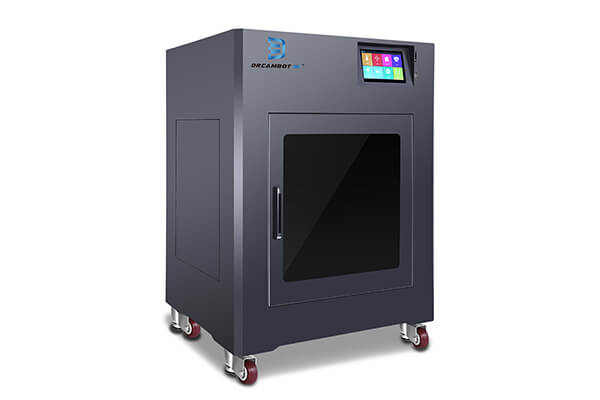

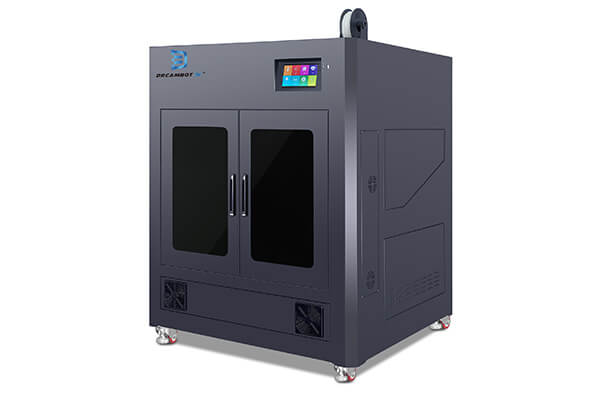

500x500x500mm 3D printer

L-500 FDM 3D Printer

- Using FDM process principle, it can support industrial-grade printing size up to 500x500x500mm. Its high precision can reach 0.05mm

- Industrial-grade FDM 3D printers are used in a variety of materials: PLA, ABS, PC, Nylon, Carbon Fiber, etc.

- Adopts PLC intelligent control and can print offline. Can continue printing after power failure

Dreambot3D 500x500x500mm 3D printer

The Dreambot3D L-500 500x500x500mm 3D printer is used for speedy and accurate prototype printing of digital designs. The 500x500x500mm 3D printer makes it possible to print heavy and complex 3D objects across industries like automotive, aerospace, educational, manufacturing, etc. It is an easy and reliable prototyping experience for users.

The 500x500x500mm 3D printer is applicable for use in personal interest projects and commercial projects. The FDM 500x500x500mm 3D printer makes use of easy to find materials such as ABS, PLA,PC, nylon, etc.

| Technical parameters | Model | L5-500 | L8-500 |

| Photo | / | / | |

| Max printing volume | 500x500x800MM | 500x500x800MM | |

| Printing platform | The platform moves down when printing | Fixed at the bottom | |

| Technical principle | FDM fuse manufacturing technology | ||

| Print head | High-precision extrusion system (double nozzles can be customized) | ||

| Nozzle diameter | 0.2, 0.3, 0.4, 0.6, 0.8MM | ||

| Consumable diameter | 1.75MM | ||

| Printing materials | PLA, TPU, 95A, water-soluble materials, wooden PLA; customizable ABS, PC, PETG, nylon, carbon fiber, metal filling materials, glass fiber addition materials, etc. (not available for 300 size machines) | ||

| Positioning accuracy | X axis 0.0011, Y axis 0.0011, Z axis 0.00125MM | ||

| Printing layer thickness | 0.05-0.3MM | ||

| Printing speed | 20-150MM | ||

| Printing platform | Heating aluminum substrate + black crystal glass platform | ||

| Platform temperature | 30-50℃ (30-120℃ optional) | ||

| Platform calibration | Automatic pre-calibration leveling | ||

| Nozzle temperature | 75-280℃ | ||

| Movement noise | 50 dB | ||

| Connection method | U disk, SD card (both as a gift) | ||

| Screen control | 7 inch full color touch screen (support all languages) | ||

| Chassis structure | 3MM thick sheet metal, fully sealed chassis | ||

| Filter function | 2 air filter devices | ||

| Lighting | LED lighting | ||

| Mechanical transmission | Double linkage gantry type machine tool linear navigation | ||

| Physical parameters | Dimension | 80x74x129CM | 80x82x160CM |

| Package Size | 85x80x144CM | 95x87x174CM | |

| Net weight | 100KG | 128KG | |

| Gross weight | 130KG | 160KG | |

- The FDM 500x500x500mm 3D printer is compatible with these 3D modeling software; UG, Solidworks, ProE, CAD, Rhino, Maya, Sketchup, etc.

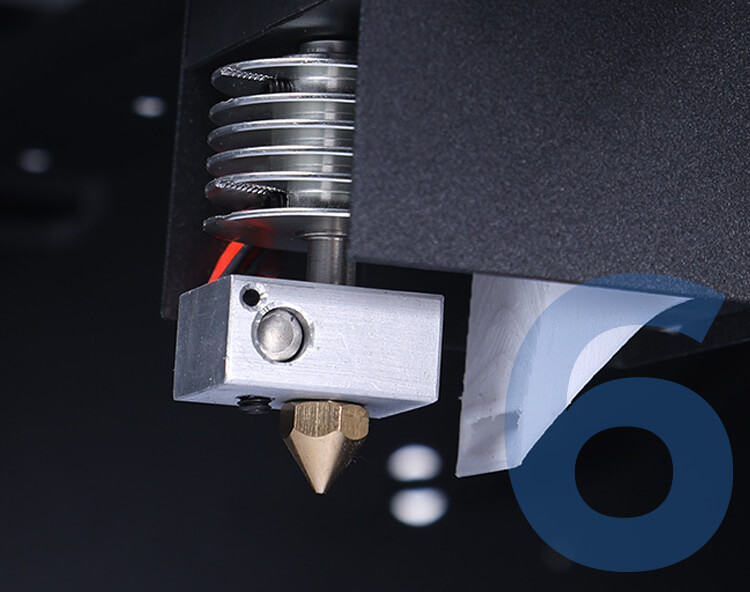

- The special nozzle system in the 500x500x500mm 3D printersmoothly discharges material on each layer, which gives detailed printing of all your objects.

- The power use of the Dreambot3D L-500 500x500x500mm 3D printeris between 110-220V. The printer power supply has a continuous warranty of five years. Therefore, you don’t need extra costs for power supply, this saves the costs of production.

- Power failures are bound to occur when printing is ongoing, this however does not hinder the printing process. The dimensional 3D printerhas an in-build memory that allows it to continue print even after an interruption.

- In some cases, materials can finish while printing is on, this often causes fear of error in printing for many users. The Dreambot3D L-500 500x500x500mm 3D printernotifies you with an alarm system. After filling with material, printing continues without any defect or error in printing.

- Printing 3D objects can now be done with details and accuracy of up to 0.05 to 0.2mm.

- The hydraulic buffer push rod allows for a more convenient opening and closing of the cover of the 3D printer.

Test your part

We provide sample testing service, allowing you to check the working quality of our 3D printer before placing an order

6 points why choose us

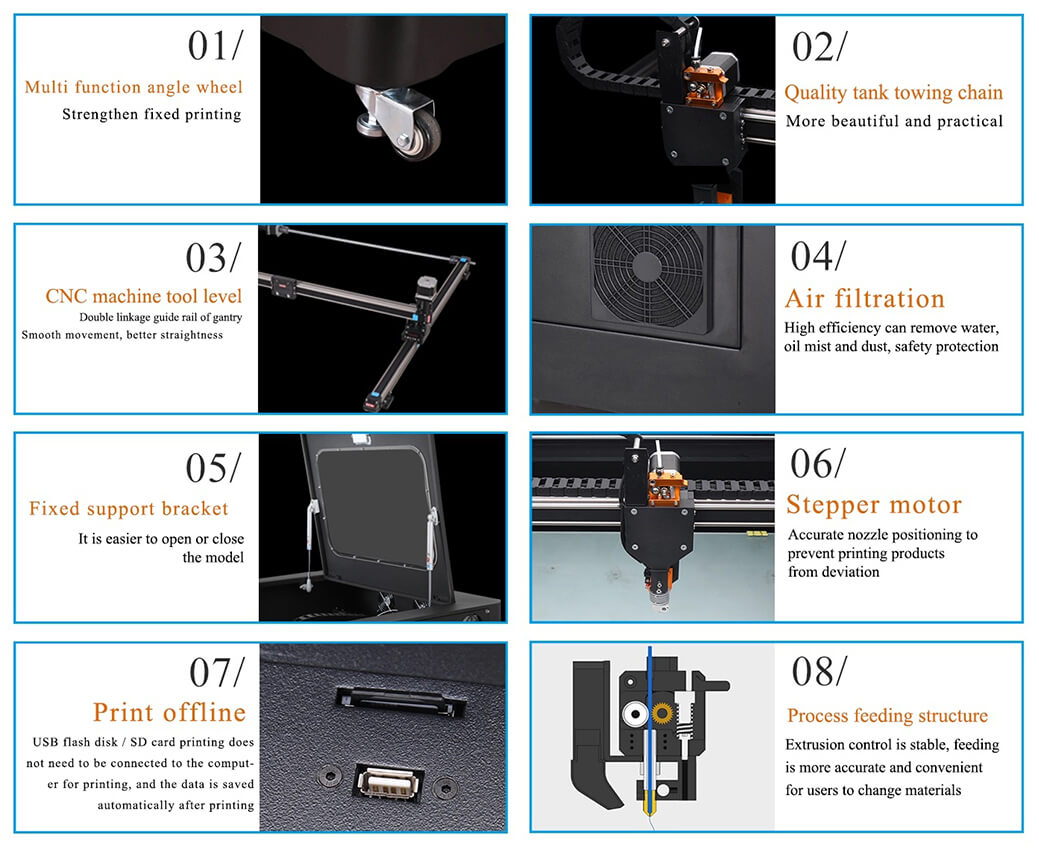

Automatic resume printing

Full enclose stable frame

The whole machine case is thickened by CNC cutting, with accurate hole position, better assembly stability, and higher positioning accuracy of printer operation.

Allow offline printing

Use U disk or SD card to print without connecting to a computer to print. After starting to print, the data is automatically saved and the U disk or SD card can be removed.

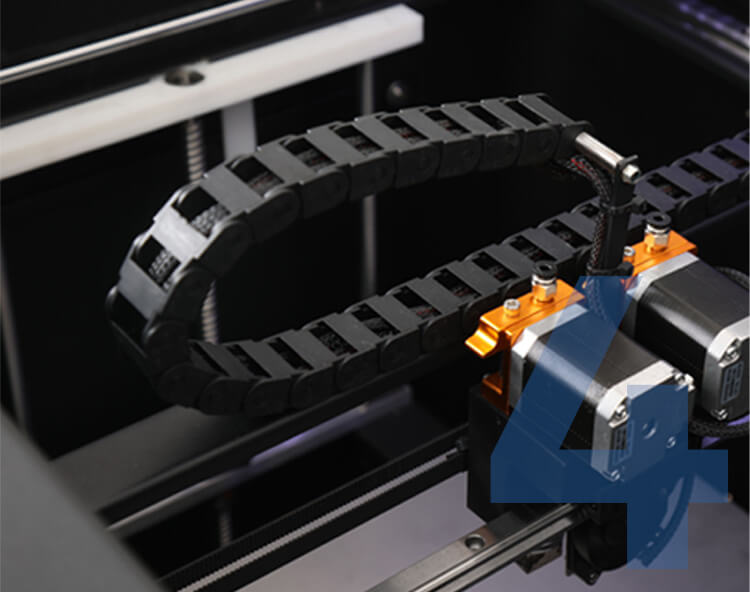

Drag chain wiring design

The wire is installed in the inner casing of the drag chain to effectively ensure that the wire will not be damaged for a long time when the printer moves at high speed.

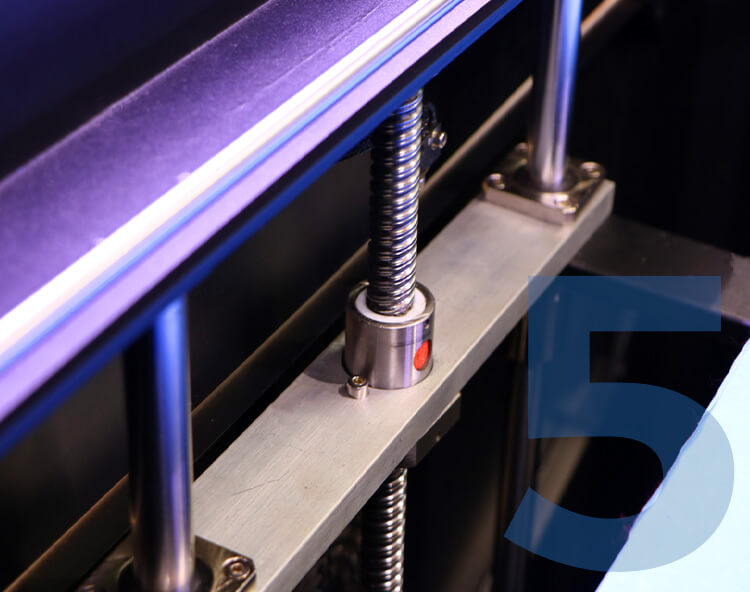

Precision ball screw

Using the latest Taiwan ball screw, it has higher straightness, lower friction coefficient, better smoothness, higher positioning accuracy and more stability during printing.

Alloy nozzle

Independently developed a unique bullet nozzle with uniform heating and a patented head assembly, so that it can work smoothly without interruption.

More FDM 3D printers

L-300 FDM 3D Printer

The L-300 is used for mini sized printing operations occupying up to 300x300x300mm size. It is mostly used for personal projects.

L-800 FDM 3D Printer

L-800 3D printer is used for professional, reliable and convenient 3D printing experience for individual and commercial uses.

L-1000 FDM 3D Printer

The L-1000 is the largest model with 1000x1000x1000mm size which makes it very suitable for printing larger objects or multiple prints at once.

Industrial FDM 3D Printer Buying Guide

FDM 3D Printer Introduction

Fused Deposition Modelling (FDM) is a 3D printing process that prints using a continuous filament of a thermoplastic material. The technology was created in late 1988 by S. Scott Crump, and it was later commercialized to the public as an FDM machine by his company Stratasys that patented the technology.

In 2009, the patent on FDM technology expired, giving the public access to FDM 3D printing technology without having to pay Stratasys. This encouraged people to embrace the technology for commercial, open-source, and DIY applications. The patent expiration also played a critical role in reducing the price of FDM 3D printers though Stratasys still owns the trademark on the term “FDM.”

1.1, Principle of FDM 3d printer

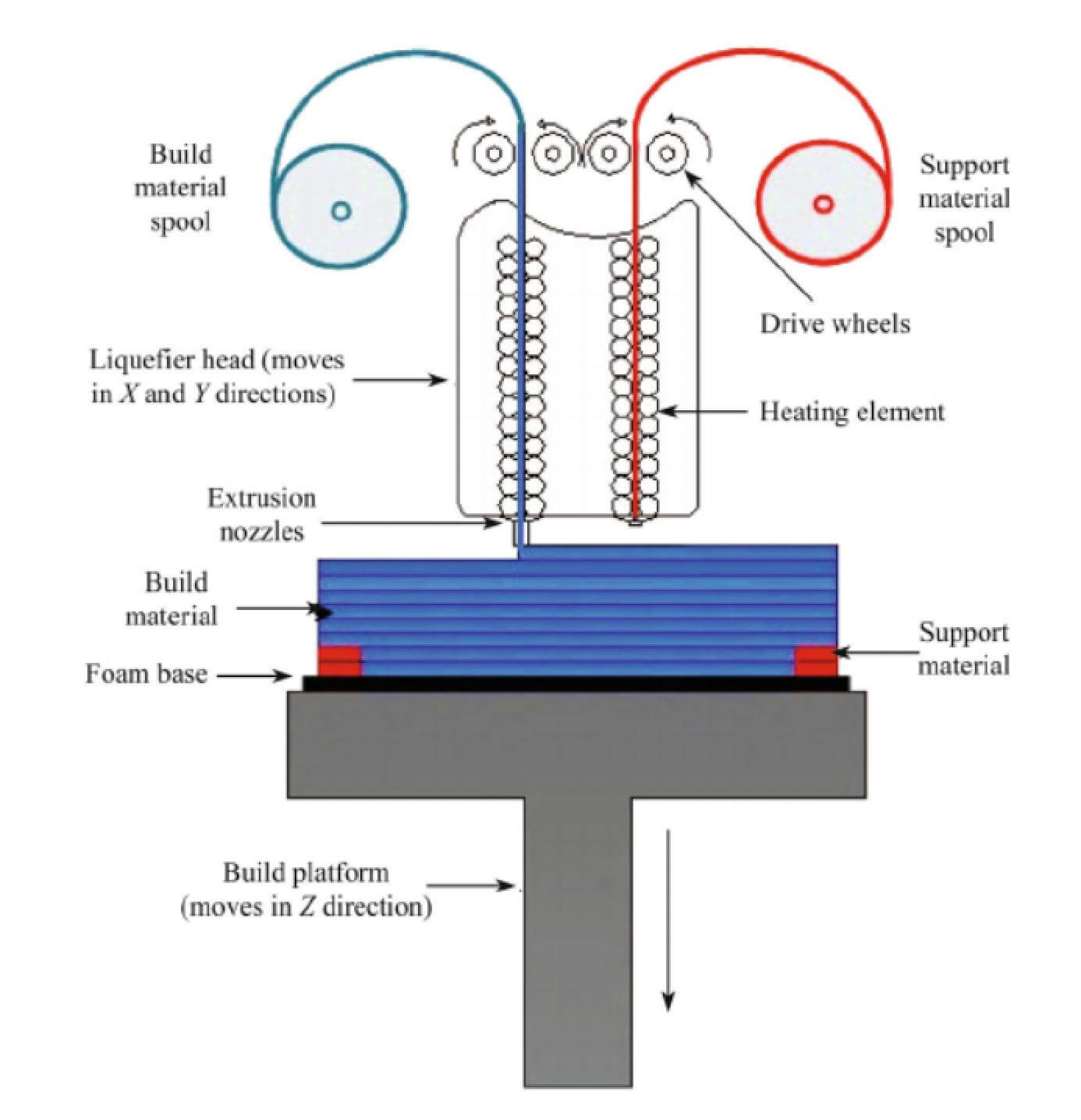

The Fused Deposition Modelling 3D printing is also known as additive manufacturing (AF), and it’s just depositing materials layer by layer. It allows for rapid prototyping, especially during research and development for new products, but how does an FDM 3D printer really work?

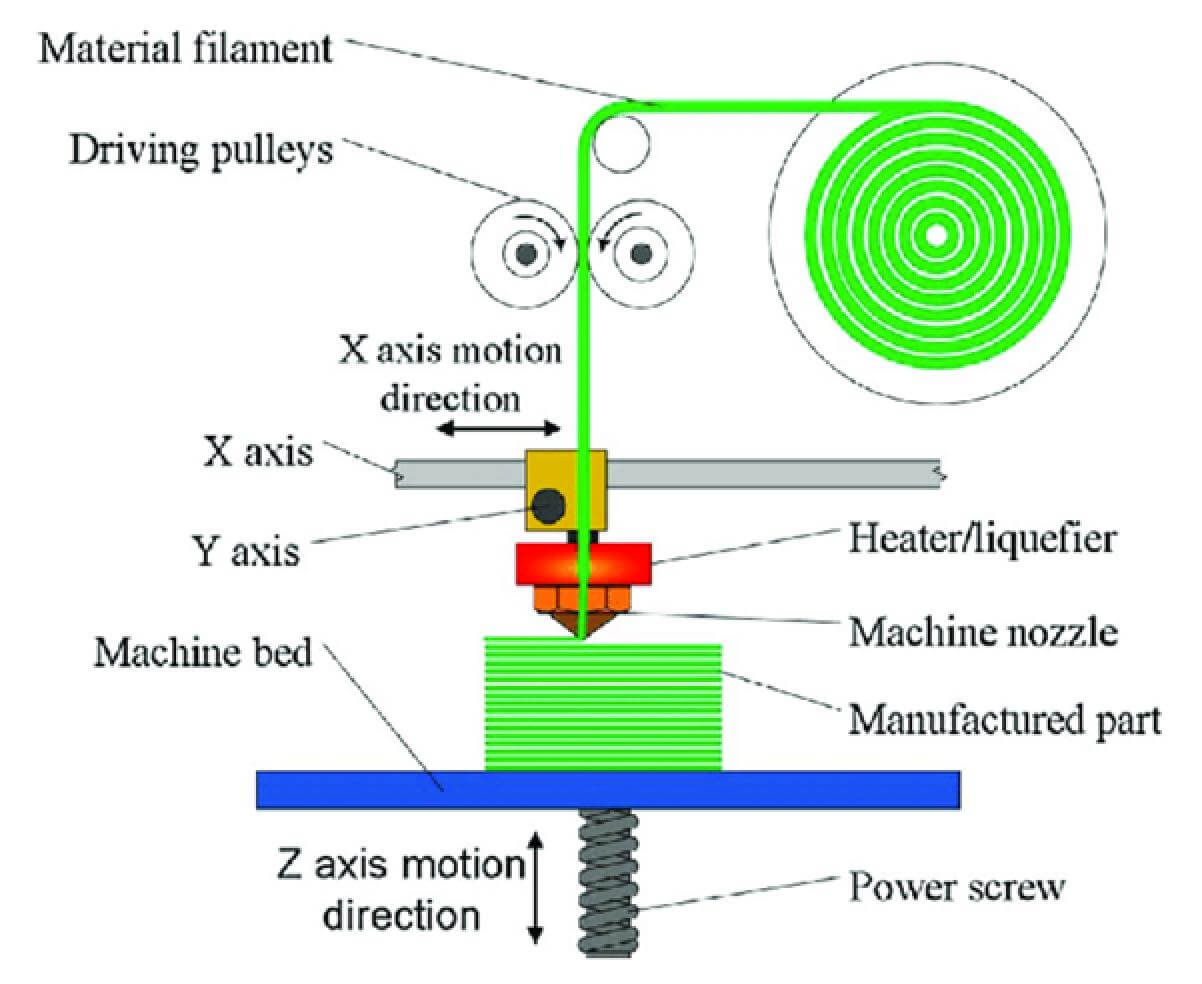

FDM 3D printers consist of a printer head/ nozzle, the printer platform, and the raw material in filament form. The product to be printed is designed on 3D printing software, which precisely defines dimensions, but you must convert the file into G-code, a programming language that the 3D printer can read.

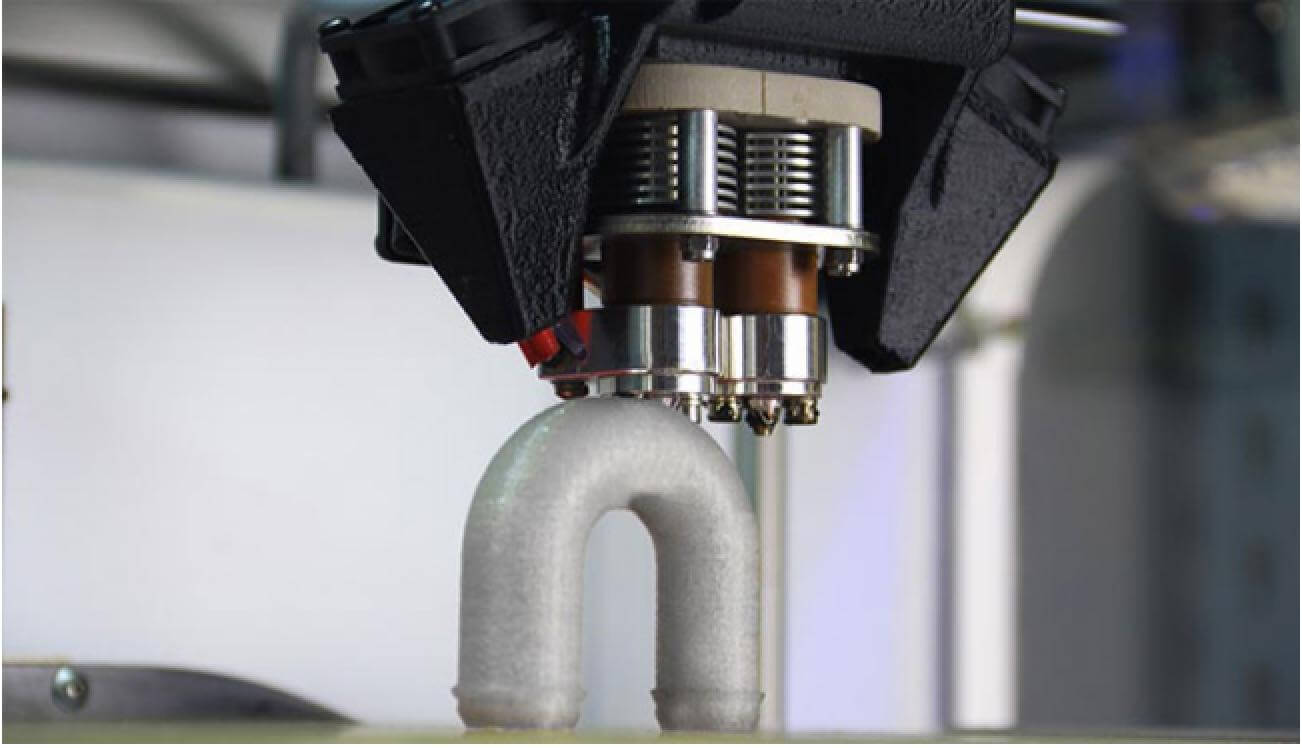

The raw material is melted into a liquid state in a liquefier head and then selectively deposited through a nozzle that traces the part’s cross-sectional geometry to produce 3D parts directly from a CAD model in a layer-by-layer manner.

1.2, What Materials can be Printed by FDM 3D Printer?

A wide range of materials are available for this manufacturing process, such as Polylactic Acid (PLA), Acrylonitrile Butadiene Styrene (ABS), and Polyethylene Terephthalate (PET), among others. Keep in mind that the more the material is resistant and robust, the higher the temperature they require to print.

This leaves out most desktop printers since they are not capable of printing parts from such filaments. Still, an industrial 500x500x500 3d printer such as an L-500 FDM 3D printer can handle most of the materials available in the market. Here are some materials that are used for 3D printing in different industries.

Polylactic Acid (PLA)

This is one of the most used materials for FDM 3D printing, especially in desktop 3D printing. It does not require a heated bed because it prints at a lower temperature making it the default printing material for most FDM 3D printers. PLA is also among the most environmentally friendly materials in the market with good dimensional accuracy, longer lifespan, cheap to buy, stiff, and good strength, which ensure products printed are of the highest quality.

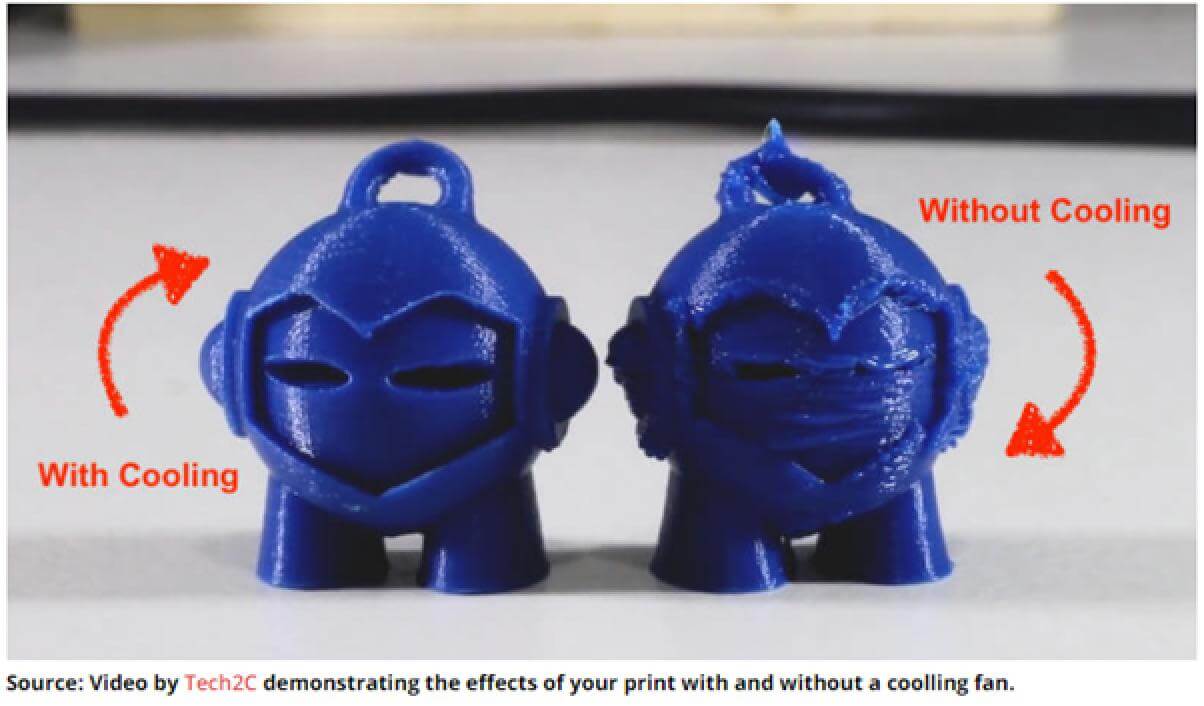

It’s excellent for people beginning to learn 3D printing because it is easier to work with, giving out a sweet aroma while printing, so you don’t get irritated with the fumes. It would be best if you were careful while using PLA because it could ooze, and a cooling fan could be needed for that. It is also unsuitable to use PLA outdoors or when directly exposed to sunlight because filament can become brittle and break.

The material has low heat resistance, limiting application to desktop printing, but with companies investing more in 3D printing, different variations have made it to the industrial stage. They are mainly producing common PLA household goods.

Acrylonitrile Butadiene Styrene (ABS)

ABS has a long history in 3D printing. It was created in 1990 and was the third major 3D printing technology to be developed, and currently, it’s among the most used. It is a thermoplastic copolymer that can be melted to liquid-form and then cooled back to solid-form without any degradation in its properties regardless of how many times you repeat the process.

It is widely known for its heat and chemical resistance, exhibiting high structural strength, excellent low and high-temperature performance that makes it attractive to the automotive sector for producing components and rapid kitchen appliances’ production.

Due to its low production cost, ABS is also used for the mass production of everyday household products. Still, it also has excellent electrical insulation properties making it an ideal material for electrical components casing.

It’s a bit difficult to print with ABS because heavy warping parts successfully tend to shrink, leading to dimensional inaccuracy. It requires a heated chamber or bed for it to work and produces a pungent odor while printing.

But for the L-500 500x500x500 3D printer, it’s easy to work with given the safety features Dreambot3D equipped to the printer.

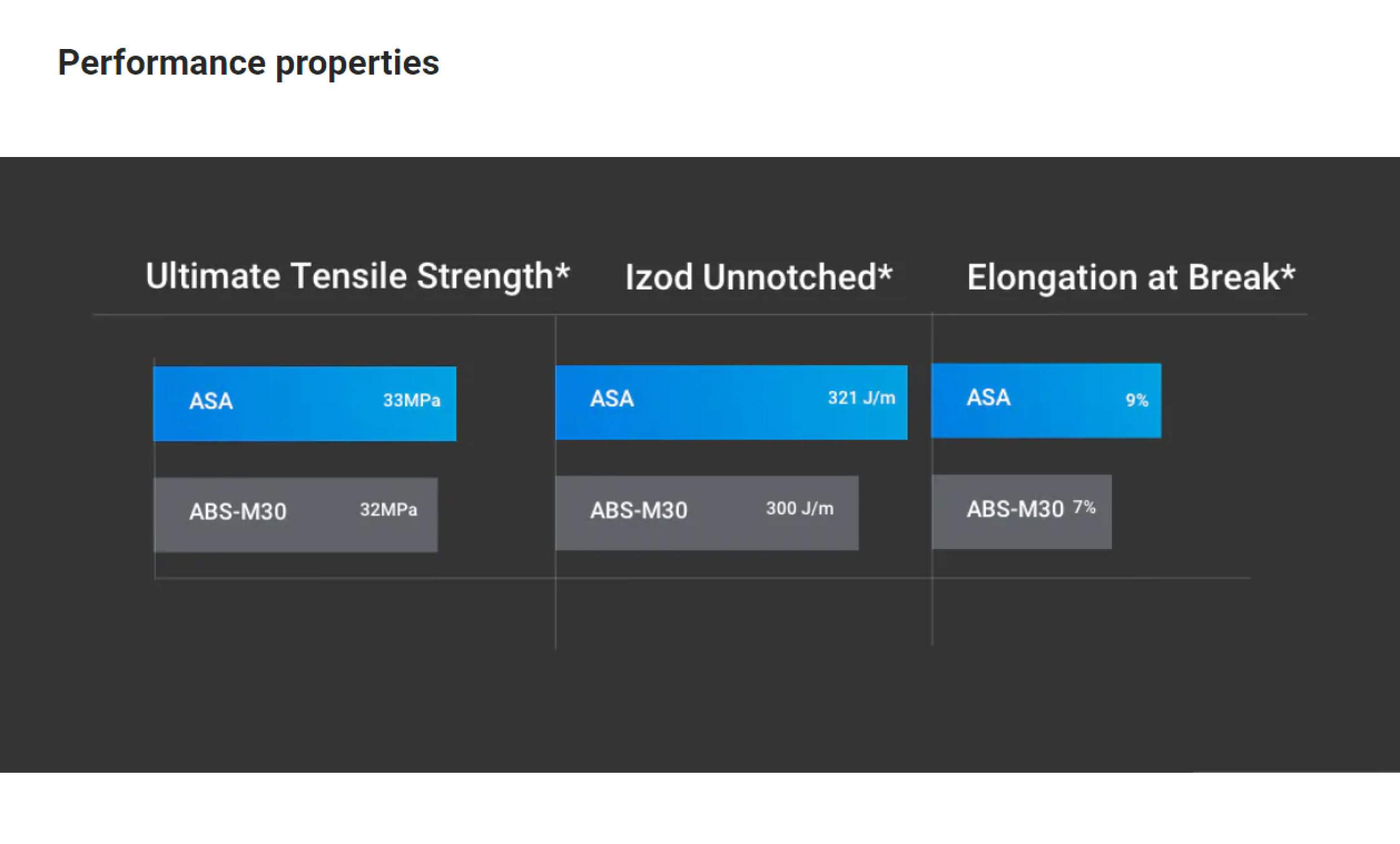

Acrylonitrile Styrene Acrylate (ASA)

Though Acrylonitrile Styrene Acrylate (ASA) has a similar chemical structure to Acrylonitrile Butadiene Styrene (ABS), it is the perfect thermoplastic for all-purpose use in 3D printing. It improved the drawbacks of ABS by offering superior aesthetics, better mechanical properties, and UV resistance.

It contains acrylic ester elastomer, which makes the material capable of outdoor use. Even at low temperatures, ASA parts have good heat and chemical resistance and high impact strength, making them suitable for construction/building, recreational and automotive parts. For use in FDM 3D printers, ASA has to be vacuum-packaged and should not have been in contact with water during its production phase.

You need to be careful of potentially dangerous fumes that it emits while printing by wearing the necessary safety gear or ensure sufficient ventilation in your printing room. It is also costly, requires higher extruder temperatures, and since it was supposed to be an alternative to ABS, it still has some of its printability drawbacks. Like warping, though minimized, it is still an issue in ASA, but when working with an industry-grade 500x500x500 3D printer, manufacturers tend to place cooling fans to dissipate heat.

Polyethylene Terephthalate (PET)

Have you ever heard of PET before? Yes, this is the plastic material mainly used to produce bottles. IT is a polyester-based filament that combines its thermal, electrical, and mechanical characteristics with its accurate dimensional stability and outstanding chemical resistance qualities. PET products have a low moisture absorption rate making them an excellent material for lightweight waterproof products.

PET is used as a more robust and stiffer alternative to ABS, which makes it great for producing tooling materials like thermoforming molds and assembly aids. Because of its resistance capabilities, PET can be applied to electronic materials like lamp housing and lighting frames. There are many variations of PET material in the market, and they include PETE, which is recycled PET and PETG.

Polyethylene Terephthalate Glycol (PETG)

The glycol module is added to PET during the polymerization process for the material to become more durable, less fragile, and easier to use. It is commonly used for FDM filaments and is primarily colorless but is available in different colors. It has a melting point of around 260°C and starts to liquefy at about 230°C, and a build plate is highly recommended when using the material.

Polycarbonate (PC)

Polycarbonate, commonly known as PC, was in the headlines a few years back when there was a debate about whether it was safe to produce baby bottles. At the time, PC was mainly used for manufacturing baby bottles, given that the material could release bisphenol A particles which are harmful to your health.

This lead to some countries banishing the use of polycarbonate for producing baby bottles. Still, it is used for other products such as bulletproof windows due to its high impact resistance and also the production of motorcycle helmets. The 3D printing community highly values PC given that it can withstand temperatures ranging from 140°C to -150°C, and because of its lower density which is lower than glass, it is suitable for designing decorative objects, protective screens, and optical parts.

However, the material can absorb moisture from the air, which means it must be kept in a dry environment; otherwise, it will swell and cause extrusion issues. It is also sensitive to hydrolysis and UV, making it extremely hard and inefficient for outdoor use. Warping is still an issue with polycarbonate; it tends to peel off the plate due to high printing temperatures.

ULTEM

Developed at General Electric’s Plastics Division in the 1980s by Joseph Wirth and was acquired by SABIC in 2017. Compared to its rival PEEK, it’s significantly cheaper though it has a lower impact strength and usable temperature. But when compared to other materials, ULTEM is superior to most of them.

Most 500x500x500 3D printers can withstand the temperature required to work with ULTEM because they can still maintain their physical properties in temperatures of around 170°C. Apart from high heat resistance, it has high dielectric strength with its strength-to-weight ratio comparable to aluminum.

The thermal and mechanical traits are applicable in most industrious sectors from medical, electrical, to aerospace. ULTEM is FDA compliant and holds several aerospace certifications where it’s used on cable ducts, ventilation systems, hinges, and latches. It’s also used in electrical component manufacturing, producing chip test sockets, connectors, and insulation parts.

There are two types of ULTEM materials, one with a resin material called ULTEM 1010 and one with a filament material called ULTEM 9085. Both materials are used for different products and different print settings.

ULTEM 1010 is mainly used in the medical and food industry, whereas ULTEM 9085 is primarily used in the aerospace and automotive sectors.

1.3, How does the FDM 3D Printer Develop from Desktop to Industrial Level?

Just like inkjet printers, 3D printers are replacing traditional factory lines with a single machine. A metal material is used on an industrial level, and a laser or binding solution is added to it for solidification. In contrast, for desktop 3D printers, a plastic or resin material is used for producing products.

How a desktop 3D printer develops products

You start by first designing your 3D object on an ordinary pc or a tablet that can connect to the printer. Once done with the design, connect it to the printer and let the magic begin.

If you have ever seen how a regular printer works, that could give you some insights. A regular printer starts printing from the top of the paper to the bottom, going line by line; in 3D, it’s almost the same. The printer adds the material layer by layer, working from the bottom going to the top. This allows it to be capable of producing even the most complex or moving shapes.

Once the product solidifies, it is ready for use. You can make some post-print adjustments to the product, like paints or assembling the parts together after the printing process has been completed without using any specialized tools.

How industrial 3D printers develop products

Industrial 3D printers created the path for desktop 3D printers to follow, and it’s not surprising that they work on the same concept. Printing an object from the bottom to the top from a design generated from a computer to which the printer is connected to. Industrial 3D printers have different applications in the real world and are very effective in their respective areas. Huge 500x500x500 3d printers are used for creating components on an industrial scale, especially in the automotive industry.

Application Field of FDM 3D Printer

3D printing application has gained a lot of traction because the Fused Deposition Modelling (FDM) printing process patents created by S. Scott Crump expired back in 2009. This allowed the public to use the technology without paying Stratasys, Scott’s company, for it. Which has made 3D printing attractive to various significant industries. Here are some real-world applications of 3D printing.

2.1, For Industrial R&D

As a manufacturer, you have to evolve to stay up to date with popular trends, or competition constantly will get to you. Research and Development form the foundation for the product innovation cycle and also offer guidelines for the future of the product. The use of 3D printing in industrial R&D has turned the time and capital-consuming process into one that is easy and fun to participate in.

An industrial 500x500x500 3D printer is guaranteed to prototype even the most extensive complex products. Here are more benefits 3D printing has introduced to the industrial R&D sectors.

- They allow effortless design modifications and replication giving you higher design iterations.

- You will prototype products much faster, giving you ample time to test different product designs.

- 3D printers are flexible to work with in terms of design complexities, geometrics, colors, and material type.

- They produce exact replicas of what you designed up to the minute details.

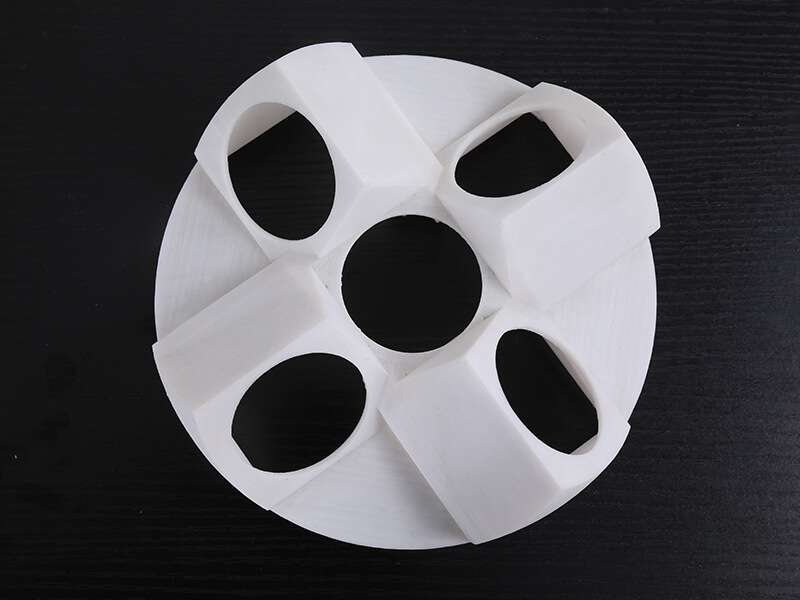

2.2, For Molds Making

It’s not only possible to create molds using a 3D printer but also relatively easy. The main difference between 3D printing molds and your standard 3D printing projects is how you will get the final product. There are extra steps to follow for printing molds, which tend to consume more time, but here is why we think it’s totally worth it.

- You can easily calculate how much volume your mold could hold

- Design and print your own pour vents and holes

- Save the mold box and re-use it for creating multiple molds.

- You will create a package that fits perfectly the parts you designed.

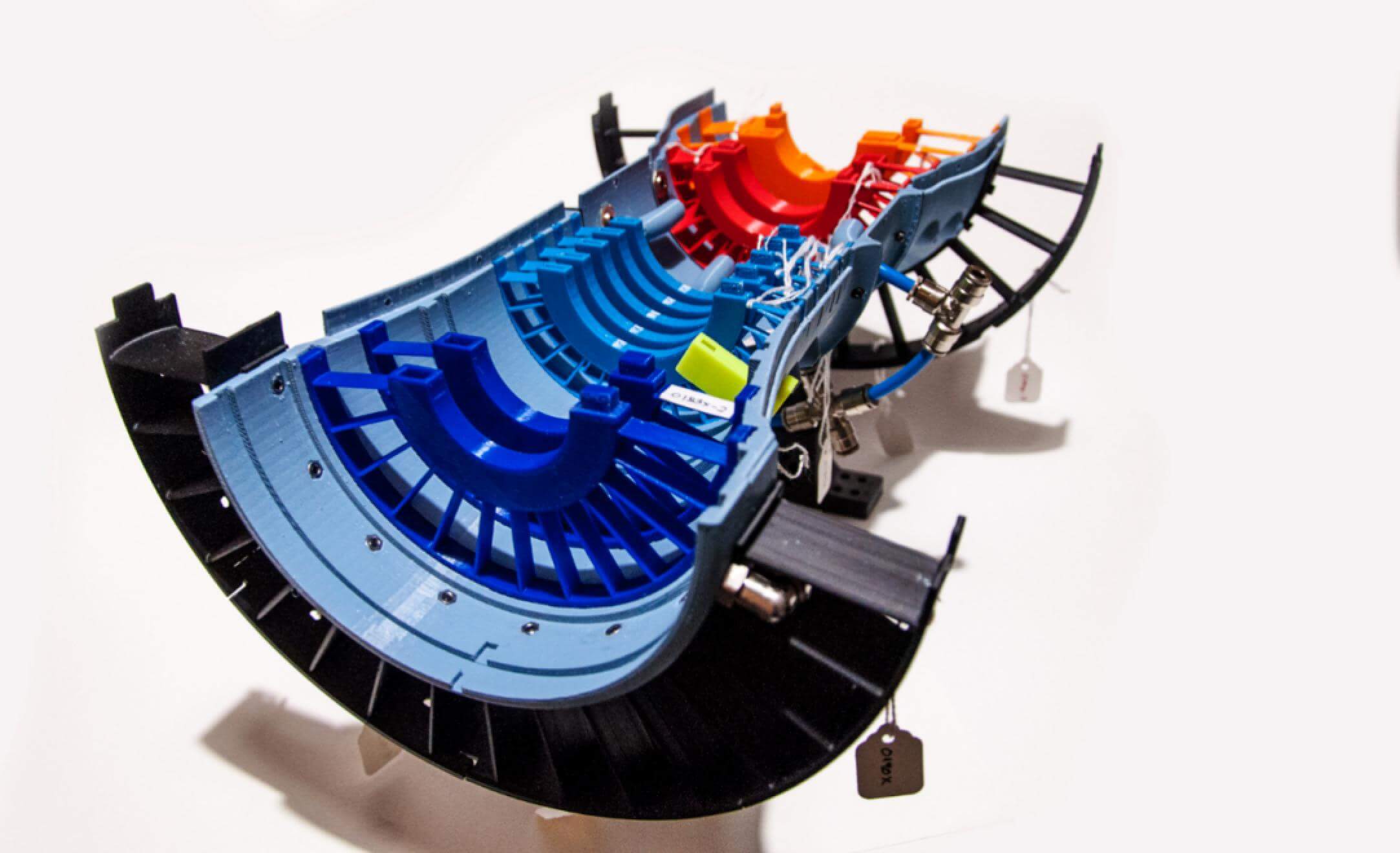

2.3, For Aerospace Printing

A 500x500x500 3D printer is capable of building large-size products suitable for aerospace prototyping, such as turbine blades and impellers. Compatibility with magnesium, aluminum, and other casting materials combined with a larger build volume, reduced person-hours required, and a faster build rate, 3D printers are slowly taking over the aerospace industry.

Additive Manufacturing is used in the aerospace sector for developing lighter and stronger parts that are harder to produce using traditional methods. The Aerospace and Defence industry was among the primary adopters of Additive Manufacturing or 3D printing technologies, some beginning as early as 1989, and by 2015 the sector contributed $4.9 Billion or approximately 16% to the global 3D industry.

2.4, For Car Parts Printing

Imagine if you could print or design a car part for yourself, relieving the stress and all the extra work of forcing it to fit. With 3D printing, you can produce quality replacement parts at the comfort of your seat and at a lower cost and faster rate. Of course, to make quality parts, you’ll need to consider one of the best printers; in this case, the 500x500x500 3D printer can be used especially for steel casting.

2.5, For Medical

3D printing is the perfect technology when creating or designing medical devices. Thanks to the low cost, medical device manufacturers can develop new products, ranging from bioprinting artificial organs to prosthetics and many more.

You don’t have to worry anymore about your child outgrowing and not fitting the prosthetic as you can print one for them every few months.

2.6, For Various Models Making

2.6.1 Anime figure

Bet some of you didn’t know you could create or design your anime with the use of a 3D printer; it doesn’t sound very easy, but it’s not. However, it’s actually fun and exciting and doesn’t require lots of understanding once you get the hang of it. For life-size dolls, we’d recommend a 500x500x500 3D printer; for instance, the L-500 FDM 3D printer should work well for large formats.

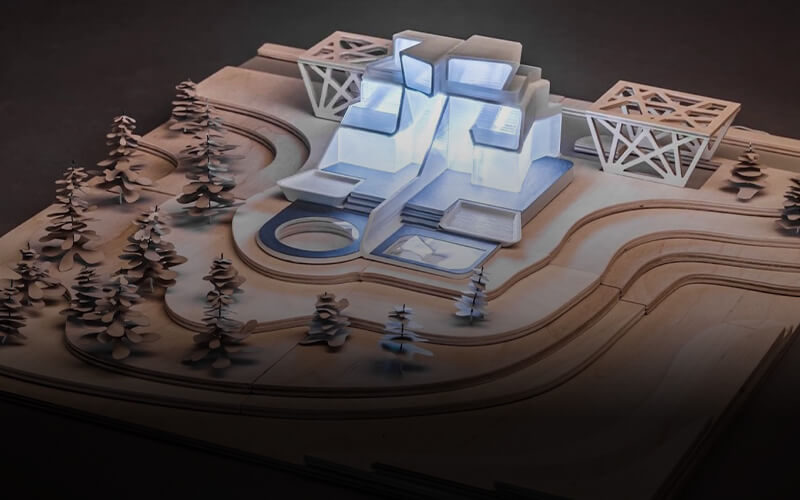

2.6.2 Architectural models

In architecture, every project starts with a concept model. A 3D printer helps a lot and saves you time by doing all the work for you. Instead of shaping one with your hand, it creates a tangible model based on your idea. This technology also allows architects to print and design interior projects and decorative objects like sculptures and lamps.

2.6.3 Mannequin

Do you want your shop to stand out from others? How will you grasp customers and all the passers-by attention and keep them as your regulars? This is where custom mannequins can make an impact. With a 3D printer, you can produce a life-size dummy in just a matter of days or hours. On the other hand, ordering a clay mannequin will subject you to weeks or even months of waiting. After all, they are created with manual labor.

2.6.4 Gun

3D printing continues to amaze everyone as you learn more; it has so much power that it brings almost any design to life, including making a gun. Still, when making your gun, there are certain metallic parts that you’ll need for the weapon to function fully, which are only accessible through the proper channels; to be specific, we mean the authorities.

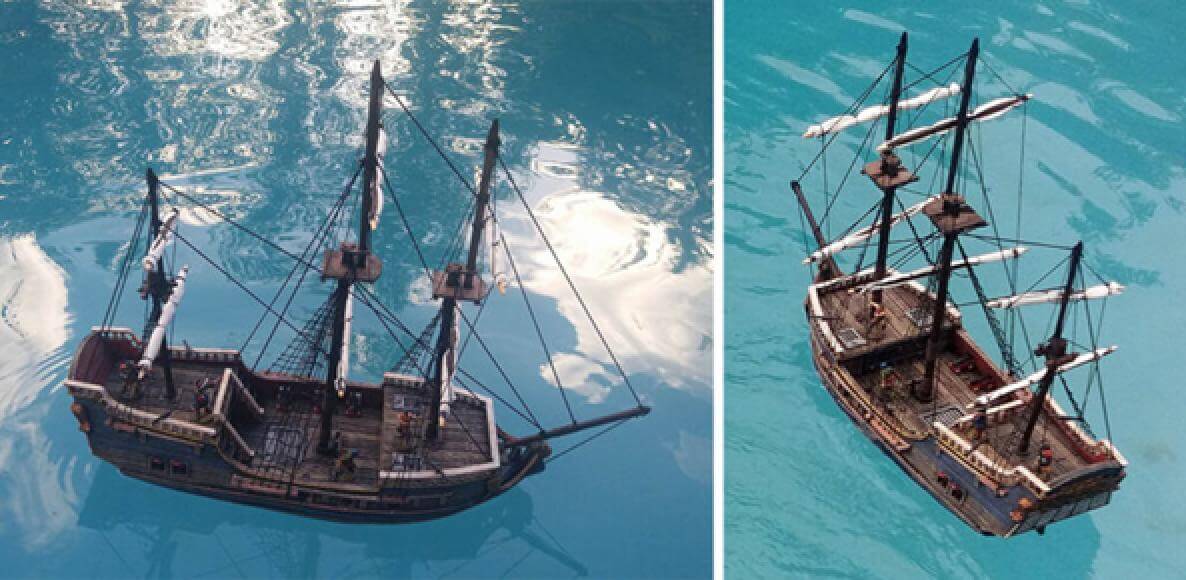

2.6.5 Ship models

If you love the sea and sailing then you’d surely wish to collect your favorite craft as a 3D printed ship, there are tons of detail in all models that you’ll never get boring, even though you aren’t sailing, you can take a single look at your detailed vessel and imagine the waves directing your ship to all the islands you’ve sailed before.

2.6.6 Airplane models

Do you love soaring up in the sky? Are you looking for the best plane model to add to your personal collection? Or maybe you just want to print your own custom plane? Either way, you’re at the right place. With a 3D printer, you can print your own model, which will be cheaper and faster than buying and assembling one, considering you already own a 3D printer.

Because airplane companies need to produce low volumes of models for testing, Dreambot3D’s L-500 500x500x500 3D printer is recommended for speedy and accurate airplane model printing.

2.7, For Cosplay Props Making

Like many industries, cosplayers have also moved into 3D printing technology, which has allowed producers to bring their favorite movie characters to life. Buying a costume can be very expensive as opposed to designing your own. With a 3D printer, you’ll end up saving a lot of cash, and in addition, you have the freedom to create an outfit of your choice.

2.8, For Drone Manufacturing

3D printing can be beneficial for many of your projects, especially your drone project, and it certainly has its benefits. Not only can you create your own custom drone, but you can print almost every part of the assembly. If you damage any part, do not worry as you’ll have an infinite supply of parts, excluding electronic components of-course.

Due to the many parts needed for drone manufacture, we recommend a 500x500x500 3D printer that prints size the double of a basketball, enabling you to create commercial size drones.

Factors Affecting Efficiency of FDM 3D Printer in Manufacturing Industries

FDM 3D printers have been heavily adopted into various manufacturing because of their high efficiency. The materials used in industrial-grade 3D printers are easily available and are cheaper than conventional materials, making it easier to test new products or even develop finished products quicker.

Top industrial 3D printers are equipped with cooling fans to regulate the temperature from exceeding the set limit and use ventilators to contain the material in case it oozes, ensuring optimal safety during the manufacturing process. This has allowed its massive adoption into the manufacturing sector, especially for small-scale production factories.

Most 3D printing machine manufacturers place a 250x250x250 mm working area for large format 3d printing. Still, Dreambot3D’sL-500 FDM 3D printer is among one of the few large industrial printers capable of a printing size of up to 500x500x500 3D printers that have come to take over the manufacturing industry, and here are the main factors pushing the change.

Cost Reduction

Though traditional manufacturing machines cost a lot of money to design and install, they are capable of handling large volumes of products. Still, maintenance, repair, and overhaul can be pretty expensive for these machines. Making matters worse, if they experienced any sort of failure, it could hold up the manufacturing process resulting in unprecedented losses.

This is where industrial FDM printers step in. They are cheap to buy with the capability to handle metal powder and engineering-grade thermoplastics, so there is no excuse for the product’s quality. For traditional manufacturing properties, different workers were needed to operate different machines, or a production line was required to assemble the product.

FDM 3D printers require only one operator who initiates the printing process, and everything else is done by the computer and the printer. This has reduced the costs associated with labor either for the direct use of the machine or the design and building of the device.

Part consolidation

This is the best benefit of using a 3D printer. Part consolidation is the ability to integrate multiple parts into a single component. It reduces the number of parts needed simplifying both the maintenance and assembly process by reducing the time required. Complex products such as engines contain very many features that have to be interlocked for them to work; FDM 3D printers excel at such designs as long as everything is symmetrical.

Shorter lead time

According to a study report conducted by Sculpteo in 2018, 52% of manufacturers within the industrial goods sector are in favor of using 3D printing. FDM 3D printing does not require any tools. Once a manufacturer is done designing the product, they go directly to production, saving the time-consuming process of moving from design to finished product.

ArianeGroup, which produces rocket components, claims that they used a 3D printed injector head for the Ariane 6 launcher. Ariane designers say they reduced the injector head from 285 different parts that needed to be machined and welded together to a one-piece component that could be printed as a whole.

The process of creating an injector head would take up to three months, casting and machining the product but now it takes only 35 hours using an EOS M 400-4, which is short of 100 mm to reach the exclusive 500x500x500 3D printers club. ArianeGroup also reported a 50% reduction in costs.

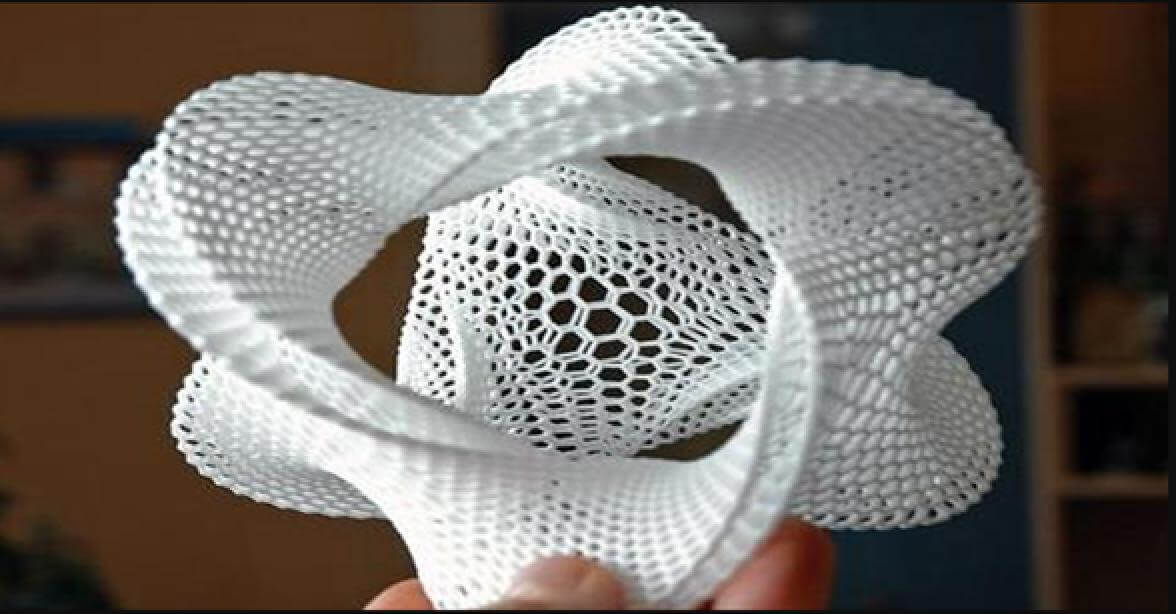

No limitation in geometrics

One of the most significant advantages of a 500x500x500 3D printer is its ability to print complex geometric shapes challenging for traditional machines without using expensive tooling equipment. Complex aeronautical components require precision to produce products of the same geometry as the design and are still durable and lightweight at the same time.

This allows aerospace component suppliers and manufacturers a cost-effective way of producing small batches of parts at a friendly cost.

Enhanced product development

Quality assurance is something that is vital for all manufacturing industries, which means before a product reaches the market, the design must be validated, tested, and approved. This happens during the product development stage, and the design is called a prototype or a model, and they are crucial in the research and development of new concepts.

FDM 3D printers have significantly increased the speed of producing prototypes by enabling the rapid production of components. By using 3D printing technology, product engineers and designers are capable of developing and testing multiple product iterations in a shorter time frame. The fastest FDM 3D printer should have a printing capacity of 500x500x500 3D printer should reduce the development time.

Mass customization

In the medical area and, to some extent, the automotive industry, the customer usually requires a personalized product tailored to specific requirements. Conventional machines produce components in huge volumes, making it difficult or expensive to get a customized product. Commercial FDM 3D printers are changing that too.

For example, in the dentistry sector, every patient requires personalized molds or braces for their teeth. With digital technologies finding themselves inside a dentist’s place, traditional processes are slowly being phased out. Dentists are combining intraoral scanning with 3D printing to produce products that match perfectly with a patient’s anatomy.

Faster-time-to-market

The ability to accelerate product development has directly affected the speed products reach consumers with. When products are available on time, everybody in the cycle is satisfied, from the consumer to the producer, and how 3D printers affect the speed of delivery of finished products.

Given the short time a 500x500x500 3D printer takes from designing a product to its finished state where they have passed the quality assurance test, manufacturers can definitely speed up their time to market. In 2015, PepsiCo produced several prototypes into the market to determine which product consumers mostly liked.

There are mostly positive factors affecting the use of FDM 3D printers in the manufacturing sector. The only limitation to using FDM 3D printers could be that they can’t handle large-scale designs. The bigger the design is, the higher the chance that the product will not print correctly because the printing material is too hot or solidifies quickly.

Main Components and Parts of FDM 3D Printer

The FDM process includes three parts, a printing plate on which the product is printed, a filament coil that serves as the printing material, and an extrusion head, also known as an extruder. The extruder melts the extrusion filament-producing material layer by layer on the printing page. The process involves designing the object using CAD 3D software, where the design is split into different layers through a slicer.

Understanding how the different parts of an FDM 3D printer works are crucial before determining the type of 3D printer you want to purchase. A 500x500x500 3D printer will be capable of handling even industrial tasks, though understanding some of the printer components should help in the decision-making. Here are ways that understanding different parts will help you out:

- You will be able to fine-tune printing speeds

- Better quality prints will be produced

- Your printer will have a longer lifespan

- You could upgrade and modify parts accordingly

Here are the features and parts that make up an FDM 3D printer and factors you should consider so that you can instinctively troubleshoot the printer whenever it starts developing problems.

Build area for print size

The build area is commonly referred to as the build volume, which is more accurate as an indicator of the maximum size you can 3D print an object. The image below shows the L-500 FDM 3D printer from Dreambot3D, which is among the printers with the most significant build volume. The 500x500x500 3D printer is capable of printing objects twice the size of a basketball.

It is essential to know the type of objects you will be printing before deciding on your final printer of choice.

Filament diameter

The filament is a thermoplastic feedstock that is used for fused modeling 3D printers. They come in various materials with different properties and printing temperatures, but filaments commonly exist on two standard diameters of 2.85 mm and 1.75 mm. However, the type of filament diameter to use depends on which hot end and extruder your printer is built with.

FDM 3D printers using Bowden extruders work well with a filament diameter of 1.75 mm, and printers equipped with a direct drive usually prefer a diameter of 3 mm. The L-500 500x500x500 3D printer has a consumable diameter of 1.75mm and utilizes the bowmen extruder as well.

FDM extruder types

In FDM 3D printing, there are two main types of extruders being equipped with 3D printers. The direct drive extruder and the Bowden extruder which is used to feed the filament to the hot end so it can be melted. Most 500x500x500 3D printers are equipped with the Bowden extruder, and they use motors to push the filament down the hot end but let us take a look at the two extruders and compare them.

Direct drive extruder

For direct drive feeders, the extruder pushes the thermoplastic material directly into the nozzle due to its location directly above the hot end. This gives the motor more control over what it can do with the filament. It involves pushing the filament at close proximity, which enables the desired motor control, which in theory produces more accurate prints. Here are some pros and cons of using the direct-drive extruder.

Advantages of using the direct drive extruder

Faster retraction: Due to the extruder’s close proximity to the nozzle, it can quickly retract the filament between various printing stages, reducing the chances of OD stringing or oozing.

Extensive range of filaments: The short distance between the extruder and the nozzle allows the use of a broader range of filaments handling even softer pliable filaments.

Less powerful Motor: The motor is less powerful because of the short distance required to push the filament to the print head.

Better Control: As discussed earlier, since the extruder is located directly above the hot end, the less powerful motor has more control over how the filament is being handled.

The disadvantage of using the direct drive extruder

Burdened Movements: The extruder position above the hot end adds weight to moving parts. The parts need to overcome momentum, and the weight causes wobbling and loss of print accuracy in all axis directions.

Bowden Extruder

In contrast to direct drive extruder motors, Bowden motors are located far away from the hot end, which reduces the weight on moving parts. In theory, having less weight on moving parts results in more accurate prints because the momentum is decreased significantly, particularly making a difference at higher speeds. This means that Bowden extruders should be able to print faster than the direct drive extruder, which is why the L-500 500x500x500 3D printer utilizes this feature.

But there are many factors that affect print speed, and the Bowmen extruder comes with its challenges too. Here are some advantages and disadvantages to consider before choosing a Bowden extrusion 3D printer.

Advantages of using the Bowden extruder

Increased build volume: Being more compact and having small print head cartridges allows more significant build volumes, which translates to more oversized prints.

Smoother movements: Bowden extruders are mounted on the frame of the printer rather than the moving print head, which means less weight on the cartridge allowing for more accurate prints.

Disadvantages of using the Bowden extruder

Decreased response time: Since the distance between the nozzle and the hot end is excellent, more friction in the tube means a slower response time.

Smaller material range: Bowden extruders have to push the flexible material through a tube, and due to its length, it’s likely to bend and twist inside the tube.

More powerful motor: Compared to a direct drive extruder, Bowden requires a more powerful motor to feed the filament to the hot end due to its distance.

Hot end

The hot end is a very simple device yet one of the most critical components. It is used to melt the filament, ready for use to build up your 3D model. Health safety measures have to come into play when interacting with the hot end because as it turns plastic into fumes, the nanoparticles could be breathed in.

Some critical factors to consider for your FDM 3D printer are the maximum print temperature, the nozzle size, and the fixtures. There are several variations of hot ends, but the most common ones are two types:

Volcano: This has a giant nostril to allow more significant amounts of plastic to be extruded for larger print sizes like 500x500x500 3D printers.

V6: this is used for smaller print sizes and is most common for desktop 3d printers

FDM 3D printer nozzle size and type

The nozzle is the tip of a hot end where the melted filament is pushed out. There are various sizes available for nozzles that are easily exchangeable depending on your design’s desired result. The size ranges from 0.25 mm to 1.0 mm, with the most common size being around 0.44 mm, and they also come in a variety of metals. Here are what the different size nozzles are commonly used for and what advantages they have.

Smaller nozzle size

There are smaller nozzles which are about 0.1mm, but they are not typically used that much. This is because smaller nozzles create thinner layer thicknesses which produce finer details hence increasing print quality. They, however, require more time to make molds because of the tiny layers of thickness. Another disadvantage is that they tend to clog up due to their smaller diameter.

Bigger nozzle size

A 0.8 mm diameter nozzle is considered to be as big as they can get, but few manufacturers produce wider diameters of up to 1.2 mm. As a result, they have an increased printing speed because it takes fewer layers to complete the print, which translates to shorter print time. They are also compatible with exotic filament materials like metal and wood fillings.

However, the increased diameter means a loss of finer details in the final product. Also, loss of heat is another factor affected by nozzle diameter, which reduces temperature resulting in clogs.

Cooling fans

Most people focus on the heating properties of an FDM 3D printer and usually overlook cooling fans. After the nozzle has deposited the material, it’s beyond the control of the hot end, and the model is left to its own devices. If the material is resting on a flat layer, then ambient room temperature will be enough to cool it down.

But for more complex models, a cooling fan is required, and Dreambot3D 3D manufacturers have taken this into consideration when producing their 500x500x500 3D printers, ensuring your production does not stop due to malfunctions. In addition, they place multiple cooling fans under the built-in screen to dissipate heat during the printing process.

Flat bed

This is the platform where your model rests while the FDM 3D printer is adding layers to the model. A flat bed is usually made out of various materials such as metal, buildtak, flexplate, and glass, each bringing its own advantages when being used. For example, a flat glass bed is superbly flat, which means layers will be added ideally on top of each other; it is very easy to clean, has effortless print removal, and is reasonably cheap.

When choosing the right flat bed, it’s crucial to find the suited material for your requirements; the L-500 500x500x500 3D printer can be superb as a control measure for choosing the correct flat bed. Here are some things to consider:

Easy removal of completed model: you want a flat bed whose material will be easy to pull your model from the flat bed. If fixed to the surface, it will be hard to pry out the model, which means yanking it could damage the print.

Smooth printing process: If you have a cold flat bed, it cools down the first layer of the model before the second one is added, which results in inferior binding between layers and compromised model strength.

Easy to clean: Sticking your model to the flat bed gives it stability during the printing process, which makes for accurate models. Substances like glue are used to hold the model, and the flat bed material should be easily cleanable before the next model is printed.

How to Choose a Suitable FDM 3D Printer for Your Industry

Although 3D printing has been around since the 1980s, it wasn’t as widely known as it is now, mainly because it’s now affordable on the market, making it available to everyone who has ever wanted to own one. As a result, everyone from all industries (ranging from architecture, aerospace, medicine, and many more) wants to experiment with a 3D printer.

But you can’t buy just any printer; various aspects need to be considered when choosing a 3D printer for different industries. Of course, a 500x500x500 3D printer will be capable of handling most products, but here are more factors to consider:

Intent

Before you decide to buy a printer, it is very crucial you define its work, as choosing a printer depends on the purpose of the printer. What is the printer for? Is it intended for the purpose of creating prototypes of models? If so, a 3D printer that uses plastic filament should serve.

But if you plan on using it to create finished products, a high-grade 500x500x500 3D printer like the L-500 FDM 3D printer from Dreambot3D will be more than enough.

Time

Are you focused on the final result? But don’t want to know about every little detail of how the print is produced. Or are you curious and want to know the whole kit? How you answer these questions will help you when choosing the right printer for your Industry. On the other hand, if you are focused on the final by-product, you want a readily available machine and doesn’t require much need for maintenance.

If you’re more curious about how everything works, then a “kit” printer is the right choice for you. Kit printers are a lot cheaper, but you have to assemble them.

Maintenance

All machines like the 3D printers require maintenance every once in a while. The heating bed has to be cleaned after every print, LCD screens must be replaced, etc. Maintenance is vital in all printers, whether they are kit printers or not. But assembling your own printer educates you bit by bit, and you learn all the ins and outs of how you will maintain the machine, which parts to grease, which not to, how to replace the nozzles, and so on.

The L-500 500x500x500 3d printer is easy to maintain and comes equipped with a user manual that focuses on common problems and how to troubleshoot them.

Price

3D printers are now widely available and affordable; you can easily purchase a printer for under $100, but don’t forget you get what you pay for. Such a printer will need a lot of add-ons to make it produce high-quality prints. In this case, it is easier and better if you could spend more on a high-quality printer from the start.

It is also recommended to have replacement parts should the need arise; if any part of the printer fails, it is most likely unreliable till a replacement arrives. 500x500x500 3D printers are pretty expensive considering their printing volume, but Dreambot3D offers customized pricing on its L-500 FDM 3D printer.

5.1, Your Application Industry

The most common aspect that one has to contemplate when purchasing a 3D printer is asking themselves the main application of their 3D printer. What is it for? Is it for home use, industrial, medicine, hobby, etc.? All these are factors you need to consider, different 3D printers for various purposes.

You can’t buy an industrial printer for a household or vice-versa. Selecting the right printer will entirely depend on what you want to use it for. Let’s dive into a few of the industries where there is rapid use of 3D printers.

Aeronautics and defense

This is one of the early adopters of additive manufacturing, popularly known as 3D printing. Defense and aeronautics revolve primarily on research and development, focusing on improving efficiency on their current products or even designing new models.

A lot of 3D printing material is suitable for this industry application, and they come with case studies showing areas where 3D printing has been a success. Due to the large size required for models, an industrial 500x500x500 3D printer will meet all requirements needed for printing 3D models in the defense and aeronautics industries.

Medicine

The health sector has seen tremendous growth in the adoption of 3D printing technologies ranging from prosthetics to bioprinting. Biomaterials like cells and growth factors are combined to create a tissue-like structure that imitates its natural counterparts. Prosthetics and pills are the commonly produced models using 3D.

Construction

Using 3D printers with construction material like concrete has been in development since the 90s because it was a cheaper and faster way of constructing a building or other structures. In the current time, the technology was perfected, and it now has a wide array of application areas either for commercial, private, public, or industrial use.

The benefits of using 3D technology include lower labor costs, less waste, faster construction, more complexity, and accuracy. However, given the vast amounts of models to be printed like walls, a 500x500x500 3D printer won’t cut it; you need a heavy-duty printer capable of handling construction material.

The gantry printer BOD2 manufactured by COBOD is an example of a 3D printer capable of printing an entire house layer by layer. PERI GmbH is currently using it to create the largest 3D printed residential building in Europe with a living space of 4090 sf (380 m2).

5.2, Print size requirements

Printing a 3D object requires you to remember that your final product will be a tangible object with height, weight, and size. Even if your model seems to be at the dimensions you had planned, it is still vital that you examine if the printed model matches your expectations and the printer’s restrictions.

Different industries require different 3D printers for various applications. Your application industry plays a vital role in determining the printer size. Suppose a 500x500x500 3D printer cannot get the work done; we recommend a heavy-duty industrial 3D printer. Here is a list of the typical build size for different 3D printers.

FDM 3D Printer Buying Guide

Your first printer will be determined by the type of projects you intend to use it for; of course, no one is ever satisfied with less, and you want the best printer on the market that will offer you as many functions and unique possibilities as possible. Still, such a printer doesn’t come cheap. Choosing the right FDM 3D printer isn’t easy if you have no prior knowledge, but through this guide, we will help you become a pro in no time, even when using an all-purpose industrial 500x500x500 3D printer.

And that is why you’ll have to be very selective when choosing a printer. Do you want a vast 3D printer or a small one? Is it for personal use, educational, hobby, or professional use? Everything will be a lot easier once you narrow down your choices. Let’s go through a few factors that will help you when buying your first 3D printer.

6.1 Check the Brand Reputation

Are you looking to buy the fastest FDM 3D printer? Why not buy the best there is? The best advice we can offer is: First narrow down your choices and make a shortlist of the printers that you find to suit your needs, then read up about them online, you’ll find this information to be of great importance when it’s time to shop.

Once you’re familiar with the models, you can visit the shop to see the live demos for yourself and get expert advice from people who understand 3D printers inside out. Like Dreambot3D’s 500x500x500 3D printer technology is among the best, having passed several quality assurance tests.

6.2 Safety Configurations of the Machine

Proper and frequent maintenance of every manufacturing equipment is very vital to keep the machine running smoothly. Still, sad to say, people tend to ignore these instructions, and that is why most appliances do not last long before troubleshooting.

Before you get going, it’s best to always have a tool kit at arm’s reach, spare some time to check your machine and its prime components, check all the electrical cables and connectors for any damage, and make sure they are firmly connected. Simple polishing, dusting, and lubricating your linear rods can go a long way.

6.3 Resolution Requirements of the Machine

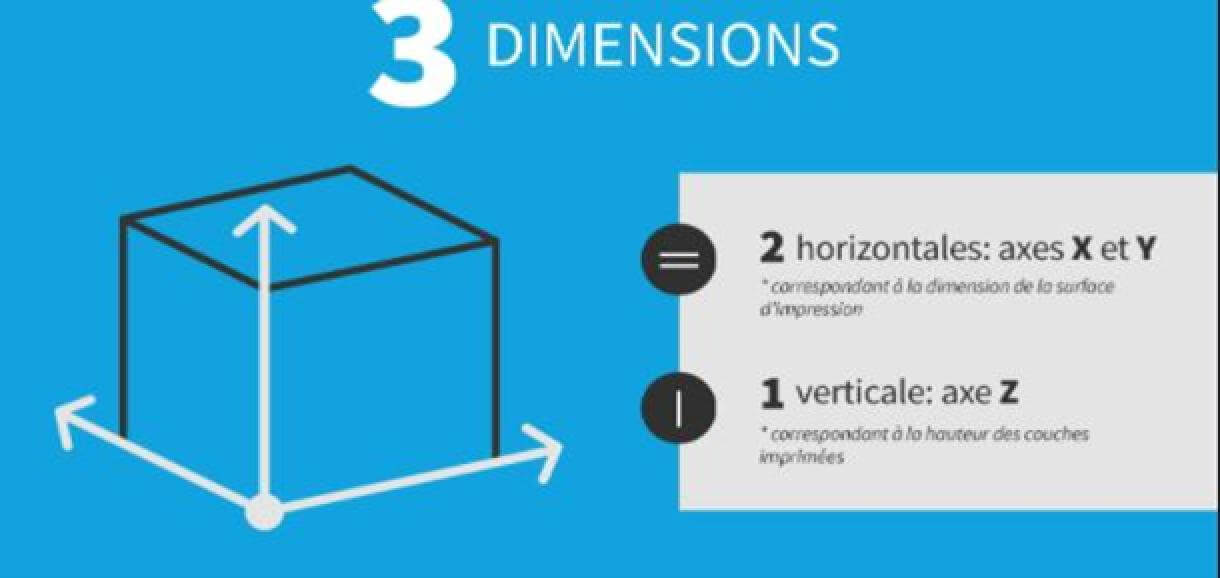

3D printer owners and designers all want one thing: to achieve the top-most results. To get quality printed parts, you’ll need to understand 3D printing resolution, or else it will affect your printed part or model. So, how do you know if a 3D printer has a high resolution? There’s more than one answer to this question. 3D printers generate parts in 3 dimensions, so you’ll have to consider at least two factors: the XY plane feature and the Z-axis resolution (layer diameter and height).

Most importantly, you’ll have to consider the XY resolution; the Z-axis resolution can be easily determined. More or less, you should pick a printer that doesn’t favor one side but performs well on both sides. A 500x500x500 3D printer is guaranteed to print out models with the highest resolution given their high precision margins.

6.4 Consider whether the Price of the Machine is acceptable

FDM Printer price will depend on your needs. Is it for professional use, industrial use, or just a hobby? There are tons of printers, and all vary depending on size, quality, performance, or durability, and the printer should fit your requirements. What is the printer for? How often will you be using the printer, and who can use it? You will want to ask yourself these questions before you go shopping.

Most hobbyist 3D printers are cheap and can buy one for as little as $200 – $500. While some, like the professional 3D printers, are a little more expensive and range between $1,500 and $6000. Lastly, the industrial 3D printer costs more than the hobbyist and professional 3D printers and is not easy to operate without the required knowledge, and they range anywhere from $20,000 to $100,000. With that said, if you want the printer for industrial use, go for the super large L-500 FDM 500x500x500 3D printer.

6.5 Consider the Supplier’s After-Sales Service Capability

Checking out potential 3D printer manufacturers in advance can be a smart move to make. It would be best if you approached it strategically to make the right move. Ask around for testimonials from previous clients and read the reviews. In addition, you may ask friends for their honest opinion and thoughts about a specific 3D printer supplier.

With hundreds of companies offering 3D printing services, it can be hard to find the right service provider to fit your needs, whether you’re buying it for the first or the tenth time. You’ll still have to consider their customer service before and after you’ve purchased your printer.

6.6 Go for Flexibility

Every day more good 3D printers are manufactured, making it less easy to choose. Think of your level of skills, and if you’re a beginner, you will need a 3D printer that is flexible, easy to adapt regardless of the size of the printer. A user-friendly 3D printer will allow you to begin production sooner.

Look for a manufacturer that will assist you with a program, training, or video-assisted guide to make your training short. For example, the L-500 500x500x500 3D printer manufactured by Dreambot3D has a great support feature and comes with a detailed user manual that covers the most frequently asked questions.

6.7 Pay Attention to Details

So, you’ve finally decided to buy a 3D printer after learning about the unique possibilities it has to offer. In this segment, we will highlight a few details you should pay attention to when buying a 3D printer of your own. Before purchasing your first printer, think of the most significant object you would want to print and buy one with a large build volume. It will determine the maximum size of the height, width, and length.

Getting the right building platform is very crucial, quickly explained; it is the base where your print begins setting up. There are many heating beds on the market but what mainly differentiates them is whether they are heated or not. A heated bed improves the quality.

Heating bed

The printer software is beneficial, but fewer people pay attention, which is very wrong to think you’ll do fine without. You can buy a device with plug & play versions; everything else will make more sense from the beginning.

The smallest of details do matter.

6.8 Put Safety First

Is 3D printing safe? Just like many machines, it’s safe using one as long as you take precautions. If you’re buying a 3D printer either for your home or just business, always ensure you have installed proper internal and external ventilation in your house or shop, and understand all the risks first. External ventilation is as vital as internal ventilation; external ventilation sucks out all the emissions from the heated filaments out (hazardous air), replacing the air inside with fresh and cool air.

The fact that there are hazards related when using a printer means you need to read up on 3D printers before you buy one, and don’t use the printer anywhere in your house, set aside a specific room for 3D printing use. The L-500 500x500x500 3D printer looks like a safe enclosing the printed process and protecting you from toxic fumes emitted during the printing process.

6.9 Select the most Cost-effective

The cost of 3D printed models is often determined by the material used in printing and manufacturing time. First, consider your budget because 3D printers are readily available from $200, do not go for an industrial printer if it’s for home use.

Which material you want to print with is also an essential factor to consider. Often these materials will cost more due to their physical, chemical, and mechanical properties. Suppose you’re looking for the easiest and less expensive printer. In that case, I’d suggest FDM printers because of their plastic filaments, which are easy to process and cheaper when compared to other materials.

6.10 Why is Dreambot3D’s FDM 3D Printer So Prominent?

Dreambot3D is a 3D technology company which is specialized in the production of high-quality 3D printers like the L-500 500x500x500 3D printer for all different applications. There are several reasons why our FDM 3D printer stands out from many printers:

- In the event of unforeseen power failure while still printing, dreambot3D’s printer is designed with a memory module that saves all the printing data so you can continue printing once power is restored.

- The printer allows offline printing with the use of an SD card; if you don’t want to connect to your PC, all your data will be automatically saved even after you’ve removed your SD card.

- The whole 3D printer is fully enclosed by CNC cutting, with precise hole settings and top positioning precision of printer operation.

With over 12 years of experience in the 3D printing industry, we can assure you prints produced by our 3D printers are highly accurate. Not to forget affordable printing materials, either for medical use, architecture, or aerospace, etc.

FAQ Guide

Is FDM printing faster than SLA?

It depends; SLA is faster, but FDM can be easily adjusted and set to print at higher speeds than SLA. Even so, this is a quid pro quo between quality and speed. Do you want quality or speed? The faster you print your object, the lower the quality will be; if you wish to increase the speed, you can choose to print thicker layers.

The FDM printers are slower because they give off plenty of heat, so you have to give it time to cool down the material if you want quality prints.

Which is better: TDM or FDM?

Both TDM and FDM are widely known multiplexing techniques, and both work well when transmitting multiple signals. Still, the most significant difference between TDM and FDM is that TDM is a lot more efficient and more straightforward than the FDM system.

FDM is a bit complex and will only work with an analog signal, unlike TDM, which will work well with analog and digital signals.

Do FDM printers smell?

Yes, FDM 3D printers emit fumes from the melted plastic filaments, which can be harmful to those in close proximity, especially if inhaled in large amounts, accompanied by very displeasing smells. But it all depends on the filament used; other filaments aren’t that toxic or harmful.

So, make sure every time you print with an FDM printer, you’re in a well-ventilated room and away from children. Then, always use it with caution.

Is FDM safe?

FDM 3D printing is safe as long as you follow safety precautions, for example, not being close when the 3D printer gives off unpleasant smells or fumes or not touching the nozzles when hot. In addition, printing materials such as PLA, nylon, and ABS should be highly noted when working with; such materials can be the starting point for many dangerous VOCs.

VOCs can be extremely harmful to one’s health. Some of the effects of VOCs include organ damage, nausea, and eye problems, among others. However, if you take safety precautions seriously, there shouldn’t be a problem.

What is an example of additive manufacturing?

For example, rather than grinding your print from a solid block, additive manufacturing will build up the part layer upon layer from a material that will be imparted as a fine powder. Additive manufacturing can be applied in countless industries and offer convincing results which standard methods cannot achieve.

Will additive manufacturing replace conventional manufacturing?

Highly unlikely that additive manufacturing will replace conventional manufacturing. Despite all the hype and benefits of additive manufacturing, certain factors hold it back, especially when it comes to mass production.

I have to say additive manufacturing is quite efficient at product redesigning and designing but slow when printing a part as opposed to our standard manufacturing, which is the best for mass production.

Is 3D printing commercially viable?

3D printing takes time per part which makes it commercially viable for a small number of pieces. There are tons of 3D printers accessible for commercial use. Still, it’s time-consuming and tedious going through hundreds of printers, screening out each printer that will cater to your needs, especially for one who has no experience.

Which is the best FDM printer?

The dreambot3Ds 500x500x500 3d printer is amongst the best you will find in the maret. Despite being a bit expensive, it can account for the price tag, having the best performance, accuracy, high-quality prints, and fastest FDM 3D printer. It will surely knock your pants off.

What is a good resolution for 3D printing?

0.01 millimeter, also equivalent to 100 microns, is a good resolution for 3D printing. We usually see 3D printers running from 10 to 300 microns layer heights. In theory, if printing with lesser microns, you should achieve good results. If your objects do not require too much detail, you can print at lower resolutions not exceeding 1000 microns.

How can I improve print quality?

- Be sure that you’ve correctly set the distance between your bed level and nozzle.

- Regularly check the nozzle temperature; it shouldn’t be too hot.

- Control the bed temperature; it should not be too high.

- Handle the filament with care.

- Avoid printing at high speeds to avoid ringing.

Is PETG stronger than PLA?

Very strong, PETG is a lot stronger than PLA in more than one way. It is more durable and flexible than PLA but more robust in terms of tensile power. Even though PLA is the most commonly used filament, PETG outperforms PLA, mainly because of its strength and ability to resist heat. Having said that, PETG is a little bit harder to print with than PLA, but once you use it once or twice, you’ll get the hang of it. PETG is still the number one choice for 3D printer users who want to print tough and durable models.

Be that as it may, it doesn’t mean PLA is terrible to print with; it’s still the most used filament, mainly because it’s a lot easier to print with.

What happens if you print PLA too hot?

If, and when you print your PLA with a bed too hot, it will cause your print to be messy, melt, and disfigure, but if printed at the correct temperatures, PLA will hold up fine. So not only is PLA easy to use, but it also goes easy when it comes to the temperatures so long as you don’t print it too hot, so what is the best temperature to print PLA with?

Well, there isn’t an exact temperature to use. Alternatively, you could print with a range of temperatures but based on what you want to print. The standard printing range when using PLA is around 190 to 230 ⁰C.

Can a car be 3D printed?

With all the advancing technologies and upgrades in 3D printing materials, believe it or not, you can now 3D print a car; several companies have been printing car parts for a while now. Even so, we still have to wait for a while before we find 3D-printed vehicles on the streets or from our car dealers. This is because most of the previously 3D printed cars are just prototypes or car parts.

Manufacturers all over have had a glimpse of the many advantages of these mechanics (from developing the product to mass production) and started showing interest in the future of 3D car printing.

What is the highest resolution in a 3D printer?

The highest resolution you can find in 3D printers is 200 microns. Almost all printers on the market today can print at a resolution of 200 microns which will give you decent results or even better in terms of quality. Still, most 3D printers print at a resolution of 100 microns, which should give you satisfactory results.

Resolution is among the few factors you need to consider when assessing the quality of 3D printers.

Why is my 3D print rough?

If your 3D print comes out rough, it usually is because of two things: Either your heating bed is set too high or over-extrusion. So how do I fix this problem?

- Reducing the layer height is among the major fixes that will ensure your prints are smooth.

- Lower your print speed till the issue has been resolved. It also helps in ensuring you create a more accurate model.

- Check if your temperature is set too high; if they are, reduce the printing temperature. Excessive high temperatures can cause the filament to be more melted.

- Use the suitable filament. Using substandard filaments will form your prints rough.

- Improving your cooling system can improve the quality of your print; it hardens the model swiftly.

Conclusion: Why Our FDM 3D Printer is the best Choice

After going through this guide and you are about to make an informed purchase for an FDM 3D printer, ensure that you choose an FDM 3D printer from a reputable 3D printing machine manufacturer like Dreambot3D.

Given that most 3D models being printed are almost the size of a basketball that is around 250x250x250 mm, Dreambot3D has overdone it by producing a 500x500x500 3D printer called the L-500 used for both industrial and home manufacturing.

Compatible with most printing materials

It is easy to use and is compatible with various materials such as Nylon, ABS, PLA, PC, Carbon Fibre, among others. This has seen its adoption in designing complex 3D models across multiple industries such as aerospace, manufacturing, automotive, education, etc. It is also compatible with most 3D modeling software like CAD, Solidworks, ProE, Sketchup, and Maya, among others.

High precision and resolution

The 500x500x500 3D printer has a high precision that can reach 0.05 mm, making it suitable for speedy and accurate prototyping of digital designs. It is also equipped with a unique nozzle system that smoothly discharges the filament on each layer, giving a highly detailed print of all your creations.

Power supply and failures

Huge 500x500x500 3D printers are susceptible to power failure and consume vast amounts of the power supply. Dreambot3D thought this through when designing the L-500 3D printer; that is why the power use is set between 110 and 220 volts and is warrantied for five years after purchase.

In case there is a power failure, no need to worry. The L-500 3D printer adopts PLC intelligent control, which saves and automatically continues to print after a power failure. It also enables you to print when offline and has an alarm system to notify you in case the printing material is depleted before the model is fully printed.

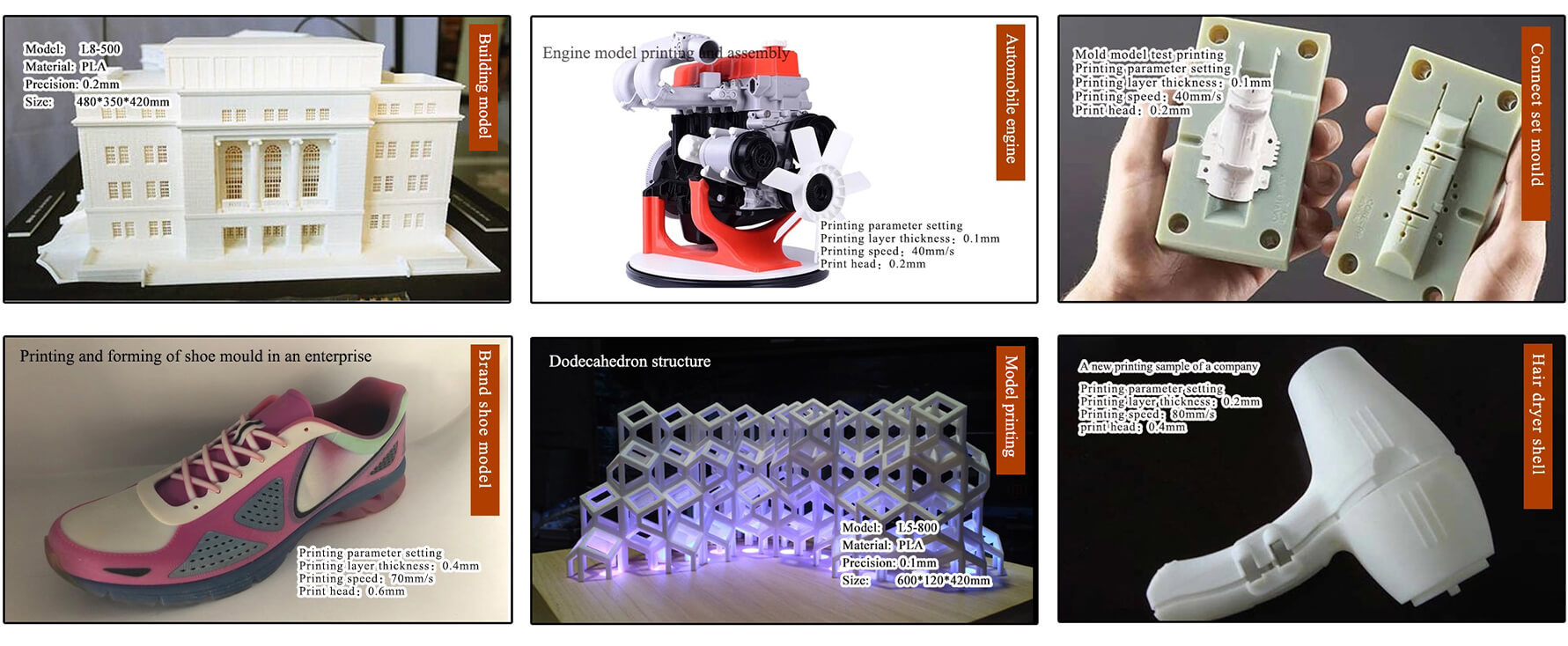

Application areas

L-500, the 500x500x500 3D printer, has seen successful application in different industries varying from building models, brand shoe modeling, and the creation of hair dryer shells to connect set molds. It was also used to create the complicated dodecahedron structure using PLA as the filament, a precision of 0.1mm and a size of 600x120x420mm.

This makes it suitable for application in almost all industries and can also print complex geometrical shapes. In addition, L-500 has proven to be a speedy and accurate 500x500x500 3D printer that can be used for both personal projects and industrial manufacturing.