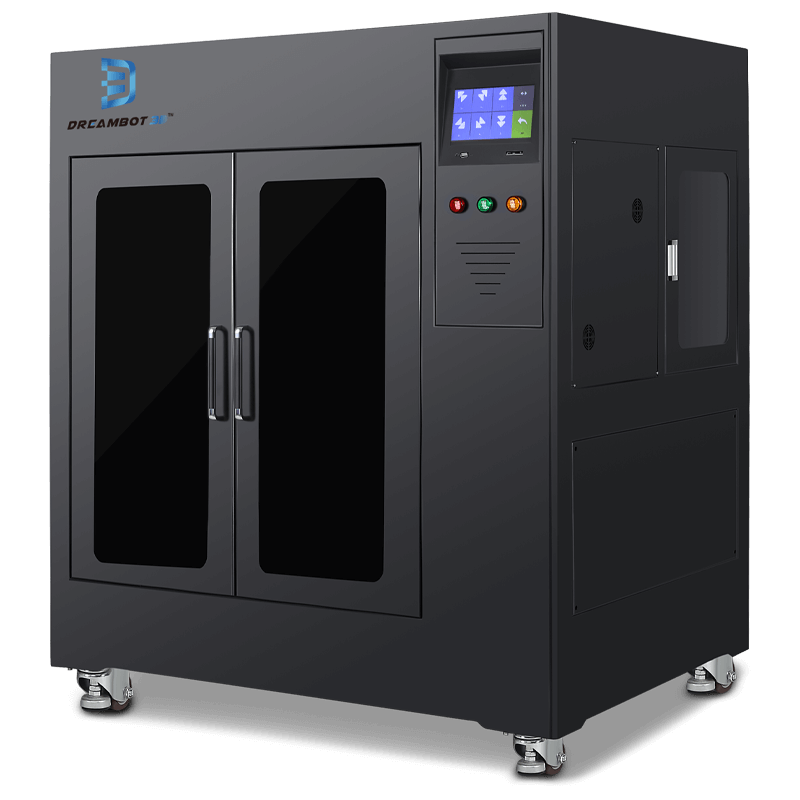

1000x1000x1000mm 3D printer

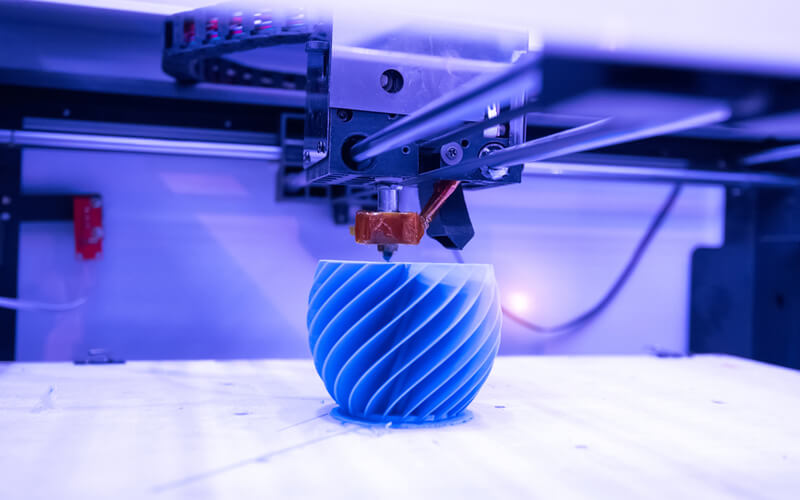

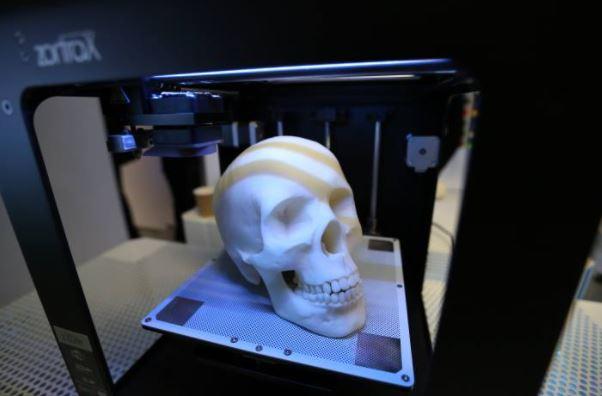

L-1000 FDM 3D Printer

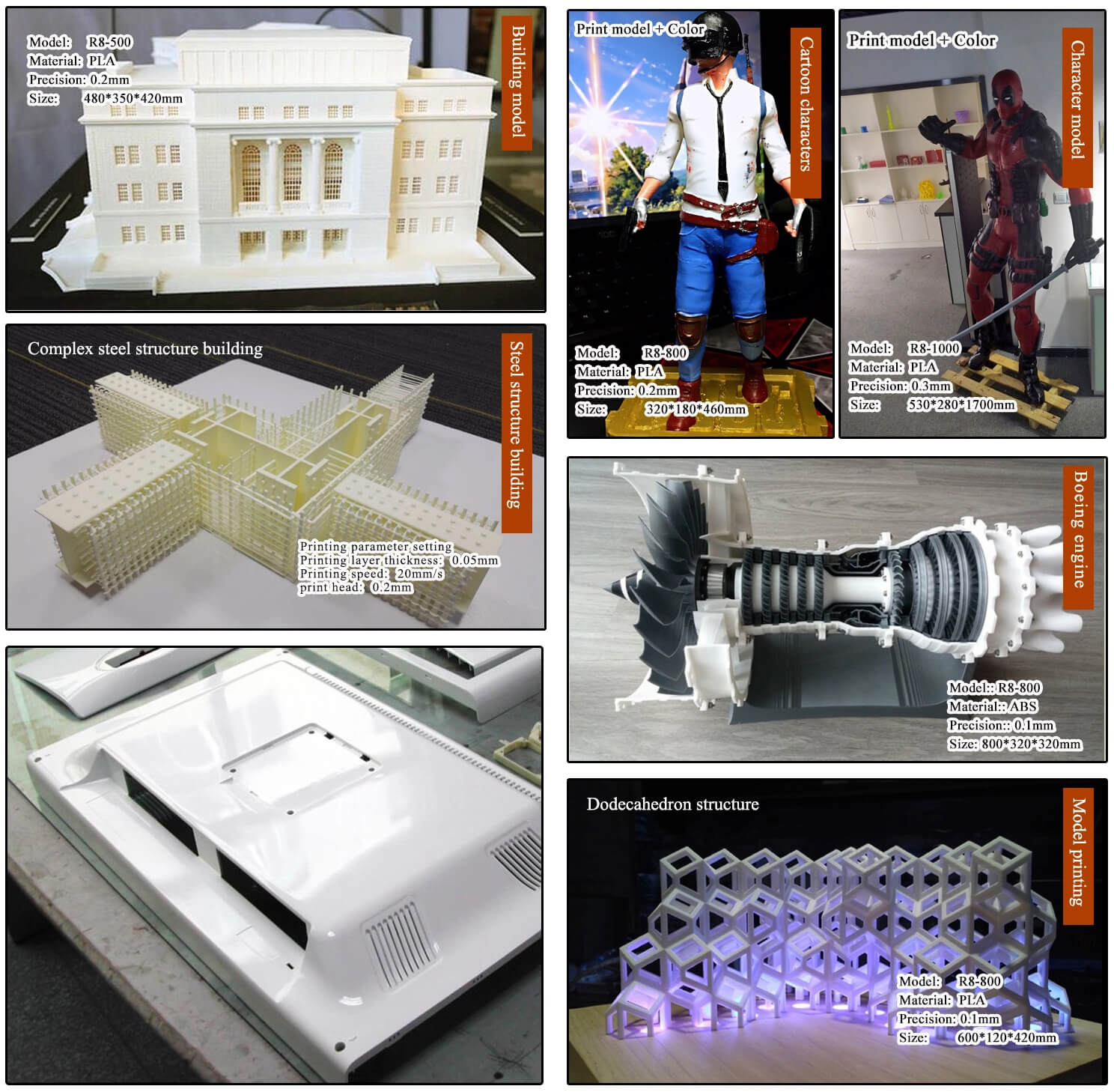

- Using FDM process principle, it can support industrial-grade printing size up to 1000x1000x1000mm. Its high precision can reach 0.05mm

- Industrial-grade FDM 3D printers are used in a variety of materials: PLA, ABS, PC, Nylon, Carbon Fiber, etc.

- Adopts PLC intelligent control and can print offline. Can continue printing after power failure

Dreambot3D 1000x1000x1000mm 3D printer

The 1000x1000x1000mm 3D printers are designed for industrial purposes where large 3D objects are printed. This dimension 3D printer is able to print prototypes of large sizes up to 1000x1000x1000mm.

The dimension 3D printer is used in industries such as robotics, aerospace, automobile and other industries that use heavy equipment.

With the industrial FDM 1000x1000x1000mm 3D printer you can print large parts in a single operation. Industrial FDM 3D printing can be accomplished using a wide range of thermoplastic materials. The lead time for printing is short, hence it can produce more compared to other technologies.

| Technical parameters | Model | L5-1000 |

| Max printing volume | 1000x1000x1000MM | |

| Printing platform | The platform moves down when printing | |

| Technical principle | FDM fuse manufacturing technology | |

| Print head | High-precision extrusion system (double nozzles can be customized) | |

| Nozzle diameter | 0.2, 0.3, 0.4, 0.6, 0.8MM | |

| Consumable diameter | 1.75MM | |

| Printing materials | PLA, TPU, 95A, water-soluble materials, wooden PLA; customizable ABS, PC, PETG, nylon, carbon fiber, metal filling materials, glass fiber addition materials, etc. (not available for 300 size machines) | |

| Positioning accuracy | X axis 0.0011, Y axis 0.0011, Z axis 0.00125MM | |

| Printing layer thickness | 0.05-0.3MM | |

| Printing speed | 20-150MM | |

| Printing platform | Heating aluminum substrate + black crystal glass platform | |

| Platform temperature | 30-50℃ (30-120℃ optional) | |

| Platform calibration | Automatic pre-calibration leveling | |

| Nozzle temperature | 75-280℃ | |

| Movement noise | 50 dB | |

| Connection method | U disk, SD card (both as a gift) | |

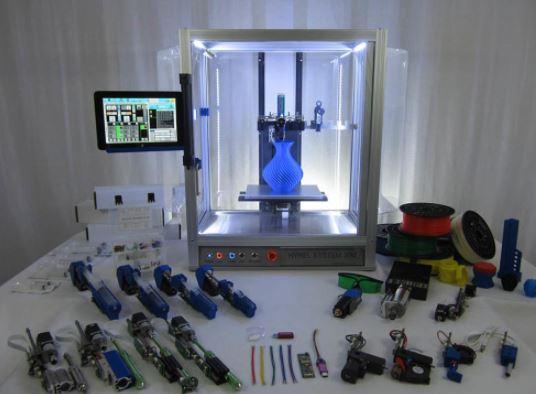

| Screen control | 7 inch full color touch screen (support all languages) | |

| Chassis structure | 3MM thick sheet metal, fully sealed chassis | |

| Filter function | 2 air filter devices | |

| Lighting | LED lighting | |

| Mechanical transmission | Double linkage gantry type machine tool linear navigation | |

| Physical parameters | Dimension | 138x129x152CMM |

| Package Size | 143x135x167CM | |

| Net weight | 260KG | |

| Gross weight | 310KG |

- Industrial FDM 1000x1000x1000mm 3D printers use thermoplastic materials such as PLA, ABS, PC, PVA, TPU, nylon etc. These materials easily pass through the printer nozzle immediately and are melted in the temperature control unit, therefore, printing accurate 3D objects without wrapping.

- As large as the 1000x1000x1000mm 3D printers only require between 100-220V of power supply. There are no extra charges on power use when printing.

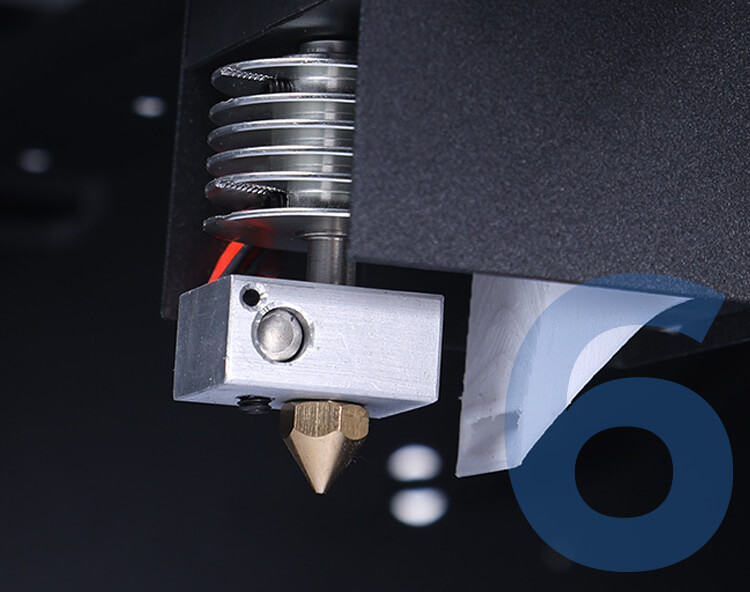

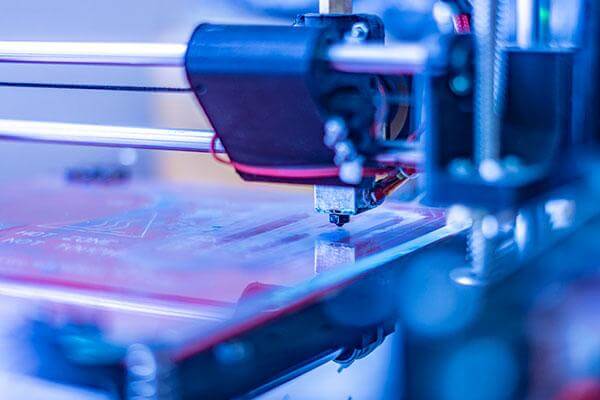

- The printing process of an industrial FDM 1000x1000x1000mm 3D printer basically involves the rollers, filament, temperature control units and the nozzle. The nozzle releases the printing material accurately, building the 3D object layer by layer.

- The feeding structure, i.e. when the filament passes through the temperature control unit and then goes through the nozzle, has no requirements for the torque of the extrusion stepping motor, therefore making the extrusion controllable.

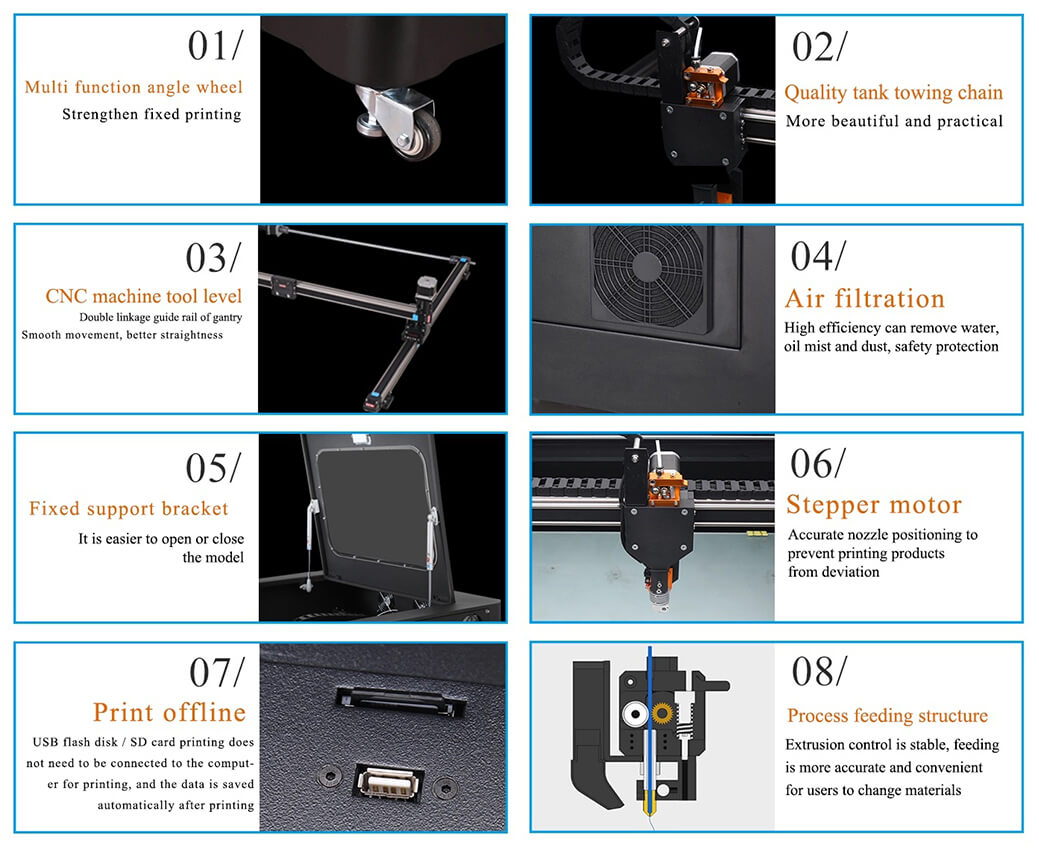

- The four universal wheels have multiple functions making fixing and leveling easier for you. The rubber wheels have no impact on the rubber floor.

- The high-strength composite coating glass has a strong printing adhesion that makes the removal of printed objects easy.

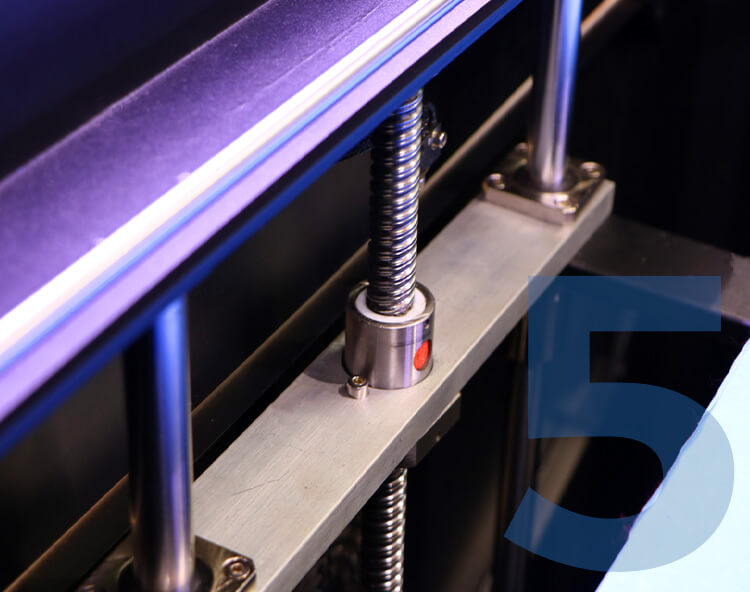

- The four linear bearings makes the industrial 1000x1000x1000mm 3D printer stable such that the z-axis twin-screw four linear bearings ensure that the z-axis is accurate while making the printing platform stable.

Test your part

We provide sample testing service, allowing you to check the working quality of our 3D printer before placing an order

6 points why choose us

Automatic resume printing

Full enclose stable frame

The whole machine case is thickened by CNC cutting, with accurate hole position, better assembly stability, and higher positioning accuracy of printer operation.

Allow offline printing

Use U disk or SD card to print without connecting to a computer to print. After starting to print, the data is automatically saved and the U disk or SD card can be removed.

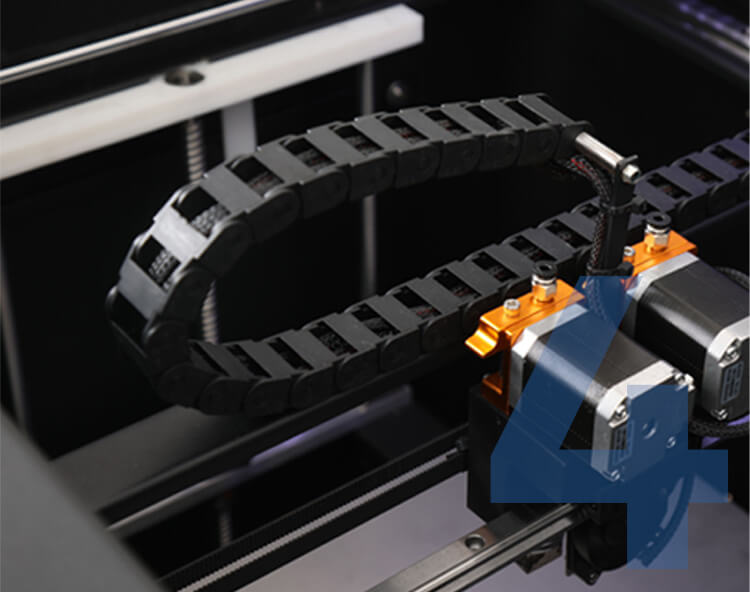

Drag chain wiring design

The wire is installed in the inner casing of the drag chain to effectively ensure that the wire will not be damaged for a long time when the printer moves at high speed.

Precision ball screw

Using the latest Taiwan ball screw, it has higher straightness, lower friction coefficient, better smoothness, higher positioning accuracy and more stability during printing.

Alloy nozzle

Independently developed a unique bullet nozzle with uniform heating and a patented head assembly, so that it can work smoothly without interruption.

More FDM 3D printers

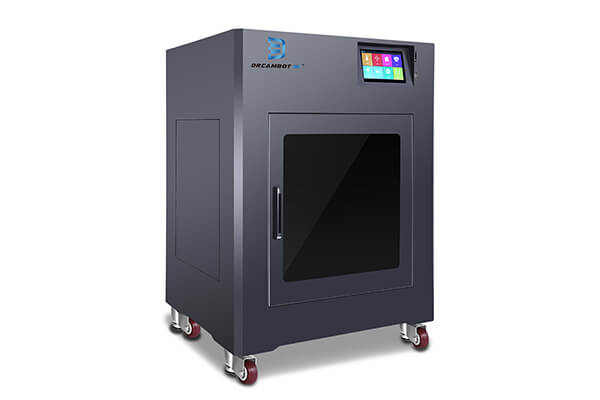

L-300 FDM 3D Printer

The L-300 3D printer allows you to print precise 3D objects. The L-300 model only prints objects of 300x300x300mm sizes. It is particularly suitable for hobbyists.

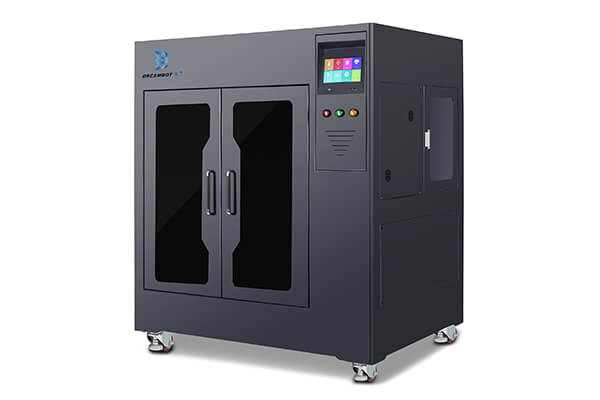

L-600 FDM 3D Printer

The L-600 3D printer is able to print 3D objects of 600x600x600mm sizes. The can be used for printing for educational purposes or any other medium sized printing.

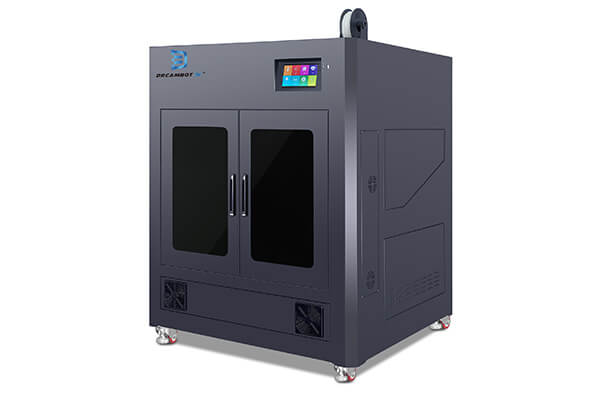

L-800 FDM 3D Printer

The L-800 3D printer fits into the category of industrial 3D printing as it is able to print large objects with sizes reaching 800x800x800mm.

XXXX Buying Guide

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

FDM 3d printer introduction

FDM 3D printers are running riots in numerous industries. Their ability to help tackle complex day to day work load have made them the preferred pick by multiple experts and technicians around the globe.

In this buying guide, we aim to help you understand all the intricacies attached to purchasing a 1000X1000X1000 FDM 3d printer. This is the biggest industrial printer in the market. Its durability, efficiency and reliability are seconded to none.

And to help you better understand how the 1000X1000X1000 FDM 3d printer can help hasten your workload and keep your production line booming, we highlighted all there is to know about the FDM 3D printer, industries of application and the buying process involved in making a purchase.

1.1, Principle of FDM 3D Printer

FDM 3D printing is an elaborate process that starts with 3D CAD (computer-aided design) models using software like AutoCAD, CATIA®, Inventor®, Solidworks®, and so on. The model then goes through the slicing process, which involves preparing the model in a format that an industrial FDM 3D printer can interpret.

When the model is ready, a manufacturer loads a spool of printing filament into the printer, turns on the machine, which starts feeding the extrusion head and the nozzle with molten printing material. After melting the filament, the nozzle releases the material onto the table or bed, creating the desired object.

Therefore, FDM 3D printers can only work with the presence of the following primary conditions:

Printer Platform: The printer platform or bed usually consists of a hard surface like plastic, ceramic, and metal. Its primary purpose is to hold the object that being printed as the nozzle deposits the molten material. In that case, a 1000X1000X1000 3D printer has a large bed capable of producing larger objects.

Nozzle/Printer Head: An industrial FDM 3D printer has a nozzle that moves with the power of a lead screw or belt on a mechanical chassis in the X, Y, and Z dimensions as it creates the additive part. It also has the stepper, a fourth motor for pushing the thermoplastic material through the nozzle. A computer controls all the head and raw material movement, ensuring precision during the depositing process.

Raw Materials: The raw materials used in FDM 3D printers is primarily thermoplastic, which can repeatedly melt on exposure to heat and re-solidify when it cools. However, some machines may use a blend of metal, especially where the additive part requires it. Material for FDM 3D printing is wound on a spool. It uncoils when fed into the printer nozzle; as the printer nozzle melts and releases the material, the spool rolls, releasing more filament for a continuous printing process.

A 1000X1000X1000 3D printer can keep the nozzle temperature at a level close enough to the material’s glass transition temperature. Because of that, the material extrudes at a semi-liquid state, returning to a solid-state almost immediately. That’s how the top industrial 3D printers ensure greater dimensional accuracy every time it produces an additive. Thermoplastic FDM printing materials include urethane, polystyrene, ply-lactic acid, polycarbonates, nylon, and acrylonitrile butadiene styrene. Different manufacturers have 3D filament of distinct quality, giving users various materials from which, they can choose. Of course, the choice of materials depends on the industry and the product, prototype, or additive part one intends to make.

FDM 3D Printing Process: The FDM 3D printer works by extruding the thermoplastic material through the hot nozzle. It deposits the material on the printer platform and continues to do so as the thermoplastic solidifies, building the object layer by layer upwards. The previous layer fuses with the succeeding one at every stage until one gets the object in question. The average 1000X1000X1000 3D printer, like the Dreambot3D 3D, initially prints the object’s outer edges followed by the interior trims and, lastly, the inner part of the layer before solidifying.

In some cases, a professional FDM printer incorporates struts or support structures to hold thin overhanging sections. That happens throughout the printing process to ensure that the object comes out just right. However, the props aren’t permanent and require prompt removal once the printing process is over.

Instead, they are made from the material as an object and released via a second extruder that deposits soluble thermoplastic struts to avoid drooping overhangs. It is the 3D printing machine manufacturers who determine whether a device has two extruder nozzles or not. When placed in a solvent, the thermoplastic dissolves, leaving the desired object.

Printer Parameters: FDM 3D printers have several adjustable parameters, including build platform temperature, nozzle temperature, layer height, build speed, and cooling fan speed. The operator adjusts the build platform temperature, nozzle temperature, cooling fan speed, and build speed, ensuring that the printing process works as well as possible.

On the other hand, the designer is in control of the layer height and build size. An industrial 3D printer machine has a build size ranging from 400x400x400mm to 1000x1000x1000mm. So one can buy a1000X1000X1000 3D printer if they need one for use on an industrial scale. Regardless of its size, an FDM 3D printer has a height of 50 to 400 microns, which is also adjustable. A smaller layer height has smoother parts and helps accurately capture curved geometries. However, a more significant layer height least to faster object printing.

Warping: FDM 3D printing may result in warping due to the molten material cooling and solidifying. That mainly because different sections of the object cool down at different speeds causing dimensional change at different rates. There is a general internal stress build-up with differential cooling, pulling underlying layers upwards, causing warping in the object.

However, one can prevent warping by closely monitoring the build platform and chamber temperatures. Increasing how tightly an object adheres to the build surface can also help. Warping worsens when dealing with things with expansive plat areas, thin protruding features, sharp corners, and the use of certain materials. When it comes to materials, the one that’s most prone to warping is ABS.

Layer Adhesion: One of the essential principles enabling FDM 3D printing is the adhesion between the layers deposited on the additive part as it’s being printed. As the molten thermoplastic filament extrudes through the nozzle, it sits and adheres to the previous layer, which is already drying. The pressure and temperature are so high that it re-melts the last layer, enabling bonding of both layers. Layer adhesion is essential since it determined how quickly and effectively one can print 3D quality products.

The inter-layer strength between any two successive layers is always less than the material’s base strength. Since FDM printed additives are anisotropic (have a lower z-axis strength), the design process usually incorporates part orientation. The depositing of a material layer over another also means the finished object has a wavy surface when dry. It also means there must be post-production inclusion of features such as thread and holes.

Support Structure: In FDM 3D printing, the support structure is beneficial for propping up overhangs with an angle of more than 45 degrees. One can use either bridging or support, where bridging involves stretching the material between two points. That removes the need for support and is useful where the bridge is 5mm long or less. Anything more than that requires extra support to hold the material in position. Support often involves some form of post-processing, which consists of removing the support from the printed object. Since it utilizes additional materials, support makes FDM 3D printing slightly more expensive.

Infill and Shell Thickness: Large format 3D printing doesn’t lead to the production of outright solid objects. Instead, it involves tracing the outer perimeter to create a shell, which is then filled with a low-density material called the infill. For example, with a 1000X1000X1000 3D printer, the infill setting can start anywhere from 25 percent of the object’s total density with a 1mm shell thickness.

1.2, What materials can be printed by FDM 3d printer

The material for your 3d printer depends on the object you are printing and the type of FDM machine you are using. Thermoplastics are the most common materials used for industrial 3D Printing. This is because they are malleable and can be melted by the printer head. Also, since FDM 3d printing machines use a layer-by-layer printing system, the thermoplastic filaments make it easy for each layer to stick to the layer beneath it.

These thermoplastics include Nylon, Carbon fiber, PLA, ABS, PC, PETG, PVA, HIPS, TUP, and ULTEM. Each filament material is made up of its unique characteristics, making it better for some applications than others. When choosing the material for your 3D Printing, you must consider strength, flexibility, durability, ease of use, the complexity of print, heat resistance, and complexity. Our 1000X1000X1000 3D printer can print all materials because of its anodized aluminum template.

Some of these materials are stronger than others, and your filament requirement will determine which one you pick. If you are printing concept prototypes, you will go with the soft and easier materials since your prototype will not face physical pressure. If you want to print an object for functional testing, on the other hand, you will need a tougher and hard-to-print filament material. Let us briefly look at the different properties, cons, and pros of the printing materials mentioned above.

Nylon: Nylon is also known as Polyamide, and it is a commonly used material in the 3d industry. It is commonly used because of its flexibility, durability, abrasion resistance, chemical stability, low coefficient of friction, and it takes up coloring agents very quickly.

Nylon is the best option when you are printing any object that will experience a lot of mechanical wear and tear. This material is best used for creating tools, functional prototypes, and mechanical parts such as hinges, buckles, and gears. Since your FDM machine carries out layer to layer printing, Nylon’s layer to layer adhesion is impressive and excellent. Although nylon filament requires an extrusion temperature of 250-degree Celsius, some FDM printers allow for lower printing temperatures at 220 degrees Celsius.

Although Nylon comes with many advantages, it also has its perks which you need to be mindful of. Nylon filaments absorb moisture quickly, and this is a blessing because it is easy when applying other coloring agents and dyes. But this hygroscopic nature is also a disadvantage. Absorbing moisture can lead to quality print issues. You will need to store your nylon filaments in airtight packaging to guard against this. The closed-door chassis of our 1000X1000X1000 3D printer helps against absorbing moisture while printing.

You need high temperatures when printing with Nylon; this leads to high stringing and warping, affecting your object’s outcome. Also, you will end up using a lot of power to heat your print bed and nozzle. Using nylon filament is very tricky, and it will require you to use many tricks to surmount these difficulties, but the end product is satisfying.

PLA: Polylactic Acid (PLA) is the most widely used material for FDM 3D printing because it is easy to use and cheap. Some of its characteristics include low-temperature Printing, less prone to warping, flexibility, does not emit fumes, heat stability, and sub-par durability. In addition, it is ideal for a lot of applications because it also comes in different shades and styles.

It is easy to use and very ideal for beginners. PLA is a toxic-free material because it is made from lactic acid monomers. It can also be made from renewable sources like potato starch, sugar cane, and corn starch. In addition, it requires low heat printing temperatures, which means that you will not encounter warping and stringing.

PLA filaments absorb moisture quickly, which means that you have to store it in an airtight container. If you use a PLA filament that is not well dried, it will affect the quality of your final print. This material is best used for printing prototypes and display items.

HIPS: High Impact Polystyrene (HIPS) is made from polybutadiene and polystyrene, which gives this filament material its strength and flexibility. This filament can absorb more impact without breaking, and it is not expensive. Some of its qualities are heat stability, good impact strength, flexibility, prints at high temperatures, and prone to warping.

This filament is best used for Printing moving parts with high-impact applications and support structures. It is easy to absorb dyes and colors, and it works with several adhesives. However, HIPS filament is not commonly used in 3D Printing as the primary material.

Instead, it is used as a supporting material, especially when working with ABS. It is used as a supporting material because of how easy it is to dissolve it in limonene, a cheap and easily obtainable solvent. In addition, it is best used for ABS because HIPS prints at nearly the same temperature as ABS. This means that you can print both filaments simultaneously using a multi-extruding printer without changing the temperature setting in the middle of the printing.

HIPS is prone to warping and stringing, it is very soft when hot, and it emits toxic fumes, which means you need to use it in a well-ventilated environment. Another good thing about it is that it has been declared food-safe by the FDA, making it a good material for printing food-related objects.

Carbon Fiber: this is a thin filament material made from bonded carbon in a crystalline formation. This filament material is solid, abrasion-resistant, durable, lightweight, and exceptional rigidity. It most times enhances the strength of polymers used in sporting goods, automotive, and aerospace industries.

It is best suited for scenarios where weight is an essential factor. This filament is resistant to chemical degradation and corrosion, and its volume is not affected when exposed to extreme hot or cold temperatures.

One of the difficulties with using this filament is that the carbon fiber particles do not melt during the nozzle’s extrusion. This can make your nozzle clog frequently. Also, these carbon fiber particles work as abrasives that can wear down your nozzle. Therefore, it is advisable to use hardened steel for your nozzle when working with this material. The 1000X1000X1000 3D printer on our catalog is a perfect 3d printer for this material because of the high heat temperature of the nozzle.

ABS: Acetonitrile Butadiene Styrene (ABS) is a polymer made from three monomers; butadiene, acrylonitrile, and styrene. These three monomers give it the qualities of durability, chemical stability, high-temperature printing, rigidity, soluble in acetone, and it emits fumes during Printing. You can use this material for outdoor items and functional parts like brackets and hinges.

It requires a high temperature for Printing of about 220 – 250 degrees Celsius, and our 1000X1000X1000 3D printer is compatible with this filament. Although it gives its objects high durability and strength, it makes printing complicated. Its rapid cooling creates a high tendency for the object to warp. This means that you need to use a heated printing bed to control the temperature of your building platform.

You need a well-ventilated area when using this material because of the toxic fumes that it produces. Also, because of the complexity of using this material, many things might go wrong when printing, especially if you are new to the 3D printing world. You will need to understand the fundamental of 3D Printing for you to perfect the art of Printing with ABS.

PC: Polycarbonate or PC, as commonly called, is the strongest material used for 3D Printing. It has superior strength, good optical properties, high impact resistance, heat-stable, and high tensile strength. It is best used for safety equipment, electronic display screens, and construction equipment.

This filament transmits visible light in a far more superior way than other filaments. This material also exhibits some amount of flexibility that is not found in PLA and ABS filaments. You can use this for creating some other objects like bulletproof glass and riot gear. This filament is tricky to work with because of its printing temperature.

Printing with this filament requires a temperature that is higher than that needed to print ABS and Nylon. This requires you to print your PC filament on a heated bed with a slightly higher setting. This filament is not recommended for beginners because it is challenging to work with.

PETG: Glycol-modified Polyethylene Terephthalate (PETG) is one of the commonly used plastics in the world. It is a variation of polyethylene terephthalate, and it is highly valued in the 3D printing industry for its mechanical strength. Its qualities include; high-impact resistance, high strength, heat-stable, clear, chemically stable, and prone to damage by UV.

It is used to produce mechanical parts, protective components, and objects that come in contact with food. Its laminating and printable characteristics make it an excellent material for store fixtures, electronic devices, credit cards, and signages. In addition, it is a perfect material for medical containers because of its heat stability which can withstand steam sterilization.

This material is challenging to work with, it degrades quickly when constantly exposed to sunlight, and it is not a good material to use for support structures.

TUP: Thermoplastic Polyurethane (TPU) possesses a desirable combination of rigidity and elasticity. This material is very flexible, abrasion-resistant, impact-resistant, stable against solvents and oils, it cannot be polished or sanded, and it is prone to deformation in the extruder. This material is used to produce inflatable rafts, footwear, mobile device cases, and sporting goods.

Although it is recommended, TPU does not require a heated bed when printing. This material exhibits minimal shrinkage and warping, and it does not produce fumes while printing. However, you will need to store this material in an airtight atmosphere because it is hygroscopic and quickly absorbs moisture.

1.3, How does FDM 3D printer develop from desktop to industrial level

Just like inkjet printers, 3D printers are replacing traditional factory lines with a single machine. A metal material is used on an industrial level, and a laser or binding solution is added to it for solidification. In contrast, for desktop 3D printers, a plastic or resin material is used for producing products.

How a desktop 3D printer develops products

You start by first designing your 3D object on an ordinary pc or a tablet that can connect to the printer. Once done with the design, connect it to the printer and let the magic begin.

If you have ever seen how a regular printer works, that could give you some insights. A regular printer starts printing from the top of the paper to the bottom, going line by line; in 3D, it’s almost the same. The printer adds the material layer by layer, working from the bottom going to the top. This allows it to be capable of producing even the most complex or moving shapes.

Once the product solidifies, it is ready for use. You can make some post-print adjustments to the product, like paints or assembling the parts together after the printing process has been completed without using any specialized tools.

How industrial 3D printers develop products

Industrial 3D printers created the path for desktop 3D printers to follow, and it’s not surprising that they work on the same concept. Printing an object from the bottom to the top from a design generated from a computer to which the printer is connected to. Industrial 3D printers have different applications in the real world and are very effective in their respective areas. Huge 1000X1000X1000 3D printer are used for creating components on an industrial scale, especially in the automotive industry.

Application field of FDM 3d printer

3D printing application has gained a lot of traction because the Fused Deposition Modelling (FDM) printing process patents created by S. Scott Crump expired back in 2009. This allowed the public to use the technology without paying Stratasys, Scott’s company, for it. Which has made 3D printing attractive to various significant industries. Here are some real-world applications of 3D printing.

2.1, For Industrial R&D

As a manufacturer, you have to evolve to stay up to date with popular trends, or competition constantly will get to you. Research and Development form the foundation for the product innovation cycle and also offer guidelines for the future of the product. The use of 3D printing in industrial R&D has turned the time and capital-consuming process into one that is easy and fun to participate in.

An industrial 1000X1000X1000 3D printer is guaranteed to prototype even the most extensive complex products. Here are more benefits 3D printing has introduced to the industrial R&D sectors.

- They allow effortless design modifications and replication giving you higher design iterations.

- You will prototype products much faster, giving you ample time to test different product designs.

- 1000X1000X1000 3D printer are flexible to work with in terms of design complexities, geometrics, colors, and material type.

- They produce exact replicas of what you designed up to the minute details.

2.2, For Molds Making

It’s not only possible to create molds using a 3D printer but also relatively easy. The main difference between 3D printing molds and your standard 3D printing projects is how you will get the final product. There are extra steps to follow for printing molds, which tend to consume more time, but here is why we think it’s totally worth it.

- You can easily calculate how much volume your mold could hold

- Design and print your own pour vents and holes

- Save the mold box and re-use it for creating multiple molds.

- You will create a package that fits perfectly the parts you designed.

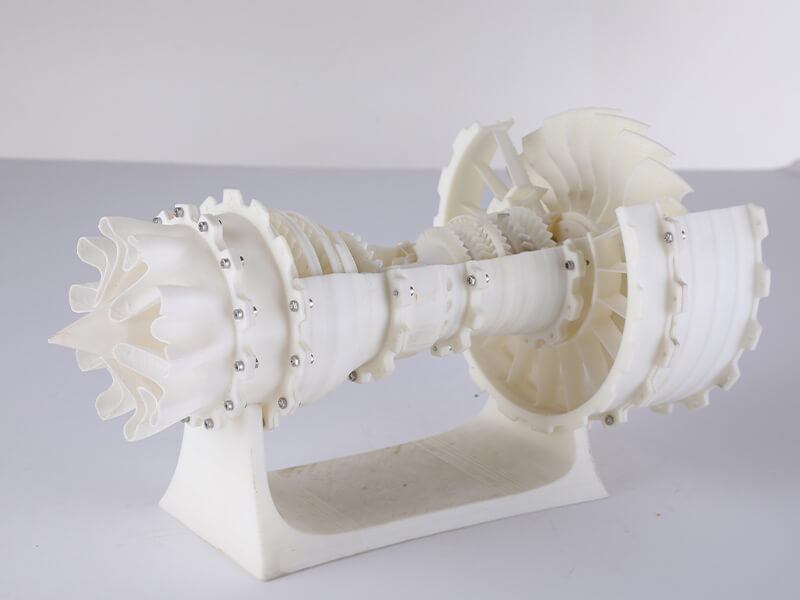

2.3, For Aerospace Printing

A 1000X1000X1000 3D printer is capable of building large-size products suitable for aerospace prototyping, such as turbine blades and impellers. Compatibility with magnesium, aluminum, and other casting materials combined with a larger build volume, reduced person-hours required, and a faster build rate, 3D printers are slowly taking over the aerospace industry.

Additive Manufacturing is used in the aerospace sector for developing lighter and stronger parts that are harder to produce using traditional methods. The Aerospace and Defence industry was among the primary adopters of Additive Manufacturing or 3D printing technologies, some beginning as early as 1989, and by 2015 the sector contributed $4.9 Billion or approximately 16% to the global 3D industry.

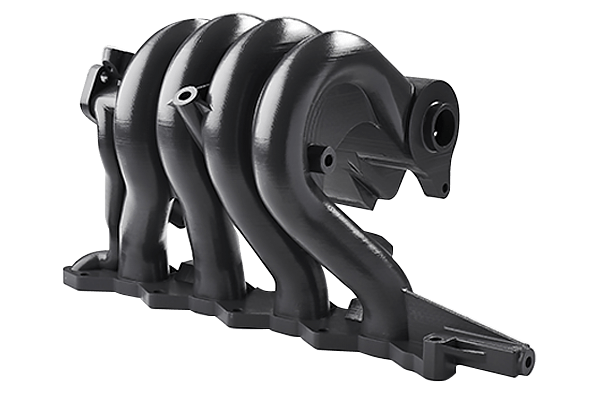

2.4, For Car Parts Printing

Imagine if you could print or design a car part for yourself, relieving the stress and all the extra work of forcing it to fit. With 3D printing, you can produce quality replacement parts at the comfort of your seat and at a lower cost and faster rate. Of course, to make quality parts, you’ll need to consider one of the best printers; in this case, the 1000X1000X1000 3D printer can be used especially for steel casting.

2.5, For Medical

3D printing is the perfect technology when creating or designing medical devices. Thanks to the low cost, medical device manufacturers can develop new products, ranging from bioprinting artificial organs to prosthetics and many more.

Five-year-old Katelyn poses with her new limb.

You don’t have to worry anymore about your child outgrowing and not fitting the prosthetic as you can print one for them every few months.

2.6, For Various Models Making

2.6.1 Anime figure

Bet some of you didn’t know you could create or design your anime with the use of a 3D printer; it doesn’t sound very easy, but it’s not. However, it’s actually fun and exciting and doesn’t require lots of understanding once you get the hang of it. For life-size dolls, we’d recommend a 1000X1000X1000 3D printer; for instance, the L-1000 FDM 3D printer should work well for large formats.

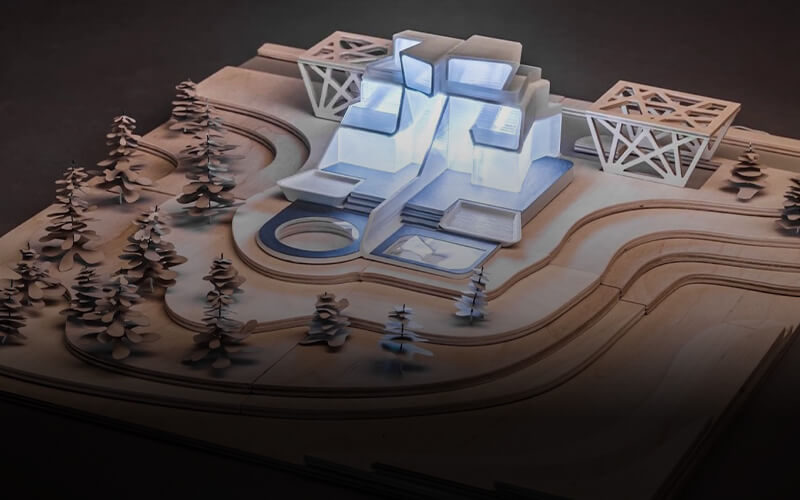

2.6.2 Architectural models

In architecture, every project starts with a concept model. A 3D printer helps a lot and saves you time by doing all the work for you. Instead of shaping one with your hand, it creates a tangible model based on your idea. This technology also allows architects to print and design interior projects and decorative objects like sculptures and lamps.

2.6.3 Mannequin

Do you want your shop to stand out from others? How will you grasp customers and all the passers-by attention and keep them as your regulars? This is where custom mannequins can make an impact. With a 3D printer, you can produce a life-size dummy in just a matter of days or hours. On the other hand, ordering a clay mannequin will subject you to weeks or even months of waiting. After all, they are created with manual labor.

2.6.4 Gun

3D printing continues to amaze everyone as you learn more; it has so much power that it brings almost any design to life, including making a gun. Still, when making your gun, there are certain metallic parts that you’ll need for the weapon to function fully, which are only accessible through the proper channels; to be specific, we mean the authorities.

2.6.5 Ship models

If you love the sea and sailing then you’d surely wish to collect your favorite craft as a 3D printed ship, there are tons of detail in all models that you’ll never get boring, even though you aren’t sailing, you can take a single look at your detailed vessel and imagine the waves directing your ship to all the islands you’ve sailed before.

2.6.6 Airplane models

Do you love soaring up in the sky? Are you looking for the best plane model to add to your personal collection? Or maybe you just want to print your own custom plane? Either way, you’re at the right place. With a 3D printer, you can print your own model, which will be cheaper and faster than buying and assembling one, considering you already own a 3D printer.

Because airplane companies need to produce low volumes of models for testing, Dreambot3D’s L-500 1000X1000X1000 3D printer is recommended for speedy and accurate airplane model printing.

2.7, For Cosplay Props Making

Like many industries, cosplayers have also moved into 3D printing technology, which has allowed producers to bring their favorite movie characters to life. Buying a costume can be very expensive as opposed to designing your own. With a 3D printer, you’ll end up saving a lot of cash, and in addition, you have the freedom to create an outfit of your choice.

2.8, For Drone Manufacturing

3D printing can be beneficial for many of your projects, especially your drone project, and it certainly has its benefits. Not only can you create your own custom drone, but you can print almost every part of the assembly. If you damage any part, do not worry as you’ll have an infinite supply of parts, excluding electronic components of-course.

Due to the many parts needed for drone manufacture, we recommend a 1000X1000X1000 3D printer that prints size the double of a basketball, enabling you to create commercial size drones.

Factors affecting efficiency of FDM 3D printer in manufacturing industries

The top FDM 3D printers are efficient, producing objects faster and more efficiently. However, an FDM 3D printer may work at different levels of efficiency, depending on the variation of certain factors. This chapter discusses the factors affecting the efficiency of FDM 3D printers in manufacturing industries. Knowledge of these factors makes it possible to institute the necessary controls to keep the printer working more efficiently.

Printing Materials

The choice of materials and their amount is the most significant factor in determining the cost of printing and the lead times. Thus, one should be careful when selecting printer materials like ABS, nylon, PLA, PET, or PTU. ABS provides good strength and temperature resistance, even though it is susceptible to warping.

Nylon also has high power and resistant to chemicals and wear, even though it absorbs a lot of ambient moisture. Although PLA isn’t so strong, it is easy to print with and provides outstanding visual quality. PETG is strong, fire, and chemical-resistant. It is also food-safe and easy to print with.

The best 3D printer for industrial design utilizes differently-priced materials based on their chemical, mechanical, and physical properties. Apart from the printer, the filament material determines the build process and speed one can attain.

Thus, some materials are more efficient than others, making it possible to build objects faster. Even though most of the filament materials for FDM printers are thermoplastics, some are fast to print, given their little or no shrinkage. Others require more careful handling and a controlled environment, such as a heated chamber.

Orientation and Supports

A 1000X1000X1000 3D printer may print objects faster and at a lower cost if the supporting angle isn’t too high. At higher orientation (more than 45 degrees), support becomes necessary, prolonging the printing process and consuming more materials.

Thus, it is possible to get more printing efficiency using self-supporting angles. It is not only faster but also costs much less. In the same way, the part orientation determines the amount of support an object requires. Under normal circumstances, it is essential to re-orient the design to reduce the number of materials supporting the structure.

With that, it is possible to reduce the cost of printing an object. However, that doesn’t mean basing your design totally on the x-y plane in a cost-saving bid. That only results in the additive part losing the original mechanical integrity and feature definition.

Layer Height

FDM 3D printers often print objects with a 50 to 400-micron layer height. It refers to the preset height of materials deposited in each layer as the printing process continues. A large industrial 3D printer can produce smoother, geometrically accurate additive parts when the layer height is at the lowest level.

It is crucial to choose a smaller layer height if the object has holes or curved surfaces. Visual appearance is more important than functionality, and there won’t be any finishing after 3D printing. However, the printing process isn’t fast enough.

With a more significant layer height, it is possible to print objects faster and more cheaply. Therefore, you can increase the efficiency of an FDM 3D printer by increasing the layer height. Most printers in this category, such as the Dreambot3D 3D, use a layer height of about 200 microns. Apart from being faster, a higher layer height produces parts with better mechanical properties. Therefore, it is suitable for sand, paint, or acetone-smooth the finished product.

Wall Thickness

Every 1000X1000X1000 3D printer comes with settings for determining the wall thickness of the object. A thicker wall is more robust and slower to print than a thinner one. However, it also consumes slightly more materials and is more costly. That’s because a thick wall consists of several nozzle diameters and takes time to print. In most cases, the wall thickness consists of two nozzle diameters or 0.8mm for the top industrial 3D printers.

While thinner walls lower the build time, they may result in flimsy features, exposing the object to warping or unexpected fragility. That’s why designers must seek to establish a balance between the layer and wall thickness for the desired performance and detail without additional printing time or material cost.

The Infill

FDM printed objects are like wooden doors, which often feature a low-density core. After printing the outer shell, it is necessary to finish the additive part with a low-density infill. The infill density can be as low as 20 percent for those looking for a less robust model and between 50 and 75 percent for those who consider strength necessary. A lower infill density is easier and faster to print but not so strong. On the other hand, a higher infill density makes the model stronger, even though it might take longer to print.

Labor or Workforce

A large industrial 3D printer might not produce 3D objects with finality. Some additive parts might require substantial post-processing work and finishing. Anything that involves coating, painting, or smoothing costs more in terms of materials and labor. That may diminish the overall efficiency of the project because of the additional time and cost. By analyzing the project needs and determining the need for finishing, you will be better prepared to manage and deliver more efficiently.

Machine Build Size

FDM 3D printers have a build size ranging from 400x400x400mm to 1000x1000x1000mm. The lower limit represents mostly desktop printers that can print either smaller objects or bigger ones bit-by-bit. For larger, small objects, a printer with a smaller build size is very efficient. However, if the object is industrial-scale, you have to print different parts separately, which might take too long. Thus, a smaller 3D printer is less efficient when printing larger objects. In that case, a 1000X1000X1000 3D printer is good enough to print larger objects quickly and at a lower cost. It is, therefore, more efficient than a 3D printer with a smaller build size.

Main components and parts of FDM 3D printer

To get the satisfying and efficient result of your FDM 3d printer, there are outstanding components and parts that make this particular 3d technology different from other 3d printers. First, let us look at some of the core and fundamental parts of the FDM 3d printer.

The Extruder: the extruder can also be referred to as the printer head. This printer head is directed by the computer, directing the nozzle’s path and movement as it moves across the build platform. This printer head movement creates the object according to the calculated path as set up by computer-aided design software.

The heated nozzle draws the object by melting the filament and extruding it onto the building platform. The nozzle extrudes this melted filament layer by layer, and when each layer has been printed, the height of the nozzle increases by an increment as it prepares for the next layer.

The print head can be categorized into two sections; the cold end and the hot end. The cold end is the part that locks the filament and gradually pushes it towards the hot end. As the name implies, the hot end possesses the hot temperature that melts the filament and deposits it on the printer bed.

Some FDM 3d printers come with dual extruders like our 1000X1000X1000 3D printer. This means that you can simultaneously print with two different filaments. These double extruders can either be attached to the same print head or connected to different print heads.

Print Bed: this is the component where your printed model rests while printing. The FDM 3d filaments are deposited on this flat surface layer by layer. The print bed can be made with different materials like glass and metal. Each of these materials has its various advantages,

For example, the glass flatbed material is superbly flat, meaning that layers can be added easily and easy to clean, and inexpensive. Aluminum, on the other hand, heats up faster than glass. Our 1000X1000X1000 3D printer is made up of heating aluminum substrate plus a black crystal glass platform

Also, there are different kinds of print beds; there are heated and non-heated print beds. A non-heated print bed might be ideal for lower materials like PLA, but it might require you to use heated print beds for advanced filament materials. The type of print bed used helps to enhance adhesion and the stability of your first layer.

Motion Controllers: the motion controllers are fed with instructions by the motherboard. They receive the instructions and do the movement, and these motion controllers move around three axes; XYZ. The X-axis and Y-axis movement is controlled by the belts connected to the motors. The stepper motors are responsible for the mechanical movement of the print head. These motors rotate in steps; that is why they are called stepper motors. The stepper driver controls them, and they connect with the X, Y, Z-axis. Our 1000X1000X1000 3D printer has accurate nozzle positioning, which prevents printing products from deviation.

Threaded rods are another set of motors that help the print head move upward and downward. The Z-axis is dependent on the threaded rods for its movement. These threaded rods are connected to the stepper motors.

Print Material: this refers to the filament used for Printing. FDM 3d printers use polymers as filament materials, and a variety of them are used for different objects and industries. These filaments are heated to different temperatures, causing them to melt, and are deposited on the print bed to print the required object.

These different types of filaments have their advantages and limitations. It is necessary to know what you want to print before you purchase any filament. Also, when you buy a printer, you need to be sure of the filament that is compatible with your printer. Not all FDM 3d printers are compatible with multiple filament materials. Our 1000X1000X1000 3D printer is compatible with a wide variety of filaments.

Motherboard or Controller board: the control or mainboard is the component of the FDM 3d printer responsible for the smooth processing of the machine. We can call the mainboard the brain of the 3d printer because it is responsible for the fundamental operation.

The control board receives the instructions sent from the computer, and it directs the motion component. The mainboard also interprets sensors and signals, so your control board needs to be of excellent quality to achieve high performance.

Frame: The frame of your 3d printer helps keep all the components together. The frame maintains the stability of your machine, and it is made with different materials. The common materials used for frames are acrylic and metal.

It is essential to buy an FDM 3d printer with a robust frame; it makes your printer more durable. Also, there are open and closed frame designs. You will find some printers with semi-closed frames. One of the advantages of the closed frame over the open frame is that it maintains consistent temperature around the print space. Our 1000X1000X1000 3D printer has a fully sealed chassis.

User Interface: Most 3d printers these days come with a user interface, an LCD controller that allows you to use your 3d printer without a computer. This display can help you control the printer’s settings, and the 3d printer can work as a stand-alone.

This means that the printer also comes with a space for an SD card for your FDM 3d printer to read the software instructions. Our 1000X1000X1000 3D printer comes with a free U disk and SD card.

How to choose a suitable FDM 3d printer for your industry

Although 3D printing has been around since the 1980s, it wasn’t as widely known as it is now, mainly because it’s now affordable on the market, making it available to everyone who has ever wanted to own one. As a result, everyone from all industries (ranging from architecture, aerospace, medicine, and many more) wants to experiment with a 3D printer.

But you can’t buy just any printer; various aspects need to be considered when choosing a 3D printer for different industries. Of course, a 1000X1000X1000 3D printer will be capable of handling most products, but here are more factors to consider:

Intent

Before you decide to buy a printer, it is very crucial you define its work, as choosing a printer depends on the purpose of the printer. What is the printer for? Is it intended for the purpose of creating prototypes of models? If so, a 3D printer that uses plastic filament should serve.

But if you plan on using it to create finished products, a high-grade 1000X1000X1000 3D printer like the L-500 FDM 3D printer from Dreambot3D will be more than enough.

Time

Are you focused on the final result? But don’t want to know about every little detail of how the print is produced. Or are you curious and want to know the whole kit? How you answer these questions will help you when choosing the right printer for your Industry. On the other hand, if you are focused on the final by-product, you want a readily available machine and doesn’t require much need for maintenance.

If you’re more curious about how everything works, then a “kit” printer is the right choice for you. Kit printers are a lot cheaper, but you have to assemble them.

Maintenance

All machines like the 3D printers require maintenance every once in a while. The heating bed has to be cleaned after every print, LCD screens must be replaced, etc. Maintenance is vital in all printers, whether they are kit printers or not. But assembling your own printer educates you bit by bit, and you learn all the ins and outs of how you will maintain the machine, which parts to grease, which not to, how to replace the nozzles, and so on.

The L-1000X1000X1000 3D printer is easy to maintain and comes equipped with a user manual that focuses on common problems and how to troubleshoot them.

Price

3D printers are now widely available and affordable; you can easily purchase a printer for under $100, but don’t forget you get what you pay for. Such a printer will need a lot of add-ons to make it produce high-quality prints. In this case, it is easier and better if you could spend more on a high-quality printer from the start.

It is also recommended to have replacement parts should the need arise; if any part of the printer fails, it is most likely unreliable till a replacement arrives. 1000X1000X1000 3D printer are pretty expensive considering their printing volume, but Dreambot3D offers customized pricing on its L-1000 FDM 3D printer

5.1, Your application industry

The most common aspect that one has to contemplate when purchasing a 3D printer is asking themselves the main application of their 3D printer. What is it for? Is it for home use, industrial, medicine, hobby, etc.? All these are factors you need to consider, different 3D printers for various purposes.

You can’t buy an industrial printer for a household or vice-versa. Selecting the right printer will entirely depend on what you want to use it for. Let’s dive into a few of the industries where there is rapid use of 3D printers.

Aeronautics and defense

This is one of the early adopters of additive manufacturing, popularly known as 3D printing. Defense and aeronautics revolve primarily on research and development, focusing on improving efficiency on their current products or even designing new models.

A lot of 3D printing material is suitable for this industry application, and they come with case studies showing areas where 3D printing has been a success. Due to the large size required for models, an industrial 1000X1000X1000 3D printer will meet all requirements needed for printing 3D models in the defense and aeronautics industries.

Medicine

The health sector has seen tremendous growth in the adoption of 3D printing technologies ranging from prosthetics to bioprinting. Biomaterials like cells and growth factors are combined to create a tissue-like structure that imitates its natural counterparts. Prosthetics and pills are the commonly produced models using 3D.

Construction

Using 3D printers with construction material like concrete has been in development since the 90s because it was a cheaper and faster way of constructing a building or other structure. In the current time, the technology was perfected, and it now has a wide array of application areas either for commercial, private, public, or industrial use.

The benefits of using 3D technology include lower labor costs, less waste, faster construction, more complexity, and accuracy. However, given the vast amounts of models to be printed like walls, a 1000X1000X1000 3D printer won’t cut it; you need a heavy-duty printer capable of handling construction material.

The gantry printer BOD2 manufactured by COBOD is an example of a 3D printer capable of printing an entire house layer by layer. PERI GmbH is currently using it to create the largest 3D printed residential building in Europe with a living space of 4090 sf (380 m2).

5.2, Print size requirements

Printing a 3D object requires you to remember that your final product will be a tangible object with height, weight, and size. Even if your model seems to be at the dimensions you had planned, it is still vital that you examine if the printed model matches your expectations and the printer’s restrictions.

Different industries require different 3D printers for various applications. Your application industry plays a vital role in determining the printer size. Suppose a 500x500x500 3D printer cannot get the work done; we recommend a heavy-duty industrial 3D printer. Here is a list of the typical build size for different 3D printers.

FDM 3D printer buying guide

It is not enough to know how to choose an FDM 3D printer. Knowing how you can purchase one is also essential. Some things to consider may include the brand reputation, the machine’s safety configuration, resolution requirements, FDM 3D printer price, after-sales service, flexibility, safety, and cost-effectiveness.

6.1: Check the Brand Reputation

The number of 3D printing machine manufacturers has been on the rise over the last few years. While there are old players in the industry, some are still relatively new. To know whether an FDM 3D printer manufacturer is correct, check their brand reputation based on reviews from past users of the machines. There is no doubt that a reputable manufacturer would always provide machines of the highest quality.

6.2: Safety Configuration of the Machine

A printer’s safety configuration is one of the most important considerations when buying an FDM 3D printer. Several printers have an automatic shut-off feature that enables them to detect when being opened and pausing to keep their users safe. Some printers also have flexible steel plates for removing printed objects before they cool down. Apart from protecting users, a good printer should keep tabs on the task’s progress to resume when power is restored. That way, it won’t be necessary to start printing the model from scratch.

6.3: Resolution Requirements of the Machine

Each 1000X1000X1000 3D printer comes with a different resolution, referring to the smallest feature a machine and material can print. FDM 3D printers have a resolution of between 50 and 500 microns. A micron represents 0.000001 meters, 0.001mm or 0.00004 inches. For printers meant for exacting designs, the resolution can be as low as possible. Machines with a more precise resolution are great for making microscopic machinery and parts and prosthetic devices.

6.4: Consider Whether the Price of the Machine is Acceptable

The FDM printer price varies from one manufacturer and model to another. A good 1000X1000X1000 3D printer may cost anything from $10,000. However, the cheaper FDM 3D printers are not as robust, feature lower resolution, and may not provide industrial-grade printing.

Still, few of these machines can operate 24 hours a day, seven days a week, 52 weeks a year. If you are looking for the best 3D printer for industrial design, you should be prepared to pay anything between $60,000 and $1 million. With that expensive price range, you get a fully-fledged industrial-grade 3D printer.

6.5: Consider the supplier’s After-Sales Service Capability

Whether a manufacturer of FDM 3D printers offers after-sales service is another important consideration before purchasing a machine. Examples of after-sales service include manuals, setup instructions, white papers on the best use of the device, and training videos.

While these can be found online, some manufacturers offer installation and repair services for their clients online. Apart from that, the manufacturer should provide support around the clock to meet the needs of international clients.

Another important consideration for a 1000X1000X1000 3D printer is the warranty period, which should be long enough. So, it is essential to purchasing a 3D printer from a company that provides setup assistance, training, documentation, online help, and a service contract for support and repairs.

6.6: Go for Flexibility

Going for a flexible 1000X1000X1000 3D printer is one of the best choices one can make. Flexibility essentially implies a printer that can use different types of materials and print varied objects. For example, a good FDM 3D printer should utilize ABS, PLA, PET, PETG, or nylon materials without discrimination. That way, it is possible to fall back to a particular material when the main one isn’t available. The printer should also be operational across different industries and print differently sized objects.

6.7: Pay Attention to Details

Before purchasing the best 3D printer for industrial design, it is essential to pay attention to details to avoid missing any details. Some of the critical things to consider are the connectivity options like Wi-Fi, USB, and Ethernet. A good 1000X1000X1000 3D printer should have connections that work perfectly for the user.

Another thing to check includes touchscreen control, which helps during setup, configuration, and customization of the build process. The type of extruder, monitoring mechanism, build plate, stands, and raw material control also matters. Failure to pay attention to details may miss an important feature that may render the printer virtually unusable.

6.8: Put Safety First

FDM 3D printers have various safety issues, including mechanical hazards and emissions. For example, a heated print bed can present a severe mechanical hazard due to high temperatures of up to 100°C. That’s also true for the heated extruder block and nozzle, which can reach 270°C. At the same time, the extruder motors might also heat up quite considerably. Apart from the heat, another mechanical hazard comes in fast-moving components and sharp tools for removing finished printed objects.

Additionally, a 1000X1000X1000 3D printer may release ultrafine particles (with 0.1 microns, or less, in diameters) into the air. The ultrafine particle emission rate depends on the type of filament used, with PLA having the lowest emissions. On the other hand, ABS has the highest ultrafine particle emission rates. Also of great concern are the volatile organic compounds that result from melting thermoplastics. The speed and type of mixture also depend on the kind of materials used.

It is essential to buy an industrial-grade 3D printer with the lowest mechanical risks and minimal emissions. For example, a good printer should have its print bed secured so that it becomes hard to accidentally touch the heater block, nozzle, motors, heated print bed, moving parts, or sharp object removal tools. At the same time, a printer that utilizes materials with little or no emissions is the best.

6.9: Select the Most Cost-Effective

Some 3D printing machine manufacturers build FDM printers that solely rely on their branded filaments. Unfortunately, using such machines can be too expensive since it limits the user to just one type of printing filament. Therefore, before purchasing a 1000X1000X1000 3D printer, it is essential to ask about the overall cost of producing a model using it. That way, you will avoid ending up with a printer that isn’t cost-effective enough to serve your needs.

6.10: Why is Dreambot3D’s FDM 3D Printer So Prominent?

Dreambot3D 3D Technology Company is one of the foremost 3D printing machine manufacturers in the world. Its industrial FDM 3D printers have a 0.05mm accuracy, resulting in smooth, accurate models all the time. They rely on different materials, including nylon, PLA, ABS, TPU, PC, PET, PETG, and PC.

Besides, the company’s machines are approved by some of the best professional certification global bodies. A single Dreambot3D 1000X1000X1000 3D printer is suitable for multiple industries, including education, industrial design, automotive, aerospace, medical, manufacturing, and dental.

Other popular industries are mannequins, electronics manufacturing, and crafts and sculpture. Dreambot3D’s FDM 3D printer stands out because the company focuses only on the FDM technology and not any other. Therefore, it has perfected its printers, making them stand out from the crowd.

FAQ guide

How do FDM 3d printers work?

Fused deposition Modelling {FDM} printers or Fused Filament Fabrication {FFF} printers {as they were formally known till the FDM term was trademarked by Stratasys in 1991; the company behinds its first design} are machines built to deposit melted material in a pre-determined path layer-by-layer selectively.

Fused Deposition Modelling {FDM} printers are 3D printing machines that create images one at a time. FDM printing process revolves around a three-dimensional output. Each layer of the material you are printing is placed on top of another again and again till a finished product is acquired.

The printing process begins after the modeling software slices the 3D CAD file creating an extrusion path for the nozzle to follow. All necessary support needed by the object is factored into the extrusion path, and the nozzle movement is controlled via the interactive interface found on the machine.

What are the benefits of additive manufacturing?

Additive manufacturing simplifies the printing process to an extent where even the average joey can enjoy an out of the box printing experience. Additive manufacturing aids users in printing assemblies as a single piece. That’s you get to save money from every printing process.

Additive manufacturing also gives users the opportunity of printing multiple movable parts as a single piece. Compared to other conventional manufacturing processes, additive manufacturing helps you enjoy a simplified yet highly accurate printing process.

Is 3d printing cheaper than manufacturing?

Yes. 3D printing is cheaper than manufacturing when printing 407 units at most. Unlike manufacturing, where the design is fixed, 3D printing makes it possible to change design details unlimited times. However, where more than 407 units are required, manufacturing is infinitely less expensive.

Is 3d printing good for mass production?

Yes. 3D printing is suitable for mass production since it helps one avoid traditional tooling methods. As a result, it reduces prototype and end-user product lead times. Users can also change the product design details quickly, reducing the time required to make a prototype.

Furthermore, where there’s a need for low-volume production, 3D-printed molds can drastically cut the printing cost and time. Therefore, 3D printing is excellent for mass production, both as a prototyping method and production method.

Can a car be 3d printed?

With all the advancing technologies and upgrades in 3D printing materials, believe it or not, you can now 3D print a car; several companies have been printing car parts for a while now. Even so, we still have to wait for a while before we find 3D-printed vehicles on the streets or from our car dealers. This is because most of the previously 3D printed cars are just prototypes or car parts.

What is the highest resolution 3d printer?

The highest resolution 3d printer is the 1000x1000x1000 3d printer. The highest resolution you can find in the 3D printers is 200 microns. Almost all printers on the market today can print at a resolution of 200 microns which will give you decent results or even better in terms of quality. Still, most 3D printers print at a resolution of 100 microns, which should give you satisfactory results.

Resolution is among the few factors you need to consider when assessing the quality of 3D printers.

What is the best industrial 3d printer?

When looking at the best industrial 3d printer, it is good to consider the brand reputation, application requirement, price, after-sales services, safety configurations, and materials requirement. Hence it is safe to say that our 3d printers are the best industrial ed printers in the market.

Our machines are made with quality materials. We pay attention to your particular needs. Even our prices for industrial printers benefit medium and small businesses that cannot afford the more significant 3d printers. Our 1000X1000X1000 3D printer is an example of a quality and effective industrial machine; it prints industrial-grade size, has high precision, is compatible with many filament materials, and is affordable. You can check our catalog for more of 3d printer price.

Is a 3d printer worth buying?

A 3d printer is worth buying, especially for creators, experimenters, makers, product development, and industrial manufacturers. 3D Printing has brought a lot of delight to the research and industrial field, also for recreation. This technology has made it easy and less time-consuming to develop prototypes and exact copies of objects and images.

How can 3d printing be used in manufacturing?

The manufacturing industry is always looking at new and innovative ways of working, and in recent years, 3D printing has been at the forefront. Advancements in 3D printing technology, equipment, and materials have resulted in the costs being driven down, making it a more feasible option for general manufacturing use.

- Low volume manufacturing

Moving across to 3D printing will make it possible for businesses to consider short-run part production, where focused product teams can launch new products more frequently. They will be able to work beyond the realms of their imagination and certainly beyond the restraints that come with traditional methods. It delivers an agile development process for physical parts and has the ability to accelerate the production and the time it takes to get to market.

- High volume manufacturing

3D printing is a technology that is developing and growing faster than most other technologies due to the way it can influence manufacturing processes and help businesses perform to a higher level. A production line that is set up for 3D printing is easier to alter than that of a production line for traditional manufacturing, making 3D printing a feasible option for many reasons.

Is it worth buying a 3d printer?

Yes. It is worth buying a 3D printer, whether you are a hobbyist, designer, or manufacturer. Hobbyists can quickly print objects of desire, such as models, for their enjoyment. On the other hand, designers can quickly develop prototypes of various products for testing on the market. Later on, they may change the design in line with the prevailing reception in the market. Similarly, manufacturers can create injection molds using a 1000x1000x1000 3D printer and create various products.

What is the most accurate 3d printing technology?

The most accurate 3D printing technology is material jetting with a ±0.05mm to ±0.1mm dimensional tolerance. However, the objects created from material jetting are not as durable as those from FDM.

Why is my 3d print rough?

If your 3D print comes out rough, it usually is because of two things: Either your heating bed is set too high or over-extrusion. So how do I fix this problem?

- Reducing the layer height is among the major fixes that will ensure your prints are smooth.

- Lower your print speed till the issue has been resolved. It also helps in ensuring you create a more accurate model.

- Check if your temperature is set too high; if they are, reduce the printing temperature. Excessive high temperatures can cause the filament to be more melted.

- Use the suitable filament. Using substandard filaments will form your prints rough.

- Improving your cooling system can improve the quality of your print; it hardens the model swiftly.

How durable are 3d printed items?

It can depend on what material you use, but even cheap abs and PLAis extremely durable. For seriously strong stuff, you can use PETG, Polyflex, Polymax, and flexible materials. But yes – parts are as good as commercially produced parts, in many cases stronger and lighter.

To a large extent, for FDM machines, it depends on the orientation you print them in.

So the same part can be printed in different orientations, and one will be weak and break easily, and the other will be strong, flexible, and hard to break. Getting really good 3d printed parts is as much an art as a science.

How much does an industrial 3d printer cost?

Buying an industrial 3d printer is a serious investment that one should not take for granted. An industrial 3d printer can cost you from $10,000 to $100,000. The prices of these machines differ depending on the unique features and the size.

So, before you commit yourself to buy a 3d printer, you need to decide what you want to use it for, what features you need for your industry, and your budget. These factors will help you decide the best range of 3d printers.

Conclusion: Why our FDM 3D printer is the best choices

At this junction, we believe you have all the information you need to make a sustainable 1000X1000X1000 3D printer purchase. From the industries where FDM 3D printers are widely used to the dos and don’ts involved in purchasing An FDM 3D printer, we’ve covered it all.

However, this buying guide wouldn’t be complete if we don’t direct you to our catalog. Dreambot3D is a 3D printer manufacturer dealing in industrial and small FDM 3D printers. We offer worldwide delivery service. If you are looking to arm your production line with a 1000X1000X1000 3D printer notable for reliability, efficiency and portability, we recommend you visit our catalog.