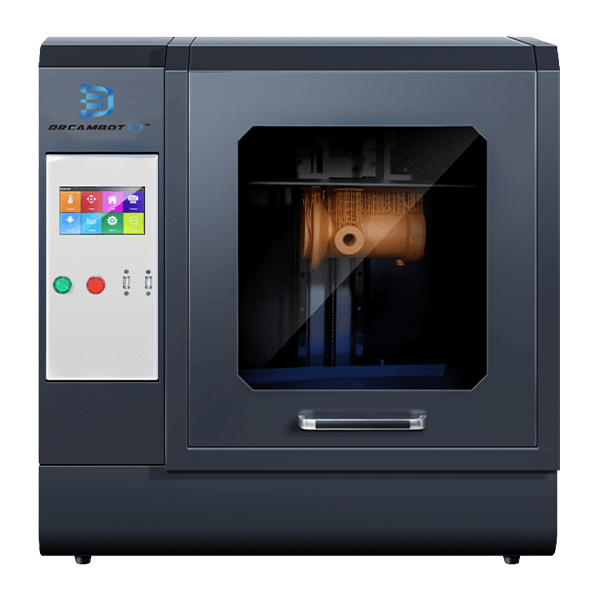

LCD 3d printer

We are a factory that produces high quality LCD 3D printers for 3D printing for different applications. The Dreambot3D LCD 3D printer is used in medical, dental, aerospace, automotive industries, etc.

The Dreambot3D LCD 3D printer is affordable, prints highly accurate 3D prototypes and makes use of affordable printing materials.

Contact Us

industrial LCD 3D printer manufacturer

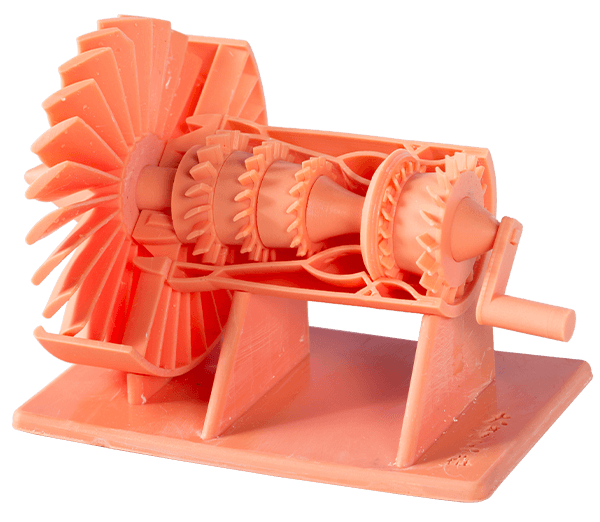

- The 4K resolution feature contributes to high accuracy and a smooth surface finish of models.

- The printing speed is 20mm/h for every printing operation, therefore contributing to a fast production process.

- The LCD printer supports various printing sizes reaching up to 15.6 inches.

industrial LCD 3D printer list

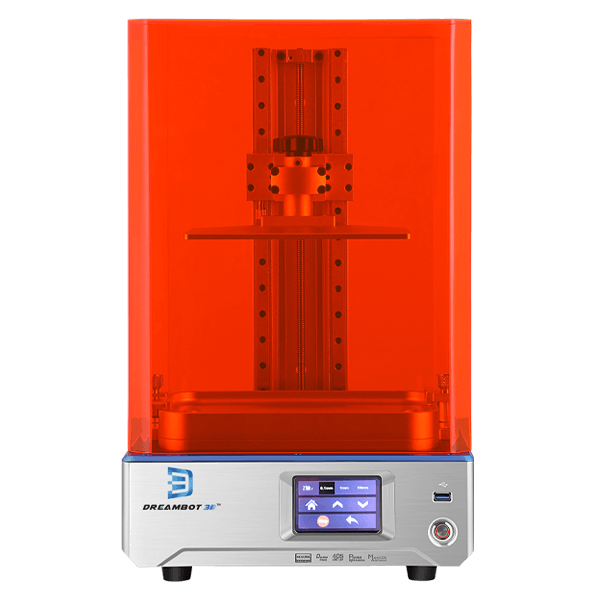

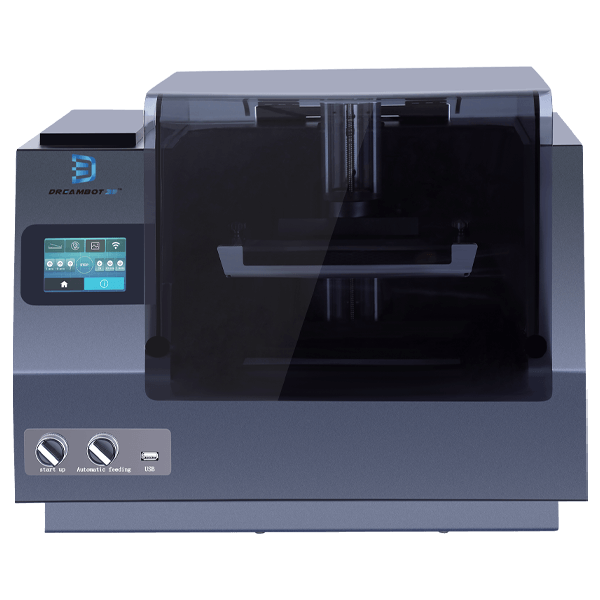

The ME-192 3D printer works with CHITU software. The ME-192 model has a printing accuracy of 0.025 to 0.1mm and a speed of 20mm/h.

The ME-215 LCD 3D printer prints accurately at L215 W135 H200. The ME-215 model works with LINUX printing software at a speed of 20mm/h.

The ME-345 LCD 3D printer prints prototypes at L345 W195 H335. The ME-345 model works well with LINUX printing software at a speed of 20mm/h.

The DB-293 LCD 3D printer prints model objects of L293 W165 H400. The printing speed of the DB-293 20mm/h with 4K pixel size.

The DB-345 LCD 3D printer prints prototypes at L345 W195 H335. The printing speed is 20mm/h with 4K pixel size.

The DB-550 LCD 3D printer print size is L527 W295 H550. The DB-550 model printing speed is 10mm/h with 4K pixel size.

Application of LCD 3D printers

Test your part

We provide sample testing service, allowing you to check the working quality of our 3D printer before placing an order

6 points why choose us

4K resolution printing

4K black-white industrial screen, 0.01-0.05mm layer thickness accuracy, more accurate printing of details.

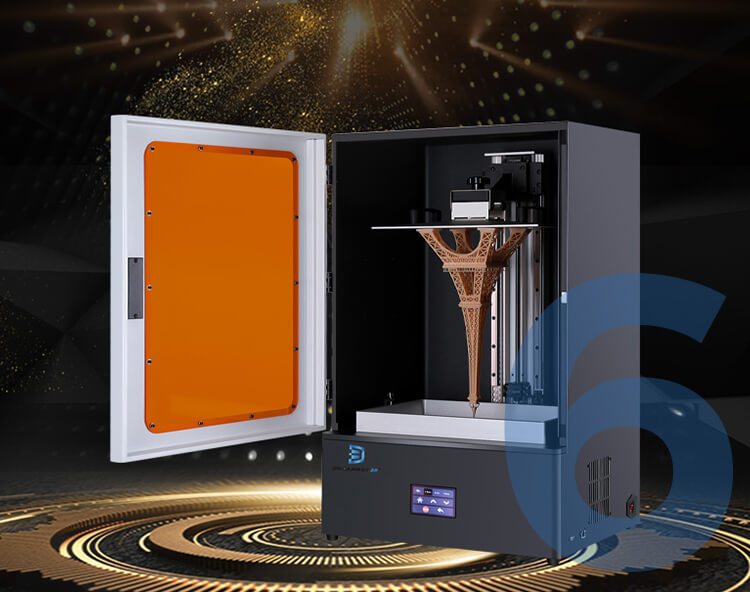

Large size printing

Our newly developed industrial-grade LCD 3D printer can support print sizes up to 24 inches. (6 inches is a common size)

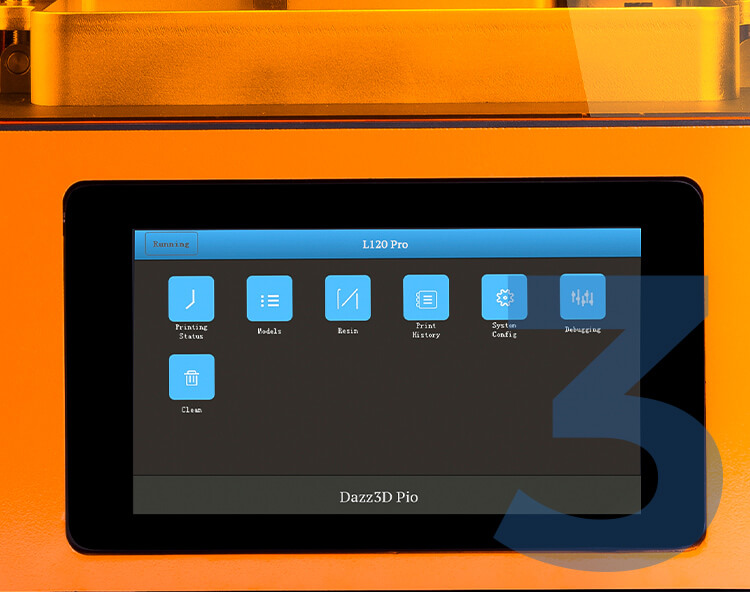

PLC control system

Equipped with PLC control system as standard, makes the operation more convenient, and reduces the error.

Extremely speed printing

Large printing size, 20mm/h printing speed, complete your printing tasks faster, greatly improve production efficiency

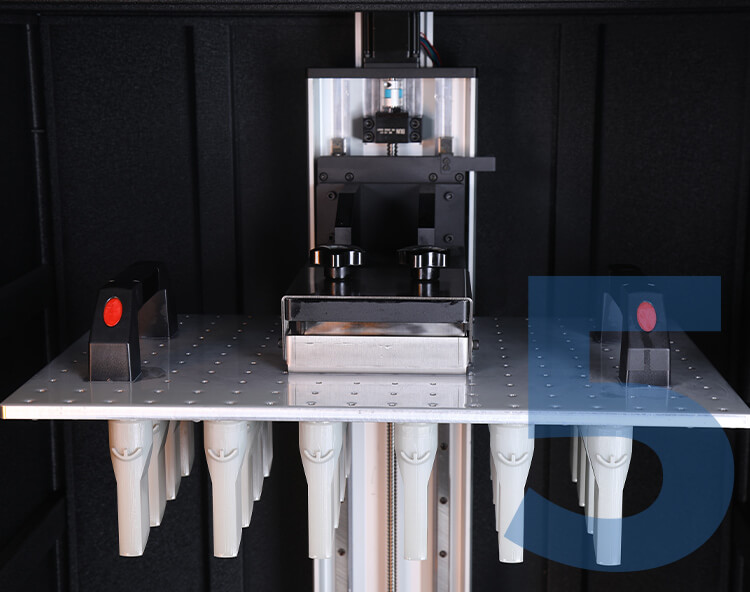

Industrial grade ball screw guide

It ensures the smoothness of the printing surface, better control, and achieves micron-level high-precision printing

Reinforced structure

The all-metal one-piece shell reduces resonance, makes printing more stable and improves printing accuracy.

What Our Customers Say

LCD 3D Printer Buying Guide

What is an LCD 3D Printer?

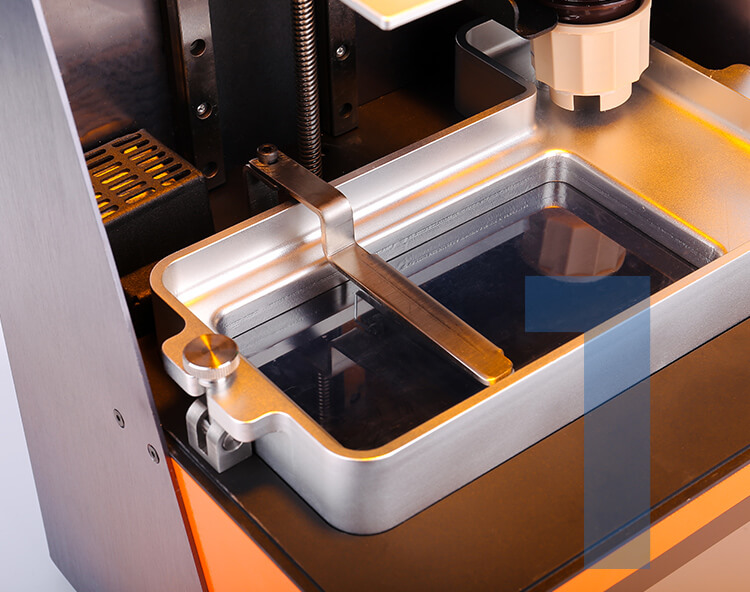

If you have come across a laser printer, you basically have an idea of what an LCD printer looks like. Just like a laser printer, LCD 3D printers can imprint images or patterns on flat surfaces, but unlike laser printers, which depend on laser beams to imprint patterns, LCD 3D printers create images through a liquid crystal panel.

LCD 3D printers generate their light source via an array of LCDs. This resin printer creates patterns or images composed of dots by either allowing or blocking light from passing through individual pixels in the panel. With an LCD 3D printer, the print quality depends on the density of the pixels contained in the panel.

What does LCD Mean and Where Does it Come From?

LCD means a liquid crystal display. Sounds like it’s contradicting itself, right? How can a liquid be in the same sentence as crystals {which are known to be solid}? This billion-dollar question is what makes the LCD tech unique.

LCD is amongst the few substances that can exist in an odd state – that’s like a liquid and solid combine. LCD cannot be termed entirely liquid or entirely solid. LCD are molecules that tend to maintain their orientation while existing as solid and liquid.

1.1, How Does an LCD 3D Printer Work?

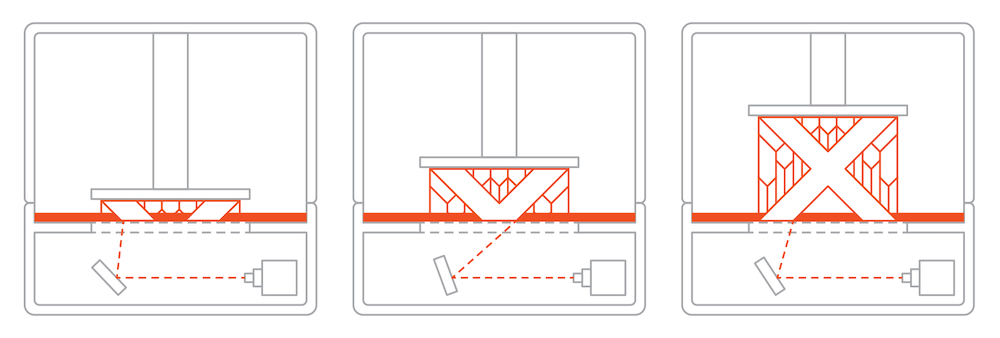

For an LCD 3D printer to display images, it typically sends light from a metal-halide lamp through a prism or series of dichroic filters that separates light into three polysilicon panels. In simple terms, a liquid 3D printer uses an array of UV LCD as its light source. The printer shines light directly from the flat LCD panel in a parallel fashion onto the build area.

As the light travels through the light source, the individual pixels open up to allow light to pass or close to block the light. This combination of open and closed pixels creates room for the liquid polymer 3D printer to produce multiple colors and shades on the projected image.

The light emitted from an LCD 3D printer isn’t expanded—that’s, it doesn’t spread beyond its projected frame. When using these 3D printers, you can design patterns and images of multiple variations; rest assured you wouldn’t experience pixel distortion halfway. Note that unlike most other resin printers, the LCD 3D printer print quality depends on its LCD density.

1.2, LCD vs. DLP vs. SLA: All You Need to Know

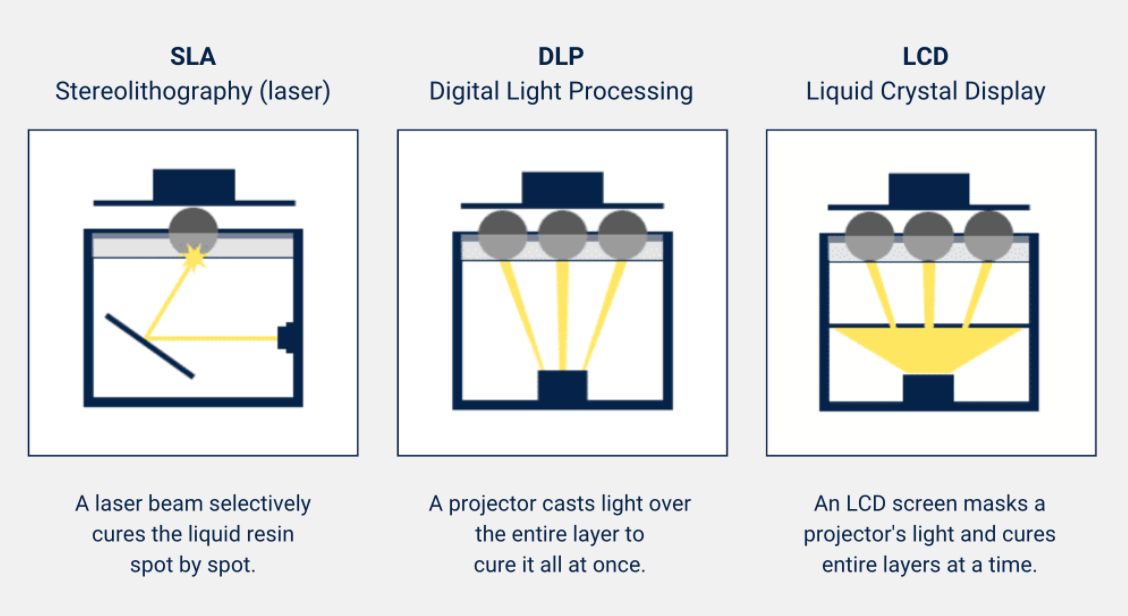

The fair mention of the term ‘resin 3D printing technology’ arouses many questions about what LCD, DLP, and SLA stand for, what role they play, and what importance they are to the industry.

What these three printers have in common is that they all use photopolymer resins in a resin tank and cure the resin to form solid 3D printer models.

If you are on the verge of investing in a 3D printing services and need detailed information as to which of these three printers would best suit your style of work and business model, stick with this buying guide for a while—its high time we demystified all the jargon attributed to this resin printers and help you make a well-informed decision.

LCD 3D Printers

Liquid Crystal Display {LCD} 3D printers are a low-cost resin 3D printer using LED lights to imprint patterns on flat surfaces. These 3D printers provide high precision with a smooth and delicate surface finish.

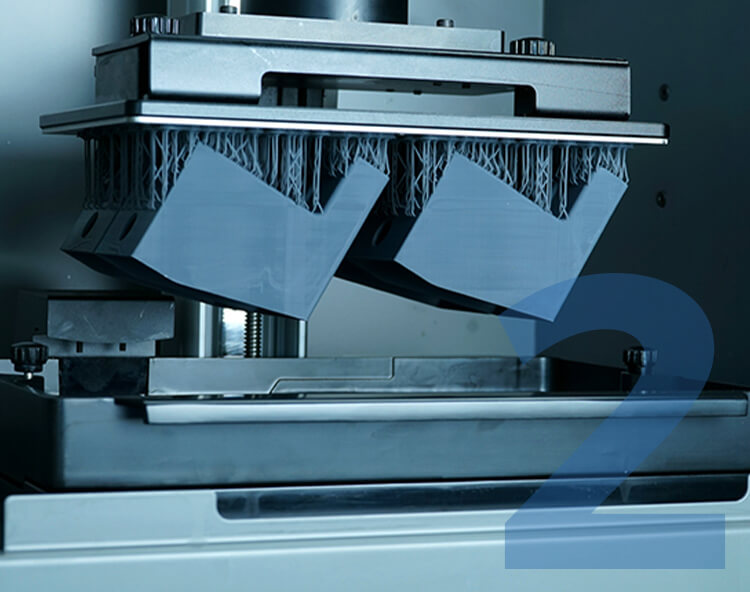

Unlike most other resin printers available, the liquid 3D printing process involves flashing entire layers at once to imprint patterns on the material housed in the resin tank without the interference of an external object or material.

The LCD 3D printers involve a simplified process similar to that of laser beams {note that LCD 3D printers use an array of UV LCD as its light source} but provide a more thorough finish.

DLP 3D Printers

Larry Hornbeck is the mind behind the Digital Light Processing {DLP} 3d printers. Invented in 1987, DLP first served as a tool used for movie projection—its original design and sequence was meant to serve the movie industry. But with the mindless advancement and growth in technology, it didn’t take long for the printing industry to adopt the tech.

DLP 3D printers make use of a projector. The projector flashes light onto the resin’s entire layer at once, selectively solidifying the part using thousands of minuscule mirrors called DMDs (digital micromirror devices).

The DMDs direct the projection of light. Like the regular 2D and 3D printers, these projectors are made of Pixels with layers consisting of voxels.

SLA 3D Printers

Stereolithography {SLA} 3D printer is widely viewed as the oldest 3D printing technology. SLA set the framework for the designs and concepts used in most modern-day 3D printers. SLA printers use a laser beam to selectively solidify parts of the resin stored in a resin tank or resin vat.

The laser beams radiate from the bottom part of the tank and are directed by mirrors {galvanometers} to the area or surfaces that need to be marked. This process is carried out continuously till the intended pattern is fully imbibed into the material.

Basic Difference Between LCD, DLP, and SLA Printers

| LCD 3D Printers | DLP 3D Printers | Stereolithography {SLA} 3D printer | |

| Cost | Budget-friendly | Quite expensive | Quite expensive |

| Method Used to cure resin | Uses an LCD screen | Uses a projector | Uses a UV laser |

| Printing Speed | Fast. Does not require a manual tracing of each layer. | Fast. Does not require a manual tracing of each layer. | Slow. Requires manual tracing of each layer with the laser. |

| Resin tank size | Deep resin tank | Shallow resin tank | Deep resin tank |

| Print Quality | Depends on the printer used | Depends on the printer used | Depends on the printer used |

LCD, DLP, and SLA printers all proffer remarkable 3D printing solutions. However, it’s important to note that SLA 3D printers have lost their influence in the global market in terms of viability and usage amongst the three variants. SLA printers are quite slow and require manual labor to complete a task.

DLP, on the other hand, is one of the most viable. Its comes in different range and size and provides a smooth and highly efficient printing experience. Though in comparison with LCD 3D printers, DLP 3D printers are quite expensive. For the day-to-day hobbyist, any DLP or LCD 3D printer might look perfect for the job, but the same cannot be said for specialized experts looking to print high-quality resins.

LCD 3D printers are not just the cheapest available worldwide; they also provide a more durable and stress-free printing process. Liquid 3D printers come in multiple variations and are built with easy to use controls. Most LCD 3D printers are portable and can be used for both personal and industrial printing purposes.

Suppose you are still skeptical and don’t know the type of resin 3D printer to opt for. Don’t worry; this buying guide is optimized to help you make the right decision. To better understand why we made LCD 3D printers our preferred pick, let’s explore its relevance in numerous industries.

Application Field of LCD 3D Printer

LCD 3D printers come in different shapes and sizes and are used in numerous industries. While these resin printing machines are yet to garner mainstream usage in some of the industries listed below, the printers are already pioneering multiple innovations set to lead the bandwagon for the coming generation in the shoe molding jewelry casting, dentistry, and medical industry.

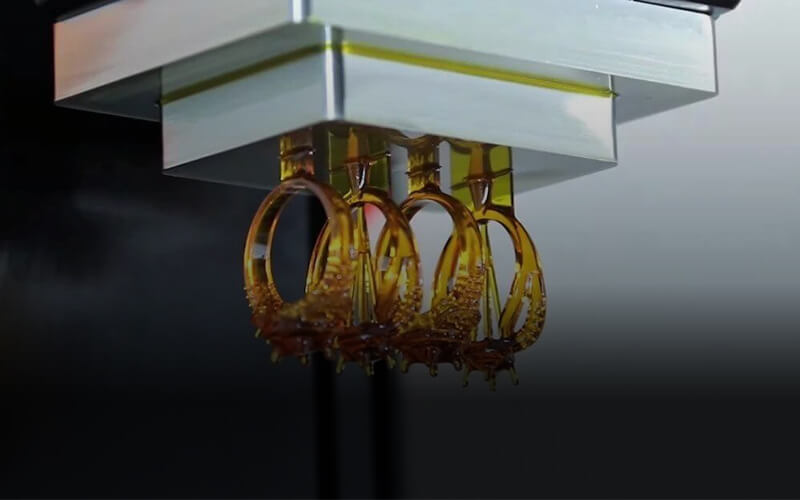

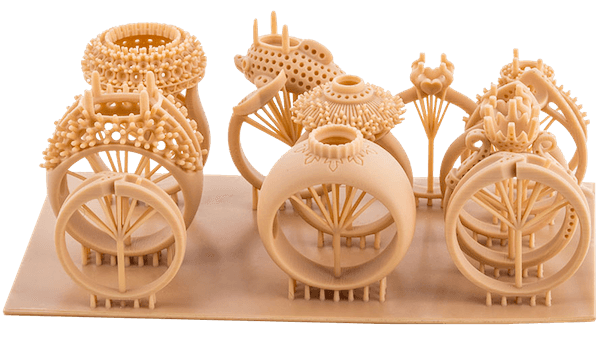

2.1, Used in the Jewelry Industry

Before the dawn of digitalized tech, making customized jewelry was incredibly expensive. Lost wax casting or investment casting, as it is widely known, was the only viable option. Back in the early 1950s, if you wanted a piece of customized jewelry, you would have to place your order months before the required time and pay twice or even three times the price.

The method of creating jewelry mold through lost wax casting is extremely complex. The precision and time required is quite daunting and made many folks disregard the rare privileges that come with a piece of customized jewelry.

However, since the inception of multiple 3D resin printing methods, the workflow and customization process has changed. Almost every jeweler now offers customizable options with unique designs. 3D printing made the jewelry mold creation process fast and accessible; it also made it cheap and affordable.

With an LCD 3D printing machine, creating a castable resin or prototype of a customer’s design is easy. The process is digitalized. That’s you can design 3D printed patterns for a jewelry design of choice via a CAD software tool and use an LCD 3D printer to produce high-resolution 3D printed patterns. Designers no longer have to spend countless hours designing precious one-off.

While the traditional method of creating jewelry still comes to play after burnout of the positive pattern, the production and manufacturing time is drastically shortened. With an LCD 3D printer, you can order and access your customized jewelry design within an hour.

Liquid polymer 3D printers are the most used resin printing machine around the globe. The design, freedom and fast production rate make it a viable option for every jewelry casting task.

2.2, Used in the Medical Industry

From dentistry to surgery and even in medical equipment, the LCD 3D printer has earned a renowned reputation for itself.

If you have ever visited a dentist, then you might have come across the term biocompatible materials. If such information is sounding alien, stick with this piece a bit; in a heartbeat, detailed info will be thrown your way.

Biocompatible materials are substances that elicit no unfavorable reactions from tissues. Visiting a dentist becomes crucial when you start experiencing unwanted pain or abnormalities within the mouth.

Biocompatible materials consist of intraoral parts such as night guards, surgical guides, and digital dentures. These materials are mostly 3D printed to have great strength and high resistance to wear.

With accuracy and repeatability being a vital part of dental procedures, most of the biocompatible materials used are designed to suit a specific patient’s needs. While a dentist can use biocompatible materials to kill pain and restore strength and vitality to your tooth, the process needs to be streamlined. Hence, it is accurate and can be repeated.

Another factor that comes into play when using 3D printed materials in the dental sector is production speed and scalability. To keep it simple, LCD 3D printers are amongst the few resin 3D machines pioneering remarkable development in the dental industry.

LCD 3D printer design process is not just optimized to create 3D resins of biocompatible materials used for dental procedures; it is also structured to maintain a specific level of precision and accuracy that can be seconded to none.

Note that our focus on the impact of LCD 3D printers in the dental industry does not in any way undermine its influence on surgical procedures and day to day medical appliances.

LCD 3D printers can customize pre-surgical planning models, identify patient-specific anatomical features, shape implants during surgery, and help communicate complex surgical procedures to patients.

2.3, Used in Production and R&D

When it comes to keeping up with the ever-changing trend, the pressure is always more on individuals in the production and R&D industry. Keeping up with customers’ constant demands, challenging competition, and varying customer needs requires materials and resources that can easily adapt to structural or categorical change.

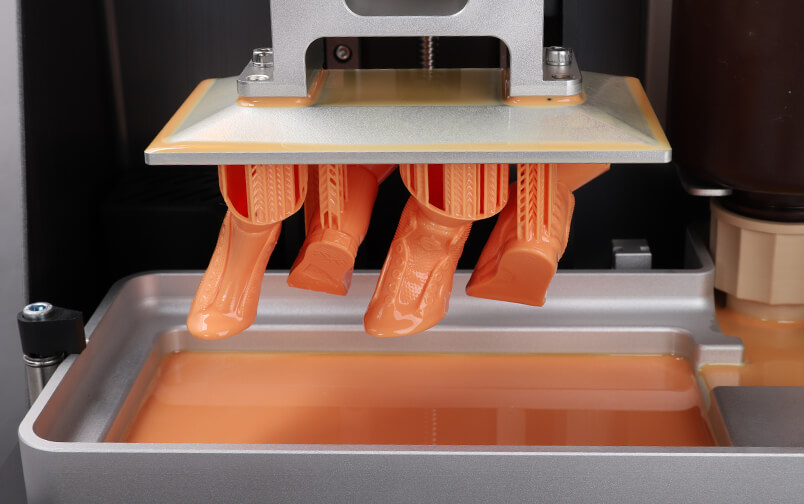

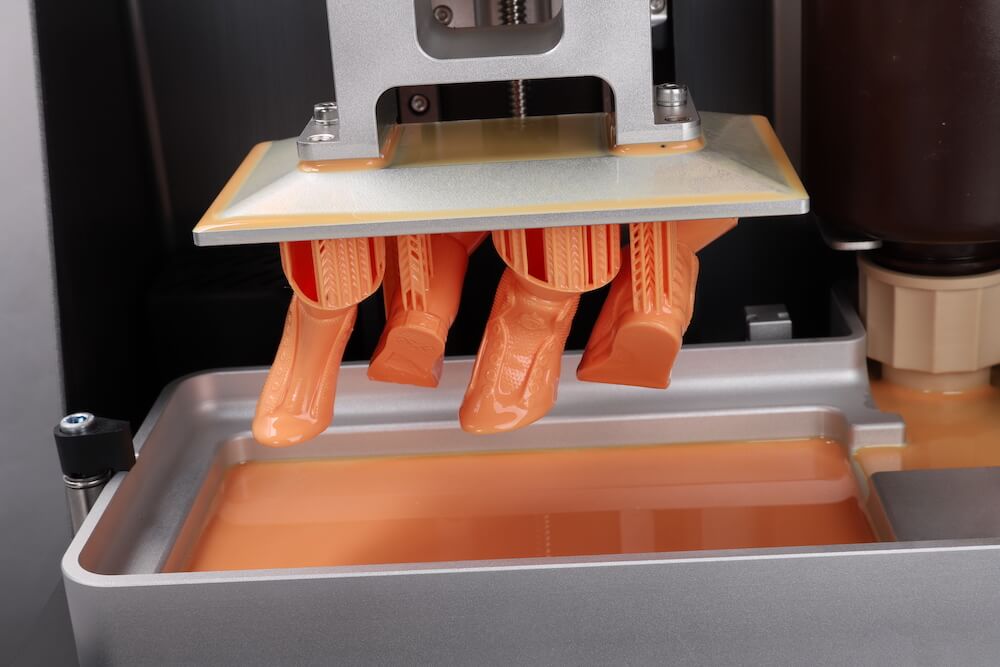

While the R&D industry is vast, shoe soles’ design and production hardly come to mind each time the term is used. LCD 3D printers play a substantial role in the design and creation of shoe molds.

With multiple variations of the liquid 3D printing machine available, small and large shoe companies enhance productivity and growth via the simple and fast mold creation process LCD 3D printers offer.

Ranging from show models, shoe molds to finished shoe soles, the introduction of LCD 3D printers influenced the production cycle.

Using an LCD 3P printer, hobbyist and professionals in the shoe making industry get to enjoy a 360-degree prototyping process, shorter labor time, accurate finish to complex shoe patterns and higher efficiency when printing multiple models of different specifications at a time.

The digital sector is also a major benefactor of the remarkable opportunities LCD 3D printers provide. Most of the innovation the digital sector brings to the world on a day to day basis underwent critical research and development procedures. From prototyping to modeling, production to manufacturing, numerous 3D models were created along the way.

LCD 3D printers remain a handy machine to professionals in the R&D industry because of the flexible operation sequence it brings to the table. Some of the major benefits LCD 3D machines bring to the production and R&D industry include

Design Iteration: the production sequence in most industries require a repetitive process. Although with the continuous change in customer requirements and the endless modification that comes with constantly evolving industry trends, effortless replication is essential. Liquid 3D printers help streamline an iterative process that keeps the production line on a constantly evolving front to meet its customers’ dynamic needs.

Fast and Efficient: designing and testing prototypes is a necessary task in R&D. To create viable products, due precautions must be applied during the design and testing phase. LCD 3D printers play an important role in this phase. With a 3D model to direct the workflow, individuals in the R&D team can enjoy a fast and efficient prototyping process.

Flawless Production: with a 3D resin model directing the flow of affairs in a production line, the mode of operation and workflow becomes easy, and durability of the end product is guaranteed. The use of LCD 3D printers in the production industry creates room for a flawless production line and also helps keep R&D experts operating at the same pace.

2.4, Used in the Education Industry

When it comes to the educational sector, 3D printing is exposing eager learners to practical real-time knowledge. While comparing the impact of 3D printers in the education industry to the mindless advancement extended reality tech is bringing to the sector might be a far cry at its current position, the possibilities 3D printers are opening up in education is limitless.

What is it you are trying to explain? The pathways in the brain? Genetic makeup? DNA? Complex algebraic algorithm? Name it, and you will have a 3D printed pattern delivered to your doorstep in no time. 3D printings make complex concepts look simple; it’s restructuring the learning sequence at a primary and university level.

At Primary Level

Saying LCD 3D printer can be used to make learning fun doesn’t do justice to the machine. 3D printings breathe life into everything they come across. It makes every design and model structured to communicate a specific information look and feel real.

Its introduction to the educational sector at a primary level has heightened student engagement with ‘otherwise boring topics’ to a formidable degree. With an LCD 3D printer at your disposal, you can help your students learn and grasp details the traditional educational spectrum leaves little to no room to explore.

At University Level

A lot of engineering concepts are alien to the mind. Field practicals are, in most cases, required to explain the design process attributed to these concepts.

With 3D printings, such concepts’ complexity can be demystified and practically broken-down from the four walls of a brick-and-mortar class—3D printings create room for a structural understanding of multiple designs. LCD 3D printers are widely used in numerous educational institutions around the globe.

2.5, Used to Make Various Models

Design and production models have gained widespread usage across multiple industries. Whether you are a jewelry hobbyist trying to create a prototype for a client or an architect looking to bring CAD designs to life to attract investors to a pending project, 3D models can help you get started on the right footing.

3D printings provide a real-time representation of an expected outcome. From fashion to tech, medicine to education, its usage is enjoying remarkable dominance.

LCD 3D printers are the leading resin 3D printing machine for designing models flexible enough to meet dynamic needs. LCD 3D printers come in different type, size, and range; you can explore our collection to get detailed info on a model suitable for the task at hand.

While 3D printings can help you get a step closer to your goal, creating high-quality 3D imprints isn’t a regular walk in the park. 3D printing requires 3D printers and resins that are compatible with each other. Feeling confused already?

Not to worry, this buying guide is detailed to walk you through every step of the way. The next chapter covers the type of resins you can print on using LCD 3D printers.

Which Resins can be Printed on LCD 3D Printers

If you have been in the printing line for a while, you wouldn’t need a buying guide to tell you that there are many resins with limited printers to do justice to them effectively.

LCD 3D printers can be used to print on numerous resins. Note that liquid 3D printers are not only useful for creating resin 3D models; they are also built to demystify the complex nature of multiple resins ensuring smooth and efficient finish on all fronts.

Below are some of the most widely used resins and compatible LCD 3D printers capable of creating beautiful 3D models out of their dynamic nature. Note that most of the LCD 3D printers mentioned below are available in our store.

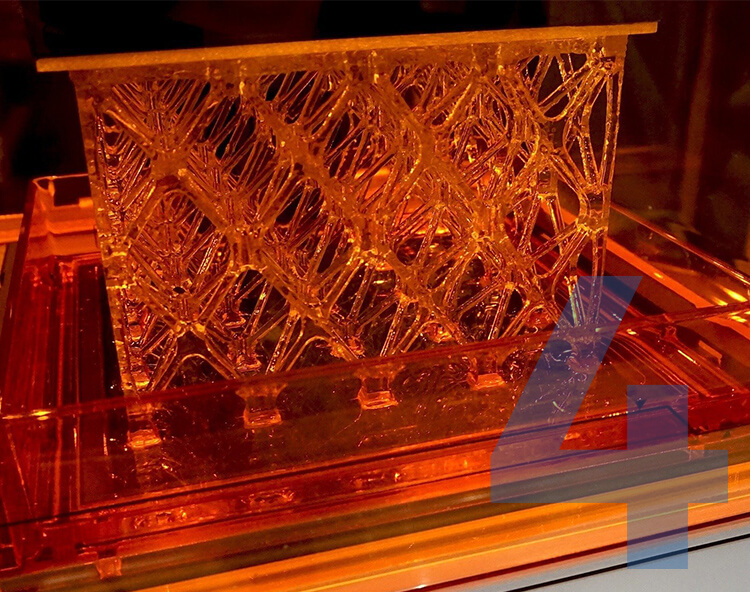

3.1, For Transparent Resin Printing

3D resin machines that can offer colorless and transparent 3D printings are in high demand. While SLA, DLP, and LCD printers can create transparent patterns and designs on any material of choice, not all of them can provide the smooth and efficient finish required.

One major problem affecting the transparent resin printing process is the elimination of bubbles. Most jewelers and hobbyists find it hard to eliminate bubbles when creating transparent resin prints, and in most cases, settle for end products not in line with their CAD model or design.

If you have encountered such a problem during a transparent resin printing process, you don’t have to settle for the notion that it’s unavoidable. With our DB-345 LCD 3D printer, you get to enjoy an efficient cooling process free of bubbles.

Our DB-345 LCD 3D printer comes with a 15.6-inch 4K high-precision screen and possesses a printing speed of 20mm/h—that’s you get to enjoy HD pixel printing and complete complex task within a short period.

The DB-345 LCD 3D printer is optimized to provide its model with a surface smoothness that eliminates bubbles. It’s important to note that while most of the information we have detailed thus far about the DB-345 LCD 3D printer is focused on its ability to keep your transparent resin printing free of bubbles, its functionality goes above such spectrum; here are some of the notable features you get to enjoy when using an DB-345 LCD 3D printer to cater to your transparent resin printing needs.

Exclusive UV Heat Dissipation Chanel: LCD printers, as you already know, make use of UV light to imprint patterns. Using an LCD printer for an extended period can result to overheating or malfunctioning. At Dreambot3D, one of our primary goals is to help our customers enjoy an impeccable printing process for long hours.

We built our DB-345 LCD 3D printer with an exclusive heat dissipation channel that helps regulate our liquid printing machine’s temperature, enhance print quality, and keep the LCD machine operating far longer than its warranty certifies.

4K High-precision Screen Exposure Imaging Display Technology: no one likes a complex machine. No matter how proficient a device is, complexity in its controls can hinder functionality.

We are well aware of this fact, and to ensure our customers are enjoying the all-round proficiency our DB-345 LCD 3D printer offers, the machine comes with an interactive panel that supports real-time human interaction. That’s you get to communicate with the DB-345 LCD 3D printer at an intelligent and humane level.

High Precision, Smooth and Delicate Surface Finish: Precision in design and finish is of utmost importance not just to the day to day hobbyist but also to the final consumer. A machine that doesn’t guarantee a finished product of high accuracy doesn’t only hinder sales; it can chase away existing customers.

At Dreambot3D, we love it when our customers provide feedback with a subtle yet priceless smile on their faces. The DB-345 LCD 3D printer is optimized to provide high precision with a smooth and delicate surface finish to all prints.

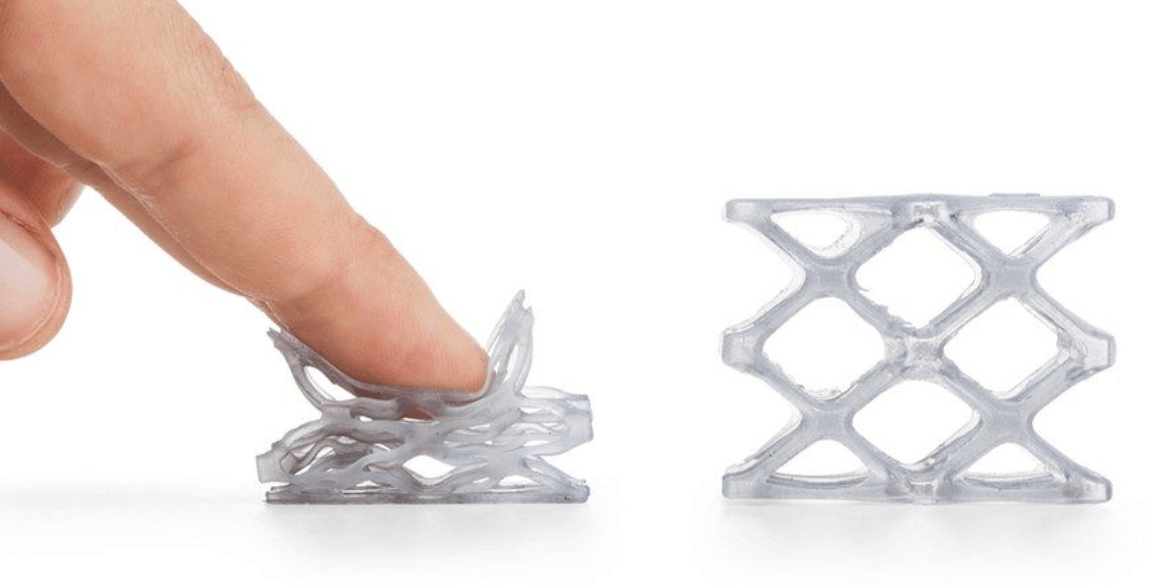

3.2, For Flexible Resin 3D Printing

You can use flexible resins in creating coatings, adhesives, and high-performance composites. This resin is dynamic and is widely used in numerous industries. Printing on flexible resins isn’t as complex or complicated as printing on transparent resins.

However, the importance of having the right 3D printing machine should not be in any way undermined. SLD 3D printers are quite outdated; you hardly find their dominance in any industry. DLP 3D printers, currently enjoying widespread usage, are quite expensive for day-to-day hobbyists looking to design a simple 3D model for jewelry casting.

When it comes to flexible resin 3D printing, the most viable option is LCD 3D printers. There are numerous models and variants of LCD printers available in the market. We know you wouldn’t fancy scouring multiple catalogs to find the right liquid 3D printer for flexible resins.

To hasten the process, we recommend trying out our DB-345 LCD 3D printer. The DB-345 is suitable for transparent as well as flexible resin 3D printing. Here are some of the perks you get to enjoy from using our DB-345 LCD 3D printer.

USB plug-and-play stand-alone offline printing: many printing companies shy away from LCD printers because of their reliance on computer plug-ins. Not anymore; the DB-345 LCD 3D printer is built to stand alone.

Whether you are offline and need to create a 3D model using flexible resins or are always finding it hard to configure your LCD printer to easy printing, the DB-345 got you covered. The machine is built to operate in offline mode with a transparent cover that allows you to observe your prints first-hand.

More Uniform Illumination: the DB-345 LCD 3D printer relies on light-activated resins to build objects. This LCD printer uses a large-format light source and directs the UV light into areas layer by layer to solidify them.

That’s you get to design 3D models or imprint patterns on materials systematically and uniformly. The Stereo-light curing 3D printing also provides an incredible surface finish with fine adhesion to details.

Reduced Resonance: having a noisy machine doesn’t just attract lousy neighbors; it also limits your workflow. At Dreambot3D, we know how important time is to productivity and wouldn’t for any reason create machines that hinder workflow.

The DB-345 LCD 3D printer comes with an all-metal integrated shell built to make printing more stable and improve accuracy. Our DB-345 LCD 3D printer is also built with a touch-screen interface that supports man to machine interaction. You can interact with the machine via Chinese or English.

3.3, For High Hardness Resin 3D Printing

Printing on high hardness resins requires an Industrial-grade large-size 3D printer. A simple google search would expose you to hundreds of such printers but guaranteeing the authenticity and credibility of the product can keep you scouring the internet for hours.

At Dreambot3D, we value LCD printers to any other. The smooth and unique finish LCD 3D printers are known for is in line with our brand value. We want to give our customers the best at the most cost-effective price, and the LCD modeling sequence seems to the most viable option for propagating such an outcome.

For high hardness resin 3D printing, we recommend you check out our ME-345 LCD 3D printer. The ME-345 LCD 3D printer uses cutting-edge light-curing 3D printing technology, which places liquid photosensitive resin in the printing area and selectively irradiates it with ultraviolet light.

The material is cured layer by layer under the action of ultraviolet light to form a three-dimensional product. The printing size is large, fast speed, smooth surface, high stability, low cost of use, widely used in engineering design, artistic handicrafts, dental care, and small-batch products.

Here are some of the Extraordinary Perks you will love the ME-345 LCD 3D printer for:

Humanised Operation Interface: yeah, there is no doubt that the ME-345 3D printer is big and bulky. A machine this big is certainly going to leave a lot of customers confused about its operational sequence. Like always, Dreambot3D R&D team considered this factor.

The ME-345 3D printer is equipped with a new UI interactive interface that supports humanized interaction. You can operate the machine via a man-machine communication sequence that supports English and Chinese.

Uninterrupted Workflow: creating 3D models might not require the endless hassle and stress individuals operating on a 9 to 5 basis experience daily, but that does not in any way means the workflow doesn’t get tedious at times. Our ME-345 machine is designed to support the alternate use of multiple work platforms.

That’s you can quickly replace a 3D model you are working on with another without interrupting the workflow. The LCD 3D printer can function for 24 hours non-stop without affecting the overall work quality.

Automatic Detection and Feeding: the ME-345 LCD 3D printer comes with a 2*1kg material box that automatically detects and replenishes low-volume reminders to ensure sufficient material, constant material, high stability, simple operation, plug-in and use, and clean flow. With this 3D printer, you get to enjoy a fast, efficient, and detailed printing process void of excessive waste.

3.4, For Castable Resin 3D Printing

Castable resins are widely used in the dental and jewelry casting industry. This resin is easy to mold and is quite cheap. While castable resins do not come with a lot of complications, the wrong printing process can hinder the final output.

DLP and LCD 3D printers are the dominant machines used for castable resin 3D printing. With our focus fixated on proffering the most durable LCD 3D printer for creating smooth and efficient 3D printings using castable resins, we believe it’s high time we introduced the ME-192 3D printer.

The ME-192 3D printer goes with the hashtag ‘born to be extraordinary and create the future.’ This tag gained traction around the ME-192 due to the remarkable features it possesses.

Unlike most of the other LCD 3D printers stocked in our store, the ME-192 3D printer provides a more delicate and detailed printing and is backed by an LCD Light-curing printer with nine high-end configurations and smart black technology.

Here are some of the advantages you get to enjoy from using the ME-192 3D printer to cater to your castable resin 3D printing needs

Powerful Cooling System: the saying that a cool head gets the job done doesn’t just hold through for humans. An LCD 3D printer that’s blazingly hot not only hinders productivity, but it can also get you frustrated.

At Dreambot3D, the last thing we want to see is our customers getting frustrated due to product malfunction. The ME-192 comes with a powerful Colling system that keeps the temperature of the machine in check.

A large area under the built-in screen with multiple fans for heat dissipation ensures that the heat generated by continuous printing for a long time can be effectively dissipated. With our LCD 3D printer, you can design and imprint patterns on models all day long without having to worry about the efficiency or durability of the machine.

CNC Machining: if you have been in the jewelry casting line for a long time, you would definitely look at the good old days of hand-made cast with a smile thanking technology for the remarkable advancement it has brought thus far.

With our ME-182 LCD 3D printer, you don’t have to design or structure any model manually. The ME-192 is an automated printing machine. Designs are modeled via pre-programmed sequences.

Larger Molding Area: if you have been looking for a 3D printing machine with room for you to enjoy creativity without boundaries, then you need look no further. The ME-192 LCD 3D printer comes with a large molding area that can complete bulky printing tasks at once.

The large molding area is backed by a more stable slide rail performance helping retain precision and balance regardless of the size of the castable resins inserted in the molding area. The print size of the DLP 3D printers in comparison with LCDs are relatively small.

Most DLP printers possess a print size of about 6 inches while LCD printers possess a print size of 5.5 inches to 8.9 inch.

However, our latest invention, the ME-500 printer broke remarkable boundaries with the exceptional screen size it possesses. Purchasing our DB-550 LCD 3D printer grants you access to a large screen machine of up to 24 inches.

With the DB-550 at your disposal you can print 3D models of choice rest assured you wouldn’t have to contend with a small interactive screen that’s not flexible enough to touch nor bold enough to read.

One Time Printing and Direct Use: For wind blades with complex structures that are difficult to design, the ME-192 LCD 3D printer can be used to complete such printing structures without breaking the bank.

The light-curing printer has high precision, and the printing effect is close to the finished product, which can help design new products quickly with low-cost Research and development.

High-definition Display Screen: Many production lines settle for outputs far below their production capabilities due to lack of instructional information on how to use a 3D printer effectively. The ME-192 is built to curb such issues.

The LCD 3D printer comes with a high definition display screen that supports offline printing. The interactive display brings about a more conformable and highly convenient visual experience.

Our ME-192 uses a black-white screen with better light transmittance, exposure time is 3-4 times faster than the original color screen, the overall printing speed is higher, and the accuracy is higher.

3.5, For Photosensitive Resin 3D Printing

Photosensitive resins are a mixture of photo-initiator, monomer polymer, and prepolymer; this material can be cured under ultraviolet light focusing on specific wavelengths. The model printed with photosensitive resin material has a smooth surface, high printing accuracy, and high molding quality. Photosensitive resin 3D printing is compatible with the SLA, DLP, and LCD 3D printers.

Focused on LCD 3D printers known to handle all the challenges of photosensitive resin 3D printing proactively, we present the ME-345 LCD 3D printer. ME-345 has a larger printing space, high-volume product mold, low costs, and a short production cycle.

The finished product can be printed directly through 3D printing to realize small-batch production. Some of the benefits of using the ME-345 LCD 3D printer for photosensitive resin 3D printing include

High-Resolution Surface Effect: Purchasing the ME-345 LCD 3D printer grants you access to materials such as ABS resin material tray, spare film kit, and post-processing cleaning box.

With such a supporting list backing up the Tiny XY spot (0.008mm²) and fine layer thickness selection (0.02mm), the ME-345 printer is optimized to provide a printed product with clear details smooth surface finish is guaranteed.

Feel the Fun of Printing: are you tired of a boring printing process? Use this Dreambot3D 3D printer to step up your game. ME-345 uses cutting-edge light-curing 3D printing technology, which places liquid photosensitive resin in the printing area and selectively irradiates it with ultraviolet light.

The material is cured layer by layer under the action of ultraviolet light to form a three-dimensional product. The printing size is large and can design multiple 3D models at high speed.

3.6, For Heat Resistant Resin 3D Printing

Heat resistant resins are common in almost every industry. This low-cost resin does not require a dynamic printing process. Heat resistant resins are suitable for most LCD / DLP UV cured 3D printers with a wavelength of 405mm. Heat resistant resins possess high strength with 2% low shrinkage capacity.

Its ability to ensure the strength of the molded component instead of shrinkage improves printing speed, reduces hardening time, and maximizes LCD machines’ printing efficiency.

While most of the machines available in our store can serve as durable options for heat resistant resin 3D printing, we recommend the ME-192 LCD 3D printer.

The ME-192 is built with a layer thickness accuracy is 0.02-0.1mm optional, and the single spot area is only 0.01mm². The surface of the finished product produced by the 3D printer is smooth and delicate, showing the beauty of details.

Support Wireless Transmission Printing: with the ME-192 3D printer, you can enjoy a wireless transmission printing process. While a computer’s presence in designing and creating a CAD model is still essential, the machine can function perfectly via wireless transmission of the design.

That’s you don’t have to always connect the 3D printer to a computer each time you want to finalize a heat resistant resin printing task.

No need for Levelling Design: the ME-192 is not only popular for the unique surface finish it provides, but it’s also regarded as a more convenient option. The machine leaves room for you to access a new generation of leveling-free designs and enjoy one-time leveling. The machine is firmly fixed by 4 screws operating via a self-leveling core.

Shortens Production Cycle: when using a heat resistant resin material for printing, and the molding accuracy is high, and the processing of accessories with complex structures is difficult. 3D prints can be molded at once, and the molding strength of the accessories, which is high, can be directly applied to the product. That’s with a ME-192 LCD 3D printer at your disposal; you get to finalize hefty printing tasks within a short period of time.

3.7, For Conductive Resin 3D Printing

LCD 3D printers are popular amongst most experts specialized in Conductive resin 3D printing. Unlike the DLP 3D printer, which is widely known for the smooth and efficient surface finish it provides, LCD 3D printers are cheaper and can finish bulk work within a limited period of time.

Conductive resin 3D printing is not as complicated as the transparent 3D resin printing process. However, it’s recommended you take special precautions when picking a 3D printer for conductive resin printing.

LCD 3D printers come in different variants. Each variant possessing unique features suitable for a specific task. When it comes to conductive resin 3D printing, any LCD 3D printer can efficiently handle the task. In order not to keep you second-guessing yourself each time you come across a durable 3D printer for the job, we recommend checking out our DB-345 printer.

Our DB-345 LCD 3D printer comes with standard version configurations. That’s if you have ever used any LCD 3D printer before, you wouldn’t have a hard time navigating your way around the control sequence. With the DB-345, you are guaranteed a printing thickness accuracy that fully reflects the products’ details. Some of the bonus you get from purchasing our DB-345 printer include

High-definition printing: the DB-345 LCD 3D printer leaves room for every bit of the printing process to be shown in detail. The machine is built to accurately reflect the model’s subtle structural changes and add a qualified delicate texture till the physical model is created.

Life-Time Technical Support: at Dreambot3D, it’s not just about producing an innovative machine at low cost; it’s about satisfying an individual’s needs. Purchasing our DB-345 machine grants you automatic access to lifetime technical support—that’s you can contact our support team on a 24 hours basis, 365 days a year rest assured someone would be active to tend to your every need.

2 Years Warranty Policy: While all our machines are tested multiple times during the research and development phase, we are well aware that issues can arise at any time during or after shipping. Regardless of when and how such problems occur, we got you covered. Using our DB-345 machine to cater to your conductive resin printing needs entitles you to a 2-year warranty policy.

How to Buy A 3D Printer – Questions You Should Ask

By now, we believe you are familiar with all the intricacies attached to buying a Liquid 3D printer. From LCD’s meaning to comparison with other available printers, the application field, and the resins that can be printed on using the LCD 3D printers available in our store, we have covered it all.

We think it’s high time we focused on the most crucial aspect. This buying guide wouldn’t be useful without adequate information on the basic questions to consider when buying a 3D printer.

If all you did was to skimp through the previous chapters, we recommend that you don’t do the same here. Knowing and asking the right question is crucial to the buying process. Take out time to consider the factors listed below.

![]()

4.1, Before Buying, You Should Consider Your Own Needs

You don’t walk into a shopping mall without a detailed idea of the product you want to purchase. Yeah, you might have limited information of the product variants and the brands offering top notch quality, but not knowing the needs and desires you wish to fulfill from purchase can keep you scouring endless catalogs for hours.

Bear in mind that ‘needs’ and ‘wants’ are two different things. While they both go hand in hand, need comes before want. When looking to purchase an LCD 3D printer, your needs should be at the top of your priority list. To know what your needs really are, ponder on the below-listed questions;

On a scale of 1 to 10, which feature or services is the most prioritized for the LCD 3D printer I am looking to purchase? Are you of the notion that a machine capable of providing a smooth and efficient finish overrides all other features? Are you encountering overheating issues with your current machine and desire an LCD 3D printer offering an exclusive UV heat dissipation channel?

Pinpointing your priorities helps you determine the number one feature to look out for in any UV machine variant thrown your way.

Another way to determine your needs is by specifying what’s important and what’s not important. Will a USB plug-in and play standalone offline 3D printer add value to your business, or can such a feature be termed luxurious at the moment? What about the machine’s resonance? Do you have nosy neighbors you would like to keep off your back?

Note that what’s important for you might not be as important to the competition. Endeavor to take out time to pinpoint all the LCD 3D printer features and specifications that are in line with your business needs before exploring any catalog for a favorable option.

4.1.1 What is the Thing to Be Printed

If you have successfully pinpointed the prioritized features you require from an LCD 3D printer; it’s time to consider some basic factors influencing your buying decision from the side-lines.

Since you have taken out time to read through this buying guide this far, we are certain you do not require an LCD 3D printer just to show-off or make the competition know that you have arrived. At this point, we are confident you mean business and helping you make the best buying decision is of utmost priority.

It’s time to consider your industry and the resin you would be printing on regularly. While most LCD 3D printers are compatible with most of the resins available on the market, there are slight differences you might want to take note of. For detailed info on palatable resins that can be printed on using specific LCD 3D printers, please refer back to chapter 3.

If you have been in business for a while, you would know the type of resin you use in creating models for your clients on a regular. However, if you just started and are confused about the type of resin you would come across regularly, book appointments with industry experts and ask the right questions.

Bear in mind that if you don’t specify the thing to be printed on, you can end up settling for LCD 3D printers not in-line with your needs and goals.

4.1.2 What is the size of the Print?

You now know your needs and the thing to be printed; it’s time to consider the size. LCD machines come in multiple variants. Some are suitable for large printing tasks, while others possess printing molds that can cater to only small tasks.

How big is your business, and what size of prints do your customers demand from you regularly? At Dreambot3D, we have seen the irregularities and extra expenses that come with purchasing an LCD 3D printer that’s not compatible with the print size.

As you already know, we exist to serve you better. All the LCD 3D printers available in our collection can create prints of any size. You can spare yourself countless hours of stress by contacting our support team today—they would have a liquid 3D printer with the desired specification ready for you in no time.

4.1.3 What are the Special Needs for Printing Materials

For every purchase we make, there are always special needs attached. While you might prioritize purchasing an LCD 3D printer based on the smoothness and durability of the prints it provides, you don’t have to feel shy if you see a part of yourself longing, hoping, or praying the variants thrown your way should possess automatic detection and feeding features.

Yes, putting your special needs for printing materials last is the ideal thing to do, but that does not in any way mean you should settle for any LCD 3D printer without first investing quality time in scouting for a machine that can cater to your all-round needs.

If you have explored the above-listed factors and still feel you don’t have enough information to pinpoint the best LCD 3D printer for your business, put a call through today; our support representative is here to guide you every step of the way.

4.2, When Buying, Consider External Conditions

The fact that your needs come first doesn’t mean there are no external factors to consider. LCD 3D printers are high-value purchases—they are quite expensive and require a sizable investment.

Regardless of how big or small your business is, only the best LCD 3D printer can keep your customers satisfied on all fronts. Since we have considered the basic factors that authenticate such a purchase from your end, let’s take a look at some of the questions you might have to consider if keeping your customers satisfied is the desired goal.

4.2.1 Determine Your Ideal 3D Printer Style

Every liquid polymer 3D printer comes with numerous features that help it stand out from the crowd. It can be a unique multifunctioning sequence, short production cycle, wireless transmission printing, etc. The best way to determine an ideal 3D printer style is by navigating the needs and wants of your client base.

Are you buying the 3D printer to cater to your personal needs, or have a client base you need to keep satisfied? What sort of clients are you serving? What sort of 3D models do you create on a regular?

If you took out time to understand your needs and desires for a 3D printer, determining an ideal 3D printer style wouldn’t be a problem. If you find yourself caught in a situation where you can’t pinpoint the ideal 3D printer style that would help you better serve your customers, it’s best you go back to the drawing board and consider your own needs.

4.2.2 Resolution Requirement of the Machine

Your 3D printer’s resolution is the quality or level of detail at which your models are created. For an LCD 3D printer, movement on both the XY and Z axis determines the smoothness and durability of the output; smaller movements typically yield higher resolutions.

The output you obtain from a 3D printer is based on the resolution of the machine. An LCD 3D printer built with a low-resolution display would definitely leave you with shabby models, not in any way presentable. While most 3D printer’s resolutions are optimized based on make and model, it’s advisable you settle for a liquid 3D printer with a resolution of either 20 or 50 microns.

Note that the resolution requirement is based on the type of resin you print on regularly and the industry. Before settling for any LCD 3D machine, it’s important you get expert information on a resolution or display that would not only provide credible 3D models but would also serve a dynamic customer base.

4.2.3 Choose a Reliable Brand

For most professionals in the printing industry, it all comes down to brand. Hundreds of brands have built a formidable reputation for themselves by offering 3D printers with remarkable features.

While it’s essential you check out a brand’s track record and reviews from previous customers, it’s also important you don’t base your buying decision entirely on a brand’s name.

There are a lot of 3D printers available world-wide with reputable brand tags but void of the innovative design and features required to keep your printing line functional. Many brands built a good name for themselves in the early 90s but haven’t been able to keep up with the diverse changes needed to excel in the 21st-century market.

Before putting hours of research into exploring a brand’s portfolio or track record in the global market, make sure the 3D printer you want to buy possesses features in line with your needs and has been ascertained satisfactory by other users and experts in your industry.

4.2.4 Consider Weather the Price of the Machine is Acceptable

When buying an LCD 3D printer, the price rarely comes to mind until you are faced with the cashier at the front door ready to pay, only to find out your card has been declined. It might sound funny, but it’s true.

The best LCD printers are expensive, though not as expensive as DLP 3D printers. While the price tag attributed to a 3D printer shouldn’t be your number one focus when considering a formidable machine for your business, you might want to state your budget from the onset.

If you are on a budget and would like to be on a safe end, it’s advisable you put a call through to our support representative stating the basic features you require from the LCD 3D printer and the budget at hand.

4.2.5 Consider the Supplier’s After-Sale Service Capability

Many folks place all their focus on the remarkable features a machine offers and forget to obtain detailed info on what their suppliers after service is like. From experience, we can boldly tell you that a remarkable LCD 3D printer with no warranty policy guiding its purchase would do you more harm than good.

Every reliable LCD 3D printer supplier attributes a warranty policy of not less than 1 year to each product available in its collection. If you are about to purchase a 3D printer and a warranty policy of less than 1 year is thrown your way, abort purchase.

Also, take note of technical support. 24 hours support service is ideal. However, there are a lot of formidable companies not offering round the clock support. Before finalizing your purchase, try to ensure that the brand you are banking with possesses technical support with a viable track record.

4.2.6 Safety Configuration of the Machine

By now, you have made up your mind on the LCD 3D printer you want to purchase. You have set your needs and that of your client base ahead of budget, and you are all good to make payment; Wait! one more thing.

What’s the safety configuration of the machine-like? Hope you are not about to purchase a ticking time bomb? LCD 3D printer’s safety configuration can look complex, especially during rough situations.

Explore the dos and don’ts of the machine’s safety configuration, know where and where not to press in case of overheating, and above all, make sure your purchase is backed with an instructional guide.

Conclusion

At this junction, we believe you are well-equipped with all the information you need to purchase the best LCD 3D printer for business or home use.

3D models are gradually taking over the daily activities of professionals in numerous industries. From health care to education, Jewellery to R&D, you find LCD printers playing essential roles.

Buying an LCD 3D printer is in no way complicated; if you can stick with the outline we made evident in chapter 4 of this buying guide, we are certain the best LCD printer would be handy in no time.

However, if you are still second-guessing your decision, not certain the LCD 3D printer you have in mind would effectively cater to the task at hand, our support representatives are here to for you – put a call through today.

FAQ Guide

What is LCD 3D printing?

LCD 3D printing is the action or process of creating a physical object from a three-dimensional model using UV lights. There are different types of LCD 3D printers available, each possessing unique features. An LCD 3D printer can be used to make everyday objects. Ranging from cups to toys to machine parts, name it. While the end product of liquid 3D printers is geared towards creating physical representations of 3D models, patterns, and designs and are incapable of producing the real thing, 3D printings are currently enjoying widespread usage across numerous sectors.

Is it illegal to 3D print a 3D printer?

Nope, 3D printing a 3D printer is in no way illegal. The best LCD 3d printers available in the global market were 3D printed during the research and development phase. However, it’s important to note that while it’s entirely legal to create a digital model of a 3D printer before executing the design, there are few items that are practically illegal to create a 3D representation of. One notable example is the printing of guns or ammunition in Europe. This act is strictly prohibited and is punishable by law. Before 3D printing any material, try to check out the legal standing with the region’s authorities.

Are resin 3D printers better?

When it comes to 3D printing, the best printer depends on the task at hand. Filament printers are regarded as the most durable machines for creating massive 3D printings, while resin 3D printers are renowned for printing small models with high precision to detail. So if you are trying to create a gigantic 3D model of an object, you should opt for filament printers. But if you are trying to print high quality and well detailed 3D models, then a resin 3D printer should be your go-to option.

How do LCD 3D printers work?

For an LCD 3D printer to display an image, it typically sends light from a metal-halide lamp through a prism or series of dichroic filters that separates light into three polysilicon panels. In simple terms, an LCD 3D printer uses an array of UV LCD as its light source. The printer shines light directly from the flat LCD panel in a parallel fashion onto the build area. As the light travels through the light source, the individual pixels open up to allow light to pass or close to block the light. This combination of open and closed pixels creates room for the LCD 3D printer to produce multiple colors and shades on the projected image. The light emitted from an LCD 3D printer isn’t expanded—that’s, it doesn’t spread beyond its projected frame. When using these 3D printers, you can design patterns and images of multiple variations; rest assured you wouldn’t experience pixel distortion halfway. Note that unlike most other resin printers, the LCD 3D printer print quality depends on its LCD density.

Is LCD better than DLP?

LCD 3D printers offer the same specifications and features as DLP but at a cheaper rate. DLP 3D printers make use of a projector. The projector flashes light onto the resin’s entire layer at once, selectively solidifying the part using thousands of minuscule mirrors called DMDs (digital micromirror devices). On the other hand, LCD printers involve a printing process that flashes entire layers at once to imprint patterns on the material housed in the resin tank without the interference of an external object or material. While LCD and DLP are both known for their high-speed operation and detailed finish, the price tags and modeling process are quite different.

How dangerous is resin 3D printing?

Resins are not as toxic as acid, but they are capable of causing unwanted burns if due precaution is not taken. The resin printing process can in no way be termed dangerous if you are the type of guy that adheres to safety instructions and take precautionary measures when needed. However, if you are the reluctant type, it’s important to bear in mind that the resin 3D printing process is quite toxic. A simple act of not wearing gloves can leave you with mild skin irritation. Not wearing eye protection can cause eye irritation. The resin 3D printing process is quite toxic; try to adhere to every safety recommendation.

Is LCD faster than DLP?

The speed of the modeling or designing process attributed to LCD printers varies based on the machine variant. High valued DLP printers operate at a relatively faster pace than the regular LCD printers. However, if pricing and portability come into play, liquid 3D printers are a faster and more durable option.

What should I know before buying a 3D printer?

There are a lot of factors to put into consideration when buying a 3D printer. First things first, you might want to take note of what you need the 3D printer for. Are you into commercial 3D printing, or are you a hobbyist looking to design personalized models? If you are looking for a 3D printer to satisfy your personalized 3D printing needs, you need not worry much about your buying decision; detailing out the features and specifications you require from the machine would do the job. But if you are looking to fill a market need and need a 3D printer for the job, put the following factors into consideration; who is my target audience? Do I need a filament or resin 3D printer to fulfill my customer’s needs? What specification and features do I need from a preferred 3D printer? What’s my budget like? To get detailed info on all the factors you need to consider when buying a 3D printer, please refer back to chapter 4 of Dreambot3D’s LCD 3D printer buying guide.

What is the most common 3D printer?

The most common 3D printers in the market are LCD and DLP. SLA 3D printers, which were once known for the remarkable modeling process they offered, are currently regarded as outdated printers in numerous industries. If you are looking for 3D printers that support a fast and efficient printing process, don’t hesitate to check out the LCD 3D variants available in our catalog.

How do resin 3D printers work?

Resin 3D printers make use of liquid resin. The LCD printing process occurs in a large tank and begins with a layer of liquid polymer spread over a platform. Since this piqued polymer is UV-sensitive, an array of UV LCD serves as its light source, hardening the area that forms one layer of your 3D print. The rest of the layer stays liquid. The platform is lowered, and the next layer is drawn directly on top of the previous one. When the object is complete, it is raised out of the tank via the supporting platform – much like a submarine rising to the water’s surface – with the excess liquid flowing away.

What is the best resin 3D printer?

LCD 3D printers are the best resin printers available. LCD printers are known for the smooth and efficient resin modeling process they offer. While there are numerous variants of LCD 3D resin printers available, they all possess some basic features that keep them operating at a preferred pace ahead of DLP and SLA 3D printers. Some of the features LCD 3D printers are known for include exclusive heat dissipation channel, high-precision screen exposure imaging display technology, high precision, smooth and delicate surface finish, more uniform illumination, reduced resonance, etc.

How strong are resin 3D printers?

Most 3D resin printers are designed via CNC machining. They possess structural makeup that can help them withstand high temperatures and reduce noise to the bare minimum. SLA, DLP, and LCD resin 3D printers are made from different materials based on the type of resin they are designed to mold and the industry they serve. With most LCD printers possessing a 24-hour nonstop operational capacity, you can purchase any 3D resin printer of choice rest assured; it’s built with materials durable enough to serve you for a long period of time.

Are resin printers faster?

Resin printers’ speed is dependent on the type, mold capacity, and model. When designing small 3D models with precision and accuracy, the reliability resin printers provide can be seconded to none. On the other hand, filament printers can be regarded as a more durable option when trying to create large 3D models within a limited amount of time.

Do LCD printers use a toner?

Yes, LCD printers make use of toners. Toners are designed for LCD and laser printers. Toner is a powder mixture made of granulated plastic. Laser printers and photocopiers use these mixtures to form printed text and images on paper. Toner is still widely used in SLA, DLA, and LCD printers. They are inserted into the printer through a toner cartridge.

Can you 3D print liquid?

Yes, you can 3D print liquid. It sounds bizarre, but it’s true. Researchers at the US Department of Energy’s Lawrence Berkeley National Laboratory developed a way to 3D print liquid using modified conventional 3D printing equipment. This equipment supports the printing of stable liquid structure. That’s for you to 3D print liquid; the liquid must be in a fixed and stable containment. Note that 3D printing liquid is quite complex; if you are not familiar with the regular printing procedures, it’s best you seek expert advice from a professional before embarking on the task.

How do liquid 3D printers work?

Liquid 3D printers make use of UV lights to create 3D models or designs out of resins. These printers generate their light source via an array of UV LCDs. This resin printer creates patterns or images composed of dots by either allowing or blocking light from passing through individual pixels in the panel. With an LCD 3D printer, the print quality depends on the density of the pixels contained in the panel.

How long does it take to 3D print a gun?

3D printing a gun can take from 30 minutes to 7 days. When it comes to 3D printing a gun, a lot of factors must be put into consideration. The first thing to consider is the individual or company’s experience catering to the printing task; if it’s a one-person job, what’s your experience or track record like? With that in mind, the CAD design, printer, resin, and other materials required for the printing process are to be considered. Note that the type of 3D printer you are using plays a vital role in determining the amount of time that would be spent or needed for the task.

What is an LCD printer?

Liquid crystal display {LCD} 3D printers are a low-cost resin 3D printer using LED lights to imprint patterns on flat surfaces. Unlike DLP printers, LCD printers don’t use mirrors to direct flashes across layers that cure resins. The LCD panels shine light via LEDs at the model, which the LCD panel blocks off in the areas that are not to be solidified. LCD printers are known for the incredible surface finish and fine details they provide.