ship model is with a 3D printer. 3D printers are suitable for printing almost anything and everything. From the little concepts that amount to the big ideas to the finalized piece, 3D printers can help facilitate ease every step of the way.

Note that most of the static ship models you strongly admire were once designs dangling around in the form of 3D prints. 3D Printing a model ship helps simplify the manufacturing process. It takes away the constant hassle that comes with try and error and streamlines a more efficient and precise production process.

1.2, Dynamic Ship Model with Remote Control

With a basic understanding of what the static ship models are all about, you wouldn’t need a smooth sawyer to tell you that the dynamic models are the opposite. Dynamic ship models comprise the multiple ship variants used in different sectors across the globe.

Dynamic ship models are quite expensive and require sizable budgets. The design and implementation needed to bring a dynamic ship model to life isn’t something an individual can handle on his own—you might want to refer to a shipbuilding company.

Designing a dynamic ship with remote controls requires experts and architects with profound skills in shipbuilding. And while the processes and steps involved might vary in comparison with static models, the need for a 3D printer remains the same.

Remote control boats and submarines, which run rampant in numerous industries, were once simple designs in 3D prints. 3D printers help brings designs to life, highlighting factors conventional methods would deem otherwise impossible for the average eyes to find.

If you are looking to build dynamic ship models with remote controls, then you must have it at the back of your mind that investing in formidable 3D printers is a must. For the remaining part of this piece, you will gain all the information you need to weigh the countless opportunities 3D printers are bringing to the shipbuilding industry and the factors to keep in mind when making a purchase.

The Impact and Changes of 3D Printers on Ships Model Production

The ship model industry was not always as buoyant or as vibrant as it is today. Most of the accolades and recognition it’s receiving from experts in multiple sectors worldwide were once wild goose chase. And since this might seem alien to a shipbuilder well invested in all the tools and equipment the 21st-century tech brought to fusion in the ship-making industry, we would like to use this section to highlight what the industry was like before 3D printed model ships took center stage. First things first, we need to ensure that you know what ship-making is all about. To facilitate a seamless ride, let’s look at the basic processes involved in ship production.

2.1, What is the Original Production Process?

Design: This is where simple yet profound ideas come to life. Every ship you now see sailing fearlessly across the ocean were once heedless designs in the mind of a shipbuilder. The design phase allows ideas to come to light—weighing potentials and possibilities. The hull form and arrangement of the ship are determined on the design stage. The research and development needed to actualize the design are also conducted at this stage.

Production Planning: You have a probable design to work with; what’s next? It’s time for detailed planning. Ship design requires funding to streamline the process. At this phase, funds are raised, investor pitched, and working and production schedules are developed in line with basic production requirements.

The arrival of Steel: Yeah, the arrival of steel is one of the many production phases shipbuilders celebrate over. Building a ship is an expensive venture that requires steels of different sizes and shapes. The arrival of the much-needed steel from the iron mill by ship is worth having a few cups of beer over.

Primer coating: Now, the room wasn’t built in a day, and in line with that, you can’t expect even the most skilled shipbuilder to finish designing and developing your ship within a month, not to talk of a day. Prior to processing operation, you need to surface-treat the steel to prevent corrosion.

Cutting of steel: You’ve had it simple for a while, and at this junction, the hard work begins. It’s time to start shaping the steels in line with your design. Cutting of steel is the first step of production. Note that there are multiple tools available for cutting or shaping steel; to find out which tool would be proficient for the job, we recommend you contact the shipbuilder in charge of the project.

Processing of steel: Since you now possess multiple pieces of steel duly shaped to suit specific production needs, it’s high time you designed the hull. The shape of the hull is formed in this phase.

Panel line: The panels for hull blocks are made efficiently using a dedicated production line system. Endeavor to stay on top of the hull block design process, mistakes at this stage can lead to unprecedented expenses.

Subassembly: With the hull block complete, you now have a compatible design to work with. It’s time to assemble the many parts you once shaped into form.

Block assembly: After the subassembly, seamlessly creating a block assembly becomes possible.

Outfitting for blocks: Time to introduce the many interior designs you plan to have on your ship. Pipes and equipment are also installed in the blocks during this phase.

Block joint on the dock: Hull blocks are joined on the dock efficiently.

Goliath crane: A giant goliath crane is the symbol of a shipyard—that’s to say, your ship is ready for a test ride.

Sea Trial: Ship trial confirms whether the hard work, time, and effort put into production was worth the ride or if you would need to carry out some basic adjustment before your ship would be sea-ready. Regardless, just bear in mind that your ship’s performance is confirmed by sea trial.

Naming and delivery ceremony: After the completion of all construction procedures, the naming and delivery ceremony is held for the ship, and the ship is delivered to the owner. And this finalizes the process.

2.2, What Processes Can 3d Printers Replace?

With all the information required to understand the intricacies of ship making clearly portrayed above, it’s time we returned back to the simple idea or notion behind this chapter: what processes can 3D printers replace in a shipbuilding production line? If you read the previous section, you might’ve instinctively deciphered some of the points we are about to highlight.

But anyways, 3D printed model ships are vital to the industry, and we wouldn’t for anything skip an opportunity to demystify its importance. Here are some of the basic processes 3D printers are helping shipbuilders replace.

Design: It’s practically impossible to build a ship without first creating a concise schematic of its design. Every ship you now see sailing valiantly on troubled waters were once prototypes with little to no durability to their name. And amongst the many processes involved in shipbuilding, structuring a design that’s in line with the client’s goal is the most strenuous.

Luckily, 3D printers have simplified this process in the most seamless way possible. Designing a 3D printed model ship during the prototyping stage gives you an edge. It helps you proffer a clear description, bridging the gap between the client’s expectation and what is realistically possible.

Production Planning: when building a ship, the planning phase is never a one-man job. In most cases, multiple shipbuilders are involved—each weighing ideas and offering probable solutions. And with most of the preliminary discussions happening at this phase are void of real-time descriptions, mental pictures and analogies are stood as the most viable method to understand all the many ideas raised during this process.

The conventional production planning methods do take not only time but also stretches the budget. However, with a 3D printed model ship, you can easily break down expectations, weigh possible outcomes and shorten the time needed for production planning. In simple terms, 3D Printing a ship model or sailboat during the planning phase hastens production time.

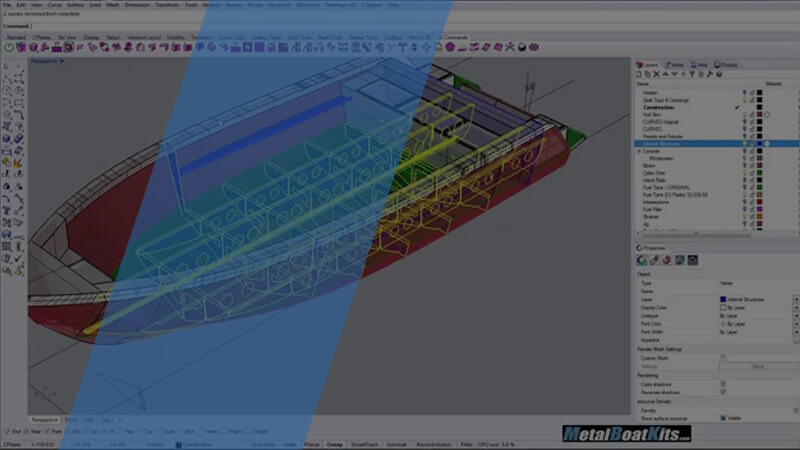

Rapid Prototyping: Several shipyards use 3D Printing for rapid prototyping. No matter how good your virtual reality model is, sometimes the most effective way to communicate your design is by 3D Printing the portion of the ship model you want to create.

Rather than making something out of metal, which would probably take two to three months just to see fit-up purposes, you can create a 3D printed model ship and put it on a mock-up. Rapid prototyping or proving a concept for actual use can save time, material money, and labor.

Combining cost-efficient additive manufacturing technologies with complex Computer-Aided Design (CAD) 3D printed ship models creates a novel approach for naval engineers to showcase their work and design capabilities to potential stakeholders.

Spare Parts: It is not currently feasible for any ship to carry many spare parts when out at sea. Imagine if a ship had installed a 3D printer and an available As-Built 3D CAD model of the entire ship. If a particular part (as complicated as a pump or as simple as a gasket or bolt) malfunctioned, you would be able to print the part and get back to your voyage in relatively short order. This might sound a little futuristic, but it is much closer than you think. 3D printed model ship spare part strategy is similar to the strategy NASA is using for space exploration.

Though on-site 3D Printing solutions are prominent in shipbuilding, numerous initiatives and projects are propelling the industry towards the implementation of onboard 3D printed ship models that make sailing safer, more reliable, and self-sufficient, especially in emergency cases where repairs are needed while at sea.

Maintenance: While not all of the sea-worthy components of naval vessels can be produced using 3D printing methods, their maintenance and repair works are being disrupted by this technology, making the whole process more automated and cost-effective. One of the more popular techniques in such processes is powder-bed fusion, which implies using a laser or electron beam in order to fuse and melt the powder into compounded structures and parts.

2.3, What are the Changes After the Intervention of 3D Printers

The global shipbuilding industry has been maintaining steady growth, mainly fuelled by increasing international imports and exports in recent decades. This industry is responsible for the construction of large commercial vessels intended for the merchant fleet (cargo or passenger transport), oil container ships, and military ships.

Therefore, it plays a crucial part in regional and global economic development. One of the latest global shipbuilding industry trends has seen 3D printing technology adopted during the ship manufacturing process to improve efficiencies and quality of the products. 3D printed model ships are expected to facilitate the growth of the global shipbuilding industry over the next 4-5 years.

In this section, our focus is on the changes the intervention of 3D Printed model ships brought to the shipbuilding industry.

- Disrupting the Conventional Supply Chain

Before the introduction of 3D printers to ship modeling, the shipping industry revolved around an inefficient and rigid supply chain, hindering production and growth across multiple horizons.

But with 3D-printed model ships becoming taking precedence, shipbuilders have the ambition to fulfill the vision of disrupting the supply chain for marine parts whereby the existing inefficient and rigid supply chain process is replaced with a customized, on-demand, and more efficient process of 3D Printing.

- Reduced Cost, Time, and Environmental Footprint

In the previous section, we highlighted the processes and procedures involved in shipbuilding. And amongst the many factors, time and cost of operation play a major role in the durability and efficiency of the process.

Before 3D printers took center stage, estimating the average cost and time needed to actualize a project was a major problem. But now, such issues seem irrelevant. With a 3D printed boat model or a 3D printed yacht, shipbuilders can effectively break down the cost of production and the time required to actualize specific designs.

- Simplifying Niche

Although 3D printed ship models have the potential to impact the whole industry, it is specifically niche applications in the market that will benefit most from its widespread introduction. Additionally, the more complex the ship, the bigger the benefit gets.

In particular, merchant vessels such as container ships, which are frequently equipped with energy-saving devices, would profit from a more cost-effective testing process. Thanks to 3D printed ship models, the testing of such complicated devices is now possible: “The optimization of those parts would be extremely expensive if it was done by traditional means of manufacturing.

- Lighter Ships

One of the main benefits of using additive manufacturing in ship production is that the ships developed can be lighter and faster. This is because 3D printers print in 10% to 30% infill, which produces somewhat hollow materials that are light but still very strong.

Lighter 3D printed boats are also better balanced, as well as travel faster. With a 3D printed ship model, shipbuilders wouldn’t have a hard time implementing materials that lead to the creation and development of lighter 3D boat prints and ship models.

- Less Waste

Traditional, subtractive boat manufacturing methods like CNC milling use a lot of materials, resulting in high levels of waste. In contrast, 3D printed models and parts waste less and are cheaper to make.

3D printed ship models minimize waste, only using what is required for a part, with any excess material reusable in other printing jobs. Typically, in a shipyard, you see about 15 to 20 percent raw material wastage. With 3D Printing, it’s around 2 percent, so it’s a huge saving in material, huge savings in labor.

- Faster and Cheaper Repairs

3D printed ship models can be used to efficiently produce spare ship parts – already widely used in the automotive industry. This is particularly beneficial as ship hull parts are often damaged and dirtied at sea, wherein 3D Printing offers faster repairs at a lower price.

A paper written by researchers from the University of the Aegean states that 3D printed ship models can be used to streamline the spare parts supply chain by allowing spare parts to be 3D printed by the end-user at the place it is needed. Rather than going to a shop and having to purchase parts that take days to arrive, you can instead 3D print the part from your garage or studio.

Analysis of the Advantages of 3D Printers to the Ships Model Industry

According to recent market research, the global 3D printed model ship industry is projected to grow by USD 13.14 billion from 2019 to 2023, registering a CAGR of over 2% during the forecast period. One of the key factors contributing to the global growth of the 3D printed boat model industry is the increasing international seaborne trading. Rapid industrialization and the liberalization of economies coupled with rising consumer product demand are some of the main reasons boosting the trade in the global market.

Advances in technology are another factor contributing to the growth of the 3D printed model ship industry. Factors such as improved fuel efficiency and multi-fuel engines have made shipping an efficient method of transportation, which is expected to pose higher demand in the global shipbuilding industry.

When it comes to the largest shipbuilding countries, although Europe remains a crucial market for the production of cruise vessels, the East Asian region dominates the industry as China, Japan, and South Korea are the largest 3D printed model shipbuilding countries in the world. The leading 3D printed sailboat companies worldwide include Hyundai HI, Daewoo Shipbuilding, China State Shipbuilding Corp., and Samsung HI.

The adoption of ship 3D printers in shipbuilding is one of the major trends being witnessed in the global market. 3D printed model ships undergo a computer-controlled process in which materials are layered consecutively to form objects.

Since the application of 3D printed model ship technology, especially in shipbuilding, can bring new approaches for manufacturing a wide-ranging and voluminous number of ship components, the shipbuilding industry is increasingly adopting this 3D printing technology to improve efficiencies and quality of the manufactured part. 3D printed model ships are also expected to improve design standards in the global shipbuilding industry.

One of the easiest ways to design a 3D printed model ship is by making use of Direct Metal Laser Sintering (DMLS). It is an additive manufacturing process that uses a laser as a power source to sinter powdered metal in the space defined by a 3D model. This technique can bind the metal material together to create a solid and high-density structure, which is extremely useful in building 3D printed boat models.

Another common application of 3D technology in shipbuilding is Fused Deposition Modeling (FDM) to produce ship parts, which involves using lasers to cure powdered materials, forming solid material layer by layer. This application is mainly used to create custom items quickly and without the need for expensive tooling.

In the shipbuilding industry, such 3D printed model ship tools can be adopted to manufacture and supply ship parts with lower cost and less environmental impact. The world’s leading tank ship company, Maersk Tankers, has already installed 3D printing facilities in its vessels so that the vessel can print its own parts on board rather than transporting a part to the ship.

Moreover, 3D printed model ships are widely adopted in conjunction with a 3D CAD model to create shop prototypes during the design process. A 3D printed model ship, the exact model of a vessel, can be used as the perfect solution for hydrostatic or another testing in a pool or other real-world environment as a complement to computer-aided analysis. It is believed that the global shipbuilding industry will adopt more and more 3D printing applications over the near future.

How to Choose a 3D Printer and Assemble Your Ships Model Production Line

3D printed ship models are already leaving their mark on the shipping industry, with great potential in creating intricate vessel appendages and energy-saving devices and freeing up extensive research potential. Pioneering research organization Dreambot3D has brought the technology in-house and can shed light on the practical advantages of using additive manufacturing to build the ships of the future.

In this section, we would like to help you make the right 3D printer buying decision. While you might be a skilled shipbuilder or navigator with a clear understanding of what the shipbuilding industry entails and all the intricacies involved in designing a ship, such expertise wouldn’t suffice when purchasing a 3D printer for your production line.

To facilitate a seamless and efficient buying process, we optimized this action with all the information you need to equip your production line with a 3D printer capable of providing accurate 3D boat prints, designs, and models.

4.1, What Type of 3D Printer can Dreambot3D Provide

Dreambot3D is a one-stop 3D printer production company dealing in the manufacturing and distribution of 3D printers worldwide. Our expertise has helped us facilitate the easy development and distribution of reputable 3D printers to over 30 countries worldwide. With regards to your need for a 3D printer capable of creating accurate 3D prints for your shipbuilding production line, below is a list and brief descriptions of the 3D printers available in our catalog.

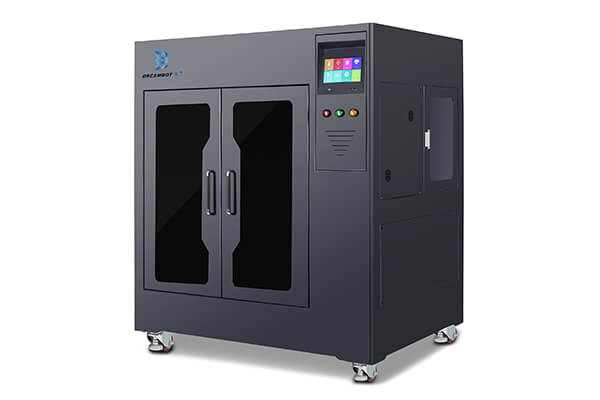

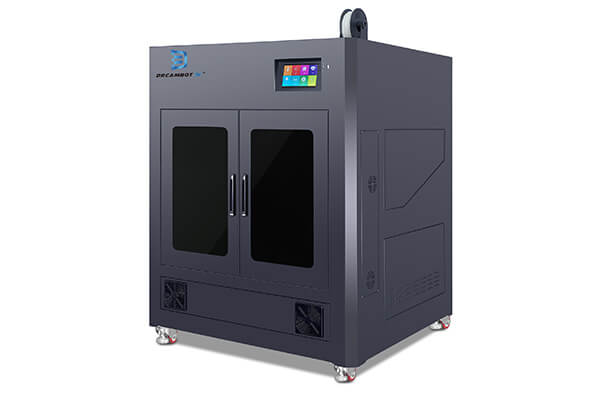

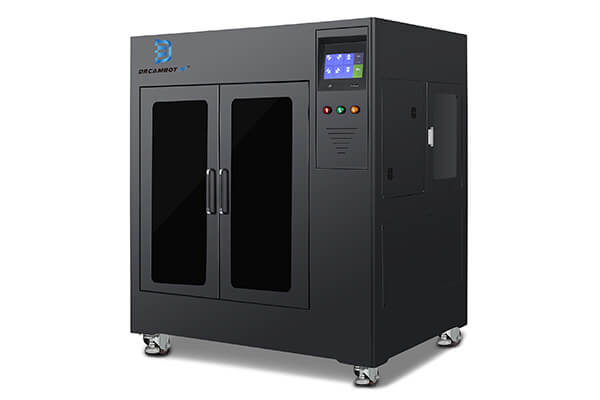

L-500 FDM 3D Printer

The L-500 FDM FDM 3D printer is a high-precision extrusion system using double nozzles that can be customized. With our L-500, shipbuilders get to enjoy a print size of up to 500x500x800 mm with automatic pre-calibration leveling that guarantees a smooth and efficient printing process of 3D printed model ships. Dreambot3D L-500 drone 3D printer also comes with newly upgraded Taiwan ball screws. Compared with the regular T-shaped screw, the Taiwan ball screw proffers higher straightness, lower friction coefficient, better smoothness, and more stability.

L-600 FDM 3D Printer

They are obtaining L-600 grants you instant access to an FDM drone 3D printer with a 7-inch colored touch screen capable of offering a print size of 600x600x800 mm. The L-600 FDM printer can print any filament of choice and is regarded as one of the best FDM machines for creating 3D printed model ships. Dreambot3D L-600 FDM 3D printers come with a drag chain wiring design; that’s, the protective wire is installed in the drag chain’s inner casing granting it access to play a protective role, thereby guarantying a safe printing experience.

L-800 FDM 3D Printer

Need a drone 3D printer with a 3MM thick sheet metal, fully sealed chassis with two air filter devices capable of creating prints of 800x800x800 mm? Then you definitely need to check out the Dreambot3D L-800 FDM 3D printer. The L-800 printer is also built with an automatic recognition system that automatically pauses the printing process and raises a flashing red light alarm each time you fail to replace the model. That’s with our L-800 FDM printer for creating 3D printed model ships; you need not worry about material waste or breakage.

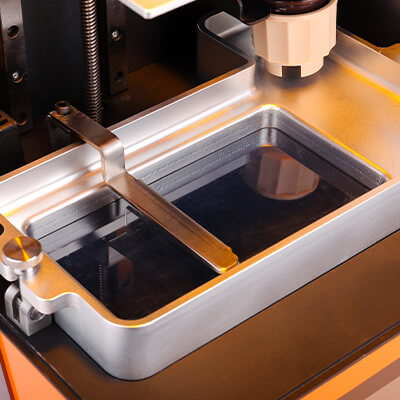

ME-192 LCD 3D Printer

if you have been looking for an LCD 3D printing machine with room for you to create 3D printed model ships without boundaries, then you need to look no further. The ME-192 LCD 3D printer comes with a large molding area that can complete bulky printing tasks at once. The large molding area is backed by a more stable slide rail performance helping retain precision and balance regardless of the size of the castable resins inserted in the molding area.

ME-215 LCD 3D Printer

Are you looking to enjoy the smooth and efficient printing process that comes with 3D printed model boats? We recommend you check out our ME-215 LCD 3D printer. The ME-215 LCD 3D printer uses cutting-edge light-curing 3D printing technology, which places liquid photosensitive resin in the printing area and selectively irradiates it with ultraviolet light. The material is cured layer by layer under the action of ultraviolet light to form a three-dimensional product. The printing size is large, fast speed, smooth surface, high stability, low cost of use, widely used in 3D printed RC boat, engineering design, artistic handicrafts, dental care, and small-batch products.

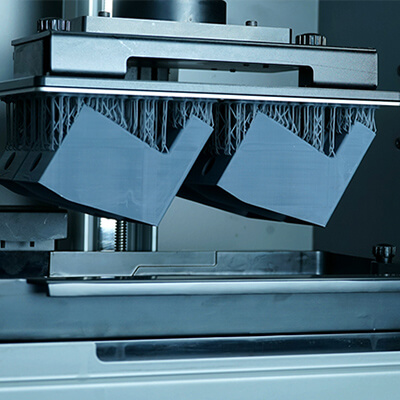

4.2, How to Combine FDM and LCD 3D Printer for Production

LCD and FDM 3D printers are renowned machines for creating dynamic 3D printed model ships. A lot of shipbuilders find it convenient to settle for one of the two falling for the notion that using a specific type of 3D printer would enhance reliability. While this stands true to a specific degree, the opportunity attached to combining both isn’t something you wouldn’t want to miss out on. From expenses to time and reliability, the adoption of FDM and LCD 3D printers in printing large 3D objects gives you an unprecedented edge.

3D printing systems which use FDM Technology construct objects layer by layer from the very bottom up by heating and extruding thermoplastic filament. The whole process is somewhat similar to stereolithography. Specialized programs or Slicers “cut” CAD models into layers and computes the manner printer’s extruder would assemble each layer.

While LCD 3D printers display images by sending light from a metal-halide lamp through a prism or series of dichroic filters, this dichroic filter separates light into three polysilicon panels. In simple terms, a liquid 3D printer uses an array of UV LCD as its light source. The printer shines light directly from the flat LCD panel in a parallel fashion onto the build area.

With both printing systems in your 3D ship model production line, you get to enjoy a printing process built on flexibility, durability, and efficiency. FDM 3D printing systems support operational sequences that boost your confidence to try out new models and create fun and useful things all through a custom button that quickly loads and unloads filament. LCD resin printers are semi assembling systems not susceptible to print failures; you can enjoy around-the-clock printing operation with these industrial FDM printers.

Combining both printers also gives you the opportunity to enjoy a 3D ship modeling process built around the professional, household, and industrial settings. While LCD and FDM 3D printing systems are optimized to cater to individuals’ dynamic needs in different industries, their reliability only goes as far as their 3D printer components can offer.

FDM printers are not reputable enough to provide the smooth finish LCD provides in a commercial setting the same way; LCD printers are not durable enough to serve in a household setting. Together, FDM and LCD 3D printers can help you enjoyed all-around sustained printing solutions when designing dynamic 3D printed ship models.

4.3, How to Buy a 3D Printer

Since you now know all there is to know about the ship model production industry and the many possibilities 3D printers are offering shipbuilders and sea navigators, and it’s high time we focused on the buying process. Purchasing an LCD or FDM 3D printer to create a 3D printed RC boat model requires the same old cash exchange, where the issue lies is in the selection process.

There are multiple variants of LCD and FDM 3D printers available. And while Dreambot3D exists to help you make the right buying decision, without a basic understanding of your needs and the intricacies involved in purchasing a 3D printer for ship models, you would easily come across roadblocks that don’t only slow down the process but can in a lot of cases, cause extra expenses. In this section, we highlighted all the processes and procedures involved in purchasing a 3D printer for your ship models, the factors to look out for, and the expenses you would most likely incur.

4.3.1 What is the size of the Print

3D printers for ship models come in multiple variants. Some are suitable for large printing tasks, while others possess printing jet plane parts that can cater to only small tasks.

What sort of 3D printed ship model do you want to create, how big is the project, and what size of prints do your customers demand from you regularly? At Dreambot3D, we have seen the irregularities and extra expenses that come with purchasing an industrial FDM 3D printer or LCD 3D printer that’s not compatible with the print size of the 3D printed ship model you want to create.

Over the years we have been in business, we have had the opportunity of interacting with consumers from different countries and regions. One of the most highly influential factors most hobbyists or professionals who have walked through our door to purchase a ship 3D printer ignore is the size of the print.

Yeah, it’s practically impossible to determine the exact size or specification attributed, or that would be required in most of the prints you make—especially if you are a business owner looking to satisfy the needs of clients from different parts of the world. However, totally ignoring the print size of your industrial FDM 3D printer or an LCD 3D printer can create is unacceptable.

FDM 3D printers garnered renowned usage ahead of LCD, SLA, and DLP as a reputable printer for creating 3D printed ship models, not just because of its printing speed or the remarkable finish product it is known for, but also because of its ability to perfectly create sustainable 3D printed ship models using filaments.

Before buying any LCD or FDM industrial 3D printer, try to know the type of resin or filament it can print on and whether it’s durable enough to print perfect models on wide materials without leaving distorted edges.

The material you chose for your printing task has a lot to say about the printing size. The dimension, weight, and size of the object obtained from a 3D model printed with PLA are quite different from the result you would obtain using an ABS material—regardless of whether the CAD file and design are the same. Considering the type of materials, you would print on regularly can help you pinpoint a ship 3D printer that wouldn’t create constraints in your design’s dimension, weight, and size.

4.3.2 Choose a Reliable Brand

For most professionals in the printing industry, it all comes down to brand. Hundreds of brands have built a formidable reputation for themselves by offering 3D printers for ship modeling with remarkable features. While it’s essential you check out a brand’s track record and reviews from previous customers, it’s also important you don’t base your buying decision entirely on a brand’s name.

There are a lot of 3D printing systems for ship models available worldwide with reputable brand tags but void of the innovative design and features required to keep your printing line functional. Many brands built a good name for themselves in the early 90s but haven’t been able to keep up with the diverse changes needed to excel in the 21st-century market.

Before putting hours of research into exploring a brand’s portfolio or track record in the global market, make sure the 3D printer for ship models you want to buy possesses features in line with your needs and has been ascertained satisfactory by other users and experts in your industry.

There are so many 3D printers for ship models being developed and released into the market every day. While most of these printers meet the basic requirements and features of SLA, FDM, LCD, SLS, DLP printers, you should not be hasty while sealing the deal yet. Why? You may ask.

3D printers for ship models are not cheap machines. You’ll part ways with a considerable amount of your money; therefore, you must ensure that you get value for your money. While your choice should not solely be made on the brands’ name, it is crucial that you do thorough background research on the company’s Google ratings and reviews before making a purchase.

Consider buying your printer from an industrial 3D printer manufacturer that has a good track record, a high rating on Google, and a genuine customer support system. Such a company will be apt to respond to all your urgent needs. The company/brand that you’ll pick for your printer can make or break your printing experience if something goes amiss.

4.3.3 Safety Configuration of the Machine

When purchasing or using a ship 3D printer, you must keep in mind that safety is paramount. And this is not just because you wouldn’t want to expose yourself to the toxic fumes most ship 3D printers emit during the design and creation process, but also because your ability to build a lucrative 3D printing business is largely dependent on how safe and ready-to-use your ship 3D printers are.

If this is the first time you are tasked with handling all the challenges that come with purchasing a 3D printer for ship models, the safety configuration of the machine might seem alien to you. Don’t neglect the durability effect that comes with purchasing a 3D printer for ship models with safety configurations that does not reflect the productive ability of the machine.

When making your 3d printing machine buying decision, you need to be on the safe edge. The only way to achieve this feat is by putting due diligence into every step involved in the process. Note that the safety configuration of most ship 3D printers is quite complex and bulky. To demystify this tiring yet important process, consult with a support service representative before finalizing your buying decision.

4.3.4 Resolution Requirements of the Machine

3D printing resolution is the level of detail quality at which your part is created. Industrial 3D printers for ship models extrude plastic through a nozzle to create 3D-printed objects. That nozzle pin can be adjusted to different widths to allow for higher or lower resolution printing. It’s necessary that you keenly take into account the resolution of a printing machine before buying one, depending on the industry you are operating in.

While the resolution requirement of an industrial 3D printer for ship models is regarded as the number one factor to consider when making a 3D printer purchase by experts in the shipbuilding industry, this can be referred to as a myth that doesn’t apply to all. The resolution of an FDM or LCD 3D printer determines the clarity and precision that can be enjoyed from a given 3D model and pattern.

However, the resolution of a 3D printing system used in ship modeling doesn’t have to be on the same level as the one used in the jewelry or engineering industry. When looking at the resolution requirement of an industrial FDM 3D printer, it’s important you take into consideration the industry you are operating in. In which industry do you want to use the machine? What sort of models do you want to print? How clear or precise does the model have to be for it to be termed efficient?

Answering the above-listed questions would help you demystify some of the myths attached to buying a 3D printer. Yeah, buying a high-resolution industrial 3D printer for ship modeling should be considered a priority if the funds and budget to finance it is available. But in scenarios where you are on a budget, you can save cost by analyzing the machine usage and model requirement.

Industrial 3D printers for ship models come in different variants, shapes, and sizes, optimized with a fitting design and resolution. At Dreambot3D, our daily task revolves around catering to individuals’ dynamic needs and desires from numerous parts of the globe. We know how daunting navigating a machine with a proper resolution can be.

Dreambot3D core value is to provide satisfactory all-round services. To keep up with this mission, we offer a support team that can help you understand the resolution requirements of multiple machines, the industries they are optimized to serve and direct you towards multiple variants that would serve you better.

Note that while the quality of print detail is more paramount in some industries than it is in others, the resolution of a machine decides how fine the details of your part will be. A lower resolution brings about less quality and low details on the print object. The objects will have smooth surfaces at the expense of extra filament usage and time consumption. A high resolution, conversely, gives fine quality and better details on print objects.

4.3.5 Consider Weather, the Price of the Machine, is Acceptable

LCD and FDM ship 3D printers are quite expensive. A good ship 3D printer requires a substantial investment. Budget and pricing is a basic factor that must be considered before you kickstart the buying process.

While most of the renowned printing systems available are quite expensive, don’t make the mistake of basing the efficiency or durability of a commercial-grade 3D printer on the price tags attached. There are lots of LCD and FDM ship 3D printers offering high-quality printing services at cost-efficient rates.

If you run a big production line or you are a hobbyist looking to purchase a remarkable ship 3D printer, and you firmly stand by the belief that your budget is sizable enough to purchase any printing machine of choice—we recommend you explore our catalog armed with the basic features and specification you require from a preferred FDM or LCD 3D printer.

On the other end, if you are on a low budget and require something substantial to cater to your day-to-day printing needs, please put a call through today—our support representative will guide you through the buying process.

Sometimes people tend to purchase 3D printers for ship models based on the price only. The price of a ship 3D printing machine plays a big role in the decision-making process. But with so many industrial and commercial ship 3D printers available for sale at the consumer level today, you must keep a keen eye on the machine’s brand, resolution, and safety configuration.

4.3.6 Consider the Suppliers After Sales Service Capabilities

Making a purchase is one thing; enjoying the benefit of your purchase to the fullest is another. The best FDM and LCD 3D printing systems always require a sizable investment, and we are certain you wouldn’t want to make such an investment from a supplier with little to no track record of authenticity or credibility in the industry.

To avoid making such a mistake, take into consideration the technical support service offered. Every 3D printing system supplier should provide a minimum of 12 hours of technical support service Monday to Friday. However, there are a lot of reputable companies providing 24 hours technical support 365 days a year.

Vetting the technical sales service’s credibility would help you better understand the type of after-sales service a 3D printer for ship model offers. Bear in mind that it’s practically impossible to authenticate the viability of a brand’s after-sales service directly from the company. The fastest way to get ahold of such information is by contacting individuals who have done business with the brand before.

Like always, Dreambot3D is here to satisfy your every need. Our technical support service is available on a clock basis. Whether you have made up your mind about the machine you want to purchase or are still scouring our catalog for the best FDM or LCD 3D printer to cater to your printing needs, our support service is just a call away.

Before sealing the deal on your 3D printer for ship models, research and find out the company’s customer support system; you want to enjoy your printing experience, and even when things go south, you want to be assured that there is a professional ready to assist you.

4.3.7 Consider the Service Life of the Machine

The service life for most printers for 3D printing ship models is about 5 to 10 years. While the warranty policy on most 3D printers doesn’t grant you access to refunds or after-sales privileges one year after purchase, purchasing a printer for a 3D printing ship model from a reliable manufacturer comes with the guarantee that your ship 3D printer will be in shape and keep your production line running for at least five years.

With that being said, it’s important to note that the estimated service life of the machine can change at any time based on external factors. How you use your machine determines how long it would last. If you leave your industrial FDM 3D printer or LCD 3D boat printer packed dirty on a regular, you shouldn’t expect the ten years life expectancy to hold any ground.

If you went gone through the hassle of finding the right boat 3D printer manufacturer, inspecting all the necessary features, and finalizing the purchase, you wouldn’t want the whole effort you put in to go down the drain based on negligence on your part. Try as much as possible to keep your printer for 3D printed ship models clean and in good shape, and service life expectancy wouldn’t be an issue.

4.3.8 Consider the Maintenance Cost of the Machine

It wouldn’t make much sense to finalize our discussion on how you can make the right 3D printer for ship purchase without saying anything about maintenance. Ship 3D Printers require constant maintenance. The print bed must be cleaned between prints, or failures are more likely. The moving parts need to be oiled/greased once in a while. Nozzles have to be replaced. LCD screens will need to be replaced. This maintenance applies to ALL printers, whether they are out of the box ready or not.

This is where buying a kit printer is helpful. By building the kit, you learn the ins and outs of how to maintain your printer. Buying an out-of-the-box ready printer simply means you can get a few prints done before you have to learn the same lessons.

Maintaining an FDM or LCD 3D printer takes less effort. Only the Z-axis moves. Everything else would either be a wear and tear item (i.e., just replace the item when it finally fails) or a routine task that has to be done for every print anyway. FDM/FFF printers have those routine tasks, too — such as leveling the print bed. However, there are more moving parts which means more possible points of failure/maintenance.

3D Printers for ship models are not as fast as the Star Trek Replicator devices. It takes time to build a 3D object. Smaller objects can be created in 15 minutes or so, but larger objects can take many hours or even days to print. Some printers are faster than others. That speed, though, is a result of the individual 3D Printer design and how the printer is tuned. Tuning a printer is part of the maintenance time.

Dreambot3D is an industrial 3D printer manufacturer offering highly efficient 3D printing machines for ship models with minimal requirement for maintenance. With just regular cleaning, your Dreambot3D industrial 3D printer can stay functional for 5+ years.

How to Choose Materials

The big question of choosing the right material for 3D printed model ships has plundered the minds of multiple shipbuilders. While there are a couple of materials available to users of 3D printers, the type of materials needed to 3D print ship models is quite different from the regular ones. The best way to know the exact material that would suffice when creating a 3D printed ship model is by examining the basic features of the materials readily used by experts in the industry.

In the following section, we will highlight some of the material used by shipwrights to 3D print sailboats, yacht, model boats, and the likes. Note that it’s essential you compare the basic features contained in the descriptions below before settling for any when carrying out a 3D printing project for a ship model.

- ABS {Acrylonitrile Butadiene Styrene}

Acrylonitrile Butadiene Styrene is a thermoplastic polymer that can melt and cool without altering its chemical properties. That makes it an interesting FDM 3D printer material for creating ship models. The filament is known to be strong, tough, and durable. It is also forgiving to scratches, offers good resistance to heat and everyday chemicals.

It can endure heat, pressure, and stress like no other material for ship 3D printing, making it a great choice for wear and tear prints. You can try this out yourself: If you move a strain of ABS filament, it will distort and bend before breaking. PLA breaks much more easily. ABS is quite forgiving, as long as you print with the right settings and proper temperature management. You can even achieve overhangs of around 45 degrees. If the print succeeds, the results are very convincing.

Most shipbuilders like the material because you can process its surfaces with acetone, glue parts, and even file off some material. Lastly, it can be easily painted with acrylic colors. ABS filament is not toxic when 3D printed. Only at very high temperatures (400 °C), the material decomposes into butadiene (which is carcinogenic to humans), acrylonitrile (possibly carcinogenic to humans), and styrene—nothing you want to inhale under any circumstances.

If you don’t have a ship 3D printer at hand, you can have ABS parts printed by a professional 3D printing service. You can put a call through to our support representative to obtain the best deal on a high-resolution FDM drone 3D printer.

- PLA {Polylactic Acid}

PLA filament is by far the most popular FDM ship 3D printer material, and there’s a good reason for that. It comes in many shades and styles, making it ideal for a wide range of applications. Whether you’re looking for vibrant colors or unique blends, it’s an easy-to-use and aesthetically pleasing material.

PLA is short for Polylactic Acid, a thermoplastic polymer that is derived from renewable resources, more specifically from corn starch or sugar cane. This sets the material apart from other commonly used plastics, which are procured through the distillation and polymerization of non-renewable petroleum reserves.

Since PLA filament is a biodegradable product, it tends to naturally break down in about three to six months. Other thermoplastic materials can take up to a thousand years to decompose, making PLA much more environmentally friendly.

PLA material has been thrust into the spotlight by the rise of custom ship model 3D printers. PLA filament is available in a wide variety of colors and blends, and innovative PLA-based materials seem to be constantly hitting the market.

Outside of ship model 3D printing, PLA is also used to produce things like medical implants, food packaging, and disposable tableware. But within the FDM 3D printing sphere, PLA filament is widely thought of as an aesthetic material best used for prototyping.

- PETS

PETG (polyethylene terephthalate) is a thermoplastic polymer used for 3D printing ship models. Mixed with glycol (hence the “G”) exhibits good 3D printing features. PETG FDM boat 3D printer material is resistant to high temperatures and water, presents stable dimensions, no shrinkage, and good electrical properties.

PETG combines ABS durability and PLA printability, and it comes as no surprise that it’s frequently chosen by professionals seeking a reliable filament for their projects. PETG gained a lot of recognition during the coronavirus pandemic because it can be easily sanitized and therefore is useful for medical applications such as face shields.

Note that You may encounter two options — PETG (sometimes written as PET-G) and PET. The “G” stands for glycol — a substance added to prevent corrosion and crystallization effects. Glycol modified PET is easier to 3D print. PET without glycol is more fragile and prone to breaking.

On the other hand, PETG is characterized by a delicate outline that’s easy to scratch. That being said, the chemical properties of PETG are far better for 3D printing ship models despite some minor disadvantages. PETG is suitable for use on any ship 3D printer. If you are interested in created 3D prints with PETG and you are yet to find a suitable high-resolution 3D printer for the task, don’t hesitate to put a call through to our support team.

- High-Temperature Resin

While FDM ship 3D printing technology uses traditional industrial plastics like ABS and Polycarbonate (PC), SLA, DLP, and LCD 3D printers require special photopolymer resins that harden (cure) once UV light is directed at it. Most ship model 3D printing resins are either epoxy-based or acrylate-based, the latter being used more often in desktop printers.

A lot of people think of resin ship 3D printed parts as fragile and most suitable for ornamental and prototyping applications rather than functional and load-bearing components. But this is only true if the resin isn’t properly selected. That being said, if you’re buying a generic resin for a tough job, it won’t give you the strength that you’re looking for.

Examples of super-strong resin can be found in a wide variety of industries. There are castable resins for making jewelry and 3D Printing in the field of dentistry to produce mouth guards, crowns, and surgical guides. There are also high-temperature resins that are suitable for ship model 3D printing.

Note that resin tensile strength values are usually measured by a pull test that follows strict international procedures, so the results can be used worldwide. The higher the tensile strength, the stronger the material is considered to be because of how much stress it can withstand.

Just because the resin is tough, it doesn’t mean that the 3D printed ship model made from these resins will be twice as strong as if printed with a standard resin. Other factors, like model design and print settings, play important roles in the final print’s strength.

Nonetheless, comparing tensile strength is a straightforward way to determine which material is stronger, and from the numbers supplied by the manufacturers, it’s clear that high strength resins are much tougher than the standard and is a more durable option for ship 3D printing.

- Nylon

Nylon (a.k.a. Polyamide) is a popular material in the shipbuilding industry, known for its toughness and flexibility. Nylon filaments typically require extruder temperatures near 250 ºC. However, some 3D printers for industrial R&D allow Printing at temperatures as low as 220 ºC due to their chemical composition.

Many boat 3D printers do not include a hotend that can safely reach 250 ºC, so these lower-temperature versions can be useful and potentially save you from needing to upgrade your hotel. One big challenge with Nylon filaments is that they are hygroscopic, which means they readily absorb moisture from their surroundings.

Printing Nylon after it has absorbed moisture will lead to several print quality issues; thus, filament storage becomes very important and requires special attention. Some of the Pros of using Nylon filament for your custom ship 3D models include tough and partially flexible, high impact resistance, no unpleasant odor while printing, and has good abrasion resistance.

Cons of Nylon filament are prone to Warping, air-tight storage required to prevent water absorption, and improperly dried filaments can cause printing defects.

- Carbon Fiber

Carbon fiber filaments are composite materials formed by infusing fragments of carbon fiber in a polymer base, similar to metal-infused filaments but with tiny fibers instead. The polymer base can be of different 3D printing materials, such as PLA, ABS, PETG, or Nylon, among others.

While true carbon fiber materials have long continuous fiber strands that improve mechanical resistance, these FDM 3D printer materials for ship models contain short particles of around 0.01 mm in diameter. Although this is enough for improving the strength of printed parts, keep in mind that such filaments cannot compare to the actual material.

For those seeking tougher FDM 3D printer material for ship models, carbon fiber filament presents a relatively easy alternative to the more expensive and demanding materials, such as polycarbonate (PC) or PEEK. Moreover, the increased strength provided by the carbon fiber particles contributes to greater dimensional stability, helping to avoid warping and shrinking.

However, using carbon fiber to 3D print ship models does present some issues. The infused carbon fiber particles aren’t melted by the nozzle during extrusion, which may lead to frequent clogging. In addition, these particles work as abrasive agents during extrusion, which over time will wear down a brass nozzles’ internal bore. This is why special nozzles like hardened steel are strongly suggested for Printing with composite materials.

FAQ Guide

Can I 3D Print a Ship?

Yes, you can 3D print a ship model. 3D printing ship models is a common trend in the shipbuilding industry. To 3D build a ship model, you need a formidable 3D printer, printing material, and a 3D printing specialist.

What Does FDM Printer Mean?

FDM means Fused deposition modeling. FDM is regarded as a 3D printing technology often used to print 3D models and patterns. FDM machines can be found in almost every industry. The 3D printers are renowned for their ability to create 3D models of high quality with high accuracy and durability at cost-efficient rates.

What is a 3D RC Ship?

A 3D RC ship is a remote-controlled ship designed using 3D printed materials. 3D RC ships are used to provide a clear prototyping/design sequence for investors and shipbuilders to use in weighing the authenticity and practicality of the project at hand.

Will Additive Manufacturing Replace Conventional Manufacturing?

The manufacturing industry and 3D Printing are a dream team. Manufacturing is an ever-growing industry, and 3D Printing is now at the lead of many advancements and innovative techniques.

Potentially, many, many years from now, 3D Printing will expand to replace traditional manufacturing as we know it today. However, this is not likely something we will see in our lifetimes. In the near future, 3D Printing could potentially significantly modify some processes within the industry.

Rather than seeing 3D Printing as a potential ender of manufacturing as we know it, we see 3D Printing as a way to expand the field of manufacturing beyond what we can currently even imagine.

How Does FDM 3D Printer Work?

Fused deposition Modelling {FDM} printers or Fused Filament Fabrication {FFF} printers {as they were formally known till the FDM term was trademarked by Stratasys in 1991; the company behinds its first design} are machines built to deposit melted material in a pre-determined path layer-by-layer selectively.

Fused Deposition Modelling {FDM} printers are 3D printing machines that create images one at a time. FDM printing process revolves around a three-dimensional output. Each layer of the material you are printing is placed on top of another again and again till a finished product is acquired.

The printing process begins after the modeling software slices the 3D CAD file creating an extrusion path for the nozzle to follow. All necessary support needed by the object is factored into the extrusion path, and the nozzle movement is controlled via the interactive interface found on the machine.

How Can I Improve 3D Print Quality?

The most fundamental way to improve the quality of the 3D print is to make sure that the bed is level and the nozzle distance is set properly. You can use a sheet of paper or feeler gauge to determine the distance between the nozzle and bed. When the (clean) nozzle is the appropriate distance from the bed, the paper or gauge will have minimal resistance when pulled free. It will also go back underneath the nozzle without force. Repeat this procedure two or three times to ensure that it is accurate.

The temperature of the nozzle — or nozzles, if there are more than one — directly affects the appearance of the print. If the nozzle is too hot, it could leave strings of filament between separate parts. When building tall pieces, high temperatures melt the earlier layers, resulting in malformation.

When building taller prints, include a one-centimeter cube built on the opposite side of the build plate. This removes the hot nozzle from the print and allows time for cooling. If there are strings of filament between structures, use a wall or ooze shield structure, a common feature in slicer programs.

What is a Good Size 3D Printer?

The available build size of a desktop 3D printer is commonly 200 x 200 x 200 mm, while for industrial machines, this can be as big as 1000 x 1000 x 1000 mm. If a desktop machine is preferred (for example, for reducing the cost), a big model can be broken into smaller parts and then assembled.

How Durable are 3D Printed Items?

It can depend on the type of material you use, but even cheap ABS and PLA are extremely durable. For seriously strong stuff, you can use Petg, Polyflex Polymax, and flexible materials. But yes – parts are as good as commercially produced parts, in many cases stronger and lighter.

To a large extent, for FDM machines, it depends on the orientation you print them in. So the same part can be printed in different orientations, and one will be weak and break easily, and the other will be strong, flexible, and hard to break. Getting really good 3d printed parts is as much an art as a science.

What Does FDM Mean in 3D Printing?

FDM means Fused Deposition Modelling. Fused Deposition Modelling {FDM} printers are 3D printing machines that create images one at a time.

Is it Cheaper to Build or Buy a 3D Printer?

There is no right answer here; it all depends on the individual and the type of printing activity he/she wants to carry out using the 3D printer. As to which is cheaper, it’s all based on you and your personal preference.

Can You Reuse 3D Printer Resin?

You can reuse uncured resin just fine, but you’ll need to filter it out properly to ensure the larger pigments of cured resin aren’t put back into the bottle. If you do this, you might be pouring back hardened resin back into the vat, which isn’t good for future prints. Once the resin is slightly cured, you can’t practically reuse it for your 3D printer.

Note that you can leave uncured resin in your 3D printer vat/tank for several weeks if you keep it in a cool, dark area. Giving your 3D printer extra can prolong how long you can leave uncured resin in the vat, though when it comes time to 3D print, you should gently stir the resin so it is fluid.

How do the 3D Printers Work?

A typical 3D printer is very much like an inkjet printer operated from a computer. It builds up a 3D model one layer at a time, from the bottom upward, by repeatedly printing over the same area in a method known as fused depositional modeling (FDM).

Working entirely automatically, the printer creates a model over a period of hours by turning a 3D CAD drawing into lots of two-dimensional, cross-sectional layers—effectively separate 2D prints that sit one on top of another but without the paper in between.

Instead of using ink, which would never build up too much volume, the printer deposits layers of molten plastic or powder and fuses them together (and to the existing structure) with adhesive or ultraviolet light.

Is LCD Faster than DLP?

Yes, LCD 3D printers print at a relatively faster speed than DLP. Both DLP and LCD are able to achieve fast print speeds and great details, but as the price tag grows, the LCD 3D printers start to trump their DLP counterparts. If you’re a professional who needs great detail and fast print speeds, we’d suggest that you look into professional LCD printers.

Conclusion

Building a 3D printed model ship is the first step to creating dynamic ship models. The shipbuilding industry is currently enjoying multiple mind-blowing opportunities in terms of design and prototyping, thanks to the unique attributes and features 3D printers bring to the production line daily.

At this junction, we believe you have all the information you need to make an informed buying decision when looking to design 3D printed model ships or 3D print an RC boat. And you wouldn’t need a smooth sawyer to tell you that a highly efficient and durable 3D printer is key to a lucrative shipbuilding business.

So if you are looking to optimize your production line with a formidable 3D printer, we recommend you explore our catalog. Dreambot3D provides one-stop 3D printing solutions for shipbuilders and sea navigators. All the tools and equipment you need to create formidable 3D printed model ships is just a call away—get in touch with our sales representative today.