Medical Device 3D Printer

Medical device 3D printing allows users to print high definition 3D objects with the 3D printer. Medical device 3D printing is mostly found in medical, dental and educational industries.

How 3D printers work for Medical Device

3D build

Device

3D printing

Device

using

Device

The flexibility of 3D printing allows designers to make changes easily without the need to set up additional equipment and tools.

Medical devices produced by 3D printing include orthopedic and cranial implants, surgical instruments, dental restoration such as crowns and external prosthetics.

Unlike traditional methods in which products are made by shaping raw materials into a final form by carving, grinding or molding; medical device 3D printing creates 3D objects by building successive layers of raw materials with a high speed.

Medical devices with complex shapes such as prosthetics can easily be printed with the 3D printer.

3D printing allows a whole product to be fabricated at once while other techniques may require several parts to be fabricated separately and welded together.

Medical Device 3D printers for your Choice

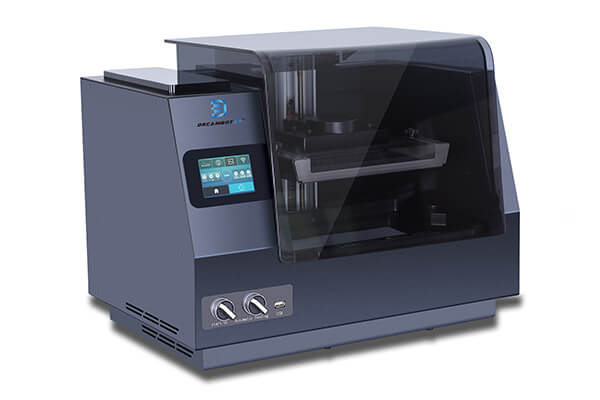

LCD 3D Printers

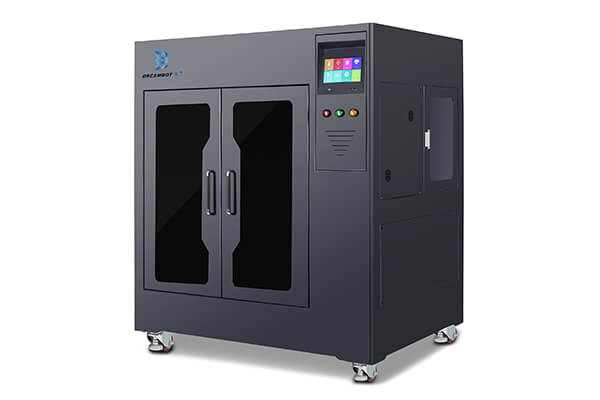

FDM 3D Printers

Don't know how to choose a model?

Are you confused about how to choose the correct model and type of 3d printer? We support 24/7.

4 points why choose us

4K resolution printing

4K black-white industrial screen, 0.01-0.05mm layer thickness accuracy, more accurate printing of details.

PLC control system

All 3d printers are equipped with PLC control system as standard, makes the operation more convenient, and reduces the error.

Extremely speed printing

Large printing size, 20mm/h printing speed, complete your printing tasks faster.

Reinforced structure

The all-metal one-piece shell reduces resonance, makes printing more stable and improves printing accuracy.

What our customers say

How 3D printers are used in medical device manufacturing - Medical device 3D printer buying guide

At a highly growing rate, the medical industry across the globe now recognizes the true importance of 3D printing, or you can say AM- additive manufacturing. They are using this modern printing technology for different types of medical applications.

For example, 3D printing is now utilized to develop more functional and advanced surgical drill and cutting guides, prosthetics, orthopedic implants, and craft patient-specific replicas of bones, blood vessels, and organs. With time medical device 3d printing has emerged as the crucial factor for the global medical industry.

As per a study conducted by Wohlers, around 14 percent of revenue related to 3D printing comes from the companies who are involved in the medical industry. More than 25 different implants, including knee, spinal implants, hip, and more approved by the FDA- Food and Drug Administration are manufactured using 3D printing technology.

On the other hand, till now, more than 110,000 hip cups of acetabular implants have been manufactured by using 3d printing devices. Well, all these milestones have continued to reinforce the crucial role 3D printing plays in the global medical industry, where customized or tailored products can be manufactured.

3D printing- Changing the way medical devices are manufactured

Speaking about 3D printing, this is one type of additive manufacturing. You will find different types of additive manufacturing; however, the terms additive manufacturing and 3D printing are generally utilized interchangeably.

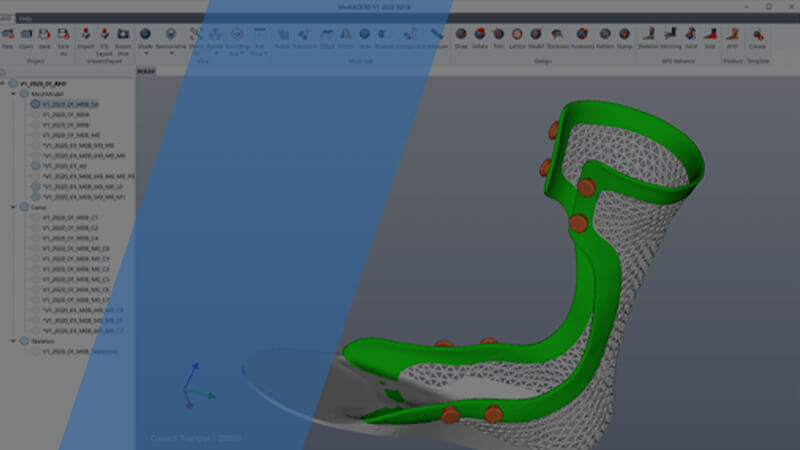

Under the printing technology, different three-dimensional objects are created by building successive layers of raw material. Every layer of the melted material is attached to another layer. The process continues until the whole object is complete. In this process, the 3D objects are manufactured using a digital 3D, for example, the MRI- Magnetic Resonance Image or CAD- Computer-Aided Design.

In the medical industry, the flexibility of 3D printing lets the manufacturers to make any alteration quite easily without investing in any additional tools or equipment. Besides, this technology has helped the products to craft various medical devices, matching the patient’s anatomy. Besides, using this, you can now create devices having very complex and detailed internal structures.

Such amazing capabilities have sparked a massive interest in the utilization of 3d printing medical devices. Besides, there are some other products also such as food, household items, and automotive parts.

Different medical devices manufactured using 3D printing technology include orthopedic and cranial implants, dental restorations, like crowns, surgical instruments, external prosthetics, and more. Due to its maximum level of versatility, this printing has medical applications in:

- Different medical devices are regulated by the FDA’s CDRH- Center for Devices and Radiological Health.

- Different product regulated by FDA’s Center for Biologics Evaluation and Research

- Drugs regulated by FDA’s Center for Drug Evaluation and Research

It can be said that 3D printing has improved the understanding of medical professionals about their patients and enhances the comfort level of the patients by interacting with the products that are developed for their anatomy.

If you are planning to set up a 3d printing medical equipment manufacturing business, then you will have to buy the best 3D printers that can offer you maximum performance. When you search, you will find a lot of options, and choosing the right one can be a very challenging task. Well, don’t worry at all as here you will get all the important information about the 3D printers and will explore some major factors that you need to consider while buying them. So, let’s get started with this.

Application of 3D printer in the medical industry

Precision medicine and personalized medical care are on the rise. On the other hand, advanced technologies and new tools are bringing doctors across the world closer to patients, delivering treatments and devices customized to better serve each unique individual.

There is no doubt that rapid advancements in medical 3D printing technology have made significant contributions in the field of healthcare. For the patients, new tools along with different therapeutic methods developed through 3D printing technology can bring a whole new degree of comfort as well as the personalization to treatment.

Besides, for doctors, 3d printing medical equipment allows for a greater understanding of different complex cases. Similarly, the technology provides them with new tools that can result in a higher standard of care.

1.1, 3D printer for dental

3D printers have hugely contributed to the current enhanced dentistry processes. In the dental industry, there is a requirement for a good customization level. Earlier, this particular industry relied on the manual method for producing custom solutions.

However, now the things have changed using 3D dental printers. One can produce different things, such as surgical guides, orthodontic models, biocompatible dental products, pressable restorations, and more.

The age of digital dentures

Instead of utilizing time-consuming and labor-intensive processes, most dentists are now going for 3D printing or digital denture. The process now involves minimal steps, leading to a consistent workflow with a superior quality product. What’s more, using this technology, you can make modified dentures in a few hours. Some experts have suggested that in the coming years, the dental industry will witness more than 50 million dentures produced through 3D printers every year.

3D printing technology and mass customization

There is no doubt that 3D printing is the ideal solution to produce customized items, not just for the dental sector but for all industries. However, it becomes more relevant when talking about the medical sectors as it enables some significant realizations such as prostheses.

As per the expert dental 3D printing is the key to modern dentistry, as it is helpful for different dental labs located across the globe. With time, the demand for digital dentistry is increasing at a higher rate. As we said, it is an easy way to get customized dental items.

On the other hand, digital dentistry is time-saving and cost-effective. For instance, if the 3D printed product doesn’t fit, then you can just change the digital design and reprint the item. There is no need to repeat the entire process as you will have with injection molding.

3D printing helping the dental professionals

- 3D printed braces with LED lights

A group of researchers from the King Abdullah University of Science & Technology, located in Saudi Arabia, has developed smart 3D printed braces. The primary purpose of the braces is to straighten and align your teeth faster, thanks to the LED lights installed in the braces.

The braces are semi-translucent and have a battery on each tooth to power the light. The energy will help your teeth to move faster. In case you are wondering, the light can’t be visible to the naked eye, well it is a unique process. The researchers have used non-toxic lithium batteries. On the other hand, the flexible properties of such braces make the process safe and comfortable.

- Repair or replace the damaged teeth

Using advanced 3D printing technology, the dentist can now scan the patient’s mouth using the 3D scanner. That will make a clear 3D image of the gums and teeth. The image filed will be saved on the PC.

Now, using a CAD- Computer-Aided Design software, the dentist can digitally design the tooth repair and print the finished product or a duplicated tooth using the dental 3D printer. The entire process will take a few hours to get complicated, and you don’t have to do multiple visits to the dental care center.

- 3D printed dental aligners

The dental 3D printing application can be seen in the case of the 3D printed models for the creation of patient-specific aligners. Different dental solutions, for example, Invisalign, utilize resin 3D printers to create highly accurate models of teeth. Then these models are used to create clear aligners.

This is an example of the process of indirect 3D printing. In the case of 3D printing, to create dental aligners, the dentist first obtains a scan of the mouth’s inside part using a scanner. The data obtained by scanning is converted into a CAD model. A 3D printer uses that CAD file to create the object.

- 3D printed casting patterns

Another excellent indirect 3D printing dentistry is the 3D printing of different types of patterns for casting. The experts can use those patterns to cast different items, for example, copings, bridges, and crowns. Well, dental experts have been using casting for years before the introduction of 3D printers.

However, now, the technology has streamlined the process, enabling dental technicians to come up with improved end products. Dental patterns are 3D printed, adequately cleaned up then utilized for the investment casting.

Besides, 3D printing can also be utilized for the fabrication of full arch models or bridge and crown models that are 3D-printed.

1.2, 3D printer for human organs model

As discussed above, 3D printing is all about fabricating different types of physical models from a 3D volumetric digital image. Professional software is used to slice the design and the printer print the design using different material.

The technique has been used to 3D print different surgical models as well as in developing personalized prostheses. Now, the ultimate goal is to develop functional human tissues and organs. This will help the medical industry to overcome the current limitation of organ transplantation.

Well, you can consider the example of bioprinting. Speaking more about it, under this method, cellular structures can be created from bioinks using stem cells. The required biomaterial is filled layer by layer for skin, organs, and tissue. With time, the demand and popularity of bioprinting are growing. On the other hand, each new project takes the experts one step closer to create a fully functional solution.

Different research centers and laboratories are now bioprinting hearts, kidneys, and livers. The primary objective is to achieve effective long-term solutions and 100 percent successful transplantation. This method can be used to solve the issue of the lack of organ donors, and doctors can study the diseases better. Now, let’s talk about some 3D-printed body parts or organs.

- Bio-printed heart

Some Israeli researchers have presented a bio-printed heart having the size of a cherry. That organ has blood vessels, chambers, cells, and ventricles. As per the report, they created the hydrogel from the fat tissue of the patient. This helped them to lower the risk of rejection after the implantation. The entire printing process took around 4 hours. It may be noted that an American company also has witnessed success in 3D printing a miniature human heart consisting of cavities and ventricles.

- Kidney bioprinting

Director of the Wake Forest Institute for Regenerative Medicine, Professor Anthony Atala, in the year 2011 developed kidney made using bioprinting. The team managed to design the organ within just 7 hours. In a similar case, researchers at Harvard have bio-printed an accurate 3D model of a vascularized proximal tubule. The model helps in understanding the function and the structure of the kidney.

- Bioprinting corneas

As per data presented by the WHO- World Health Organization, more than 12 million people across the world need surgery to avoid corneal blindness issue. In fact, around 5 million people are suffering from complete blindness caused by corneal scarring. Well, 3D printing has created hope in this.

In the year 2019, a team of scientists from the University of Newcastle managed to create an artificial cornea using 3D printing and can be used for transplantation. Well, the challenging aspect was utilizing the ideal material that can hold the shape and developing an ink thin enough to apply through the nozzle of a 3D bioprinter.

- Mini liver bioprinting

A team of scientists from the University of São Paulo, located in Brazil, have created miniature versions of a human liver. Well, for that, they took around 90 days to collect blood for tissue production. The organoids of the liver are developed through bioprinting and integrate different functionalities. For example, secretion of bile, production of necessary proteins, and the storage of different vitamins. To develop liver tissue, they used the 3D bioprinter manufactured by CELLINK.

1.3, 3D printer for medical device

With time, the medical device industry has started understanding the true power of 3d printed medical tools. Using this, they can easily optimize the instruments and design implants. Now, the industry is utilizing 3D printing to lower the number of processing steps as well as components used in a device. As a result, the manufacturing cost has gone down.

The global healthcare industry can leverage the power of this technology to propel innovation while introducing some revolutionary medical devices to offer enhanced patient care. However, now the global spine industry is using 3D printing to come up with different revolutionary products that propel bone ingrowth. As a result, it will improve implantation.

3d printer for medical devices has eliminated some manufacturing steps, making the process cost-effective. Do you know what are the leading medical device manufacturers frequently asking when it comes to orthopedic-related products’ 3D printing? Since the introduction of this technology, it has been used by various industries for their large-scale production.

But there are still some companies that need an experienced partner who can help them in this. They need a partner who can optimize their process so that they can develop innovative products quickly. Well, if you are one of them, then you can always trust Dreambot3D.

What do you mean by the medical phantoms?

Speaking about the phantom, these are objects that are used as stand-ins for human organs, tissues, as well as other biological elements to avoid an actual person being subjected to any risk. Medical phantoms have different uses, such as testing different medical imaging systems or teaching and training the surgeons or doctors about different diseases along with various surgical procedures before they deal with any living subject.

For instance, 3D printing technology is used in pre-surgical planning at the UK’s GOSH to create various phantoms of organs in different medical settings.

During 2017, many hospitals in Dubai adopted this technique. Doctors and other health experts used the 3D-printed models of a patient’s arteries, and they managed to navigate their blood vessels to treat a bleed on the brain. Just like that, doctors from Northern Island’s Belfast in 2018 developed a 3D model of the kidney of the donor to practice the transplantation process of the organ before carrying out the actual operation. The experts have stated that leveraging 3D printing surgical tools and other elements can help the industry witnessed a promising result.

Discussing the current condition of 3D printing medical equipment

If you have brought your new hearing aids from a medicine store, they are most likely manufactured using a 3D printer. 3D printing has become an essential part of the medical sector and is being used to produce unique medical devices. Let’s discuss this with some examples.

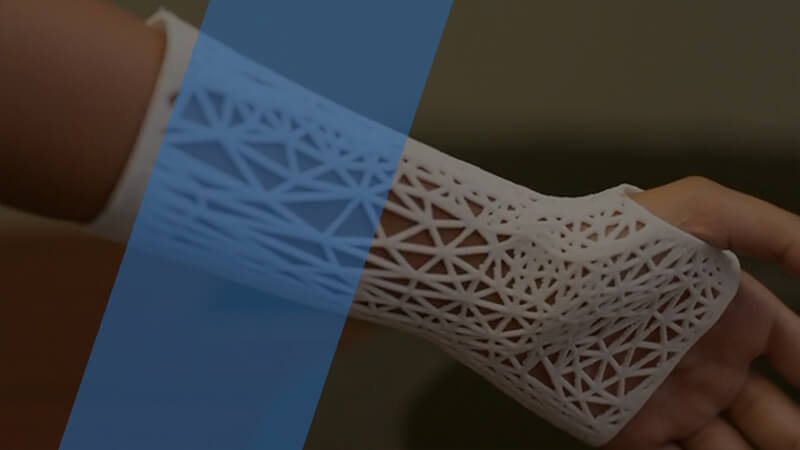

- Patient-specific prosthetics

A prosthetic needs to be developed specifically for the patient. A 3D printer enables such highly customized medical devices to be perfectly tailored for patients. And they also come under the patient’s budget. Some most common 3D printed prosthetics are arms and hands. In fact, there are some organizations, such as the e-NABLE Community who are focused on offering open-source and low-cost prosthetics made using 3D printing.

- Biodegradable stents

People suffering from arterial diseases require a biodegradable stent in order to keep open their blocked arteries. The most advanced technologies and cutting-edge research have been utilized to create sugar-based stents using a 3D printer that can help the doctor in surgical procedures.

- Patient-specific implants

You all know every person is unique, and that’s why using an implant on a specific person can be a harmful as well as a costly process. However, 3D printing technology has enabled the implant to be adapted to the patients’ body by conforming that implant to the 3D models.

These can be produced with the help of different medical imaging technologies, for example, CT – Computer Tomography, NMRI- Nuclear Magnetic Resonance Imaging. A fantastic example is an implant by Ortho Baltic Implants that can be 3D printed through DMLS- Direct Metal Laser Sintering method.

- Surgical tools

All the surgical tools made through 3D printing offer better flexibility in design and lower production time. 3D printing medical devices can be fabricated or designed for particular functions. For example, some US Army and Navy researchers developed a surgical kit using 3D printing that includes tissue forceps, Kelly hemostat, scissors made of plastic and silver, retractor, and more. Medical device 3D printing can solve the supply chain issues.

So, it can be said that 3D printing medical equipment has considerable potential for treating some health issues that are present for a long time.

1.4, 3D printer for surgery guide

With 3D printing, you can manufacture all most things; for example, needle drivers, retractors, and more. Using this technology, you can manufacturer them within a few hours. In general, these tools are invasive in terms of function and not complex. 3D printing surgical instruments are subject to fewer regulatory issues and will not face any significant practical barriers. These devices have been used widely in the global healthcare sector.

The crucial advantage 3D printing holds in producing these surgical instruments is the fact that some modifications can be done to their designs, based on feedback from doctors and surgeons after using the prototype.

The speed and precision at which the product’s designs can be enhanced as well as printed means the required alterations can be carried out rapidly, within a few minutes or even hours. 3D printing has led to highly personalized and surgeon-specific tools, and they have created a cost-effective possibility.

Some surgical instruments, such as hemostats, retractors, and more, can be created on-site using a medical 3D printer by a doctor or surgeon. Surgical devise can now be easily updated through 3D printing. There is no such thing about one-size-fits-all.

As more doctors and health experts understand and have access to 3D printing, surgical device innovations will follow; for instance, with the development of tools to enhance certain functions for specific operative methods.

On the other hand, 3D printing is also helping in lower waste by adapting the print-on-demand model. It lets them 3D print their customized surgical devices only when required. There is no need to buy the devices in a large quantity.

A study published in the year 2018 in the National Center for Biotechnology, the US science journal, stated that the utilization of 3D printing to produce surgical instruments was more feasible. The benefits can be enjoyed without dealing with any extra cost. It may be noted that a full surgical set, including forceps, needle drivers, and other tools, can now be manufactured in an average time of six hours with the help of 3D printing.

How can the 3D printed surgical guides help?

It may be noted that 3D printed surgical tools greatly help in pre-operative planning and also in carrying out different types of mock surgeries. They enable pre-adoption of the different surgical instruments, for example, fixation plates, reducing the operation and enhancing the precision. It allows accurate reconstruction of body parts’ anatomic relations. So, the function of a particular body part can be restored.

Some significant advantages of surgical guides in surgery:

- One hundred percent accurate placement of implants, for example, the dental implants using 3D surgical guides.

- Lowering the surgery time as now all the surgical plans can be made on the spot. Just use the surgical guide and place the implants in their appropriate positions.

- Implantation can be done without suturing and cutting with the medical device 3d printing.

- There will be shortened rehabilitation period.

- With digital 3D modeling, you can easily make a surgery plan before the process of implantation. Besides, you can predict the final result.

Surgical guides can be used as a temporary rehabilitation while doing prosthodontics.

Application of 3D printed medical device

- Used to fix limbs

As per some reports, there are more than tens of millions of people and kids with missing limbs due to various reasons. As per the data given by Amputee Coalition, there are nearly 185,000 amputations carried out every year in the United States of America.

However, it has not reached around 2,000,000. Earlier, getting highly accurate prosthetics was a very costly task; not all people could afford those prosthetics. Based on the limbs, the cost of a prosthetic device can range between USD 5000 to USD 60,0000. So, it can be said that these are like luxury products for some people.

Kids without limbs are a special case. In their case, they need to replace their prosthetics when they grow. Besides, as they are kids, they can damage their artificial limbs. However, with 3D printing, artificial limbs can be created in cost-effective ways and faster compared to the traditional manufacturing process.

Comfort is a crucial factor that should be considered here. Most of the regular prosthetics can’t offer the maximum level of comfort to the users. A lot of people have complained about discomfort while using limbs and prosthetics made using the traditional method.

However, the 3D printing technology has helped in offering the ultimate solution utilizing the digital design or CAD services along with utilizing the wearer’s anatomical data. The manufacturers can now craft a socket for the prosthetic that will offer a 100 percent accurate fit.

Limbs can also be comfortable while utilizing 3D printing technology that uses different materials. As a result, you can now have a natural socket that will merge with the wearer’s body.

- Used to make prostheses

The truth is medical device 3d printing and 3D printed prosthetics are now widely available in the market. They have given modern medicine a new face. On the other hand, physicians and engineers are now working to create new-style and more functional prosthetics. The models can be easily customized, matching the users’ exact needs.

With the 3D printing in prosthetics, you can’t ignore the fact that prosthetic surgery is now available for all. Speaking about the traditional prosthetic method, it is very expensive and not available for all. Now, with 3D printing, you can go for affordable alternatives. One can easily change the CAD designs and print the model within a few hours. So, it has brought a practical and affordable alternative to the bionic hands.

Speed is another crucial factor that you should consider while talking about applying 3D printing in the field of prosthetics. Compared to the traditional alternative, 3D printing prosthetics can be developed faster.

Another essential factor to consider is versatility. Now, prosthetics can be developed to meet the patients’ preferences and requirements perfectly. Whether you are searching for customized color or want a prosthetic to function in a certain way, the medical 3D printers can create the design to fulfill the requirements.

What’s more? Medical device 3d printing can be easily customized. With time, 3D printers can get more compatible with different materials. As per different studies, the average lifespan of prosthetics made through the traditional process is up to 6 years. Considering the fact of children’s growth rate, they will need more prosthetics quite frequently.

Considering the cost of such a device, this can create a burden on the parents. However, with the reduced cost and ease of prosthetic production due to the 3D printing technology, now manufacturers can create more prosthetics for children. Now, it is a lot easier to get a prosthetic for your children.

When it comes to creating a high-precision prosthetic, you may not find a better option than the 3D printing technology. 3D scanning, as well as the new body modeling technologies, are the future of prosthetic product manufacturing.

An easy option to perfectly scan the limbs will lead to creating prosthetics that are highly accurate as well as functional. On the other hand, the experts have suggested that the prosthetic products of the near future will look more lifelike. That will be an excellent thing for the users.

What’s more? There will be a perfect movement in the modern age of prosthetics. That means the patients don’t have to think hard to operate their artificial 3D printed limbs. This is all possible because of modern 3D printing technology.

- Used to make various medical tools

Here are some common medical devices that can be 3D printed using a 3D printer

Tweezers

3D printing has enabled manufacturers to produce different types of tweezers with different sizes, shapes, and purposes. For instance, you can make curved tip tweezers, needle tip, flat tip, blunt tip, angled tip, and triangular tip tweezers.

These devices can be used in medical services to building electronic parts as well as mechanical parts. They can also be used to manipulate stamps to avoid damage from handling. Dental tweezers have become a crucial part of the surgical and medical equipment category covering all expenditures related to any instruments, machines, implant, and implementation used by doctors for monitoring, treatment, and diagnosis. With 3D printing, you can create hundreds of tweezers within a few hours.

Syringes,

The entire syringe model can be produced using 3D printing. Besides, this technology is mainly used to create a 3D printed syringe pump rack. Some of the significant features of a 3D printed syringe pump rack are; compact size, open software & hardware, high precision nut and screw, low cost, and simple to use. There is a considerable demand for syringes during the current situation, and this demand can be easily fulfilled through 3D printing technology.

Oxygen masks,

As the novel COVID-19 virus begins to spread across the world, healthcare workers are now dealing with a shortage of supplies, such as gloves, protective face masks, ventilators, and more. However, to help them out in such harsh conditions, Materialise, a Belgian company, has designed the 3D printed oxygen mask that can significantly lower the time patients are connected to the mechanical ventilators. They look like a mask and deliver pressure and oxygen to the lungs, and there is no need to use any ventilator. Speaking about the entire design, the oxygen mask includes a filter, a connector made by 3D printing, and a non-invasive mask.

Surgical tools

It has been proved that 3D printing can enhance the tools doctors and surgeons have been using in different surgical cases. For example, the claws or surgical graspers. These devices are designed keeping different factors in mind. For example, they need to be small enough for internal human purposes.

Besides, they need to functional, letting the doctors grab whatever they need during the surgery. Most importantly, the devices have to be manufactured using materials that are 100 percent safe for human applications. Well, 3D printing technology has made it possible and offered a substantial functional improvement.

One of the famous cases where medical device 3d printing has revolutionized surgery is the keyhole heart surgery. The experts knew that the task would be much easier and safer if they could create a tool that can be passed through the minuscule located in the heart. 3D printing technology has made it possible. The device can hold a small subsection of the heart while the surgeon operates.

Some other critical surgical tools or medical device 3d printing that can be manufactured using the 3D printing technology are medical clamps, needle drivers, retractors, hemostats, scalpel handles, forceps, and more. As these surgical tools are not that complex, they are subject to lower regulatory problems as well as practical barriers.

The impact and changes of 3D printers on the medical device production industry

3.1, What processes can 3D printers replace?

If you look at the traditional manufacturing process, you will find it time-consuming. Besides, you can expect 100 percent accurate results every time. However, with 3D printing, it is possible. Let’s take an example of the dental industry.

In the dental industry, 3D printing has simplified the dental production process. Dentists can scan the mouth, create the design using CAD software and then create the 3D model within a few hours.

Besides, there is no need to create molds to create different medical devices as you can directly 3D-printed those designs using resins or filaments. So, it can be said that 3D printers have simplified the production process and have replaced the manual product design process.

3.2, What’s the changes after the intervention of 3D printers

3D printing has dramatically changed the way we used to produce a product. Compared to the traditional manufacturing methods, now you can have a complete product within a few minutes using a 3D printer. Some significant changes that we have witnessed after the introduction of the 3D printers are:

- Rapid and 100 percent accurate prototyping

- Short production time

- Easy process to create the most complex shapes

- Need for customizability and adaptation

- Speed to market

- Waste reduction and more

There is no doubt that 3D printing technology is very useful. The machines are easily available. The experts have suggested that the technology’s further development will be more useful in the coming days.

3.3, Research on the advantages of 3D printers compared to traditional processes

In the global manufacturing and medical industry, 3D printing has been a significant focus for some years. The advanced 3D printing technology has lowered the overall cost, and now everyone can have a 3D printer, thanks to their low-cost factors.

Some studies also have proved that 3D printing can help you by saving around 50 to 60 percent of energy. Now, let’s discuss about the advantages of 3D printers compared to the traditional manufacturing process.

- In the production of the prototype

One of the significant benefits of 3D printing, compared to traditional manufacturing, is that the process doesn’t need any special tooling for parts production. While developing a prototype, you will save a lot of time as well as money along with your efforts.

Besides, suppose the prototypes reveal that the existing products need some changes. In that case, you can edit the design within a few minutes. There is no need to change the entire molds. The process of medical device 3d printing is faster and safe.

- In waste prevention

There is no doubt that 3D printing is resource-efficient. How? With the best medical 3D printer, you will use only the material that the nozzle processes. If you compare the process with injection molds, this process utilizes a complete metal sheet, and the products are cut out from the sheet. Even though you can recycle those metal sheets, the process will require more labor and time. You can produce more 3D models using less material.

- In terms of large-scale production

Well, this is a crucial point to consider. Once the prototyping phase gets completed and you are all set to start manufacturing the parts as soon as possible, you may not get the desired result with 3D printing. Well, even though these printers are best for rapid prototyping and have a shorter lead time, for large-scale manufacturing, you should always depend on the conventional production methods.

- Availability of different materials

The rapid advancement in the field of 3D printing has made it possible to create 3D objects using different metals, filaments, and resins. But remember that to use a particular material, you will have to buy different 3D printers.

For example, you will need an FDM 3D printer for filaments, and to print resins, an LCD 3D printer will work great. But all these machines can be brought at affordable prices. However, the important thing is that you will still have a massive option of different printing materials.

3.3.1, Introduction to the working principle and development history of 3D printers

As per the records, 3D printing was first introduced in the year 1981 by a Japanese inventor named Hideo Kodama. That helped in the SLA- Stereolithography printing technology. After a few years, another technology named Selective Laser Sintering came to the limelight. Talking about FDM 3D printing, it was introduced by Scott Crump.

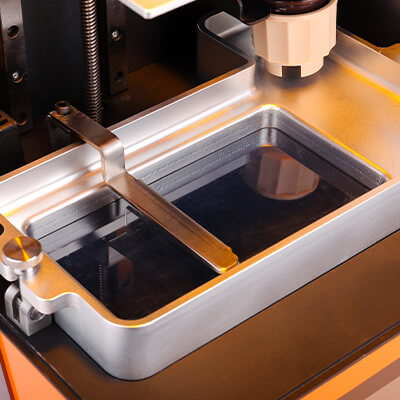

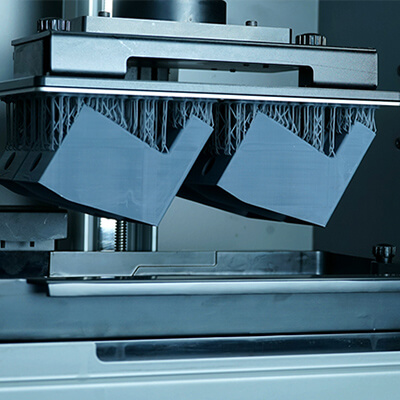

While both the LCD and FDM 3D printing can be used to manufacture medical devices, they use different working methods. First, let’s understand the working principle of an LCD 3D printer. Here, the users need to fill the tank with the desired resin. (You can’t use filaments with the LCD 3D printers).

After that, the machine will read the digital design file, and a light source will move through an LCD panel to create the pattern on the liquid resin. The part that comes into contact with light gets hard, creating layers. Once done, you need to remove the product from the build platform and carry out necessary post-processing.

Now, talking about the FDM 3D printers, they need filaments. The process starts with a CAD model. A slicing software converts the digital model into various slices and produces a G-code file. The 3D printer heats the filament and melts it, then extrudes the filament through the nozzle, creating layers on the build platform. Every layer can be 0.1mm to 0.10mm thick.

3.3,2. Analysis of the advantages of using 3D printing in the medical industry

To understand this, let’s have a look at three significant benefits of 3D printing technology.

- Patient-specific implants and personalized medical devices

3D printing can be used to create 3d medical devices and implants that are customized for the specific physiology of a patient. Customized, patient- and surgery-specific 3D printed medical tools and implants are being used in arm and knee surgery. As per some reports, surgeons from Yale Medicine have discovered that they speed up recovery time and lower the pain in the patients. Some significant development in patient-specific medical devices is customized airway stents, orthopedic implants, external prosthetics and more.

- Just in time production approach to the on-demand devices

Thanks to the speed of the 3D printers, now it is possible to produce devices in response to patient demand. If you follow the traditional approach for manufacturing a customized implant, this can take weeks or months. Combining with the possibility of personalized medical devices, the modern just-in-time approach can lead to faster production of on-demand personal devices. There will be low chances of complications and lower waiting times.

- Facilitates rapid medical prototyping

There is no doubt that 3D printing is much faster and cheaper than traditional manufacturing methods. As a result, the manufacturers can now rapidly print, design, and test the prototypes of their medical devices. Some companies have already started using 3D printing to rapidly produce and test their drug delivery equipment, such as injectors and inhalers. Traditional manufacturing methods can take weeks to create a new prototype. However, modern 3D technology lets you design and print the prototype within a few days.

How to choose materials

4.1, ABS {Acrylonitrile Butadiene Styrene}

ABS- Acrylonitrile Butadiene Styrene is one type of thermoplastic polymer. This printing material is famous for its impressive impact resistance. Besides, you can use it for 3d printed surgical and lightweight parts. This is an ideal material for an FDM 3D printer.

Talking about the melting point, ABS filament melts at about 200-degree C. So, while using it, make sure that the extruder temperature is between 230-degree C to 260-degree C. Furthermore, the heating plate’s temperature should be between 80-degree C to 130-degree C. As the ABS produces dangerous particles, you should buy a printer with closed enclosure.

Some impressive characteristics

- Cheap and widely accessible 3D printing material

- Available in different color options

- Compared to nylon, ABS demonstrate a longer lifespan

- ABS are mechanically strong

- Perfect for engineers and manufacturers who want to produce a high-quality prototype

4.2, PLA {Polylactic Acid}

When it comes to buying a popular 3D printing material, you can’t ignore PLA. Some factors like minimal warping requirements and ease of use make it an ideal material. Besides, this 3D printing material is also environmentally friendly and is biodegradable.

The material’s brittleness makes it perfect for low-stress applications, decorative and non-functional prototyping. The melting point of this material is around 150-degree C to 160-degree C.

While printing, the extrusion’s temperature should be between 180-degree C to 230-degree C. As it supports low printing temperature, it is less likely to clog the extrusion while printing. Furthermore, the 3D items produced using PLA will have sharper features and great surface details.

Some amazing characteristics

- Low warping and easy to print

- Can be printed on a normal or cold surface

- Can be printed with sharper features and corners

- Available in different colors

It may be noted that PLA-made products are not very solid, and under extreme heat, they can deform.

4.3, Carbon Fiber

Carbon fiber uses small fibers that can be infused into different base materials to enhance the material’s properties. Various filaments can be combined with carbon fiber, for example, ABS, nylon, PETG, PLA, and more. As this material is strong, it helps the filament to boost up its stiffness and strength.

As a result, the 3D models will be lighter and dimensionally stable. The material is resistant to heat and chemicals. So, this is wildly used for space and aircraft applications. With a high level of tensile strength and excellent thermal properties, carbon fiber mixed filaments are perfect for high-temperature solutions, for example, replacing the heavy composite tooling with autoclave-capable. Some of the popular carbon fiber composites are nylon carbon fiber, PETG carbon fiber, and ABS carbon fiber.

Some advantages are:

- The models will be lightweight

- Increased stiffness and strength

- Impressive dimensional stability

4.4, PETG

PETG, also known as glycolysis polyester, is one type of thermoplastic that combines the strength of ABS material and the simplicity of PLA 3D printing technology. The best thing about PETG is that the material is 100 percent recyclable.

Speaking more about it, it is an altered version of PET, and the G stands for Glycol. It is one type of molecule that is added during the process of polymerization to make the material easy to use and durable. PETG material demonstrates ideal mechanical properties and is resistant to chemicals, heat, and moisture. The melting point of the PETG is 260-degree C.

Some impressive characteristics are:

- Can be sterilized

- It is highly durable

- Recyclable and impact-resistant

- Demonstrates an excellent layer adhesion

4.5, Resin

Resin is a widely used material in the process of 3D printing. You can use this in DLP, SLA, and LCD 3D printing. Resins are also known as photopolymers that are very light-sensitive and can change their chemical as well physical properties when they come in contact with lights. Different forms of thermoplastics utilized in the FDM – Fused Deposition Modeling technology, photopolymers are generally thermosets. That means the material will strengthen when heated. Resin can be used to create objects with a higher resolution as well as a smoother surface finish. 3D printer resins are ideal for jewelry patterns, functional prototypes, and medical devices. Some of the commonly used resins are:

Standard resins

Such resins can offer you highly accurate features, and the products will have a super smooth surface finish. These are also available in different color choices. If you are looking for materials for prototyping, then go for this one.

Durable resin

This resin perfectly demonstrates the properties of PP thermoplastic and ABS. With this, you can attain strength, better durability, and toughness. The resins are ideal for low-wear and low-friction mechanical parts, functional prototypes, and consumer products. Besides, they also have semi-flexible properties.

Flexible resin

Using this, you can create flexible parts having a soft rubber-like feel. You can bend and compress the resin to create wearables prototypes, squeezable models, grips, and more. This is also useful for jewelry and fashion application.

High-temperature resin

The products made of high-temperature resin can withstand a temperature of more than 200-degree C. Due to their excellent thermal properties, the high-temperature resins can be used for creating tooling for short-run injection molding, thermoforming, fixture, and jigs.

Castable resin

It is also called jewelry printing resin. You can utilize this for the finished ring and direct investment casting. It is a cost-effective option to produce intricate patterns for investment casting. During the process, a ceramic mold is created around the wax pattern. When the mold solidifies, wax is burned, and the molten metal is applied to the part.

Dental and medical resins

If you want to create parts with biocompatible properties, then these resins are the perfect material. These resins have been used for 3D printing surgical guides, prosthetics, hearing aids, crowns, and more. You can also use a long-term biocompatible dental resin that can be utilized in creating orthodontic devices.

Major characteristics:

- Can be used for various applications.

- Demonstrates a low level of shrinkage.

- High chemical resistance.

- Rigid and delicate.

How to choose a 3D printer for the medical industry

Dentists, students, doctors, and surgeons, everyone is well acquainted with this kind of printing. Do you know that 3D printing has become a major tool in the medical industry? As a 3D printer manufacturer and supplier, we always see many new medical projects developed using resin, PVC, or FDM 3D printing.

But when it comes to buying a machine, you will find a lot of options that can create confusion about which 3D printer to buy. So, how to pick the right one for your medical project? Well, don’t worry at all as we have mentioned down some valuable tips that you can consider. Have a look.

5.1, What is the size of the print

The very first rule of buying 3d printing medical devices is the size of the print. That means you need to know the size of the item that you want to print. For instance, if you want to make dental products, they will be very small in size.

However, in the case of medical models, the print size will be a little large. Now, if you search for a 3D printer, you will come across two options, i.e., LCD 3D printer and FDM 3D printer. So, which one to choose? Well, for a small-sized object, you can buy an LCD 3D printer.

For 3D printed ventilator medical, you can go for an FDM 3D printer. While buying, don’t forget to check the built platform. As per the experts, the built platforms should be big enough to accommodate your object. If you are feeling confused, then trust the 3D printers manufactured by Dreambot3D.

5.2, Choose a reliable brand

3D printers are not an affordable product, and you will have to spend hundreds and thousands of dollars to get one. That means, while buying one, you need to make sure that you are getting a quality machine with all the necessary features.

If you choose an unknown brand here, you may get a 3D printer at an affordable price, but the result will not be satisfactory. So, it is always advisable to choose a reliable brand. For example, Dreambot3D. 3D printers purchased from a reputed brand can work for years without developing any issue.

On the other hand, in terms of performance, you will find them just amazing. Furthermore, you can only enjoy 24×7 customer support with a reliable brand. Now, you might be thinking that how to make sure that the brand is reliable or not? Don’t think much and go for Dreambot3D. We have been in this field for years and famous for our 3D printers.

Not just for medical device 3D printing, our machines can be used for different applications like education, automobile, aerospace, infrastructure, jewelry, and more. Besides, our machines are very safe to use, and you can use different types of resins. When you buy a printer from a reputed brand like Dreambot3D, you can expect faster delivery. So, what are you waiting for? Get in touch with us now and get a free quote.

5.3, Safety configuration of the machine

All the 3D printers come with moving parts that can create problems while operating. Besides, there are belts, gears, built platforms, motors, and more such parts that can develop injuries. On the other hand, a 3D printer has an extrusion tip that turns very hot while printing. In fact, the temperature can go up to 300-degree C.

In 3D printing, you generally use filaments and resins that may release VOCs, which are harmful to animals as well as humans. So, always choose a printer that comes with an enclosed structure.

What’s more? There should be the auto-off and heat control feature in the 3D printer. Dreambot3D is quite famous for offering safe-to-use 3D printers at the best prices. Moreover, we design and develop 3D printers keeping all the necessary safety features in mind. Check out our products now.

5.4, Resolution requirements of the machine

Setting up a proper resolution on your 3D printer will significantly reflect the 3D model’s appearance, printing time, and precision. If you are creating a 3D model with highly detailed parts, you should focus on the resolution.

For example, if you are making a 3D prosthetic part, it should have a better resolution. So, ensure that the 33D printer is designed to support different printing resolutions. The resolution is based on the X, Y, and Z dimensions.

Horizontal resolution (XY) is also called the planar dimension. The smaller the movement of the laser, the much better the 3D model’s details will be.

Vertical resolution (Z) is the layer height, or we can say the thickness of the layer. If the height of the layer is small, you can witness a high resolution. Choose a printer where you can configure the laser movement. However, if you want a better detailed 3D item, then buying Dreambot3D’s LCD 3D printer will be a better option, and they can form 0.155 mm of thickness. If you are not concerned about details and resolution and want a robust product, go for an FDM 3D printer.

5.5, Consider whether the price of the machine is acceptable

With time, more and more hospitals are now using advanced 3D printing technology to develop different medical devices. Using this, they can create a model within a few hours. But remember that not all 3D printers are designed for 3d printing medical equipment or 3d printing surgical instruments.

Different 3D printers will come with different features. For example, while some printers will support different printing materials, some will offer you better speed. So, while buying, make sure that the 3D printer has good features. You can expect good resolution, better speed, and more.

Besides, make sure that the machine supports a constant heat generation feature. If you think you can’t get all these features under your budget, then have a look at the 3D printers offered by Dreambot3D.

5.6, Consider the supplier’s after-sales service capability

After-sales service offered by the 3D printer supplier will matter as you are buying a machine with multiple small parts, and they can create an issue without any notice. The technical issue can significantly affect your printing process.

So, you will need to resolve it as soon as possible. It can only be possible if the company offers 24×7 hours of technical support and faster after-sales services. Well, for this, you can trust Dreambot3D. When you have Dreambot3D’s 3D printers, you don’t have to worry about its after-sale service and keep using the machine confidently.

5.7, Consider the service life of the machine

As you will be spending around USD 6000 to USD 25,000 on a 3D printer, buying a 3D printing machine is a costly investment. So, you need to ensure that the printers are of perfect quality and are ready to run for years without developing any technical issues.

As per the experts, the average life of a 3D printer is around 5 to 10 years. But how to choose a machine that can last so long? This where you can trust Dreambot3D’s 3D printer. Well, we would like to suggest you to opt for proper maintenance of the machine for a longer lifespan.

5.8, Consider the maintenance cost of the machine

Like your other machines, your 3D printer also requires regular cleaning and maintenance. Every 3D printer manufacture has provided recommended maintenance tips that you can follow to keep the machine running smoothly. Do you know that around 60 to 75 percent of downtime in the 3D printer is caused by lack of regular maintenance!

But you need to make sure that you are spending a lot of money on this. Choose a machine that needs less amount of maintenance, for example, LCD and FDM 3D printers of Dreambot3D. Just take a little care of the machines, and they will never fail to offer you the quality 3D printing result. To know more about our 3D printers, you can call us now.

FAQ guide

What medical devices can be 3D printed?

The advancement and introduction of advanced 3D printers have helped a lot in the field of medical equipment 3d printing. In fact, one can now print anything using digital design files. However, let’s talk about some significant usage of 3d printing devices, and these are:

- Human organs and tissue

- Different surgical instruments

- Orthopedics implants

How much does a medical device 3D printer costs?

Well, you would be happy to know that now you can get a 3D printer under your budget. As per the experts, almost all entry-level 3D printers come under a price range of USD 200 to USD 500. If you go for more high-end editions, that can range from USD 1,500 to USD 6,000. But, the features and specifications available with the printers will influence the cost of the printers. However, suppose you are in search of quality printers to create FDA-approved 3d printed medical tools; in that case, you can always trust Dreambot3D. All our printers will come under your budget.

How does the medical industry use 3D printing?

There is no doubt that 3D printers have become a crucial part of the global medical industry. Well, to understand this, we can consider the following points.

- For developing orthotics, prosthetics, orthopedic insoles, and more

- 3D printed models for training

- 3D printing adapted medical tools

- COVID-19 emergencies

What is the medical future of 3D printing?

Different studies and rapid integration of 3D printing technology have created a massive opportunity in the global medical industry. As per the SmarTech Analysis report, the value of the 3D printing market for the medical industry is around USD 1.5 billion. However, the firm has projected that it would reach USD 6.08 billion by the end of 2027. It is clearly showing that the potential for 3D printing within the healthcare sector is huge. Different sectors within this industry are greatly benefiting from the 3D printing technology. That covers dental, orthopedics, and more. This advanced printing technology offers some exciting new ways to provide highly personalized care as well as manufacture high-performance medical devices, enhanced surgical tools, medical and dental devices, and dental 3D printing.

What is the most commonly 3D printed thing?

While anything now can be 3D printed, there are some areas where there is massive use of 3D printing. In the field of medicine, this technology is used to create 3D-printed prosthetic limbs and other body parts. What’s more? Now it is quite easy to create homes and different types of buildings with the help of 3D printers. Another common 3D printed thing is edible 3D printing. Just like the traditional cake decorating methods, in 3D printing, edible materials are pushed through a needle to form one layer at a time. You cannot ignore the usage of 3D printing in firearm manufacturing. The fantastic thing about 3D printing is that the technology can be utilized to craft just about anything your mind can imagine. All you need is to buy the best 3D printers from Dreambot3D, and you are all set to go.

Where is 3D printing used in medicine?

In general, 3D printing is widely used to create patient-specific surgical models. Experts use scanned data to create multiple 3D-printed anatomical models. These are becoming very useful in the practice of precision and personalized medicine. Now, new medicines can be produced within a few months, compared to the traditional methods, where for one medicine, scientists used to spend years. 3D printing devices have brought a revolution in this area.

Who invented 3D printing?

Talking about the first 3D printer of the world, it was developed by Charles W. Hull during the 1980s. The machine utilized stereolithography printing technology. In general, stereolithography has been an expensive commercial technique, and the machine can cost five to six figures. However, now one can buy desktop professional stereolithography printers for 3d printing medical equipment from Dreambot3D by spending a few thousand dollars. In the year1986, 3D Systems, established by Hull, a company that sells 3D printers that used different types of technologies.

What are 3D printed medical devices?

As the name suggests, 3d printing medical devices are manufactured using a 3D printer for specific purposes. The greater level of flexibility of this technology lets the designers alter the products quickly without setting up additional equipment or tools. Now, it is possible to create 3D-printed body parts that work great. Besides, it is also widely used in the dental industry. With robust growth in personalized and precision medicine, there is a huge demand for patient-specific and bespoke medical applications customized to their anatomy. Some of the example of the possible use of 3D printing for medical purposes:

- Anatomical models for education and surgical planning

- Customized prosthetics and implants

- Organ and tissue fabrication

- Pharmaceutical research covering drug dosage forms and discovery

How many hospitals use 3D printing?

Well, there is no such accurate data about this, but it can be said that 3D printing is a crucial part of the medical industry. Different reports have shown that the number of U.S. hospitals with a 3D printing facility has gone up, from just 3 in the year 2010 to above 100 by the end of 2019. As 3D printing technology is evolving, this point-of-care model is also becoming more widespread. It may be noted that in 2018, the market size of the global 3D printing healthcare market was valued at $973 million. Now, it is estimated to reach USD 3700 million by the end of 20226. Besides, the market’s compound annual growth rate would be around 19 percent.

How is 3D modeling used in medicine?

3D-printed models and parts have been used in the different medical areas, including accurate replication of anatomy, pathology to help pre-surgical planning, simulation of complex surgical methods, and more. They serve as a crucial tool for the education of both patients and medical students. Besides, such models have greatly improved the communication between a doctor and a patient. On the other hand, 3D printed models are used as an affordable tool to create optimal CT scanning protocols.

Is 3D printing used in healthcare?

Yes, in fact, this technology and different 3d printing devices have helped doctors or surgeons to carry out some of the most complex treatments easily. In this industry, 3D bioprinting is utilized to form living human cells as well a tissue. These are used in tissue engineering and regenerative medicine. Envision TEC and Organovo are the leaders of 3D bioprinting. On the other hand, it is used in producing personalized and highly precise pharmaceuticals. Remember that the FDA can’t regulate the 3D printers, but the FDA has the right to regulate medical devices that are made using 3D printing.

When was 3D printing first used in medicine?

3D printing technology for medical purposes was first used during the 1990s for custom prosthetics and dental implants. Eventually, in 2008, scientists were able to produce the first 3D prosthetic leg. In the year 2012, the scientists 3D Printed a Jaw. It may be noted that Spritam for epilepsy by Aprecia Pharmaceuticals is the first FDA-approved 3D printed drug. The company used a method called ZipDose. The method stitches together different layers of powdered medication utilizing an aqueous fluid to create a porous.

How strong are 3D printed parts?

Well, this will depend on the type of 3D printing technology and materials used to create the parts. For example, the FDM printing process can create a vital part of LCD 3D printing. On the other hand, for a durable part, you can use PLA material as this is the most robust material used in 3D printing. The tensile strength of this material is around 7,250 PS.

Conclusion – Dreambot3D provides a one-stop solution for the medical device manufacturing industry

There is no doubt that high-quality medical equipment products are getting more and more challenging. Most of the products are manufactured with a maximum level of efficiency from the perspectives of design as well as production.

This is generally translated into different elements that require fined details, small in size, and outstanding accuracy. This is where Dreambot3D comes to play. When you are with us, you can explore our massive range of 3d printing medical equipment.

Speaking more about it, 3D printing in the global medical industry is effortless, i.e., revolutionizing healthcare. By crafting multiple patient-specific models, doctors or surgeons can prepare for the treatment and will be able to operate with a maximum level of confidence and efficiency.

They can validate the performance of the devices on patient-centric 3D printed models. Based on patient imaging, the models created through 3D printing can easily mimic different properties of tissue. Dreambot3D high-quality medical 3D printers can help you in accelerating your product development process.

If you are planning to establish your own medical device manufacturing unit and looking for an affordable yet quality 3D print, you can always trust Dreambot3D. When you are with us, nothing can stop you from witnessing the real power of 3D printing technology.

We have been working in this field for years, and we have become a reliable 3D printing solution provider. Our 3D printers are designed to take your manufacturing process to the next level. What’s more? All our printers come equipped with advanced features. We understand how 3D printing technology is changing the production process of different sectors.

Moreover, we understand how 3D printing technology is changing the medical industry. Besides, there is a rising demand for efficient and feature-loaded 3D printers. So, keeping all these things in mind, Dreambot3D has introduced high-quality and feature-loaded 3D printers. Dreambot3D’s 3D printing medical solutions perfectly combine proven and tested innovative technology, services, and 3D printing materials. We offer the economic tools and values required to print medical products.

Why Dreambot3D 3D printers?

By choosing Dreambot3D, you will be able to witness the unique world of 3D printing solutions with some fantastic benefits.

- Elimination of tools

- Decreased waste of material

- Flexibility in designing as well as manufacturing

- Faster printing machines

- Good after-sale services

- Customized manufacturing options, like prostheses, hearing aids, implants, and more

- Budget-friendly FDM and LCD 3D printers.

- Machines that support different types of resins

If you want to know more about our printers, then feel free to get in touch with us now. We are all here to support you in revolutionizing your medical device manufacturing process with our 3d printing devices.