Airplane Model 3D Printer

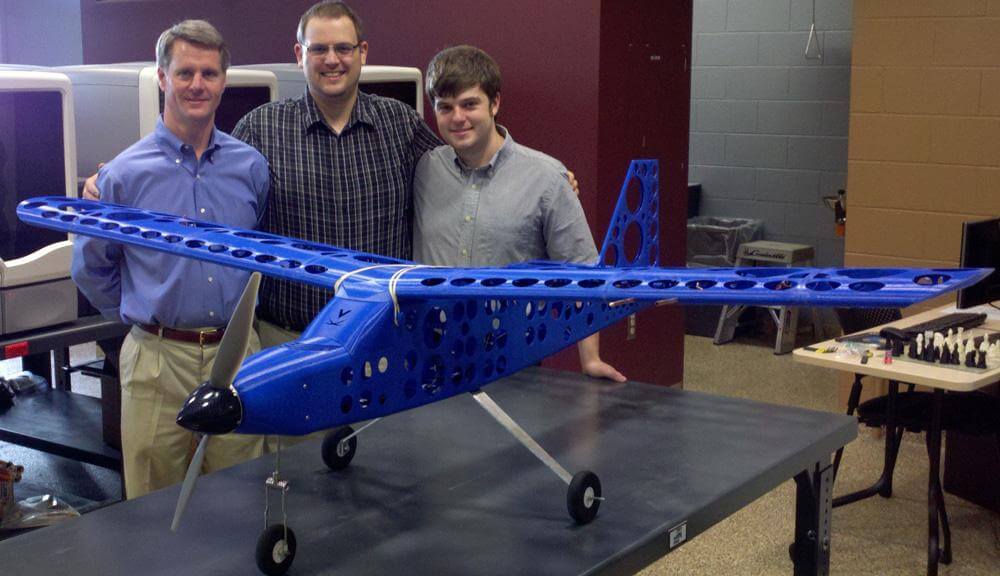

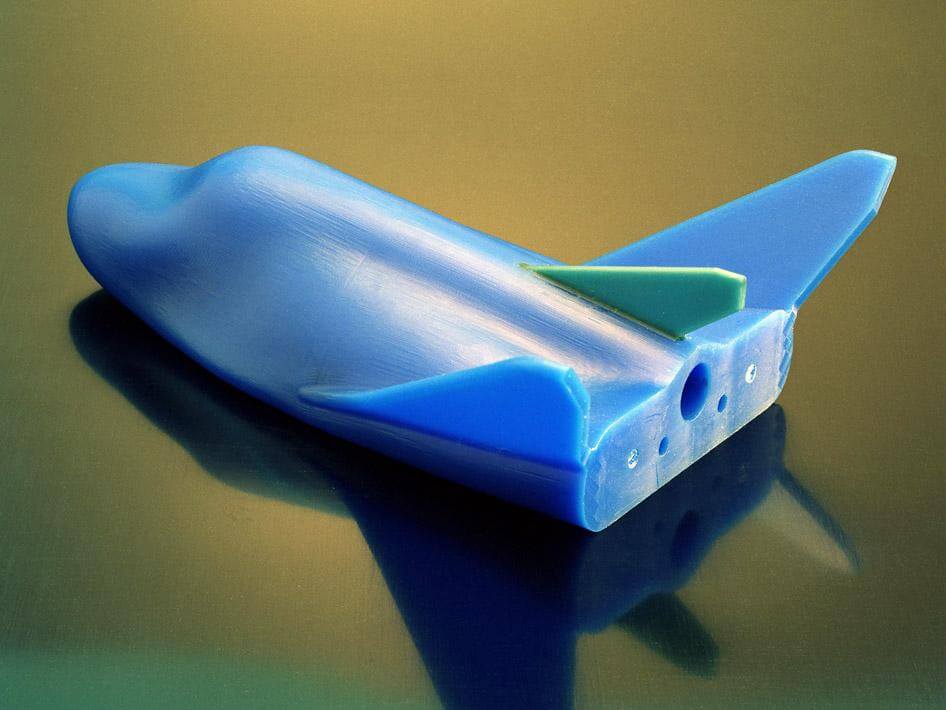

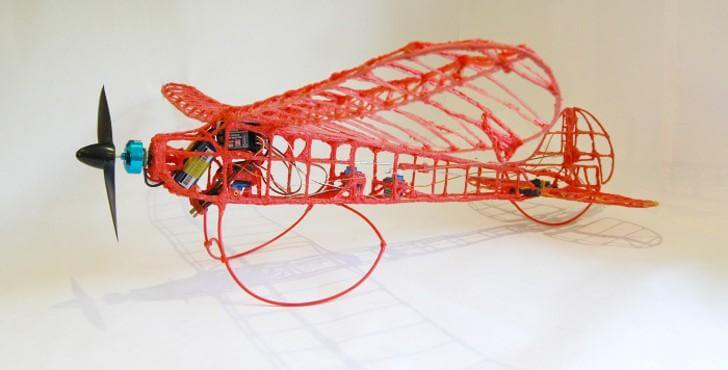

3D printed airplane models are made with the 3D printer. The 3D printed airplane models are used in the aircraft industry to create prototypes for building airplanes. It is also used by engineers and for personal projects.

How 3D printers work for airplane models

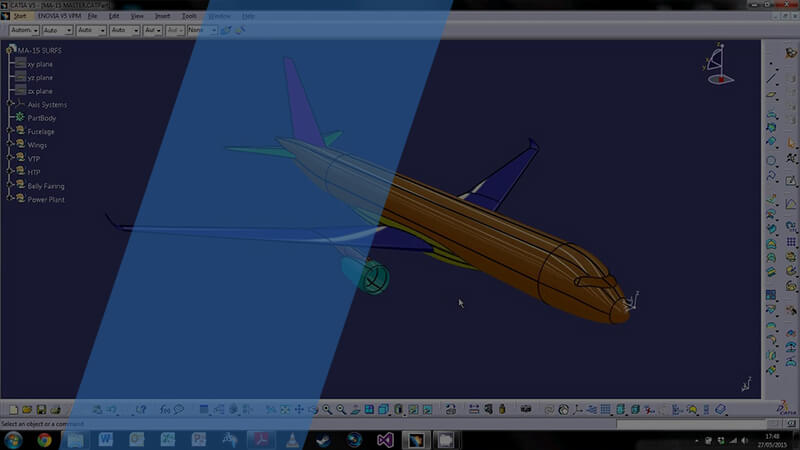

3D design

Model

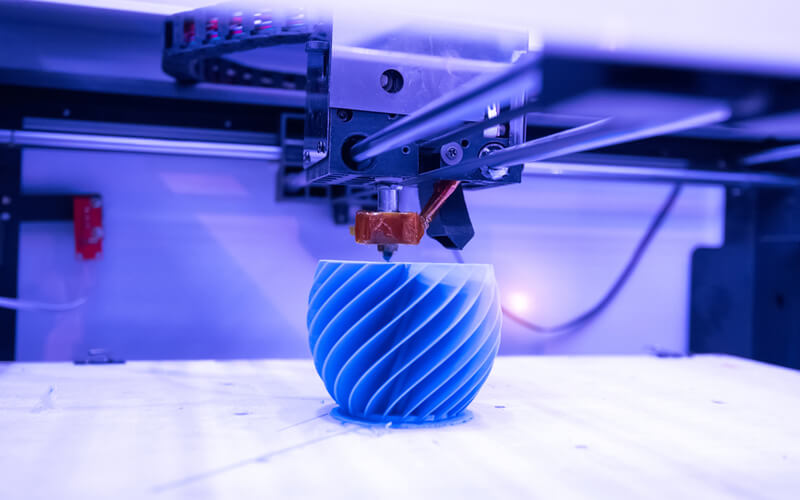

3D printing

model

Painting

model

3D printing airplane models with the 3D printer is without restrictions associated with conventional production methods. The 3D printer can create model planes with as much or as little detail as you like.

3D printing model ships enable you to print airplane models at a cost effective and relatively fast rate.

With the plane 3D printer you can print your spare parts and print model pieces for very large boat models at a reduced cost.

The 3D printer allows you to print promotional 3D printed airplanes to allow potential customers to see and feel your creations.

Large industries like the aircraft industry use the 3D printed airplane before they begin the construction of actual planes, this helps to save cost and time of aircraft building. 3D printed airplanes are also created by students for personal projects.

airplane models 3D printers for your Choice

LCD 3D Printers

FDM 3D Printers

Don't know how to choose a model?

Are you confused about how to choose the correct model and type of 3d printer? We support 24/7.

4 points why choose us

4K resolution printing

4K black-white industrial screen, 0.01-0.05mm layer thickness accuracy, more accurate printing of details.

PLC control system

All 3d printers are equipped with PLC control system as standard, makes the operation more convenient, and reduces the error.

Extremely speed printing

Large printing size, 20mm/h printing speed, complete your printing tasks faster.

Reinforced structure

The all-metal one-piece shell reduces resonance, makes printing more stable and improves printing accuracy.

What our customers say

How 3D Printers are Used in the Airplane Models Production Industry

Airplane Models 3D printer buying guide

3D printers are amongst the few design and tooling equipment that needs no introduction. Its widespread dominance is rampant across numerous industries.

From aerospace to engineering and medicine, 3D printers have become an essential part of their production line—most R&D teams rely deeply on the convenient operation and refreshing printing experience the machines offer.

However, due to differences in the mode of operation and the huge number of 3D printers available, the way individuals in medicine make use of 3D printers and the type of 3D printers required for the industry is quite different in comparison with professionals in the airplane industry.

This buying guide is focused on how 3D printers are used in the Airplane model production industry, the benefits, and the buying process.

Types of Airplane Models – The Significance of Airplane Models in the Market

There are two types of model airplanes, a static non-flying model, mainly used for collection and display, or a flying model capable of remote control flight.

This is very important to choose right from the beginning, as construction for each type will vary greatly. Of course, though, it is possible to turn a static airplane later on into a flying model; you would just need to do a major overhaul and add the necessities to get it into the air.

Model airplanes that fly can usually be placed into one of the three different groups. The first group is free flight, which basically means that the aircraft is built and designed to fly without any attachment to the ground (not even a remote control).

The second group is control line flying, and this method has a cable or two leading from the wing to the pilot. Note that it is not as realistic as a wireless one is, but it ensures your airplane won’t just fly away.

The last group is radio-controlled model airplanes, which are the most intriguing and fun to fly since you have complete freedom of movement and YOU get to control it.

There are some RC airplanes that resemble real aircraft, just like static models, but are harder considering that since they actually fly, you have to continually keep it looking nice and the engine running smoothly. Let’s take a look at the two types of airplane models and their significance in the market.

1.1, Static Model for Collection and Display

Static model aircraft (i.e., those not intended to fly) are scale models built using plastic, wood, metal, paper, fiberglass, or any other suitable material. Some static models are scaled for use in wind tunnels, where the data acquired is used to aid the design of full-scale aircraft.

Models are available that have already been built and painted; models that require construction, painting, and gluing; or models that have been painted but need to be clipped together. They are sometimes used for commercial use, such as displays in travel agencies but might also be obtained by hobbyists as a collection.

Most of the world’s airlines allow their fleet aircraft to be modeled as a form of publicity. In addition, airlines and airplane makers hand out desktop model airplanes to the airport, airline, and government officials as a way of promoting their airline, celebrating a new route or an achievement.

Making use of plane 3D printers and injection molded polystyrene plastic, using carbon steel molds is the most common way of creating static airplane models.

Injection molding allows a high degree of precision and automation not available in the other manufacturing processes used for models, but the molds are expensive and require large production runs to cover the cost of making them.

Smaller and cheaper runs can be done with cast copper molds, and some companies do even smaller runs using cast resin or rubber molds, but the durability is of a lower standard than carbon steel, and labor costs are higher.

1.2, Dynamic Model Capable of Remote Control Flight

Generally known collectively in all its forms as the sport and pastime of aeromodelling, some flying models resemble scaled-down versions of full-scale aircraft, while others are built with no intention of looking like real aircraft. There are also models of birds, bats, and pterosaurs (usually ornithopters).

The reduced size affects the model’s Reynolds number, which determines how the air reacts when flowing past the model, and compared to a full-sized aircraft, the size of control surfaces needed, the stability, and the effectiveness of specific airfoil sections may differ considerably, requiring changes to the design.

The construction of flying models differs from that of most static models as both weight and strength (and the resultant strength-to-weight ratio) are major considerations.

Dynamic flying models borrow construction techniques from full-sized aircraft, although the use of metal is limited. These might consist of forming a frame using thin planks of light wood such as balsa to duplicate the formers, longerons, spars, and ribs of a vintage full-size aircraft, or, on larger (usually powered) models where weight is less of a factor, sheets of wood, expanded polystyrene, and wood veneers may be employed.

For dynamic free flight model airplanes, an elastic motor is usually used to power them. An elastic motor is simply a rubber band that is wound up very tight before flying and then released to make the propeller turn. The elastic motor is actually the most widely used engine for model airplanes and can be found in children’s toys, all the way to professional model aircraft.

The reason the elastic motor is so popular is because of its simplicity and the ability to have a long lifetime. Also, there is no waiting for the battery to charge or having to buy fuel for the engine. The major drawback is the fact that it can only run for a certain amount of time, which depends on how long your rubber band is.

The Impact and Changes of 3D Printers in Airplane Model Production

Airplane model production requires critical planning, design, and development. If you don’t have prior experience in the development process, you would have a hard time developing an airplane of any size. With that being said, the airplane model industry wasn’t always as buoyant nor as sophisticated as it currently is.

Before the idea and development of 3D printed airplane models came to fusion, experts and professionals in the industry relied solely on traditional techniques.

3D printing has enabled the airplane model industry to create complex components previously impossible with traditional techniques. This fosters innovation while reducing costs and turnaround times in a complex, highly-regulated environment.

Due to the typically short runs of parts, the airplane model industry is a prime candidate to benefit from 3D printing. It gives companies the flexibility to 3D print airplane parts for applications in the hundreds or thousands without costly tooling changes.

Beyond part production, 3D printed airplane models improve manufacturing capabilities for tools that are needed to create those parts. It can also facilitate light-weighting efforts for airplane structures, increasing fuel savings and reducing environmental impact.

2.1, What is the Original Production Process

In today’s global world, connecting people and shipping freight through fast and cost-effective transportation has become essential for international trade and tourism.

As a leader in driving today’s global economy, the airplane model industry has a long history of latest technology inventions’ early adopters and ultimate trendsetters in manufacturing.

New materials, state-of-the-art manufacturing processes, and sophisticated software were created and absorbed by this industry decades ago and are now common for other industries.

In contrast to mass-production industries, the airplane model industry is largely focused on complex and low-volume production. Besides endless opportunities, globalization also brings unprecedented challenges such as environmental performance restrictions, high manufacturing costs, and competitive market conditions.

However, it’s important to keep in mind that the airplane industry wasn’t always as buoyant as it currently is. Plane 3D printers, which are currently leading the design and development processes in the airplane industry, weren’t always available. The original production process was reliant on traditional manufacturing methods.

Traditional manufacturing refers to the process of converting raw materials into a finished ready-to-sell product through the use of manual and/or mechanized transformational techniques. The end goal of traditional manufacturing is to add value to achieve the objective.

Traditional manufacturing methods, by contrast, are subtractive in nature. Subtractive manufacturing involves removing parts of a block of material in order to create the desired shape.

2.2, What Processes Can 3D Printers Replace

The airplane industry relies on innovation to grow and overcome challenges. 3D printed airplane models are amongst the most explosive and disruptive manufacturing processes to have hit the engineering industry in the last few years.

It has the potential to change how we create structures, components, and machines across all industries and is starting to make a difference in the aviation and airplane industries.

Traditionally, metal parts are carved out of aluminum or other materials. This can be an expensive and time-consuming process. 3D plane prints can build components automatically, adding layers of metal or other materials on top of each other.

Printed parts are typically much lighter than metal ones, which results in more fuel-efficient planes, which in turn results in savings. Over a plane’s lifetime, this can be a huge sum of money.

Roughly every fifteen years, the global aviation fleet doubles in size. This puts tremendous pressure on manufacturers, having to consistently create new planes while keeping in line with the new legislation. 3D printed airplane models can drastically reduce the time it takes to create plane parts and will soon be the industry standard for manufacturing certain elements.

However, such a massive global fleet is clearly not sustainable. Again, 3D printed planes can help in this area, as most 3D printed parts are considerably lighter.

Weight impacts a plane’s payload, fuel consumption, emissions, and speed. Key components like air ducts, wall panels, seat frameworks, and even engine components have all benefited from reduced weight thanks to 3D printed airplane models.

3D printing elements can drastically cut down the time and parts needed to build sections of a plane. A heat exchanger for a catalyst can be made of as many as 300 separate components but can now be printed as a single part.

2.3, What are The Changes After The Intervention of 3D Printers

3D printing in the airplane industry enables engineers to prototype and validate conceptual design faster. Since tooling production can be skipped to go straight to finished parts, it speeds up the overall development process. The ability to prototype without tooling enables companies to quickly test multiple configurations in order to determine customer preferences and reduce product-launch risk and time to market.

Likewise, 3D printed planes are advantageous for demonstration units and short-volume production where it brings down or eliminates the cost for expensive and poorly amortized manufacturing tooling. Here are some of the key changes the airplane industry experienced after the introduction of 3D printed airplane models.

Cost-Effective

As a single step manufacturing process, 3D printed airplane models saves time and therefore costs associated with using different machines for manufacture. Airplane 3D printers can also be set up and left to get on with the job, meaning that there is no need for operators to be present the entire time.

This rapid prototyping airplane 3D printing process can also reduce costs on materials as it only uses the amount of material required for the part itself, with little or no wastage. 3D printing equipment can be expensive to buy; you can avoid this cost by outsourcing your project to a 3D printing service company.

Weight Reduction

With fuel spending being one of the major costs for airline operators, they tend to invest in aircraft with superior fuel efficiency. However, traditional manufacturing methods have limited ability to reduce the weight of aircraft parts.

Manufacturers are, therefore, keeping the search alive for more advanced and alternative methods of manufacturing parts with reduced weight.

3D printed airplane models provide one-off solutions to achieving weight reduction through optimized part geometry that allows for material savings. With 3D printing, manufacturers can 3D print glider airplanes in lightweight materials, with thinner walls than injection molding.

Furthermore, the technology enables functional integration, whereas several separate parts of a component can be designed and printed as a single unit, further reducing a part’s weight.

Creating Complex Geometries

Needless to say, the basic physical difference in how objects are made with additive manufacturing also produces some major functional differences. The most important of these functional differences is that 3D printed airplane models can be used to create complex geometries that would be difficult or impossible to achieve with traditional manufacturing methods. These complex geometries are often stronger and lighter than their traditionally manufactured counterparts.

On-Demand 3D Printing of Spare Parts for Aircraft Interiors

Predicting the spare parts demand is challenging, and, at times, a spare part might not be in production anymore. These factors make the aircraft aftermarket service difficult and lead to the overall supply chain inefficiencies. While high inventory levels can reduce aircraft downtime, they result in astronomically high costs of maintaining such an inventory.

Furthermore, it is often problematic to provide timely MRO services. The need to produce high-quality replacement parts, with expensive materials in short times, puts the manufacturers under pressure since the lead times often stretch to several months, using traditional manufacturing processes.

On top of that, when repairing or replacing legacy aircraft components, the associated tools may no longer be available to purchase from the OEMs. There is a massive opportunity for 3D printed airplane models to overcome some of these challenges by enabling faster turnaround and reducing inventory through on-demand manufacturing.

3D printed plane models enable companies to produce parts directly from a digital design file, without using any tooling, like molds. It means that some spare parts, particularly lower-demand parts like obsolete components, can be redesigned for 3D printing and stored in a virtual inventory, freeing up space in a warehouse and reducing inventory costs.

Where there is a need for a replacement, a design can just be pulled from the virtual parts catalog and sent for printing. Thanks to its ability to produce small volumes of parts economically, 3D printed airplane models also enable companies to create only as many parts as required, solving the issue of overproduction, typical of traditional production methods.

Analysis of the Advantage of 3D Printers to the Airplane Model Industry

RC Companies and Airlines are always on the lookout for ways to improve the flying experience of their customers, and cabin design plays a critical role in that. Creating custom interiors that accommodate specific airline needs and functions is a growing trend and a perfect task for airplane 3D printing.

By utilizing 3D printed airplane models, you can get to market quicker by avoiding wasting valuable time waiting for retooling. If reworking the design is necessary, adjustments can simply be made to the CAD file and programmed into the airplane 3D printer.

It has been shown that 3D printed airplane models can outperform their traditional predecessors with respect to material properties and performance-orientated designs that are less restricted by manufacturing constraints.

3D printed airplane models unlock new possibilities for customization of cabin parts because it doesn’t require expensive tooling changes based on individual specifications. The manufacturing of custom parts is, therefore, faster and more cost-effective. Let’s look at the major advantages users of plane 3D printers get to enjoy.

- Produce Innovation

With 3D printed airplane models, you gain the ability to make parts that simply can’t be produced by traditional means. Parts can be printed with multiple integrated components, made to perfectly fit together with other 3D printed projects, and include gradients of color.

Advances in 3D printable airplane materials mean that the industry can now print in countless new materials, among the more traditional resin and metal materials. The result is that beautiful, complex, and durable end products can be produced through industrial 3D printing.

Combine that with the advanced industrial 3D printers provided by Dreambot3D, and your perfectly rendered additive manufactured part will be presentation-ready at a fraction of the time, cost, and waste of traditional manufacturing.

- In-Process Quality Assurance Reduces Overall Lead Time

The airplane industry is obsessed with performance and reliability and has since long performed quality assurance downstream to manufacturing.

The airplane industry is the largest source of demand for 3D printed production-grade systems. While many mechanical testing standards are applicable to 3D printed airplane models, there is sometimes a real challenge in applying some usual quality control procedures.

After-build inspection of complex shapes is more difficult and becomes very challenging or impossible when multiple parts are printed together, assembled, and cannot be dismounted.

One of the most promising developments of 3D printed plane models concerns the real-time and closed-loop in-process quality control. In powder-bed airplane 3D printing processes, the material is elaborated in parallel, as the part is shaped.

Monitoring the system settings and process parameters during the ongoing manufacturing permits to regulate and optimize conditions. Mechanical properties in simple plane 3D print manufacturing are all about metallurgy. In-process quality assurance and control will ensure the repeatability of parts with high material quality and consistent mechanical properties, which is essential for the airplane industry.

In-process inspection of the material health and dimensional accuracy will surely unlock the power of 3D printed airplane models for serial airplane production as qualification and consistency variation is now the main concerns. Moreover, it will ultimately decrease unit costs of 3D printable airplane components by reducing costs associated with quality control.

- Reduce Material Waste, Weight, and Bulk

In some applications, airplane 3D printing is a superior process to tooling. 3D printing allows for a single, large component to be built from the ground up in a single unit rather than a lot of small parts being assembled for a single component. In doing so, it allows manufacturers to reduce material waste, weight, and bulk.

There is another key advantage of 3D printed airplane models, which may very well trump all other applications put together. See, when legacy airframes are done being produced, particularly in defense contracts, oftentimes, the manufacturer is legally obligated to destroy the dies and tooling.

This is a contractual obligation that must be abided by. Unfortunately, as aircraft are reaching milestones far beyond what preceding generations did, or these aircraft were ever meant to do, structural components wear out.

3D printed airplane models offer solutions to this predicament. Exact replicas of structural components are now in reach built on an as-needed basis.

Since this type of repair does not require extensive tooling and die production, the turnaround time will be absolutely unheard of. It could be measured in hours or days rather than weeks.

Also, if the weight savings associated with the A380 3D print is any indicator, 3D printed plane model could end up cutting up to 25% in weight for replacement components.

With major structural components, this could end up being in the ballpark of hundreds of pounds in weight-saving, maybe even thousands depending on the size and scope of the component.

How to Choose a 3D Printer and Assemble Your Airplane Model Production Line

We have talked about the types of airplane models and their significance in the global market, the impact 3D printers have had in the airplane industry, and the rare advantages 3D printed airplane models bring to the table, now to the big questions, ‘how do I choose the right airplane 3D printer for my production line? What are the processes involved, and how do I find a reliable manufacturer to do business with?

It’s no news that they are hundreds of 3D printer manufacturers providing durable machines for creating 3D printed airplane models. While you can opt for any manufacturer of choice, it’s not advisable you make your final decision without putting some basic factors into consideration.

Before we discuss the necessary factors further, let’s have a brief overview of the types of 3D printers you can use in your 3D printing jet plane production line.

4.1, What Type of 3D Printer can Dreambot3D Provide

3D printing is the latest thing to excite anyone who loves easy-to-use interactive technology. Engineers and scientists have actually been working with this amazing equipment since way back in 1983. That’s the time when an American engineer named Charles (Chuck) Hull invented the first-ever 3D printer.

The reasons there are different types of 3D printers and printing processes are similar to that of the 2D printers we’re so familiar with. It all comes down to the following six considerations:

- Printer cost

- Print quality

- Print speed

- Printer capability

- Practicality

- User expectations

Some printers only print text—others text and graphics. The technologies and materials used also vary, and the way the machine extrudes ink to paper. 3D printers are even smarter. And like their 2D counterparts, they also offer a range of options, including quality, materials, and price.

Dreambot3D is a leading manufacturer of 3D printers for experts and professionals in diverse industries. We possess a rare catalog of FDM and LCD airplane 3D printers suitable for the design and development of dynamic 3D printed airplane models. Here are some of Dreambot3D’s 3D printer variants you can easily integrate into your production line.

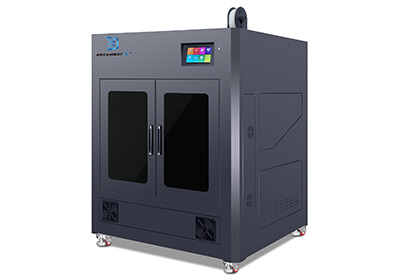

L-500 FDM 3D Printer

The L-500 FDM FDM 3D printer is a high precision extrusion system using double nozzles that can be customized. With our L-500, you get to enjoy a print size of up to 500x500x800 mm with automatic pre-calibration leveling that guarantees a smooth and efficient printing process.

Dreambot3D L-500 drone 3D printer also comes with newly upgraded Taiwan ball screws. Compared with the regular T-shaped screw, the Taiwan ball screw proffers higher straightness, lower friction coefficient, better smoothness, and more stability.

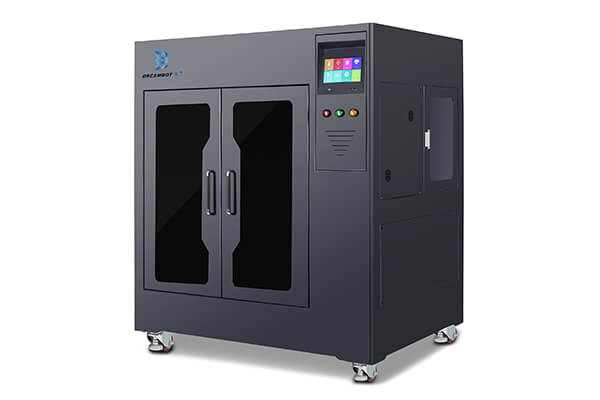

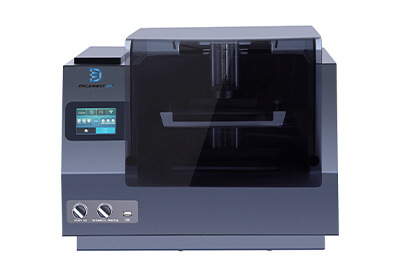

L-600 FDM 3D Printer

Obtaining L-600 grants you instant access to an FDM drone 3D printer with a 7-inch colored touch screen capable of offering a print size of 600x600x800 mm. The L-600 FDM printer can print any filament of choice and is regarded as one of the best FDM machines for creating 3D printed airplane models.

Dreambot3D L-600 FDM 3D printers come with a drag chain wiring design; that’s, the protective wire is installed in the drag chain’s inner casing granting it access to play a protective role, thereby guarantying a safe printing experience.

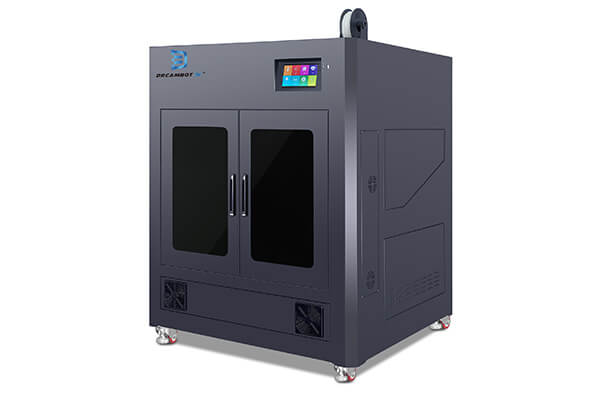

L-800 FDM 3D Printer

Need a drone 3D printer with a 3MM thick sheet metal, fully sealed chassis with two air filter devices capable of creating prints of 800x800x800 mm? Then you definitely need to check out the Dreambot3D L-800 FDM 3D printer.

The L-800 printer is also built with an automatic recognition system that automatically pauses the printing process and raises a flashing red light alarm each time you fail to replace the model.

That’s with our L-800 FDM printer for creating 3D printed airplane models; you need not worry about material waste or breakage.

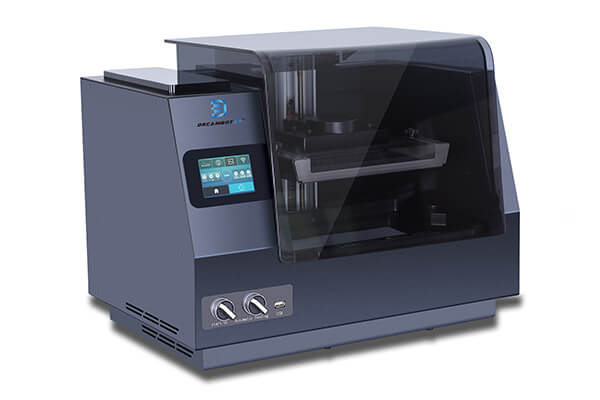

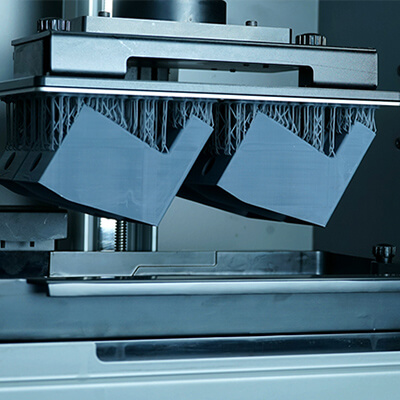

ME-192 LCD 3D Printer

if you have been looking for an LCD 3D printing machine with room for you to create 3D printed airplane models without boundaries, then you need look no further. The ME-192 LCD 3D printer comes with a large molding area that can complete bulky printing tasks at once.

The large molding area is backed by a more stable slide rail performance helping retain precision and balance regardless of the size of the castable resins inserted in the molding area.

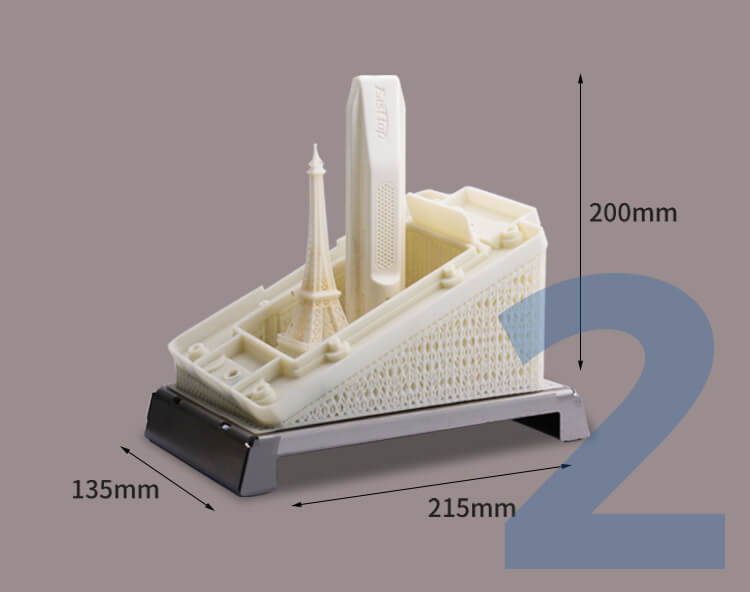

ME-215 LCD 3D Printer

Are you looking to enjoy the smooth and efficient printing process that comes with 3D printing airplane models? We recommend you check out our ME-215 LCD 3D printer.

The ME-215 LCD 3D printer uses cutting-edge light-curing 3D printing technology, which places liquid photosensitive resin in the printing area and selectively irradiates it with ultraviolet light.

The material is cured layer by layer under the action of ultraviolet light to form a three-dimensional product. The printing size is large, fast speed, smooth surface, high stability, low cost of use, widely used in 3D printable airplanes, engineering design, artistic handicrafts, dental care, and small-batch products.

4.2, How to Combine FDM and LCD 3D Printer for Production

A lot of airplane 3D printing production lines combine FDM and LCD 3D printers to better actualize print authenticity. While combining both is a bit more lucrative than settling for either, you don’t need to beat yourself up if your budget or production line does not allow it.

You can create formidable 3D printed airplane models regardless of the 3D printer you have in your production line.

However, to help you better understand the impact of having FDM and LCD 3D printers in your production line, let’s look at the working principle behind the machines.

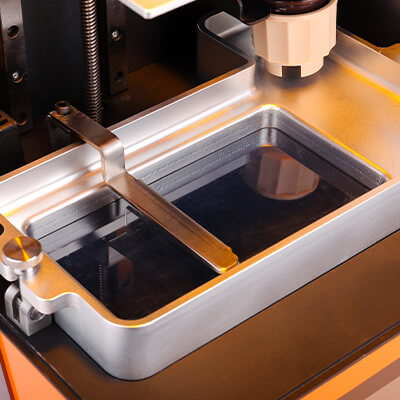

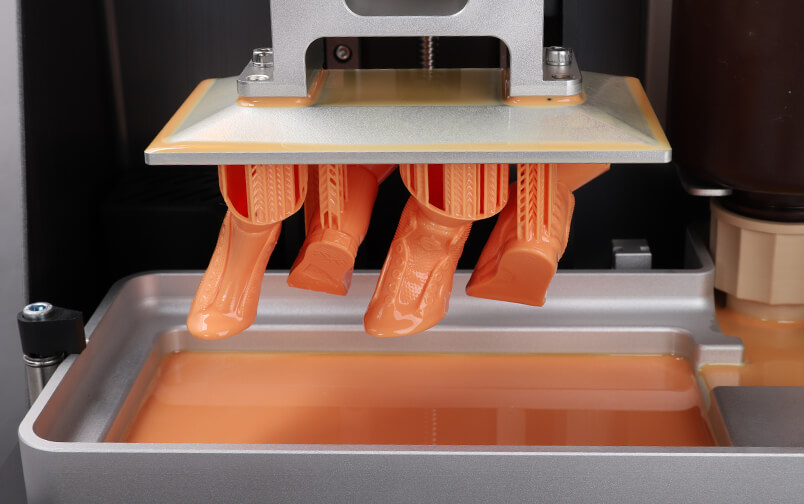

- LCD 3D Printers

Liquid crystal display printers, or LCD 3D printers as they are popularly known, are mold 3D printers use to create 3D models or designs of numerous objects in education, automotive, aerospace, medicine, dentistry, etc. LCD airplane 3D printers generate their light source through an array of UV LCDs.

These printers are used to create 3D printed airplane models or images of CAD models using materials such as resin, wax, or metals. The images or 3D models obtained using LCD 3D printers are composed of dots.

LCD 3D printers display images by sending light from a metal-halide lamp through a prism or series of dichroic filters. This dichroic filter separates light into three polysilicon panels.

In simple terms, a liquid 3D printer uses an array of UV LCD as its light source. The printer shines light directly from the flat LCD panel in a parallel fashion onto the build area.

As the light travels through the light source, the individual pixels open up to allow light to pass or close to block the light. This combination of open and closed pixels creates room for the liquid polymer 3D printer to produce multiple colors and shades on the projected image.

The light emitted from an LCD D printer isn’t expanded—that’s, it doesn’t spread beyond its projected frame. When using an LCD 3D printer to create 3D printed airplane models, you can design patterns and images of multiple variations; rest assured you wouldn’t experience pixel distortion halfway. Note that unlike most other resin printers, the LCD 3D printer’s print quality depends on its LCD density.

- FDM 3D Printer

FDM 3D printer is currently the most popular 3D printer for creating 3D printed airplane models. It is used in casting and molding 3D printed parts for jewelry, shoe industry, dentistry, aerospace, etc.

FDM printing was originally developed and implemented by Scott Crump from Stratasys, founded in the 1980s. Other 3D printing companies have embraced similar technology but under different names. A well-known manufacturer MakerBot coined a virtually identical technology, calling it Fused Filament Fabrication (FFF).

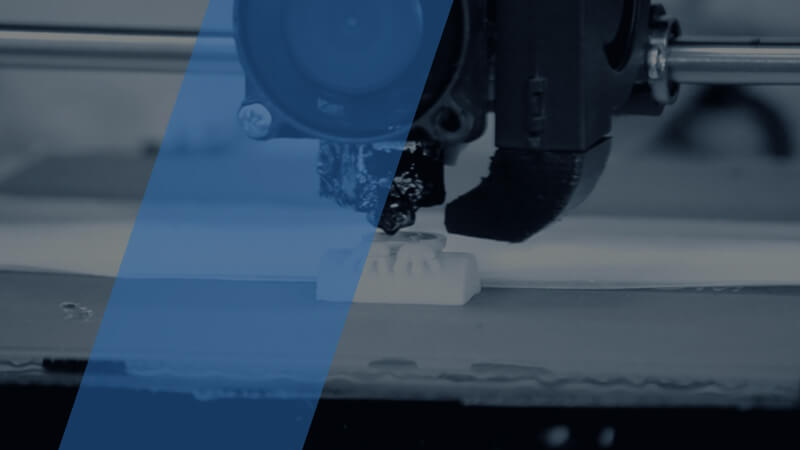

Airplane 3D printers that use FDM Technology construct objects layer by layer from the very bottom up by heating and extruding thermoplastic filament. The whole process is somewhat similar to stereolithography. Specialized programs or Slicers “cut” CAD models into layers and computes the manner printer’s extruder would assemble each layer.

In addition to thermoplastic, a printer may extrude support materials too. Then the printer heats thermoplastic until its melting point and extrudes it throughout the nozzle on a printing bed, which you may know as a build platform or a desk, on a pre-determined pattern determined by the 3D model and Slicer software.

The Slicer software running on the computer connected to the airplane 3D printer translates the measurements of an object into X, Y, and Z coordinates and controls the nozzle and the foundation to follow the calculated route during printing.

When the thin layer of plastic binds to the layer beneath it, it melts and hardens. When the layer is completed, the base is lowered to accommodate the printing of the next layer.

Combining LCD and FDM 3D Printers

The hassle of determining the type of 3D printing system to settle for can throw you off balance, especially if you are new to the industry. While it’s necessary to note the basic difference between the two and base your decision on personal preferences and the buying consideration contained in the next section, it’s important you also keep in mind that you can work with both 3D printing systems.

Yes, LCD and FMD 3D printers can serve as durable 3D printing systems for creating 3D printed airplane models. With both 3D printing systems at your disposal, you get to save tons of resources. Note that while having both FDM and LCD printers might be termed costly during purchase, the long-term advantages can help you operate at a preferred pace ahead of the competition.

4.3, How to Buy a 3D Printer

Creating 3D printed airplane models requires printers that can provide a smooth and efficient finish. There are a lot of airplane 3D printer manufacturers providing printers capable of creating highly detailed 3D parts of printed planes.

But with the huge online market, it’s evident that you would easily come across manufacturers providing 3D printers, not in line with the desired specification.

To help ensure that you obtain the 3D printed airplane model you purchased an LCD or FDM 3D printer to provide, we have detailed out all the factors you need to keep in mind when purchasing a printer for designing 3D printed airplane models. So stay tuned and stay safe.

4.3.1 What is the size of the Print

Airplane 3D printers come in multiple variants. Some are suitable for large printing tasks, while others possess printing jet plane parts that can cater to only small tasks.

What sort of 3D printed airplane model do you want to create, how big is the project, and what size of prints do your customers demand from you regularly? At Dreambot3D, we have seen the irregularities and extra expenses that come with purchasing an industrial FDM 3D printer or LCD 3D printer that’s not compatible with the print size of the 3D printed airplane model you want to create.

Over the years we have been in business, we have had the opportunity of interacting with consumers from different countries and regions. One of the most highly influential factors most hobbyists or professionals who have walked through our door to purchase an airplane 3D printer ignore is the size of the print.

Yeah, it’s practically impossible to determine the exact size or specification attributed, or that would be required in most of the prints you make—especially if you are a business owner looking to satisfy the needs of clients from different parts of the world. However, totally ignoring the print size of your industrial FDM 3D printer or an LCD 3D printer can create is unacceptable.

FDM 3D printers garnered renowned usage ahead of LCD, SLA, and DLP as a reputable printer for creating 3D printed airplane model, not just because of its printing speed or the remarkable finish product it is known for, but also because of its ability to perfectly create sustainable 3D models using filaments.

Before buying any LCD or FDM industrial 3D printer, try to know the type of resin or filament it can print on and whether it’s durable enough to print perfect models on wide materials without leaving distorted edges.

The material you chose for your printing task has a lot to say about the printing size. The dimension, weight, and size of the object obtained from a 3D model printed with PLA are quite different from the result you would obtain using an ABS material—regardless of whether the CAD file and design are the same.

Considering the type of materials you would print on regularly can help you pinpoint an airplane 3D printer that wouldn’t create constraints in your design’s dimension, weight, and size.

4.3.2 Choose a Reliable Brand

Hundreds of brands have built a formidable reputation for themselves by offering printers for 3D printing airplane models with remarkable features. While it’s essential you check out a brand’s track record and reviews from previous customers, it’s also important you don’t base your buying decision entirely on a brand’s name.

There are a lot of industrial printers for 3D printing airplane models available world-wide with reputable brand tags but void of the innovative design and features required to keep your printing line functional. Many brands built a good name for themselves in the early 90s but haven’t been able to keep up with the diverse changes needed to excel in the 21st-century market.

Before putting hours of research into exploring a brand’s portfolio or track record in the global market, make sure the airplane 3D printer you want to buy possesses features in line with your needs and has been ascertained satisfactory by other users and experts in your industry.

Many printers for 3D printing airplane models are developed and released into the market every day. While most of these printers meet the basic requirements and features of SLA, FDM, LCD, SLS, DLP printers, you should not be hasty while sealing the deal yet. Why? You may ask.

Printers for 3D printing airplane models are not cheap machines. You’ll part ways with a considerable amount of your money; therefore, you must ensure that you get value for your money. While your choice should not solely be made on the brands’ name, it is crucial that you do thorough background research on the company’s Google ratings and reviews before making a purchase.

Consider buying your printer from an airplane 3D printer manufacturer that has a good track record, a higher rating on Google, and a genuine customer support system. Such a company will be apt to respond to all your urgent needs, for instance, if your printer breaks or runs out of filaments.

The company/brand that you’ll pick for your printer can make or break your printing experience if something goes amiss.

4.3.3 Safety Configuration of the Machine

When purchasing or using a printer for 3D printing airplane models, you must keep in mind that safety is paramount. And this is not just because you wouldn’t want to expose yourself to the toxic fumes most airplane 3D printers emit during the design and creation process, but also because your ability to build a lucrative 3D printing business is largely dependent on how safe and ready-to-use your aerospace 3D printers are.

If this is the first time you are tasked with handling all the challenges that come with purchasing a printer for 3D printing airplane models, the safety configuration of the machine might seem alien to you. Don’t neglect the durability effect that comes with purchasing an airplane 3D printer with safety configurations that does not reflect the productive ability of the machine.

When making your buying decision for a 3D printed jet plane machine, you need to be on the safe edge. The only way to achieve this feat is by putting due diligence into every step involved in the process.

Note that the safety configuration of most printers for 3D printing airplane models is quite complex and bulky. To demystify this tiring yet important process, consult with a support service representative before finalizing your buying decision.

4.3.4 Resolution Requirement of the Machine

3D printing resolution is the level of detail quality at which your part is created. Airplane 3D printers extrude plastic through a nozzle to create 3D printed objects. That nozzle pin can be adjusted to different widths to allow for higher or lower resolution printing.

It’s necessary that you keenly take into account the resolution of a printing machine before buying one, depending on the industry you are operating in.

While the resolution requirement of a printer for 3D printing airplane models is regarded as the number one factor to consider when making a 3D printer purchase by experts in numerous industries, this can be referred to as a myth that doesn’t apply to all. The resolution of an FDM or LCD 3D printer determines the clarity and precision that can be enjoyed from a given 3D model and pattern.

However, the resolution of a 3D printing system used in the animation industry doesn’t have to be on the same level as the one used in the airplane industry.

When looking at the resolution requirement of an industrial FDM 3D printer, it’s important you take into consideration the industry you are operating in. In which industry do you want to use the machine? What sort of models do you want to print? How clear or precise does the model have to be for it to be termed efficient?

Answering the above-listed questions would help you demystify some of the myths attached to buying a 3D printer. Yeah, buying a high-resolution printer for 3D printing airplane models should be considered a priority if the funds and budget to finance it is available. But in scenarios where you are on a budget, you can save cost by analyzing the machine usage and model requirement.

Airplane 3D printers come in different variants, shapes, and sizes, optimized with a fitting design and resolution. At Dreambot3D, our daily task revolves around catering to individuals’ dynamic needs and desires from numerous parts of the globe. We know how daunting navigating a machine with a proper resolution can be.

Dreambot3D core value is to provide satisfactory all-round services. To keep up with this mission, we offer a support team that can help you understand the resolution requirements of multiple machines, the industries they are optimized to serve and direct you towards multiple variants that would serve you better.

Note that while the quality of print detail is more paramount in some industries than it is in others, the resolution of a machine decides how fine the details of your part will be. A lower resolution, less quality, and low details on the print object. The objects will have smooth surfaces at the expense of extra filament usage and time consumption. A high resolution, conversely, gives fine quality and better details on print objects.

4.3.5 Consider Weather the Price of the Machine is Acceptable

It’s never a fun experience to have explored all the remarkable features and benefits an airplane 3D printer is offering, weighed it with your production line, and obtained satisfactory results just to find out during checkout that the printer for 3D printing airplane models you want to purchase is far above your budget.

Airplane 3D printers are quite expensive. They require a sizable investment, especially if you are looking for industrial-grade printers. As a professional or expert looking to help individuals from different walks of life obtain the jet plane parts design or finish product they desire, having the best printer for 3D printing airplane models is essential.

Before exploring all the features and benefits of an airplane 3D printer, weigh its price range with your budget. Note that the price of a printer for 3D printing airplane models does not determine efficiency. There are a lot of airplane 3D printers with a high price but not as durable and efficient as counterparts with low price tags.

To hasten your airplane 3D printer buying process in terms of price, it’s advisable you put a call through to a support representative backing up the activities of a brand of choice stating your estimated budget and the type of 3D printing activities you would like to carry out using the machine.

4.3.6 Consider the Suppliers After Sales Service Capability

LCD and FDM printers for 3D printing airplane models are quite expensive. A good airplane 3D printer requires an investment well above a thousand dollars. Budget and pricing is a basic factor that must be considered before you kickstart the buying process.

While most of the renowned printing systems available are quite expensive, don’t make the mistake of basing the efficiency or durability of a commercial-grade 3D printer on the price tags attached. There are lots of LCD and FDM 3D printers offering high-quality printing services at cost-efficient rates.

If you run a big production line or you are a hobbyist looking to purchase a remarkable printer for 3D printing airplane models, and you firmly stand by the belief that your budget is sizable enough to purchase any printing machine of choice—we recommend you explore our catalog armed with the basic features and specification you require from a preferred FDM or LCD 3D printer.

On the other end, if you are on a low budget and require something substantial to cater to your day to day printing needs, please put a call through today—our support representative will guide you through the buying process.

Sometimes people tend to purchase printers for 3D printing airplane models based on the price only. The price of an airplane 3D printing machine plays a big role in the decision-making process.

But with so many industrial and commercial printers for 3D printing airplane models available for sale at the consumer level today, you must keep a keen eye on the machine’s brand, resolution, and safety configuration.

4.3.7 Consider the Service Life of the Machine

The service life for most printers for 3D printing airplane models is about 5 to 10 years. While the warranty policy on most 3D printers doesn’t grant you access to refunds or after-sales privileges one year after purchase, purchasing a printer for 3D printing airplane models from a reliable manufacturer comes with the guarantee that your airplane 3D printer will be in shape and keep your production line running for at least five years.

With that being said, it’s important to note that the estimated service life of the machine can change at any time based on external factors. How you use your machine determines how long it would last. If you leave your industrial FDM 3D printer or LCD 3D printer packed dirty on a regular, you shouldn’t expect the ten years life expectancy to hold any ground.

If you went gone through the hassle of finding the right airplane 3D printer manufacturer, inspecting all the necessary features, and finalizing the purchase, you wouldn’t want the whole effort you put in to go down the drain based on negligence on your part. Try as much as possible to keep your printer for 3D printed airplane models clean and in good shape, and service life expectancy wouldn’t be an issue.

4.3.8 Consider the Maintenance Cost of the Machine

3D printing airplane models for hours can cause some mechanical parts to lose their grip or hold to the machine; some might degrade after months of being used. If not upgraded, the final quality of your prints will consequently reduce.

Machine maintenance is necessary, and it might come with added costs where some parts like the nozzle may need to be replaced entirely. You must incur a reasonable maintenance cost of your machine to consistently get clean and fine detailed prints.

Dreambot3D is a 3D printer manufacturer that defied the odds by manufacturing printers for 3D printing airplane parts that are highly versatile, cost-effective, easy to use and maintain while still giving you high detail prints. If you are interested in finding out which airplane 3D printing equipment is best suited for your needs, get in touch with our support team today.

How to Choose a Material

When it comes to choosing the right materials for creating 3D printed airplane models, one of the most fundamental material properties is tensile strength, a material’s resistance to breaking under tension. It’s one of the first material properties engineers look for and is found at the very top of most material datasheets.

In conjunction with sufficient ductility, tensile strength also indicates a material’s toughness. Some materials break very sharply in a brittle failure, whereas more ductile ones, such as most plastics and metals, experience some deformation. To clearly understand this behavior, tensile strength data is commonly supplemented with a stress/strain curve.

Materials of high tensile strength are typically found in structural, mechanical, or static components where breakage is unacceptable, such as construction, automotive, aviation, as well as wires, ropes, bulletproof vests, and more.

Today, 3D printing airplane models have progressed to the extent where it is able to deliver the same, or even higher tensile strength than traditional injection-molded plastics. Here are some of the materials widely used in designing 3D printed airplanes.

- ABS {Acrylonitrile Butadiene Styrene}

As a thermoplastic polymer, it can melt and cool without altering its chemical properties. That makes it an interesting industrial FDM 3D printer material for 3D printing airplane models. The filament is known to be strong, tough, and durable. It is also forgiving to scratches, offers good resistance to heat and everyday chemicals.

It can endure heat, pressure, and stress like no other industrial FDM material for airplane 3D printing, making it a great choice for wear and tear prints.

You can try this out yourself: If you move a strain of ABS filament, it will distort and bend before breaking. PLA breaks much more easily.

ABS is quite forgiving, as long as you print with the right settings and proper temperature management. You can even achieve overhangs of around 45 degrees. If the print succeeds, the results are very convincing.

Most makers like the material because you can process its surfaces with acetone, glue parts, and even file off some material. Lastly, it can be easily painted with acrylic colors.

ABS filament is not toxic when 3D printed. Only at very high temperatures (400 °C), the material decomposes into butadiene (which is carcinogenic to humans), acrylonitrile (possibly carcinogenic to humans), and styrene—nothing you want to inhale under any circumstances.

If you don’t have an airplane 3D printer at hand, you can have ABS parts printed by a professional 3D printing service. You can put a call through to our support representative to obtain the best deal on a high-resolution FDM 3D printer for 3D printing gliders or jet planes.

- PLA {Polylactic Acid}

PLA filament is by far the most popular industrial FDM 3D printer material used for 3D printing airplane models, and there’s a good reason for that. It comes in many shades and styles, making it ideal for a wide range of applications. Whether you’re looking for vibrant colors or unique blends, it’s an easy-to-use and aesthetically pleasing material.

PLA is short for Polylactic Acid, a thermoplastic polymer that is derived from renewable resources, more specifically from corn starch or sugar cane.

This sets the material apart from other commonly used plastics, which are procured through the distillation and polymerization of non-renewable petroleum reserves.

Since PLA filament is a biodegradable product, it tends to naturally break down in about three to six months. Other thermoplastic materials can take up to a thousand years to decompose, making PLA much more environmentally-friendly.

PLA material has been thrust into the spotlight by the rise of custom industrial FDM printers. PLA filament is available in a wide variety of colors and blends, and innovative PLA-based materials seem to be constantly hitting the market.

Outside of 3D printing airplane parts, PLA is also used to produce things like medical implants, food packaging, and disposable tableware. But inside of the industrial FDM 3D printing sphere, PLA filament is widely thought of as an aesthetic material best used for prototyping.

- PETG

PET (polyethylene terephthalate) is a thermoplastic polymer used for 3D printing airplane models. Mixed with glycol (hence the “G”) exhibits good 3D printing features. PETG FDM 3D printer material is resistant to high temperatures and water, presents stable dimensions, no shrinkage, and good electrical properties.

PETG combines ABS durability and PLA printability, and it comes as no surprise that it’s frequently chosen by professionals seeking a reliable filament for their projects.

PETG gained a lot of recognition during the coronavirus pandemic because it can be easily sanitized and therefore is useful for medical applications such as face shields.

Note that You may encounter two options — PETG (sometimes written as PET-G) and PET. The “G” stands for glycol — a substance added to prevent corrosion and crystallization effects. Glycol modified PET is easier to 3D print. PET without glycol is more fragile and prone to breaking.

On the other hand, PETG is characterized by a delicate outline that’s easy to scratch. That being said, the chemical properties of PETG are far better for 3D printing airplane models despite some minor disadvantages.

PETG is suitable for use on any FDM 3D printer. If you are interested in creating airplane 3D prints with PETG and you are yet to find a suitable high-resolution 3D printer for the task, don’t hesitate to put a call through to our support team.

- High-Temperature Resin

While FDM 3D printing technology uses traditional industrial plastics like ABS and Polycarbonate (PC), SLA, DLP, and LCD 3D printers require special photopolymer resins that harden (cure) once UV light is directed at it. Most airplane 3D printing resins are either epoxy-based or acrylate-based, the latter being used more often in desktop printers.

A lot of people think of resin 3D printed parts as fragile and most suitable for ornamental and prototyping applications rather than functional and load-bearing components. But this is only true if the resin isn’t properly selected. That being said, if you’re buying a generic resin for a tough job, it won’t give you the strength that you’re looking for.

Examples of super-strong resin can be found in a wide variety of industries. There are castable resins for making jewelry and 3D printing in the field of dentistry to produce mouth guards, crowns, and surgical guides.

There’s also high-temperature resins that are suitable for 3D printing airplane models and even resins that can produce rubber-like parts.

Note that a resin’s tensile strength value is usually measured by a pull test that follows strict international procedures, so the results can be used worldwide. The higher the tensile strength, the stronger the material is considered to be because of how much stress it can withstand.

Just because the resin is tough, it doesn’t mean that the 3D printed airplane part made from these resins will be twice as strong as if printed with a standard resin. Other factors, like model design and print settings, play important roles in the final print’s strength, which we’ll discuss in more detail later.

Nonetheless, comparing tensile strength is a straightforward way to determine which material is stronger, and from the numbers supplied by the manufacturers, it’s clear that these resins are much tougher than the standard.

- Nylon

Nylon (a.k.a. Polyamide) is a popular material used in creating airplane models, known for its toughness and flexibility. Nylon filaments typically require extruder temperatures near 250 ºC. However, some 3D printers for industrial R&D allow printing at temperatures as low as 220 ºC due to their chemical composition.

Many printers do not include a hotend that can safely reach 250 ºC, so these lower-temperature versions can be useful and potentially save you from needing to upgrade your hotend. One big challenge with Nylon filaments is that they are hygroscopic, which means they readily absorb moisture from their surroundings.

- Carbon Fiber

Carbon fiber filaments are composite materials formed by infusing fragments of carbon fiber in a polymer base, similar to metal-infused filaments but with tiny fibers instead. The polymer base can be of different 3D printing materials, such as PLA, ABS, PETG, or nylon, among others.

While true carbon fiber materials have long continuous fiber strands that improve mechanical resistance, these airplane 3D printing resins contain short particles of around 0.01 mm in diameter. Although this is enough for improving the strength of printed parts, keep in mind that such filaments cannot compare to the actual material.

For those seeking tougher airplane 3D resins, carbon fiber filament presents a relatively easy alternative to the more expensive and demanding materials, such as polycarbonate (PC) or PEEK. Moreover, the increased strength provided by the carbon fiber particles contributes to greater dimensional stability, helping to avoid warping and shrinking.

Conclusion

Ranging from the types of airplane models to the impact 3D printers are having in the airplane 3D printing industry, we have covered it all. We also detailed out all the factors to consider when purchasing an airplane 3D printer, the variants available at Dreambot3D, and the buying process involved.

Most hobbyists and professionals involved in airplane 3D printing are well aware of the complexity involved. And with all the information detailed out, we believe you wouldn’t have a hard time making the right 3D printer buying decision for your production line.

However, if you are tired of scouring the endless catalogs available online and need a one-stop destination for all your 3D printing needs, Dreambot3D is here for you. Our airplane 3D printers are optimized with a user-friendly system that guarantees a smooth and efficient printing process for experts and hobbyists looking to create formidable 3D printed airplane models.

FAQ Guide

Can you 3D print a plane?

Yes, you can 3D print a plane. The great advantage of a 3D printed airplane is that in case you crash it, you can print the damaged parts again, which saves a lot of money! The electronic elements which are more expensive rarely suffer any damage during a crash. Critical parts are designed to be detachable, allowing you to replace them.

What does an FDM printer mean?

FDM means Fused deposition modeling. FDM is regarded as a 3D printing technology often used to print 3D models and patterns. FDM machines can be found in almost every industry. The 3D printers are renowned for their ability to create 3D models of high quality with high accuracy and durability at cost-efficient rates.

What is the name of the world's first-ever 3D printed aircraft?

Now, European aerospace company, Airbus, has created a mini-plane named Thor, which is the world’s first 3D printed aircraft.

What is a 3D RC plane?

3D Aerobatic RC models are radio-controlled airplanes that offer unprecedented maneuverability and excitement in a nimble form factor. Specially designed with high lift wings and powerful thrust-to-weight ratios, 3D airplanes offer the perfect punch of precision flying and acrobatic stunts, giving pilots a unique flying experience each and every time. These high-performance model aircraft come complete with many features suitable for intermediate and advanced hobbyists. Many unique design implementations include lightweight EPO foam construction, scaled control surfaces for positive control 3D stunts and aerobatic flight efficiency, wing-molded carbon spars for extra rigidity, quality surface hinges, and screw-less composition for streamlined aerodynamic capabilities, and pinned rudder hinges for increased durability, reliability, and performance.

Will additive manufacturing replace conventional manufacturing?

While additive manufacturing comes with many perks—faster printing time, cost-efficient, simplified printing method, etc.—most experts do not agree that it will replace conventional manufacturing methods altogether. Additive manufacturing enhances countless printing processes, but the materials it can process are quite limited. No, additive manufacturing will not replace conventional manufacturing methods altogether.

How does an FDM 3D printer work?

Fused deposition Modelling {FDM} printers or Fused Filament Fabrication {FFF} printers {as they were formally known till the FDM term was trademarked by Stratasys in 1991; the company behinds its first design} are machines built to deposit melted material in a pre-determined path layer-by-layer selectively. Fused Deposition Modelling {FDM} printers are 3D printing machines that create images one at a time. FDM printing process revolves around a three-dimensional output. Each layer of the material you are printing is placed on top of another again and again till a finished product is acquired. The printing process begins after the modeling software slices the 3D CAD file creating an extrusion path for the nozzle to follow. All necessary support needed by the object is factored into the extrusion path, and the nozzle movement is controlled via the interactive interface found on the machine.

Can you 3D print a drone?

Yes, you can 3D print a drone. With 3D printing, it’s possible to produce most of the components needed to build a drone or quadcopter, besides the electronics. 3D printed drone parts can include the chassis, any additional protective casing for the frame, propellers, landing gear, motors mounts, accessory mounts (i.e., for scanners, cameras, sensors, or other useful equipment), and housing for remotes and the drone’s power source. To build your own DIY drone, you can pick from a variety of off the open-source shelf designs, such as the OpenRC 3D printable quadcopter design that’s showcased on the cover of this article. 3D model databases and communities like Pinshape offer a wide selection of fully 3D printable drone designs and accessories as well. 3D modeling new parts or accessories on your own offers limitless possibilities to adopt a drone design for specific applications. Online communities such as RC Groups, DIY Drones, and of course, Reddit can also offer plenty of support and inspiration.

How can I make a homemade drone?

To make a homemade drone, follow the steps listed below.

- Assemble your grain motor

- Mount your electronic speed controllers

- Attach the landing gear

- Add your flight controller.

- Connect libre pilot to your drone

- Take your drone for a spin.

How can I improve 3D print quality?

To improve 3D print quality, explore the following tips.

- Level the bed and set the nozzle height

- Check nozzle temperature

- Find the sweet spot for your bed temperature.

- Try different build plates for different effects.

- Pay attention to printer adjustment and maintenance.

- Treat filament with care.

- Find a slicer that you like and learn it.

- Use supports with overhangs.

- Close gaps in parameters, top, and bottom layers

- Adjust Z axis movement to avoid dragging

- Slow down the print speed to avoid ringing

- Post-process for a finished look

- Patience yields quality prints

What is a good size 3D printer?

The available build size of a desktop 3D printer is commonly 200 x 200 x 200 mm, while for industrial machines, this can be as big as 1000 x 1000 x 1000 mm. If a desktop machine is preferred (for example, for reducing the cost), a big model can be broken into smaller parts and then assembled.

How durable are 3D printed items?

It can depend on what material you use, but even cheap abs and PLAis extremely durable. For seriously strong stuff, you can use PETG, Polyflex, Polymax, and flexible materials. But yes – parts are as good as commercially produced parts, in many cases stronger and lighter. To a large extent, for FDM machines, it depends on the orientation you print them in. So, the same part can be printed in different orientations, and one will be weak and break easily, and the other will be strong, flexible, and hard to break. Getting really good 3d printed parts is as much an art as a science.

What does FDM mean in 3D printing?

FDM, or fused deposition modeling, is an additive process where the material is fused together layer by layer in a specified pattern to create a 3D object. It became popular starting in the 1980s and is now widely used for cheap and easily customizable rapid prototyping. The term ‘fused deposition modeling’ and the associated acronym was trademarked by Stratasys in 1992, creating a need for an alternative term – fused filament fabrication, or FFF. Nowadays, these terms are just used interchangeably.

Is it cheaper to build or buy a 3D printer?

There is no right answer here; it all depends on the individual and the type of printing activity he/she wants to carry out using the 3D printer. As to which is cheaper, it’s all based on you and your personal preference.

Can you reuse 3D printer resin?

You can reuse uncured resin just fine, but you’ll need to filter it out properly to ensure the larger pigments of cured resin aren’t put back into the bottle. If you do this, you might be pouring back hardened resin back into the vat, which isn’t good for future prints. Once the resin is slightly cured, you can’t practically reuse it for your 3D printer. Note that you can leave uncured resin in your 3D printer vat/tank for several weeks if you keep it in a cool, dark area. Giving your 3D printer extra can prolong how long you can leave uncured resin in the vat, though when it comes time to 3D print, you should gently stir the resin so it is fluid.

How do the 3D printers work?

A typical 3D printer is very much like an inkjet printer operated from a computer. It builds up a 3D model one layer at a time, from the bottom upward, by repeatedly printing over the same area in a method known as fused depositional modeling (FDM). Working entirely automatically, the printer creates a model over a period of hours by turning a 3D CAD drawing into lots of two-dimensional, cross-sectional layers—effectively separate 2D prints that sit one on top of another, but without the paper in between. Instead of using ink, which would never build up too much volume, the printer deposits layers of molten plastic or powder and fuses them together (and to the existing structure) with adhesive or ultraviolet light.

Is LCD faster than DLP?

The speed of the modeling or designing process attributed to LCD printers varies based on the machine variant. High valued DLP printers operate at a relatively faster pace than regular LCD printers. However, if pricing and portability come into play, liquid 3D printers are a faster and more durable option. LCD 3D printers offer the same specifications and features as DLP but at a cheaper rate. DLP 3D printers make use of a projector. The projector flashes light onto the resin’s entire layer at once, selectively solidifying the part using thousands of minuscule mirrors called DMDs (digital micromirror devices). On the other hand, LCD printers involve a printing process that flashes entire layers at once to imprint patterns on the material housed in the resin tank without the interference of an external object or material. While LCD and DLP are both known for their high-speed operation and detailed finish, the price tags, and modeling process are quite different.