Drone 3D Printer

The drone 3D printer allows you to print custom made drones. The drone 3D printer is used in the entertainment, agriculture industries, military, etc. The drone 3D printer prints accurately and fast.

How 3D printers work for Drone

3D design

drone

3D printing

drone

assemble

drone

3D printing is used to create 3D printed UAV and also help you with your drone project.

Drone parts such as the propellers, frame, antenna mounts, the prop protectors, landing gear, etc can all be printed with the drone 3D printer. You can carry out rapid prototyping at the same time and produce a finished product while saving printing material.

As a large commercial company like agriculture or entertainment, you can use the drone 3D printer to develop your drones. The printer can also be used by hobbyists.

The 3D printer allows production costs to be reduced unlike traditional production methods.

Crashing and breaking parts of your drone can be expensive. Instead of buying new ones, you can 3D print your own spare parts as needed.

You can also print optional drone accessories to add-on protective equipment like a prop guard.

Printing your 3D drones saves you more cost than the traditional drone.

Drone 3D printers for your Choice

LCD 3D Printers

FDM 3D Printers

Don't know how to choose a model?

Are you confused about how to choose the correct model and type of 3d printer? We support 24/7.

4 points why choose us

4K resolution printing

4K black-white industrial screen, 0.01-0.05mm layer thickness accuracy, more accurate printing of details.

PLC control system

All 3d printers are equipped with PLC control system as standard, makes the operation more convenient, and reduces the error.

Extremely speed printing

Large printing size, 20mm/h printing speed, complete your printing tasks faster.

Reinforced structure

The all-metal one-piece shell reduces resonance, makes printing more stable and improves printing accuracy.

What our customers say

3d printer for dental

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

How 3D Printers are Used in the Drone Production Industry

Drone 3D Printer Buying Guide

2.1, What is the Original Production Process Introduction

2.2, What Process can 3D Printers replace

2.3, What is the Changes After the Intervention of 3D Printers

Introduction to the Application Field of Drones

Applications of Drones are not limited to the military world only; rather, they are serving a big part of the economy with advanced mechanisms and impressive capabilities.

The growing interests of users in drone technology have developed new fields of application for it.

Presently, 3D printed racing drones are working in so many areas, and with continuous advancements in technologies, these machines are going to be more robust and useful in the coming future too.

They are now able to carry huge payloads and can serve users with longer flight times as compared to their older versions.

With drone 3D printers growing technology, many new sensors are being added to drones so that their operation can be highly optimized and they can work for dedicated applications with high performance. 3D printed drone frames are now working in all fields where humanity uses to operate; you can find them in the agriculture industry as well as in the world of the internet.

Let’s highlight few industries where drones are widely used

Agriculture and Farming

3D printed mini drones are used in the agriculture field. It is especially right for mass farmers who had reported significant changes in agricultural output with the use of drones. Agricultural land’s routine aerial monitoring can provide you with in-depth crop performance analysis.

Moreover, 3D printed drone propellers may perform this evaluation at low expense without impacting the environment or the fields. It not only results in a healthy crop growing but also will increase their yield.

Drones are used to spray pesticides, scare away crop-eating birds, and perform other jobs. About ten days of regular work is done in around two days because of these quadcopters.

Shipping and Delivery

As advanced 3D printed drone kits are capable enough to carry heavy payloads, so they can now be utilized for shipping and delivery applications. It will help people get instant service for requested products at their doorstep, and the best part is it will not stick anywhere in a road jam. You can now get your food order within few minutes at your place.

Weather Forecasting

Meteorologists need 3D printed micro drones to make a more accurate forecasting activity regarding the current weather systems affecting a specific area. Satellite images from manmade satellites are space drones that facilitate meteorologists to capture images from space to provide a more detailed weather system to a particular area of the world. These are highly sophisticated drones that are used to interact with radar mapping technology to track any changes in the weather pattern.

Architecture

Another great application of 3D printable drones is in the field of architecture. Drones can be used in building, construction, architecture, and design. Since they are very small, they can easily reach places that humans cannot. Drones can be used for planning the construction and design. Architects also use drones for impact studies.

Law Enforcement Surveillance

Drones are commonly used by law enforcement agencies to monitor the progress of public safety. The police department, as well as the military agencies, use drones to monitor any suspicious activities that could signal safety risk to the affected community.

Both the military and the police department use some of the best 3D printed drones with specialized sensors such as infrared or heat-sensitive cameras to track any suspicious activities within the monitored target areas.

3D Printers for Industrial Application

Using a Drone 3D printer to print drones require adherence to 12 basic steps. Before we go into the steps involved in 3D printing drones, let’s list out the materials you need to have on the ready.

- 3 Cell LiPo Battery (1)

- 10×4.5 Propeller (4)

- 900Kv Electric Motor (4)

- M5 Nuts and Bolts (16 of each)

- 20A ESC (4)

- NAZA M LITE Flight Controller (1)

- Transmitter & Receiver (1)

- Power Distribution Board (1)

- 3.5mm Bullet Connectors (1 Pack)

- Shrink Wrap (1 Pack)

- Zip Ties (1 Pack)

- Drone 3D printer

Steps Involved

Print the Frame: Here are the STL files for the arms and the plates. You will need to print four arms and two plates. For design purposes, the top and bottom plates are exactly the same, so you will only need these two files.

Solder Bullet Connectors: The ESCs come without plugs attached, so you need to solder on 3 3.5mm bullet connectors onto the ends of black, red, and blue wire. Apply shrink wrap over the top of your connection by sliding the shrink wrap over the wire and connector and holding a lighter beneath it for about 3 seconds.

Solder to Power Distribution Board: After attaching the bullet connectors to one end of the ESCs, you need to flip them around and stick the red and black wire on the opposite side through the slots in the base of the arm. After doing so, solder these wires onto the power distribution board. The positive rail is on the outside, while the negative rail is on the inside. It helps if you apply some solder to the board, then to your wires, and then heat them up while making contact.

Next, you need to solder the two wires onto the input terminals—red on the outside and black on the inside just as before. You will need to have soldered on bullet connectors to each of these wires as well as applied heat shrink. After that, mount the power distribution board to the bottom of the top plate. Use double-sided tape for this and try to keep it as centered as possible.

Attach Flight Controller: mount your Naza M Lite to the top of the bottom plate. For this task, we use the same double-sided tape from the previous step. Now take the PWM connectors provided in the flight controller package and plug them into the side with A, E, T, R, U, etc., in no particular order. Leave the port labeled X3 open. Take to PWM connector from the black box and plug it into the X3 port.

Solder Wires from Flight Controlled onto Power Distribution Board: solder on the wires from the black box onto the power distribution board. As always, positive on the outside and negative on the inside.

Attach Motors: Using the screws that came with the motors, attach one motor onto the end of each arm. Be sure to put a dab of lock tight onto the threads before you screw them in. Next, attach the wires from the motors to the ESCs. Red>Red Black>Black Blue>Yellow.

You can also attach the props in this step. First, put the black washer onto the threaded rod, followed by the prop, followed by the cap.

Note that opposite motors should have the same type of prop on. For example, if motor 1 has a clockwise prop on, then motor three must also have a clockwise prop on. This means that motors 2 and 4 must have counter-clockwise props on.

Attach GPS and Receiver: Using double sided tape, attach the receiver onto the top of the top plate. Then using various nuts, bolts, and washer, find a way to secure the GPS module onto the top of the top plate.

Attach ESC PWMs to Naza M Lite: remove the positive red wire from all but one of the PWM connectors attached to the ESCs and electrical tape into the other wires.

Feed the ESC PWMs up through the arm and back down the honeycombed section of the top plate. The arrow on the GPS indicates which way is forward. From there, determine the motor numbers. Motor 1 is front right. Motor 2 is front left. Motor 3 is rear left. Motor 4 is rear right.

The PWM connector for motor 1 connects on the flight controller into the port labeled M1. The PWM for motor 2 connects on the flight controller into the port labeled M2. The PWM for motor 3 connects on the flight controller into the port labeled M3. The PWM for motor 4 connects on the flight controller into the port labeled M4.

Connect GPS and Remote LED: Find the cable coming out of the box labeled REMOTE LED and connect it onto the main flight controller into the port labeled LED. Find the cable coming from the GPS, wrap it around the mounting rod and feed it through the top plate. From there, plug it into the flight controller into the port labeled EXP.

Connect Receiver: Now, you can connect the receiver. Individually string the PWMs from the flight controller up through the top plate and plug them into the receiver as follows.

A=Channel 1

E=Channel 2

T=Channel 3

R=Channel 4

U=Channel 5

X1=Channel 6

X2=Channel 7

Finishing Touches: Now, you can put out M5 bolts through the according holes and secure them with the nuts on the bottom. Endeavor to secure the ESCs onto the arms of the drone via zip ties. Finally, make a Velcro holder for the battery on the bottom and attach it with zip ties as well.

2.1, What is the Original Production Process Introduction

Today, when we think of drones, we tend to think of sleek, advanced planes and quadcopters. However, the world’s inventors and militaries first developed drone technology as balloons, torpedoes, and aerial targets – feats of invention and innovation at the time.

The word “drone” refers to Unmanned Aerial Vehicles (UAVs). In other words, aircraft that don’t require an onboard pilot in order to operate.

For our purposes, technologies in the drone sector will be broken down into two categories: drones that require a human operator to guide their missions and autonomous drones, which do not.

Since their first use in the mid-1800s, drones have been used for photography, security, safety, and environmental applications. However, warfare is responsible for paving the way for the drone technologies we have today.

Military units across the globe were among the first to recognize the benefits drones could provide to wartime strategies and began working on expanding the industry.

A breakdown of the drone’s original design process.

Design Overview

Firstly, research is done beforehand to choose the project title. Next, the mission of the UAV is specified, and base on the missions, the criteria will be made after that.

The manufacturing process by parts of the fuselage will begin after the process of designing the drone’s fuselage. Following that is the process of assembling the parts together.

The drone will have a test to check the stability after all components are ready. If any problems happen, the UAV will be sent back, and the problems are overcome.

This process will be repeated until no problems are found in the next test. The same process goes on with any improvements needed for the drone.

UAV design

More ideas will be generated during this process by having about three draft designs. After the best one is selected, a software is used to simulate the drone. The design will be ready to be manufactured at the end if no improvements are needed before that.

Manufacturing the fuselage

This stage requires careful choice of method and materials to produce the fuselage. The mold will be produced to generate the shape of the drone. Individual parts will be produced before they are assembled in the final stage.

2.2, What Process can 3D Printers replace

Drones are on the rise: forecasts predict that the drone market will grow from its $14 billion value in 2018 to over $43 billion in 2024. In keeping with this high-paced industry growth, rapid innovation is the key to competitive success. And 3d printed quadcopter frame is ideal for facilitating this.

As both professional and hobbyist drone use cases continue to expand, from FPV racing drone 3D print to disaster relief, goods delivery, and reconnaissance, 3D drone parts will play an increasingly decisive role in producing drones capable of new levels of performance.

Drone 3D printers shorten lead times during product development, lowers production costs, and empowers designers and manufacturers to take more risks with new cutting-edge 3D printed drone frames that provide new potential applications for the technology.

With drone 3D models for printing, designers no longer need to spend hours analyzing potential risks and drawbacks for a new design feature. A high-resolution drone 3D printer can produce new prototype parts quickly for testing, incurring minimal waste. Drone manufacturers can produce exchangeable modules with pinpoint geometrical accuracy without the need for expensive, time-intensive molded parts.

Introducing a drone 3D printer to the process shortens lead times, as producing a new part takes only a few hours. For example, the MRB-1 drone went from initial concept designs to a working prototype in four weeks.

The best 3D printers for drone not only provides an advantage through greater freedom of design and time savings, but it can also save a great deal of money. The use of shareable, easily modified CAD files during the design phase also made design reproductions easy.

This makes risk-taking and innovation while designing drones much more affordable. While developing their own drone, the U.S. Marine Corps found that the process of fabricating a drone cost around $600, not including the cost of purchasing a drone 3D printer. Compare that to a ready-made Raven drone to suit their needs, which could cost the Marine Corps up to $30,000.

2.3, What is the Changes After the Intervention of 3D Printers

The good thing about using drone 3D printers to create drones is that almost every part of the assembly can be 3D printed, with the exception of the electronic components. These include the propellers, the frame, the antenna mounts, the prop protectors, the battery housing, or even the landing gear.

Drone 3D printing is not limited to hobbyists or makers. Some commercial companies, such as Blue Robotics, also use this technology for the development of their drones. In addition to the main parts, other accessories such as mounts, boosters, or cases for storing the drones can also be created.

Besides the more professional applications, developing your own drones is also a very interactive way to learn about technology. That’s why this practice is starting to be used in education, as part of learning programs around technology. To facilitate the inclusion of this learning, there are companies like Dreambot3D that is dedicated to offering 3D printers for drone parts.

Another area where the use of a drone 3D printer is very interesting is in the area of public safety. General Drones is a company dedicated to the manufacture of emergency drones, which provides assistance and training for pilots and instructors. The company makes use of FDM technology to create the so-called Auxdron Lifeguard, which is capable of monitoring and controlling beaches thanks to its fast operation. In case someone is in danger, the technology can assess, locate and intervene to help the victim – this type of intervention is faster than human intervention.

What are the benefits of 3D Printer Intervention for Drone Manufacturers

The dawn of the Drone Age has already begun. We hear about these aerial vehicles quite often now. These unmanned flyers have proven themselves to be efficient workers, capable of carrying out precise jobs, and are expected to change our world in the most interesting ways.

Drones in the sky, in the sea, and on the land are now setting examples of how the technology is going to improve our everyday life. So far, these unmanned vehicles have been widely used for purposes like journalism, aerial photography, military transport, disaster aid, and spraying crops with fertilizers or pesticides.

The best part of this innovation is that 3D printers are making the design and creation process smooth, efficient, and more detailed. Let’s take a look at some of the benefits drone 3D printer intervention brought to drone manufacturers.

3.1, The Benefit of 3D Printers for Developing Drones

Create Spare Parts to Save Time on Searching

The time you are really flying the drone is quite limited. Usually, you would need a few minutes to get familiar with it, try to handle it, and make it flying smoothly and placidly.

When the drone is hundreds of meters high in the air, you are busy finding a proper angle to shoot a perfect photo. The trick is just shooting a dozen of photos and select the best one on the way back home. The battery will not wait for your art creation.

We are all easy to drop into the trap that we have become a master of flying the drones. And that is usually when the accidents happen. You’ve seen many photos of people running to catch their drones before the batteries are drained out, right? If failed, you have to search for the dispersed parts in the bushes and grass; it’s not easy work. Even if you find them, they are often not usable anymore.

Just cherish your weekend and use a drone 3D printer to make some tiny whoop 3D print spare parts—you ought not to drive for hours in search of those unrecoverable things.

Customized Drones

Drone 3D Printers allow you to manufacture personalized 3D drone frames according to an individual’s needs and requirements. This increases the feasibility of making customized drones. Any specific part of a store-bought drone can also be tailored to suit your needs.

Improved Performance

The weight of a drone affects its flight time. The lighter the drone is, the longer it flies. A light drone has improved battery life, is more responsive and agile during flight. It also remains stable in case of hard landings or crashes. The FPV 3D Printed parts are made lighter by optimizing the design structures to carry the required weight. The choice of raw material used for drone 3D Printing also plays an important role in making the parts light.

Make New Components to Cut Down the Time and Cost on Maintaining

If you are not an experienced UAV player, crashing and breaking parts of your drone is normal. Sadly, you can’t simply use the glue to repair the broken parts. Any unsuitable repair done by players is prone to render another flight disaster.

The after-sales services of most of the consumer UAV companies are barely satisfactory. It’s seldom possible to claim compensation, and the cost of spare parts is a little expensive. You will soon find that changing the parts of the drone is such a frequent event that buying official ones is a luxury.

So why don’t you 3D print your own drone with the help of drone 3D printers rather than wait in line and spend a lot in the UAV companies?

Easy Upgradation

Drone 3D Printers support the up-gradation of the drone’s parts to make it more efficient. Design iterations are very economical with the technology as compared to the traditional ways. This brings in the scope of making many modifications in the 3D design, 3D Printing them, and testing the 3d printed quadcopter parts till the desired result is achieved. Flexibility and speed do not stand in the way of the experiment.

3.2, What Production Processes have 3D Printers Replaced

While drones have been used by the United States military since practically the start of the century, they’ve become increasingly popular amongst average consumers only in recent years. In fact, different variations of drones can be found for sale online or even in local malls. So, it’s no surprise really that the drone 3D printing community is trying to find ways to take drones to the next level.

If you’re a proud 3D printed quadcopter drone owner, you probably know how easy it is for something to go wrong or malfunction—or it may simply just fly into something you didn’t see—leaving you to find a way to replace certain parts of it. Thankfully, because of drone 3D printers, you can easily replace and repair your own drones. Here are a few ways how.

First off, if you’re not swayed quite enough yet to use 3D printing to replace your drone, consider this: Doing so cuts cost heavily. While some smaller drones may be easy to put together, many of them are complex and, because of that, can quickly rise in price. 3D printed tiny whoops will help you cut down the costs associated with replacing your drone parts or repairing them when needed.

When something malfunctions or breaks, it’s important to first figure out what part of your drone needs to be replaced. It’s likely that you’ll be able to easily replace that piece using drone 3D printers. Here is a list of pieces that can easily be repaired through 3D printing: propellers, drone frames, and equipment housing, landing gear, protective guards, exoskeleton attachments, antenna holders, and mounts for cameras and other payloads.

In addition, FPV 3D printing allows you to customize your drone to your own liking. And when you want or need to make adjustments, you don’t need to reach out to a manufacturer to do it—which can be a lengthy, stressful process. Instead, you can make the necessary changes, adjustments, and repairs on your own, at your own pace, and to your own liking.

What are the Benefits of 3D Printers for Drone DIY

If you’re not an experienced RC pilot, crashing and breaking parts of your aerial vehicle can be expensive. Instead of buying new parts at a hobby shop, you can make a 3D model of your drone frame and 3D print your own spare parts as needed.

With your own drone 3D printer at hand, part designs can be easily upgraded and further developed to improve the performance of your 3D printed quad frame. On top of that, mini drone 3D prints are quickly interchangeable, and you can do it yourself.

You can even have the parts manufactured by a professional 3D printing service. Building your own DIY 3D printed drone serves as a great opportunity to learn about how it works and how it reacts to modifications you make.

4.1, Custom Drone Style at Will

Commercial drones can be highly expensive and out of reach for smaller businesses that rely on the use of drones to grow their business. Drone 3D printers cuts costs in many different areas, including prototyping, customization, and manufacturing, and therefore make specialty drones more accessible.

It also speeds up the design and prototyping process so that changes can be implemented and the design can evolve more quickly.

Prototyping with the best 3D printer for drone parts helps make customizing drones accessible even to smaller businesses. The process allows for unprecedented speed and cost reduction in making sure your drone is the best it can be.

Instead of waiting months to test new iterations, changes can be made to 3D printed quad within hours, then printed and shipped to you in days. Implementing changes quickly allows for faster evolution of a design and to find what is right for your business.

4.2, Customise Accessories that are not Mass Produced

A lot of drone parts are not mass-produced, making it hard for individuals that are trying to repair a damaged drone. The attraction of 3D printing goes beyond customization. It also allows large companies to launch products more quickly. In an ideal world, you could look at an Instagram post and turn that into a design that can go out the next day.

The move from mass production also allows manufacturers to make their operations more local. A lot of companies are looking for ways to shorten supply chains and to bring their factories closer to their customers. This reduces the need to ship mass-produced products from jurisdictions with lower labor costs, which increases supply-chain security and reduces carbon emissions.

Drone 3D printers could also help manufacturers protect the planet’s finite resources. Traditional manufacturing often means whittling down a block of raw material or estimating how many units to run off a production line — some of which are never used. Drone 3D printers can turn out exactly the right number of products with less waste.

4.3, Used to Repair Damaged Drones

It’s normal to find your drone shattered after a long ride or race. And while you can easily scout the market for damaged drone parts, you wouldn’t be able to find an already customized accessory for all the damaged parts.

Drone parts you can 3D print range from optional accessories to add-on protective equipment like prop guards. The latter is useful for small indoor quadcopters like the Hubsan X4 and gear protectors for the very popular Parrot AR versions.

Every part that will commonly bump into obstacles (including the ground) may need replacement at some point. If you 3D print drone spares, you won’t suffer from much downtime when this occurs.

Most drone hobbyists who get into 3D printing do so as an extension of what they already love to do. Drone pilots who are into racing are very attracted to learning how to make their own customized parts. On a purely cost-analysis basis, if the replacement part is available for less than $30 to $50, then it is probably cheaper to buy it than to pay a 3D printing service to make one for you.

However, this incremental cost per part goes down if you own a drone 3D printer. Then you need only compare the cost of buying a part with the cost of paying for the materials needed to print it, assuming you can download the design model for free. If the part is very expensive, discontinued, or it is a custom-made part that cannot be purchased, then 3D printing is the way to go.

What are the Best Materials: 3D Printed Drone Parts

3D printing technology has improved significantly over the past few years, and the price of 3D printers has come way down. When 3D printers first became available, they cost a small fortune. Consumer printers used to cost at least $5,000, which was far too much for the average drone hobbyist.

Now, a good-quality professional 3D printer can be purchased for $2,500 to $4,000, and a consumer 3D printer can be bought for under $500. At that price, drone 3D printing becomes a cost-effective option for drone enthusiasts. Almost every part of a drone except the motor, battery, and electronics can be created using 3D printing.

Let’s explore the various materials that can be used to 3D drone parts.

1: PET/PETG

PET (polyethylene terephthalate) is a thermoplastic polymer used for 3D printing drone parts. Mixed with glycol (hence the “G”) exhibits good 3D printing features. PETG FDM drone 3D printer material is resistant to high temperatures and water, presents stable dimensions, no shrinkage, and good electrical properties.

PETG combines ABS durability and PLA printability, and it comes as no surprise that it’s frequently chosen by professionals seeking a reliable filament for their projects. PETG gained a lot of recognition during the coronavirus pandemic because it can be easily sanitized and therefore is useful for medical applications such as face shields.

Note that You may encounter two options — PETG (sometimes written as PET-G) and PET. The “G” stands for glycol — a substance added to prevent corrosion and crystallization effects. Glycol modified PET is easier to 3D print. PET without glycol is more fragile and prone to breaking.

On the other hand, PETG is characterized by a delicate outline that’s easy to scratch. That being said, the chemical properties of PETG are far better for 3D printing despite some minor disadvantages. PETG is suitable for use on any drone 3D printer. If you are interested in created 3D prints with PETG and you are yet to find a suitable high-resolution 3D printer for the task, don’t hesitate to put a call through to our support team.

2: TPU/TPE

Thermoplastic polyurethane, or TPU, is a very common form of elastic polymer, or elastomer, capable of being used on any properly-equipped FDM drone 3D printer. Of the many kinds of flexible FDM 3D printer material, TPU is slightly more rigid than others, making it easier to extrude and use. It’s a medium-strength material with very high flexibility and durability, able to withstand much higher compressive and tensile forces than its more common counterparts PLA and ABS.

When printing, TPU exhibits minimal warping and shrinkage and, like PLA, doesn’t require a heated bed, although it is recommended. The ideal print temperature is between 210 and 230 °C, but this may vary from one manufacturer to another.

TPU doesn’t produce any notable levels of fumes while printing, but it’s not considered to be food safe. And though it’s a non-soluble material, it is hygroscopic, meaning that it will slowly absorb moisture from its surroundings, degrading over time.

One downside to TPU is the printing speeds, which are rarely higher than 30 mm/s. This is because it’s difficult to push the proper amount of filament through the hot end, resulting in prints taking a lot longer to complete. You can use any drone 3D printer to create formidable prints using TPU.

3: PLA

PLA filament is by far the most popular FDM drone 3D printer material, and there’s a good reason for that. It comes in many shades and styles, making it ideal for a wide range of applications. Whether you’re looking for vibrant colors or unique blends, it’s an easy-to-use and aesthetically pleasing material.

PLA is short for Polylactic Acid, a thermoplastic polymer that is derived from renewable resources, more specifically from corn starch or sugar cane. This sets the material apart from other commonly used plastics, which are procured through the distillation and polymerization of non-renewable petroleum reserves.

Since PLA filament is a biodegradable product, it tends to naturally break down in about three to six months. Other thermoplastic materials can take up to a thousand years to decompose, making PLA much more environmentally-friendly.

PLA material has been thrust into the spotlight by the rise of custom drone 3D printers. PLA filament is available in a wide variety of colors and blends, and innovative PLA-based materials seem to be constantly hitting the market.

Outside of drone frame 3D printing, PLA is also used to produce things like medical implants, food packaging, and disposable tableware. But inside of the FDM 3D printing sphere, PLA filament is widely thought of as an aesthetic material best used for prototyping.

4: ABS

As a thermoplastic polymer, it can melt and cool without altering its chemical properties. That makes it an interesting FDM 3D printer material. The filament is known to be strong, tough, and durable. It is also forgiving to scratches, offers good resistance to heat and everyday chemicals.

It can endure heat, pressure, and stress like no other material for drone 3D printing, making it a great choice for wear and tear prints. You can try this out yourself: If you move a strain of ABS filament, it will distort and bend before breaking. PLA breaks much more easily. ABS is quite forgiving, as long as you print with the right settings and proper temperature management. You can even achieve overhangs of around 45 degrees. If the print succeeds, the results are very convincing.

Most makers like the material because you can process its surfaces with acetone, glue parts, and even file off some material. Lastly, it can be easily painted with acrylic colors. ABS filament is not toxic when 3D printed. Only at very high temperatures (400 °C), the material decomposes into butadiene (which is carcinogenic to humans), acrylonitrile (possibly carcinogenic to humans), and styrene—nothing you want to inhale under any circumstances.

If you don’t have a drone 3D printer at hand, you can have ABS parts printed by a professional 3D printing service. You can put a call through to our support representative to obtain the best deal on a high-resolution FDM drone 3D printer.

5: Nylon

Nylon (a.k.a. Polyamide) is a popular material in the drone industry, known for its toughness and flexibility. Nylon filaments typically require extruder temperatures near 250 ºC. However, some 3D printers for industrial R&D allow printing at temperatures as low as 220 ºC due to their chemical composition.

Many drone 3D printers do not include a hotend that can safely reach 250 ºC, so these lower-temperature versions can be useful and potentially save you from needing to upgrade your hotend. One big challenge with Nylon filaments is that they are hygroscopic, which means they readily absorb moisture from their surroundings.

Printing Nylon after it has absorbed moisture will lead to several print quality issues; thus, filament storage becomes very important and requires special attention. Some of the Pros of using Nylon filament on your custom drone 3D printer include tough and partially flexible, high impact resistance, no unpleasant odor while printing, and has good abrasion resistance.

Cons of Nylon filament are prone to Warping, air-tight storage required to prevent water absorption, and improperly dried filaments can cause printing defects.

6: High -strength Resin

While FDM drone 3D printing technology uses traditional industrial plastics like ABS and Polycarbonate (PC), SLA, DLP, and LCD 3D printers require special photopolymer resins that harden (cure) once UV light is directed at it. Most 3D printing resins are either epoxy-based or acrylate-based, the latter being used more often in desktop printers.

A lot of people think of resin drone 3D printed parts as fragile and most suitable for ornamental and prototyping applications rather than functional and load-bearing components. But this is only true if the resin isn’t properly selected. That being said, if you’re buying a generic resin for a tough job, it won’t give you the strength that you’re looking for.

Examples of super-strong resin can be found in a wide variety of industries. There are castable resins for making jewelry and 3D printing in the field of dentistry to produce mouth guards, crowns, and surgical guides. There’s also high-temperature resins that are suitable for drone 3D printing.

Note that resin tensile strength values are usually measured by a pull test that follows strict international procedures, so the results can be used worldwide. The higher the tensile strength, the stronger the material is considered to be because of how much stress it can withstand.

Just because the resin is tough, it doesn’t mean that the 3D printed drone part made from these resins will be twice as strong as if printed with a standard resin. Other factors, like model design and print settings, play important roles in the final print’s strength.

Nonetheless, comparing tensile strength is a straightforward way to determine which material is stronger, and from the numbers supplied by the manufacturers, it’s clear that high strength resins are much tougher than the standard and is a more durable option for drone 3D printing.

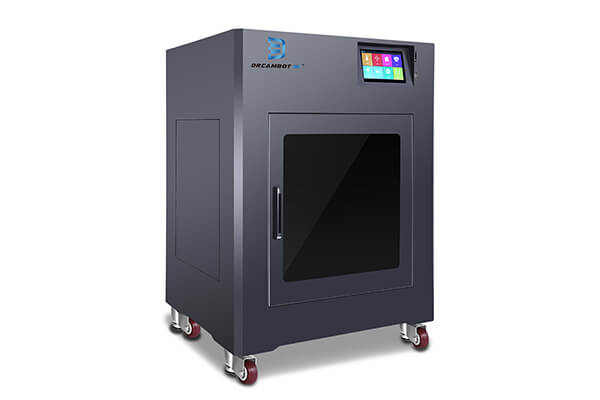

What Kind of Suitable 3D Printers can Dreambot3D Provide?

We have talked a lot about how drone 3D printers in revolutionizing the industry, the massive effect it’s having on RC pilots and drone hobbyist and the multiple professionals enjoying the impact of 3D printed drone parts in their industry, its high time we focused on the type of drone 3D printers available.

Dreambot3D is a drone 3D printer manufacturer dedicated to helping you enjoy a stress-free drone design and manufacturing process. Below is a list of some of the notable drone 3D printers available in our collection.

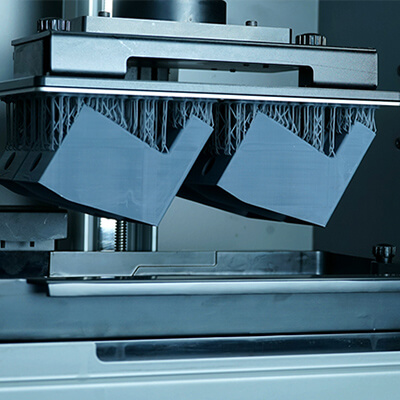

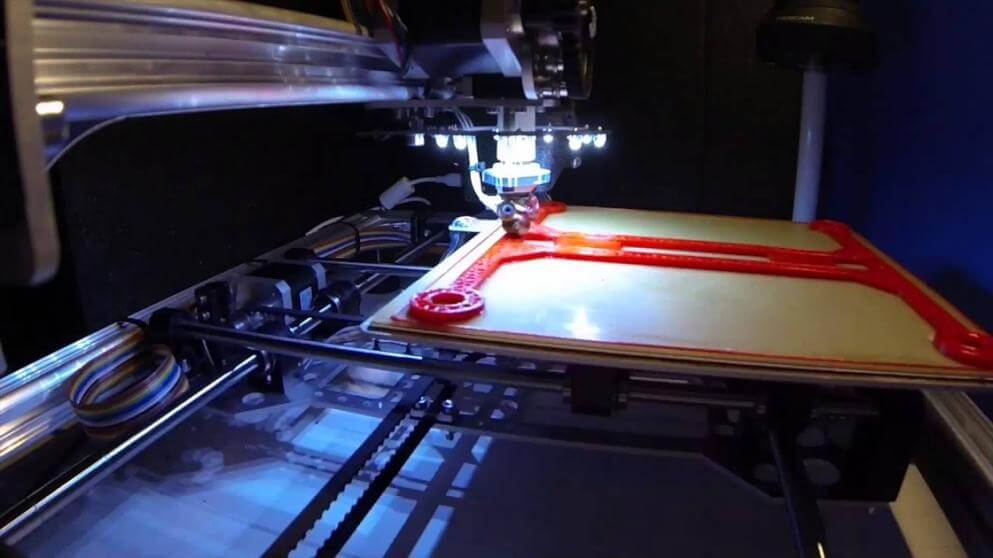

6.1, FDM 3D printers

FDM 3D printers are machines with strips that keep the plate from moving while in transit. Most FDM drone 3D printers come with a small interactive screen that’s flexible to touch and bold enough to read.

For an FDM machine to function properly, it requires a heated nozzle, a build platform, and raw material to build upon.

The printing process begins after the modeling software slices the 3D CAD file creating an extrusion path for the nozzle to follow. All necessary support needed by the object is factored into the extrusion path, and the nozzle movement is controlled via the interactive interface found on the machine. Here is a list of the FDM drone 3D printers available in our collection.

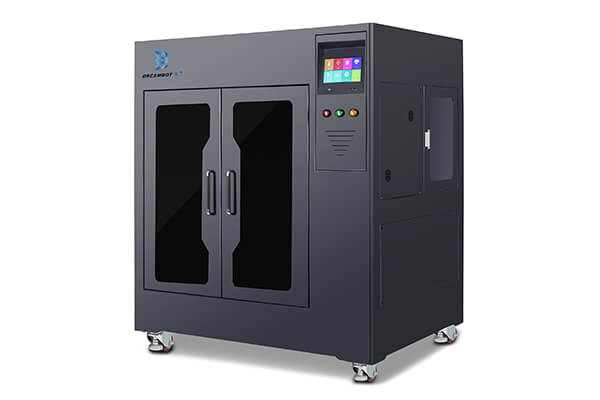

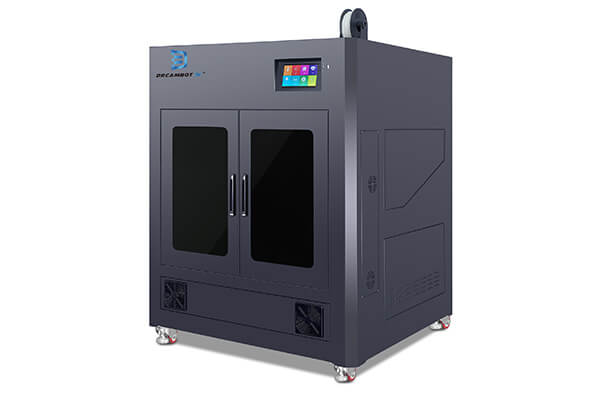

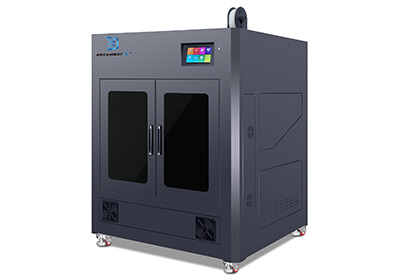

L-400 3D Printer

Dreambot3D L-400 FDM drone 3D printer makes use of FDM fuse manufacturing technology and offers a printing size of 400x400x500 mm.

Using our 400x400x400 mm L-400 FDM printer, you get to enjoy a high precision nozzle system that allows you to print any filament of choice. Our L-400 machine is designed via CNC cutting and forming. The sturdy frame design is optimized to give the machine a precise hole position and a better assembly process that keeps the printer printing with detailed accuracy even when operating at high speed.

L-500 3D Printer

The L-500 FDM drone 3D printer is a high precision extrusion system using double nozzles that can be customized. With our L-500, you get to enjoy a print size of up to 500x500x800 mm with automatic pre-calibration leveling that guarantees a smooth and efficient printing process.

Dreambot3D L-500 drone 3D printer also comes with newly upgraded Taiwan ball screws. Compared with the regular T-shaped screw, the Taiwan ball screw proffers higher straightness, lower friction coefficient, better smoothness, and more stability.

L-600 3D Printer

Obtaining L-600 grants you instant access to an FDM drone 3D printer with a 7-inch colored touch screen capable of offering a print size of 600x600x800 mm. The L-600 FDM printer can print any filament of choice and is regarded as one of the best FDM machines for creating 3D printed drone parts.

Dreambot3D L-600 600x600x600mm FDM 3D printers come with a drag chain wiring design; that’s, the protective wire is installed in the drag chain’s inner casing granting it access to play a protective role, thereby guarantying a safe printing experience.

L-800 3D Printer

Need a drone 3D printer with a 3MM thick sheet metal, fully sealed chassis with two air filter devices capable of creating prints of 800x800x800 mm? Then you definitely need to check out the Dreambot3D L-800 drone 3D printer.

The L-800 FDM printer is also built with an automatic recognition system that automatically pauses the printing process and raises a flashing red light alarm each time you fail to replace the model. That’s with our L-800 drone 3D printer; you need not worry about material waste or breakage.

L-1000 3D Printer

Are you trying to print large size materials at remarkable speed? Explore the remarkable features attached to our L-1000 drone 3D printer. The FDM printer can print large materials of over 1000x1000x1000 mm at a printing speed of 20-150MM.

The L-1000 drone 3D printers are equipped with humanize continuation mode + automatic memory function that keeps them operational at all times. If the L-1000 3D printer is seeming like the right choice for your production line, don’t hesitate to get in touch.

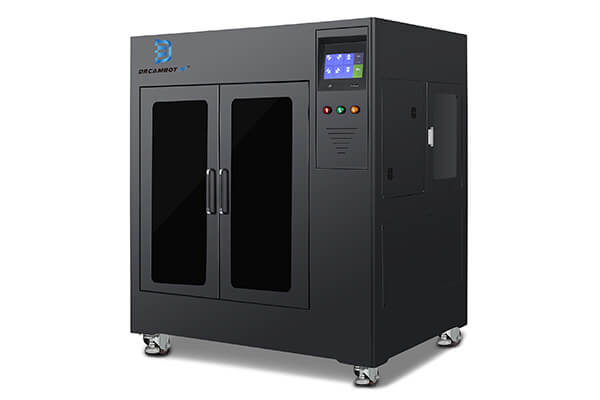

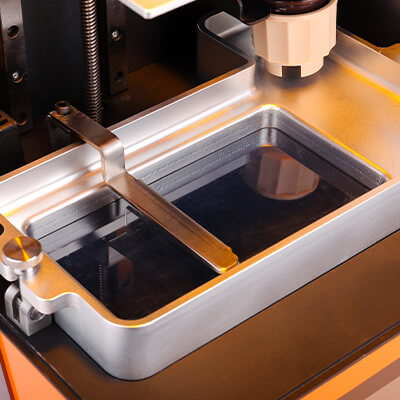

6.2, LCD 3D Printers

Liquid crystal display printers, or LCD printers as they are popularly known, are 3D printers use to create 3D models or designs of numerous objects in education, automotive, aerospace, medicine, dentistry, etc. Drone LCD 3D printers generate their light source through an array of UV LCDs.

These printers are used to create 3D patterns or images of CAD models using materials such as resin, wax, or metals. The images or 3D models obtained using LCD 3D printers are composed of dots.

The LCD 3D printer variants suitable for drone 3D printing available in our collection include;

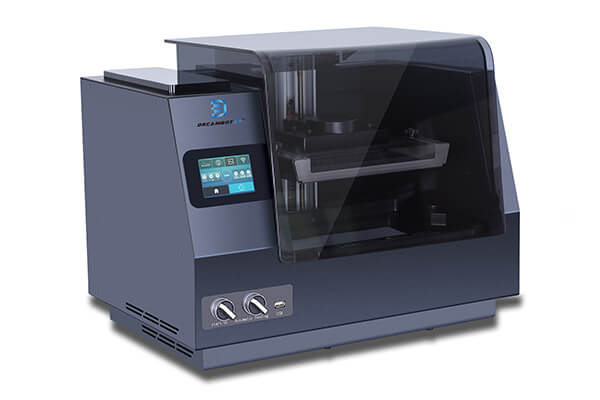

ME-215 3D Printer

With our focus fixated on proffering the most durable LCD 3D printer for creating smooth and efficient drone 3D printings using high strength resins, we believe it’s high time we introduced the ME-215 3D printer.

The ME-215 3D printer goes with the hashtag ‘born to be extraordinary and create the future.’ This tag gained traction around the ME-215 due to the remarkable features it possesses. Unlike most of the other LCD 3D printers stocked in our store, the ME-215 drone 3D printer provides a more delicate and detailed printing and is backed by an LCD Light-curing printer with nine high-end configurations and smart black technology.

ME-345 3D Printer

When it comes to drone 3D printing, any LCD 3D printer can efficiently handle the task. In order not to keep you second-guessing yourself each time you come across a durable 3D printer for the job, we recommend checking out our ME-345 printer.

Our ME-345 LCD 3D printer comes with standard version configurations. That’s if you have ever used any LCD 3D printer before, you wouldn’t have a hard time navigating your way around the control sequence. With the ME-345, you are guaranteed a printing thickness accuracy that fully reflects the products’ details.

How to Choose the Right Drone 3D Printer

Picking the right drone 3D printer requires prior experience. If this is your first time in the 3D printing market, then know that you would have a hard time pinpointing the right drone 3D printer to settle for. While the factors you need to put into consideration when purchasing a drone 3D printer are endless, we have detailed out the basic factors you need to keep in mind if you want to obtain the best 3D printing drone machine in the market.

7.1 What is the size of the Print

Drone 3D printers come in multiple variants. Some are suitable for large printing tasks, while others possess parts that can only cater to cheap 3D printed drones or tiny whoop frames.

How big is your drone 3D printing project, and what size of prints do your customers demand from you regularly? At Dreambot3D, we have seen the irregularities and extra expenses that come with purchasing an industrial FDM 3D printer or LCD 3D printer that’s not compatible with the print size.

Over the years we have been in business, we have had the opportunity of interacting with consumers from different countries and regions. One of the most highly influential factors most hobbyists or professionals who have walked through our door to purchase a drone 3D printer ignore is the size of the print.

Yeah, it’s practically impossible to determine the exact size or specification attributed, or that would be required in most of the prints you make—especially if you are a business owner looking to satisfy the needs of clients from different parts of the world. However, totally ignoring the print size of your industrial FDM 3D printer or an LCD 3D printer can create is unacceptable.

Before buying any LCD or FDM drone 3D printer, try to know the type of resin or filament it can print on and whether it’s durable enough to print perfect models on wide materials without leaving distorted edges.

7.2 Choose a Reliable Brand

Hundreds of brands have built a formidable reputation for themselves by offering drone 3D printers with remarkable features. While it’s essential you check out a brand’s track record and reviews from previous customers, it’s also important you don’t base your buying decision entirely on a brand’s name.

There are a lot of drone 3D printers available worldwide with reputable brand tags but void of the innovative design and features required to keep your printing line functional. Many brands built a good name for themselves in the early 90s but haven’t been able to keep up with the diverse changes needed to excel in the 21st-century market.

Before putting hours of research into exploring a brand’s portfolio or track record in the global market, make sure the drone 3D printer you want to buy possesses features in line with your needs and has been ascertained satisfactory by other users and experts in your industry.

There are so many drone 3D printers being developed and released into the market every day. While most of these printers meet the basic requirements and features of FDM and LCD drone 3D printers, you should not be hasty while sealing the deal yet. Why? You may ask.

Drone 3D printers are not cheap machines. You’ll part ways with a considerable amount of your money; therefore, you must ensure that you get the best drone 3D printer available. Your choice should not solely be made on the brands’ name. It is crucial that you do thorough background research on the company’s Google ratings and reviews before making a purchase.

Consider buying your printer from a drone 3D printer manufacturer that has a good track record, a higher rating on Google, and a genuine customer support system. Such a company will be apt to respond to all your urgent needs. The company/brand that you’ll pick for your printer can make or break your printing experience if something goes amiss.

7.3 Safety Configuration of the Machine

When purchasing or using a drone 3D printer, you must keep in mind that safety is paramount. And this is not just because you wouldn’t want to expose yourself to the toxic fumes most drone 3D printers emit during the design and creation process, but also because your ability to build a lucrative 3D printing business is largely dependent on how safe and ready-to-use your aerospace 3D printers are.

If this is the first time you are tasked with handling all the challenges that come with purchasing a drone 3D printer, the safety configuration of the machine might seem alien to you. Don’t neglect the durability effect that comes with purchasing a drone 3D printer with safety configurations that does not reflect the productive ability of the machine.

When making your 3d printing machine buying decision, you need to be on the safe edge. The only way to achieve this feat is by putting due diligence into every step involved in the process. Note that the safety configuration of most drone 3D printers is quite complex and bulky. To demystify this tiring yet important process, consult with a support service representative before finalizing your buying decision.

7.4 Resolution Requirement of the Machine

An FPV drone 3D print resolution is the level of detail quality at which your part is created. Drone 3D printers extrude plastic through a nozzle to create 3D printed objects. That nozzle pin can be adjusted to different widths to allow for higher or lower resolution printing. It’s necessary that you keenly take into account the resolution of a printing machine before buying one, depending on the industry you are operating in.

While the resolution requirement of a drone 3D printer is regarded as the number one factor to consider when making a 3D printer purchase by experts in numerous industries, this can be referred to as a myth that doesn’t apply to all. The resolution of an FDM or LCD drone 3D printer determines the clarity and precision that can be enjoyed from a given 3D model and pattern.

However, the resolution of a 3D printing system used in the drone industry doesn’t have to be on the same level as the one used in the aerospace industry. Buying a high-resolution drone 3D printer should be considered a priority if the funds and budget to finance it is available. But in scenarios where you are on a budget, you can save cost by analyzing the machine usage and model requirement.

Drone 3D printers come in different variants, shapes, and sizes, optimized with a fitting design and resolution. At Dreambot3D, our daily task revolves around catering to individuals’ dynamic needs and desires from numerous parts of the globe. We know how daunting navigating a machine with a proper resolution can be.

Dreambot3D core value is to provide satisfactory all-round services. To keep up with this mission, we offer a support team that can help you understand the resolution requirements of multiple machines, the industries they are optimized to serve and direct you towards multiple variants that would serve you better.

Note that while the quality of print detail is more paramount in some industries than it is in others, the resolution of a machine decides how fine the details of your part will be. A lower resolution, less quality, and low details on the print object. The objects will have smooth surfaces at the expense of extra filament usage and time consumption. A high resolution, conversely, gives fine quality and better details on print objects.

7.5 Consider Weather the Price of the Machine is Acceptable

It’s never a fun experience to have explored all the remarkable features and benefits a drone 3D printer is offering, weighed it with your production line, and obtained satisfactory results just to find out during checkout the drone 3D printer you want to purchase is far above your budget.

Drone 3D printers are quite expensive. They require a sizable investment, especially if you are looking for industrial-grade printers. As a professional or expert looking to help individuals from different walks of life obtain 3D printed foldable drone designs or finish the product they desire, having the best drone 3D printer is essential.

Before exploring all the features and benefits of a drone 3D printer, weigh its price range with your budget. Note that the price of a drone 3D printer does not determine efficiency. There are a lot of drone 3D printers with a high price but not as durable and efficient as counterparts with low price tags.

To hasten your 3D printer buying process in terms of price, it’s advisable you put a call through to a support representative backing up the activities of a brand of choice stating your estimated budget and the type of 3D printing activities you would like to carry out using the machine.

7.6 Consider the Suppliers After Sales Service Capability

LCD and FDM drone 3D printers are quite expensive. A good drone 3D printer requires an investment well above a thousand dollars. Budget and pricing is a basic factor that must be considered before you kickstart the buying process.

While most of the renowned printing systems available are quite expensive, don’t make the mistake of basing the efficiency or durability of a commercial-grade 3D printer on the price tags attached. There are lots of LCD and FDM drone 3D printers offering high-quality printing services at cost-efficient rates.

If you run a big production line or you are a drone hobbyist looking to purchase a remarkable drone 3D printer, and you firmly stand by the belief that your budget is sizable enough to purchase any printing machine of choice—we recommend you explore our catalog armed with the basic features and specification you require from a preferred FDM or LCD 3D printer.

On the other end, if you are on a low budget and require something substantial to cater to your day to day printing needs, please put a call through today—our support representative will guide you through the buying process.

Sometimes people tend to purchase airplane 3D printers based on the price only. The price of a drone 3D printing machine plays a big role in the decision-making process. But with so many industrial and commercial drone 3D printers available for sale at the consumer level today, you must keep a keen eye on the machine’s brand, resolution, and safety configuration.

7.7 Consider the Service Life of the Machine

The service life for most drone 3D printers is about 5 to 10 years. While the warranty policy on most 3D printers doesn’t grant you access to refunds or after-sales privileges 1 or 2 years after purchase, purchasing a 3D printer for the drone industry from a reliable manufacturer comes with the guarantee that your drone 3D printer will be in shape and keep your production line running for at least five years.

With that being said, it’s important to note that the estimated service life of the machine can change at any time based on external factors. How you use your machine determines how long it would last. If you leave your industrial FDM 3D printer or LCD 3D printer packed dirty on a regular, you shouldn’t expect the ten years life expectancy to hold any ground.

If you went gone through the hassle of finding the right drone 3D printer manufacturer, inspecting all the necessary features, and finalizing the purchase, you wouldn’t want the whole effort you put in to go down the drain based on negligence on your part. Try as much as possible to keep your drone 3D printer clean and in good shape, and service life expectancy wouldn’t be an issue.

7.8 Consider the Maintenance Cost of the Machine

Using drone 3D printers to create 3D printed camera drones for hours can cause some mechanical parts to lose their grip or hold to the machine; some might degrade after months of being used. If not upgraded, the final quality of your prints will consequently reduce.

Machine maintenance is necessary, and it might come with added costs where some parts like the nozzle may need to be replaced entirely. You must incur a reasonable maintenance cost of your machine to consistently get clean and fine detailed prints.

Dreambot3D is a 3D printer manufacturer that defied the odds by manufacturing drone 3D printers that are highly versatile, cost-effective, easy to use and maintain while still giving you high detail prints. If you are interested in finding out which drone 3D printing equipment is best suited for your needs, get in touch with our support team today.

Conclusion

This is where we draw the final line. At this junction, we believe you have all the information you need to make the right drone 3D printer buying decision. However, it wouldn’t be right if we draw the curtains without introducing our role in the 3D printer buying process.

Dreambot3D is a 3D printer manufacturer catering to the 3D printing needs of individuals in numerous industries. Unlike most other 3D printer manufacturers, Dreambot3D provides a one-stop solution for all things drone 3D printing.

So, whether you are looking for an FDM 3D printer or an LCD drone 3D printer capable of keeping your production line running at optimal speed, or you need individuals that have a clear understanding of what the 3D printing industry entails and are willing guide you through, don’t hesitate to get in touch.

FAQ Guide

Can I 3D print a drone?

3D printing can be a useful tool to create a drone or can help you to begin with your drone project. Indeed, this technology can be used to work on the design and the resistance of the drone. 3D printing enables you to do some rapid prototyping, but it’s also possible to produce a finished drone thanks to 3D printing.

How can I make a small drone?

The number of drones available on the market is ever-increasing. However, you may find that the drones currently on offer don’t suit your individual needs. Fortunately, you can build your own drone from scratch and create a unique, personalized gadget that is tailored to your requirements. The steps involved in making a small drone include: construct a frame

- Assemble your grain motor

- Mount your electronic speed controllers

- Attach the landing gear

- Add your flight controller

- Connect libre pilot to your drone

- Take your drone for a spine

How can I make a cheap drone?

Consult with any mechanical engineering guy, and he should provide you with the cheapest quadcopter. Fix a camera to it using light-weighted glue or tape. You can get cheap action cameras for some 1.2k. It wouldn’t be that precise like a real drone, nor will it have sensors. Just note that the more features you add, the more expensive it gets.

How can I make a homemade drone?

- Assemble your grain motor

- Mount your electronic speed controllers

- Attach the landing gear

- Add your flight controller.

- Connect libre pilot to your drone

- Take your drone for a spin.

How hard is it to build a drone?

Well, the difficulty level is pretty high, but that entirely depends on what your skill sets are; if you are new to the RC hobby, then it is far more difficult than if you’ve been building RC models for years. If you have no experience in electronics, radio engineering, programming, or any of those things, then it is quite difficult. Building a drone is literally like building a small flying computer. And one of the biggest and most important aspects of building a good, solid, reliable drone that won’t die after your first mistake is product research and product selection.

How does a drone work?

A typical unmanned aircraft is made of light composite materials to reduce weight and increase maneuverability. This composite material strength allows military drones to cruise at extremely high altitudes. UAV drones are equipped with different state of the art technology such as infrared cameras, GPS, and laser (consumer, commercial and military UAV). Drones are controlled by remote ground control systems (GSC) and are also referred to as a ground cockpit. An unmanned aerial vehicle system has two parts, the drone itself and the control system. The nose of the unmanned aerial vehicle is where all the sensors and navigational systems are present. The rest of the body is full of drone technology systems since there is no space required to accommodate humans. The engineering materials used to build the drone are highly complex composites designed to absorb vibration, which decreases the sound produced. These materials are very lightweight.

Can I 3D print a drone?

Yes, you can 3D print a drone. While it’s not yet common to fabricate electrical components like motors, sensors, or even electronics – but watch this space – it’s entirely possible to 3D print drone parts like the frame, landing gear, and propellers. And these are usually the parts that break easily.

Where can I print drone parts?

Ultimately, you will likely want to own a 3D printer, especially if you want to make many drone parts or create customized drones from scratch. However, before you jump in and buy a 3D printer, you may want to use outsourced 3D printing services to professionally produce your 3D-printed items. There are many commercial 3D printing services to choose from to get the object made based on the model design you choose

How can I make my drone faster?

There are a number of ways to improve the performance and stability of your drone, and much of this depends on how you intend to use your UAV and the weather conditions you’ll be operating in.

- Increase the Vehicle’s Power-to-Weight Ratio

- Reduce the Amount of Drag

- Add Wings to Your Drone

Is it cheaper to build a drone with a 3D printer?

Most drone hobbyists who get into 3D printing do so as an extension of what they already love to do. Drone pilots who are into racing are very attracted to learning how to make their own customized parts. On a purely cost-analysis basis, if the replacement part is available for less than $30 to $50, then it is probably cheaper to buy it than to pay a 3D printing service to make one for you. However, this incremental cost per part goes down if you own a drone 3D printer. Then you need only compare the cost of buying a part with the cost of paying for the materials needed to print it, assuming you can download the design model for free. If the part is very expensive, discontinued, or it is a custom-made part that cannot be purchased, then 3D printing is the way to go.

Is building a drone with a 3D printer worth it?

Yes, 3D printing is the most cost-efficient and easiest way to replace broken drone parts. With 3D printed parts, you have an infinite and quick supply of spare parts that will make your pilot training and everyday mishaps easier to handle. Besides easier repair, making a DIY drone will give you much more knowledge about the inner workings and mechanics of your flying machine.

Is building a drone hard with a 3D printer?

It depends. If you are new to the 3D printing technology, then you would certainly have a hard time navigating your way around the drone 3D printing process. However, if you have used a 3D printer before and are familiar with all the intricacies attached to 3D printing, then all you need is a detailed guide to direct you on how to go about the job. There are lots of online resources to explore—depending on the drone part you wish to 3D print.

How do you make a drone for a school project?

To build a drone for a school project, you would require basic equipment such as a small motor x4, motor jacket x4, propeller x4, lithium polymer battery, battery charger, ballpoint pen lead x2, Styrofoam, tape, glue gun, and 2.4GHz transceiver set. The steps involved in building the drone are:

- Place 4x small motors in a pen cartridge.

- Attach four motors to the receiver board

- Install battery

- Get a Polystyrene Cube

- Insert 2 Pen Cartridge

- Attach the Motors

- Connect and Turn on The Drone