3d printing in surgery

3D printing in surgery helps surgeons to visualize, practice and then perform surgery. 3D printing equipment allows surgeons to print high resolution 3D models for accurate surgery performance.

How 3D printers work for Surgery Guide

3D build

surgery model

3D printing

model

Simulating

surgery

3D printing enables surgeons to navigate areas of human anatomy that are complex and difficult to navigate.

The 3D printer is an affordable device that produces 3D models of an individual skull or other body parts.

3D printing in surgery enables a surgeon to visualize, practice and then perform reconstructive surgery, this therefore saves time and increases precision. By creating a 3D model prior to surgery saves time during surgery, which means less time is spent on operating a patient and there is a better surgery outcome.

3D printing aids learning for surgical students, in most cases, cadaver is not readily available. The 3D printer is able to accurately print every part of the body that needs to be studied.

3D printing is also employed for creating surgical tools and reproducing anatomical parts.

3D printing for surgical purposes is accurate, environmentally safe and cost effective.

Surgery Guide 3D printers for your Choice

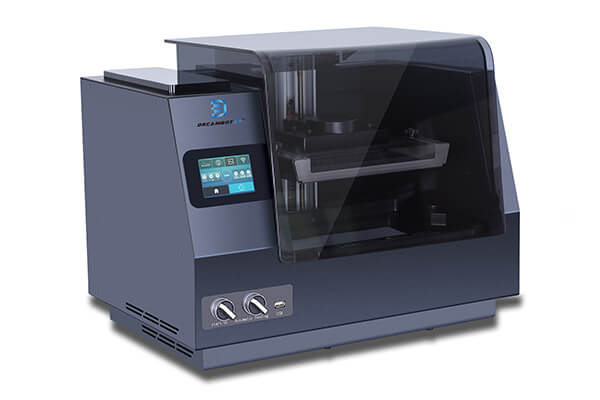

LCD 3D Printers

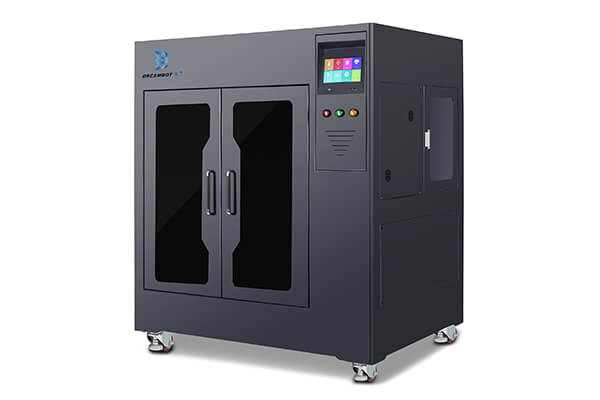

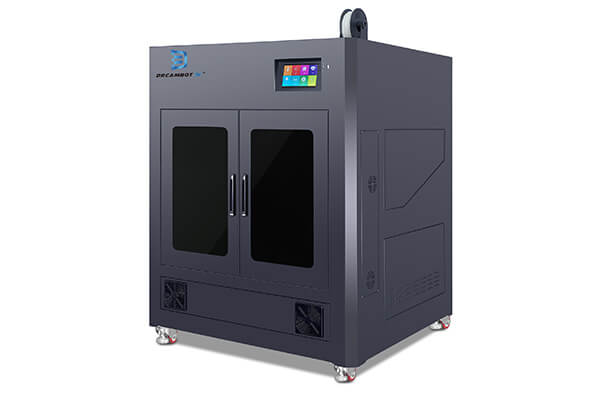

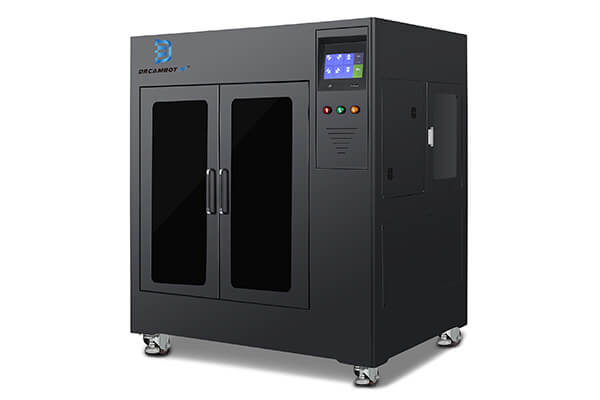

FDM 3D Printers

Don't know how to choose a model?

Are you confused about how to choose the correct model and type of 3d printer? We support 24/7.

4 points why choose us

4K resolution printing

4K black-white industrial screen, 0.01-0.05mm layer thickness accuracy, more accurate printing of details.

PLC control system

All 3d printers are equipped with PLC control system as standard, makes the operation more convenient, and reduces the error.

Extremely speed printing

Large printing size, 20mm/h printing speed, complete your printing tasks faster.

Reinforced structure

The all-metal one-piece shell reduces resonance, makes printing more stable and improves printing accuracy.

What our customers say

How 3D Printers are Used in Surgery – Surgery 3D Printer Buying Guide

2.1, What Surgical procedures Can 3D Printers Replace?

2.2, What’s the Changes After the Intervention of 3D Printers

3D printers are running riot in almost every industry. From education to military and healthcare to finance, its productive capacity is being attested to by multiple experts and specialists. 3D Printing in surgery is a typical example of the many potentials and opportunities the tech is opening up in the enterprise world.

Due to the buoyancy and prominence of the tech in different industries, all of us at Dreambot3D took it upon ourselves to provide individuals in need of formidable 3D printers with all the information they need to pioneer a sustainable purchase. Our focus in this piece is on the relevance of 3D Printing in surgery.

So, if you are looking to purchase a 3D printer for your healthcare or medical line, we recommend you explore this piece. From the everyday application of 3D printers in surgery to its impact in the medical industry, advantages, analysis, and buying process, this guide covers it all.

Application of 3D Printer in the Medical Industry

Starting with the use and application of 3D Printing in surgery, we intend to examine the many possibilities 3D printers bring to dentistry, human organ models, medical device, and surgery guide.

Before we dive into the many application of 3D printers in medicine, you must keep in mind that the 3D printing process can be accomplished using any of several different technologies. The choice of technology can depend on many factors, including how the final product will be used and how easy the printer is to use.

The most common technology used for 3D printing medical devices is called powder bed fusion. Powder bed fusion is commonly used because it works with various materials used in medical devices, such as titanium and nylon.

The powder bed fusion process builds a three-dimensional product from excellent metal or plastic powder, poured onto a platform, and leveled carefully. A laser or electron beam then moves across the powder layer and melts the material it touches.

Melted material fuses to the layer below it and to the powder around it to create a solid. Once a layer is completed, the platform moves down, and one more layer of carefully leveled powder is placed on top.

1.1, 3D Printer for Dental

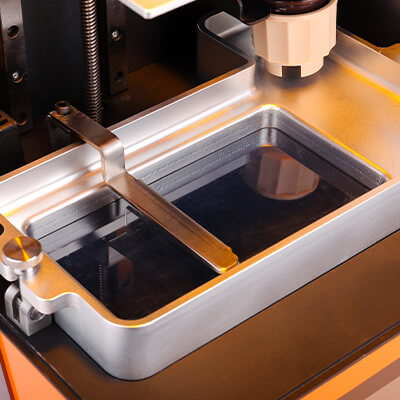

3D Printing is the catalyst for digital dentistry. It’s known for reliability and high quality. Much has changed since the first desktop 3D printers became available to the dental industry. A few years ago, 3D printers were only affordable to the most significant dental labs; now, they are common in labs and practices of any size. Dental 3D printers feature light or laser that polymerize a liquid with the computer-guided precision required to produce small objects with intricate details.

Additive manufacturing makes digital dentistry a no-nonsense business choice, combining high quality and improved patient care with low unit costs and streamlined workflows.

Dental 3D printers reached an inflection point when biocompatible materials became widely available for desktop machines. These FDA-compliant materials made 3D printed parts safe for intraoral use and offered excellent mechanical properties, propelling desktop 3D printers into dental practices all over the world.

Since the introduction of biocompatible materials for 3D Printing in dentistry, the emphasis has been on improving mechanical properties to provide intraoral parts with great strength and high resistance to wear. Because materials innovations can come from anywhere, it’s essential to choose a 3D printer that offers support for third-party materials.

One of the central requirements of dental manufacturing is very high accuracy and repeatable results. Bringing manufacturing models and other appliances in-office only pays off if the technology can provide the tight tolerances required for fitted parts. But it isn’t enough for a single print to provide accuracy; the results need to be easily replicated over time. Though printers can be easily bucketed into categories based on the details of their underpinning technologies, these categories rarely tell the whole story.

While many 3D printers on the market provide high theoretical accuracy, not all offer repeatable results over time. The hallmark of an excellent dental 3D printer is to have both high accuracy and repeatability. As 3D printing technology continues to mature, there is an emphasis on how light is delivered to the build area to ensure accurate, repeatable results.

1.2, 3D Printer for Human Organs Model

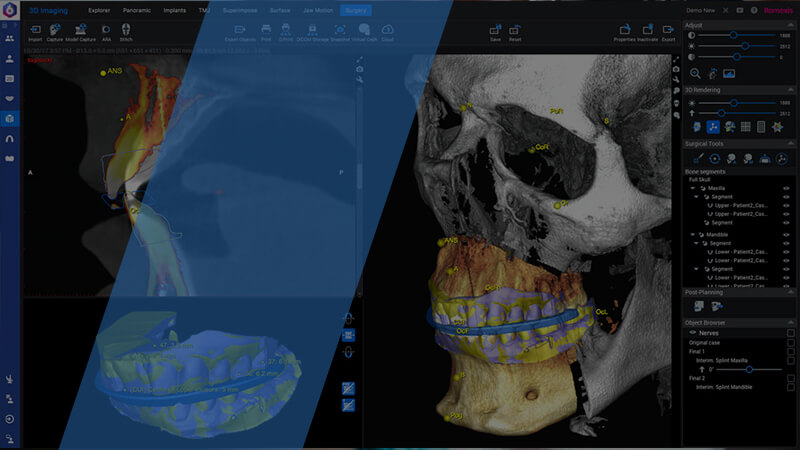

Medical errors are a significant concern in clinical practice, suggesting the need for advanced surgical aids for preoperative planning and rehearsal. Conventionally, CT and MRI scans and 3D visualization techniques have been utilized as the primary tools for surgical planning.

While effective, it would be helpful if additional aids could be developed and utilized in particularly complex procedures involving unusual anatomical abnormalities that could benefit from tangible objects providing spatial sense, anatomical accuracy, and tactile feedback.

Recent advancements in 3D printing technologies have facilitated patient-specific organ models to provide an effective solution for preoperative planning, rehearsal, and spatiotemporal mapping.

Bioprinting is a method that enables cellular structures to be made from bioinks loaded with stem cells. Layer by layer, the biomaterial is deposited to create skin, tissue, or even an organ. Bioprinting projects are growing, and each new project is one step closer to being a fully functional and viable solution. Laboratories and research centers are bioprinting human livers, kidneys, and hearts.

The objective is to make them suitable for transplantation and viable long-term solutions. This method could allow to cope with the lack of organ donors and better study and understand certain diseases. There is still progress to be made, but we wanted to present the main bioprinting projects in the listing below, including 3D-printed organs and other human body parts!

Note that scientists are researching how to use the 3D printing process to manufacture living organs such as a heart or liver, but this research is in the early stages of development.

1.3, 3D Printer for Medical Device

3D printers are used to manufacture various medical devices, including those with complex geometry or features that match a patient’s unique anatomy.

Some devices are printed from a standard design to make multiple identical copies of the same device. Other devices, called patient-matched or patient-specific devices, are created from a specific patient’s imaging data.

While 3D printers are often used to create identical copies of the same device, they can also be used to create devices unique to a specific patient. Patient-matched (or patient-specific) devices are created specifically for the patient based on individual features, such as anatomy. They can be based on a template model that is matched to a patient using medical imaging. Patient-matching can be accomplished by techniques such as the scaling of the device using one or more anatomic features from patient data.

The FDA regulates 3D printed medical devices through the same pathways as traditional medical devices; therefore, they are evaluated according to the safety and effectiveness information submitted to us by the manufacturer.

While traditionally manufactured medical devices come in discrete sizes, patient-matched devices can be made in a continuous range of shapes with pre-defined minimum and maximum specifications that we can use to review the devices in the same way as standard-sized devices. For instance, the specification may define a minimum and maximum wall thickness or how sharp a curve can be to maintain device performance for its intended use.

There is a provision in federal law that exempts “custom” medical devices from FDA review, but patient-matched devices do not automatically meet all the requirements.

- 3D Printer for Surgery Guide

Conventional bone replacement surgeries have always been associated with different critical drawbacks. Deviation of the implant from its original position is one of the most important problems associated with surgery.

The emergence of 3D Printing in surgery opened a new opportunity for the solution of this problem by the use of patient-specific surgical guides. These 3D-printed surgical guides provide a specific cut and therefore reduces the drawbacks associated with surgical techniques, including the fixation difficulties.

A surgical guide is a medical device that is 3D printed based on the DICOM data, which is patient-specific. 3D Printing in surgery is used for the accurate placement of the implant in the bone structure.

3D printed surgical models replicate the exact surfaces of the patient’s intraoral situation and assist the surgeon in performing the clinical application of drilling implants into the bone with optimal accuracy. The correct angulations are built into the guide, and the exact length is known from the top of the sleeve to the ape of the implant.

In most bone or joint cases, implants are used to restore the normal functionality of the affected part. Failure is one of the most critical problems associated with the use of orthopedic implants. Revision surgery is required in such cases, which itself is generally more complicated and time-consuming than primary surgery.

Moreover, numerous risk factors accompany such revision surgeries include increased risk of infection, fractures, and or perforation of the bone during removal of the old prosthesis. To avoid revision surgeries, better fixation processes are needed. Moving from standard off-the-shelf implants to more patient-specific implants is a means of addressing this need. 3D printed surgical guides provide accuracy and stabilization.

The Impact of 3D Printers on the Medical Industry

Unlike how the use of 3D printers in military and manufacturing came as a surprise, it was obvious from the very first day that 3D printers were going to replace numerous conventional methods used in the medical field. 3D Printing in surgery has become a widely acknowledged trend. And while it’s still quite expensive, its dominance is expected to revolutionize the medical industry.

In this section, we intend to have a birds-eye view of the many impacts of 3D Printing in surgery and other medical fields. Focusing mainly on the procedures 3D printed surgical models have replaced and the changes the medical industry has enjoyed since 3D printers intervened on a mainstream level. If you are looking to purchase a sustainable 3D printer for your medical line, we recommend you take out time to explore this chapter.

2.1, What Surgical procedures Can 3D Printers Replace?

Though printing items like chocolate and pizza might be satisfying enough for some, 3D Printing still holds a lot of unfulfilled potentials. Talk abounds of disrupting manufacturing, changing the face of construction, and even building metal components in space. While it is hard not to get a little bit excited by these potentially world-changing advances, there is one domain where 3D Printing already has a real-life impact. 3D Printing in surgery’s capacity to produce customized implants and medical devices tailored specifically to a patient’s anatomy has seen it open up all kinds of possibilities in the field of medicine.

Today’s surgeons use 3D Printing in surgery to create exact replicas of a patient’s tumor, organs, or other biological structures before they make a single incision. This gives them a hands-on opportunity to develop the most precise, least invasive approach to performing surgery. To create 3D printed surgical models, doctors use specialized equipment that converts images from a patient’s two-dimensional CT or MRI scan into a 3D model, which then is printed out using a material like acrylic.

Popular dental product Invisalign is one of the earliest, most widespread uses of 3D Printing in dentistry. This clear plastic orthodontic brace was created using scans of the patient’s teeth, then 3D printed for a custom fit. Today, 3D Printing in surgery is being considered for making scoliosis braces and orthopedic casts to splint broken limbs. Because 3D braces are custom printed to fit the patient’s actual anatomy, they not only should feel more comfortable but likely will perform better by providing support precisely where it’s needed.

Another major procedure that 3D printers in surgery replaced is the prosthetic body part process. When a person loses a limb, they must either invest in an expensive prosthetic replacement or go without. This presents a difficult situation for amputees in developing nations. But 3D printed surgical models offer a way to produce inexpensive prosthetic body parts that can be customized to the patient’s anatomy. Beyond functional prosthetics like hands, 3D Printing in surgery also can create cosmetic body parts, such as latex ears for children born without them. This helps children feel normal, and the 3D body parts can be easily replaced as the child grows.

Obtaining even the most basic pieces of medical equipment can be costly and logistically challenging. People in poverty-stricken nations often must overcome infrastructure problems and even governmental interference in obtaining medical supplies. 3D Printing in surgery enables people in these areas to cost-effectively print the instruments they need when they need them. One group in Haiti, for example, is currently making and distributing 3D printed surgical models of umbilical cord clamps.

To wrap up this section, weekend warriors and others who have worn out their knees or hips have been able to receive joint replacements. These devices generally function very well and last for years. Now, 3D Printing in surgery offers the ability to make custom artificial joints that replicate your own original joint. Studies do not yet show these joints perform as well as traditional, mass-produced prosthetic joints, but as technology advances, 3D printed surgical models will most likely become the norm.

2.2, What’s the Changes After the Intervention of 3D Printers

It’s common to find a lot of experts and specialists in the medical field in awe of the many possibilities 3D printing in surgery is bringing to the table. With that in mind, it wouldn’t do much good to finalize this chapter without taking a sneak peek at the many possibilities of the introduction of 3D printers in 3D printing surgical models and medical devices.

Use of 3D Printing to Fight the Covid-19 Pandemic

The rapid proliferation of Covid-19 has been putting great strain on healthcare systems across the world, with demand for critical medical equipment and supplies mounting. Major manufacturers to individuals have responded to the Covid-19 crisis by supporting the production of vital medical equipment for hospitals. With 3D printed surgical models, Carbon and Renishaw have begun designing and manufacturing open-source PPE for healthcare workers worldwide.

Use of 3D Printing in Regenerative Medicine

There is a major health crisis in terms of the shortage of organs, as the population is living for longer due to medical advances. Since 2013, the number of patients requiring an organ has doubled, while the actual number of available donor organs has barely moved (HRSA, 2020).

Regenerative medicine involves many different areas, using scaffolds, biomaterials, cells, or a combination of biomaterials and cells to attempt to create organs for transplants instead of relying on the current donor model. Recently, the creation of multilayered objects (tissues/organs) from soft biomaterials such as living cells and biomimetic synthetic polymers has been the most challenging technological advancement in the field.

Although many problems need to be solved for complex organs (such as the heart or liver) to be 3D bio-printed and subsequently transplanted into a patient, simple organs such as the bladder have been transplanted into patients since the early 2000s. 3D Printing in surgery is not just changing the way doctors interact with patients; it’s breading up a whole new world of possibilities for doctors and surgeons alike.

Use of 3D Printing in Personalised/Precision Medicine

3D Printing offers a completely new opportunity for the development and preparation of personalized medicines at both the pharmacy and industrial scale. Introducing 3D Printing in surgery to pharmacies and hospitals would allow physicians, nurses, and pharmacists to form a dose and delivery system based on the patient’s body size, age, lifestyle, and sex. This would make medicine personal to the patient and also save money and resources.

Streamlined and More Efficient R&D Processes

There is a growing R&D crisis occurring in the pharmaceutical industry, as drugs are failing at later and later stages. Bioprinted tissues and organs are already being used to help increase the success rate of clinical trials. With 3d printed surgical models, researchers can print fully functional organs made of human cells to test a drug’s efficacy prior to using in vivo animal or human tests. This not only reduces the damage caused to animals but also expedites the entire R&D process.

Research on the Advantages of 3D Printers in the Medical Industry

At this junction, we believe you have all the information you need to understand how impactful 3D Printing has been to the medical industry. Its high time we focused on the many advantages 3D printing in surgery is bringing to the medical industry as a whole.

3D Printing in surgery can bring massive benefits to the healthcare sector. Not only does it provide a more personalized form of care for chronic conditions, but it can also speed up processes and relieve budgetary pressures on healthcare services.

3D printed surgical model revolutionary potential isn’t going unnoticed. In a recent study exploring the impact new printing technologies are having on European healthcare systems, 68% of healthcare professionals believe new printing technologies have the potential to fundamentally transform the health sector.

3D Printing, also called additive manufacturing, is a process that turns a digital 3D drawing into an actual object, with 3D printing in surgery building this out of thin, horizontally sliced layers. The ability to produce complex shapes and levels of structural detail involved means that customized models can be made for patients.

There are different types of 3D printing technologies available which use different materials, and together, these have all made a disruptive impact on the health sector.

3.1, Analysis of the Advantages of Using 3D Printing to the Surgical Guide Industry

3D Printing is revolutionizing and enhancing various industries, and the medical industry is no exception. There are numerous benefits 3D printing in surgery provides for the field in order to improve and save patient’s lives.

- Bespoke Models

A key advantage of 3D Printing in surgery is that it produces bespoke models, which is crucial in improving patient outcomes. Take the example of inserting a cranial plate. Through 3D printed surgical models, the plate can be made to precise fit using available scan data. Additionally, the model can be manufactured in advance, meaning the surgery is a lot smoother and quicker. This also yields distinct benefits for the patient, with the customized implant fitting perfectly, subsequently reducing the chances of infection and speeding up the recovery process.

For these reasons, 3D Printing in surgery is an extremely cost-effective solution. Complications cost the NHS a huge amount of money every year. If the 3D printed surgical model can ultimately improve patient outcomes and help people to live better and longer lives, it can reduce the likelihood of a patient returning to the hospital, in turn saving health services a significant amount of money.

- Intricate Care

3D Printing in surgery creates low-cost prosthetics where people need them, for example, in war-torn countries. They are an affordable solution for people who cannot afford to buy a prosthetic. Low-cost medical equipment is also important in poverty-stricken countries and remote areas. There are areas where road infrastructure is too bad to deliver medical equipment. 3D Printing in surgery makes it easier to print the necessary equipment in those villages without having to regularly transport them.

In line with intricate care, 3D Printing in surgery also eliminates expensive procedures and long waiting. Surgical guide 3D printing allows to 3D print medical and lab equipment. It is possible to 3D print plastic parts of the equipment. This drastically reduces costs and time spent waiting to receive a new medical device from external suppliers. Furthermore, the manufacturing process and further applications are also easier. This makes the equipment more readily available and allows low-income or hard to access areas to get 3D printed surgical models easily.

- Simplifying Complex Task

Another benefit of 3D Printing in surgery is that complex designs can be achieved which cannot be manufactured in any other way. One limitation of 3D printed surgical models in the past has been the material options, but 3D printing leaders are widening these by making materials such as polypropylene available. Polypropylene’s mechanical properties are unique, and manufacturers are able to change the nature of its function through design. This is especially useful in orthotics, where solutions are improved by being more lightweight and easier to use.

3D Printing in surgery can also be hugely effective in supporting traditional medical protocols. A good example of this is maxillofacial reconstruction. MRI scans can create models of what a patient’s skeleton and skull look like, and this can be used by 3D print manufacturers to create bespoke, preoperative models.

- Customization

Making prosthetics the traditional way is very expensive because they have to be personalized to the individual. 3D Printing in surgery gives users the freedom to choose, e.g., different designs, forms, sizes, and colors of their prostheses. This makes every 3D printed surgical model personalized. 3D printers also allow prosthetics to be more widely available at a lower price.

Future doctors can practice on 3D printed surgical models. This is much more accurate than, for example training on animal organs. Training on human-like, 3D printed parts increases the quality of skills doctors obtain during training and the medical treatment of patients.

- Design Freedom

3D Printing in surgery is changing the economics of the medical design market drastically. Independent designers are now able to bring their designs into the world without having to invest a lot of money first.

Do you have a good idea? Create a CAD file and have it printed directly. Service providers are already hitting the market that provides a full list of related services, ranging from mere production to quality assurance, packaging, branding, sales, and even processing and customer care.

The designer can now cherry-pick what suits his/her talents best – s/he might decide to control the whole process or simply focus on designing great products. Giving the designer a whole new avenue to explore, there are plenty of new objects to be discovered. 3D Printing in surgery enables shapes with undercuts, complex structures, and even directly functional parts.

3.2, Introduction to the Working Principle and Development History of 3D Printers

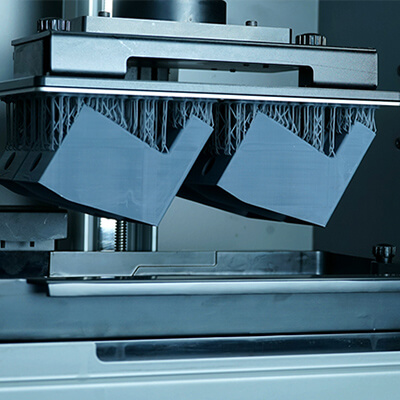

3D printing or additive manufacturing is the process of making three-dimensional solid objects from a digital file.

The creation of 3D printed surgical models is achieved using additive processes. In an additive process, an object is created by laying down successive layers of material until the object is created. Each of these layers can be seen as a thinly sliced cross-section of the object.

3D Printing in surgery is the opposite of subtractive manufacturing which is cutting out / hollowing out a piece of metal or plastic with, for instance, a milling machine. 3D Printing in surgery enables you to produce complex shapes using less material than traditional manufacturing methods.

The adoption of 3D printed surgical models has reached critical mass as those who have yet to integrate additive manufacturing somewhere in their supply chain are now part of an ever-shrinking minority. Where 3D Printing in surgery was only suitable for prototyping and one-off manufacturing in the early stages, it is now rapidly transforming into a production technology.

Most of the current demand for 3D Printing is industrial in nature. 3D printing technology is destined to transform almost every major industry and change the way we live, work, and play in the future. Companies have used 3D printers in their design process to create prototypes since the late seventies. Using 3D printers for these purposes is called rapid prototyping.

Using 3D printers in surgery for rapid prototyping leaves room for a short, fast, and relatively cheap process. From idea to 3D model to holding a prototype in your hands is a matter of days instead of weeks. Iterations are easier and cheaper to make, and you don’t need expensive molds or tools.

Besides rapid prototyping, 3D Printing in surgery is also used for rapid manufacturing. Rapid manufacturing is a new method of manufacturing where businesses use 3D printers for short-run / small batch custom manufacturing.

It’s not uncommon these days to see headlines about 3D-printed implants. Often, those cases are experimental, which can make it seem like 3D Printing in surgery is still a fringe technology in the medical and healthcare sectors, but that’s not the case anymore. Over the last decade, more than 100,000 hip replacements have been 3D printed by GE Additive.

The Delta-TT Cup is made of Trabecular Titanium, which is characterized by a regular, three-dimensional, hexagonal cell structure that imitates trabecular bone morphology. The trabecular structure increases the biocompatibility of the titanium by encouraging bone growth into the implant. Some of the first Delta-TT implants are still running strong over a decade later.

Another 3D printed surgical model that does a good job of being undetectable is the hearing aid. Nearly every hearing aid in the last 17 years has been 3D printed thanks to a collaboration between Materialise and Phonak. Phonak developed Rapid Shell Modeling (RSM) in 2001. Prior to RSM, making one hearing aid required nine laborious steps involving hand sculpting and mold making, and the results were often ill-fitting.

With RSM, a technician uses silicone to take an impression of the ear canal, that impression is 3D scanned, and after some minor tweaking, the model is 3D printed with a resin 3D printer. The electronics are added, and then it’s shipped to the user. Using this process, hundreds of thousands of hearing aids are 3D printed each year.

In the dental industry, we see molds for clear aligners being possibly the most 3D printed surgical models in the world. Currently, the molds are 3D printed with both resin and powder-based 3D printing processes, but also via material jetting. Crowns and dentures are already directly 3D printed, along with surgical guides.

They are wrapping up with the growth of 3D printers in bioprinting. As of the early two-thousands, 3D printing technology has been studied by biotech firms and academia for possible use in tissue engineering applications where organs and body parts are built using inkjet techniques. Layers of living cells are deposited onto a gel medium and slowly built up to form three-dimensional structures.

How to Choose Materials

With the advantages and impact of 3D Printing in surgery duly stated, we believe it’s high time we talked about the type of materials experts and specialists in the medical field can choose from when looking to create formidable models with a 3D printer.

Before we go into detail about all the materials compatible with surgical 3D printers, it’s important you understand the simple yet profound process behind choosing a material for 3D Printing. Surgical models are intricate parts that require precision to detail. Without the right design and features, a customized or expensive surgical model can easily end up in the waste bin.

To avoid such scenarios, it’s important you examine the necessary features and requirements needed from a material of choice before Printing. All the materials listed below are built for specific designs. If you don’t take out time to research and understand which is suitable for the job at hand, the fact that you spent all day or a few weeks 3D printing a customized surgical model wouldn’t count for much in the sight of the patient seeking the service. With that in mind, we recommend you take out time to explore this chapter.

4.1 ABS {Acrylonitrile Butadiene Styrene}

Acrylonitrile Butadiene Styrene is a thermoplastic polymer that can melt and cool without altering its chemical properties. That makes it an interesting FDM 3D printer material for carrying out 3D printing tasks in surgery. The filament is known to be strong, tough, and durable. It is also forgiving to scratches, offers good resistance to heat and everyday chemicals.

It can endure heat, pressure, and stress like no other material for ship 3D printing, making it a great choice for wear and tear prints. You can try this out yourself: If you move a strain of ABS filament, it will distort and bend before breaking. PLA breaks much more easily. ABS is quite forgiving, as long as you print with the right settings and proper temperature management. You can even achieve overhangs of around 45 degrees. If the Print succeeds, the results are very convincing.

Most surgeons and doctors like the material because you can process its surfaces with acetone, glue parts, and even file off some material. Lastly, it can be easily painted with acrylic colors. ABS filament is not toxic when 3D printed. Only at very high temperatures (400 °C), the material decomposes into butadiene (which is carcinogenic to humans), acrylonitrile (possibly carcinogenic to humans), and styrene—nothing you want to inhale under any circumstances.

If you don’t have a surgical guide 3D printer at hand, you can have ABS parts printed by a professional 3D printing service. You can put a call through to our support representative to obtain the best deal on a high-resolution FDM drone 3D printer.

4.2 PLA {Polylactic Acid}

PLA filament is a popular material used for 3D Printing in surgery, and there’s a good reason for that. It comes in many shades and styles, making it ideal for a wide range of applications. Whether you’re looking for vibrant colors or unique blends, it’s an easy-to-use and aesthetically pleasing material.

PLA is short for Polylactic Acid, a thermoplastic polymer that is derived from renewable resources, more specifically from corn starch or sugar cane. This sets the material apart from other commonly used plastics, which are procured through the distillation and polymerization of non-renewable petroleum reserves.

Since PLA filament is a biodegradable product, it tends to naturally break down in about three to six months. Other thermoplastic materials can take up to a thousand years to decompose, making PLA much more environmentally friendly.

PLA material has been thrust into the spotlight by the rise of custom 3D printed surgical models. PLA filament is available in a wide variety of colors and blends, and innovative PLA-based materials seem to be constantly hitting the market.

Outside of 3D Printing in surgery, PLA is also used to produce things like medical implants, food packaging, and disposable tableware. But within 3D Printing in the surgery sphere, PLA filament is widely thought of as an aesthetic material best used for prototyping.

4.3 Carbon Fiber

Carbon fiber filaments are composite materials formed by infusing fragments of carbon fiber in a polymer base, similar to metal-infused filaments but with tiny fibers instead. The polymer base can be of different surgical 3D printing materials, such as PLA, ABS, PETG, or nylon, among others.

While true carbon fiber materials have long continuous fiber strands that improve mechanical resistance, these FDM 3D printer materials for surgical models contain short particles of around 0.01 mm in diameter. Although this is enough for improving the strength of printed parts, keep in mind that such filaments cannot compare to the actual material.

For those seeking tougher FDM 3D printer material for surgical models, carbon fiber filament presents a relatively easy alternative to the more expensive and demanding materials, such as polycarbonate (PC) or PEEK. Moreover, the increased strength provided by the carbon fiber particles contributes to greater dimensional stability, helping to avoid warping and shrinking.

However, using carbon fiber to 3D print surgical models does present some issues. The infused carbon fiber particles aren’t melted by the nozzle during extrusion, which may lead to frequent clogging. In addition, these particles work as abrasive agents during extrusion, which over time will wear down a brass nozzles’ internal bore. This is why special nozzles like hardened steel are strongly suggested for Printing with composite materials.

4.4 PET

PETG (polyethylene terephthalate) is a thermoplastic polymer used for 3D printing surgical models. Mixed with glycol (hence the “G”) exhibits good 3D printing features. PETG FDM surgical 3D printer material is resistant to high temperatures and water, presents stable dimensions, no shrinkage, and good electrical properties.

PETG combines ABS durability and PLA printability, and it comes as no surprise that it’s frequently chosen by professionals seeking a reliable filament for their projects. PETG gained a lot of recognition during the coronavirus pandemic because it can be easily sanitized and therefore is useful for medical applications such as face shields.

Note that You may encounter two options — PETG (sometimes written as PET-G) and PET. The “G” stands for glycol — a substance added to prevent corrosion and crystallization effects. Glycol modified PET is easier to 3D Print. PET without glycol is more fragile and prone to breaking.

On the other hand, PETG is characterized by a delicate outline that’s easy to scratch. That being said, the chemical properties of PETG are far better for 3D printing surgical models despite some minor disadvantages. PETG is suitable for use on any surgical guide 3D printer. If you are interested in created 3D prints with PETG and you are yet to find a suitable high-resolution surgical 3D printer for the task, don’t hesitate to put a call through to our support team.

- Resin

While FDM surgical printers use traditional industrial plastics like ABS and Polycarbonate (PC), SLA, DLP, and LCD 3D printers require special photopolymer resins that harden (cure) once UV light is directed at it. Most surgical model 3D printer resins are either epoxy-based or acrylate-based, the latter being used more often in desktop printers.

A lot of people think of resin surgical 3D printed parts as fragile and most suitable for ornamental and prototyping applications rather than functional and load-bearing components. But this is only true if the resin isn’t properly selected. That being said, if you’re buying a generic resin for a tough job, it won’t give you the strength that you’re looking for.

Examples of super-strong resin can be found in a wide variety of industries. There are castable resins for making jewelry and 3D Printing in the field of dentistry to produce mouth guards, crowns, and surgical guides. There are also high-temperature resins that are suitable for surgical model 3D printing.

Note that resin tensile strength values are usually measured by a pull test that follows strict international procedures, so the results can be used worldwide. The higher the tensile strength, the stronger the material is considered to be because of how much stress it can withstand.

Just because the resin is tough, it doesn’t mean that the 3D printed surgical models made from these resins will be twice as strong as if printed with a standard resin. Other factors, like model design and print settings, play important roles in the final Print’s strength.

Nonetheless, comparing tensile strength is a straightforward way to determine which material is stronger, and from the numbers supplied by the manufacturers, it’s clear that high strength resins are much tougher than the standard and is a more durable option for surgical 3D Printing.

How to Choose a 3D Printer for Medical Industry

Being a good doctor, dentist or surgeon does not in any way mean you would have an eye for good 3D printers. 3D Printing in surgery is quite broad, leaving room for multiple variants. And choosing the best amongst the long list can keep you scouring the net for hours—especially if you are not familiar with the intricacies involved in purchasing a 3D printer.

In this section, we will highlight all the factors you need to look out for when choosing a 3D printer for surgical Printing. Ranging from the size of Print, you need to create formidable 3D printed surgical models to the factors you need to consider when making a purchase; this section covers it all.

5.1 What is the size of the Print

There are hundreds of FDM and LCD 3D printers available, each varying in design, shape, and size. If you have successfully navigated the industry and audience, you want to purchase an FDM or LCD 3D printer for, then you have an idea as to how big or how small your day-to-day print size would be. The type of model you can create with a surgical 3D printing system varies based on the machine you are using. Knowing your print size requirement helps break through the noise and serve your customers better.

So, how do you navigate your print size requirement for a 3D printer in surgery? There are two major actors to consider—a unit of measure for your CAD file and dimension, weight & size constraints.

Every design or model you make using an FDM or LCD printer is subject to the unit of measure in your CAD design. That’s your CAD design determines how big or how small your prints would be its dimension and design sequence. At the same time, it’s impossible to accurately decipher the type of designs your clients would require from you regularly when trying to choose an FDM OR LCD 3D printer for surgical models, opting for a machine capable of handling a CAD design with a high unit of measure is essential.

The material you chose for your surgical printing task has a lot to say about the printing size. The dimension, weight, and size of the object obtained from a surgical 3D model printed with PLA are quite different from the result you would obtain using an ABS material—regardless of whether the CAD file and design are the same. Considering the type of materials, you would print on regularly can help you pinpoint an FDM or LCD surgical 3D printing system that wouldn’t create constraints in your design’s dimension, weight, and size.

Determining the size of a print requires in-depth knowledge of the customer base or audience you create 3D surgical models for on a regular. If your day-to-day workload revolves around using 3D printers for a surgical guide to provide CAD designs and models of large print size to experts in numerous other industries, we recommend you thoroughly scout for a machine palatable enough to handle the dynamic needs of your customer base before finalizing the purchase.

5.2 Choose a Reliable Brand

Hundreds of brands have built a formidable reputation for themselves by offering surgical 3D printers with remarkable features. While it’s essential you check out a brand’s track record and reviews from previous customers, it’s also important you don’t base your buying decision entirely on a brand’s name.

There are a lot of surgical 3D printers available worldwide with reputable brand tags but void of the innovative design and features required to keep your printing line functional. Many brands built a good name for themselves in the early 90s but haven’t been able to keep up with the diverse changes needed to excel in the 21st-century market.

Before putting hours of research into exploring a brand’s portfolio or track record in the global market, make sure the surgical 3D printer you want to buy possesses features in line with your needs and has been ascertained satisfactory by other users and experts in your industry.

There are so many surgical 3D printers being developed and released into the market every day. While most of these printers meet the basic requirements and features of FDM and LCD surgical 3D printers, you should not be hasty while sealing the deal yet. Why? You may ask.

Surgical 3D printers are not cheap machines. You’ll part ways with a considerable amount of your money; therefore, you must ensure that you get the best surgical 3D printer available. Your choice should not solely be made on the brands’ name. It is crucial that you do thorough background research on the company’s Google ratings and reviews before making a purchase.

Consider buying your printer from a surgical 3D printer manufacturer that has a good track record, a higher rating on Google, and a genuine customer support system. Such a company will be apt to respond to all your urgent needs. The company/brand that you’ll pick for your printer can make or break your printing experience if something goes amiss.

5.3 Safety Configuration of the Machine

The first step in turning your dreams into a reality is purchasing the right surgical 3D printer. But this is a demanding process. There will be tons of highly affordable brands thrown in your way. Surgical 3D printers come with a substantial amount of risk, including hotbed, hot extruders, toxic fumes, and so on. While the idea behind 3D Printing in surgery is to provide a safe printing environment, it is important that you take the safety configuration of the machine seriously, especially if you have kids around.

The constant plea of safety first can seem inconsequential when an FDM or LCD surgical 3D printer offering formidable features is thrown your way at a discounted price. The idea behind 3D printed surgical models is to provide a safe printing experience and, at the same time, help users save filament, resin, and time.

Backing your purchase up with detailed information on the precautionary measures and built-in safety designs accessible via A surgical 3D printing system of choice is paramount. We believe that professionals or hobbyists who have been in the industry for a long time would understand why we took our time to emphasize the machine’s safety configuration.

However, suppose you are a newbie trying to navigate rocky paths with a 3D printer in surgery optimized with formidable advantages. In that case, we recommend you don’t allow features such as the stable default settings or the printer’s ability to keep your printing model in a perfect state make you go head over heels and forget to analyze the safety configuration of the machine.

3D Printing in surgery cannot be termed user-friendly in scenarios where issues arise during the printing process. To be on the safe side, don’t finalize your purchase without carrying out a thorough analysis of the printer’s safety configuration. If you are new to the industry and cannot navigate your way around the safety configurations, don’t hold back your questions; feel free to ask as many questions as you deem probable before paying a penny.

Safety comes first. Therefore, back up your purchase with detailed safety guidelines and precautions regarding your machine. Enclosed surgical 3D printers are highly priced compared to the open frame type. But, they are safer, and they protect their users from getting injured.

5.4 Resolution Requirements of the Machine

How important is the resolution of a surgical 3D printer to the end processor finish product? The answer to this question depends on the industry, client, and customer base you are serving. Having a high-resolution surgical guide 3D printer is quite essential for specialists and experts to design complex prototypes. A hobbyist can easily make do surgical 3D printers of any type; rest assured, the finished product and design are guaranteed.

There is no ideal benchmark or resolution requirement for hobbyists or artisans looking to provide their clients with the best 3D printed surgical models and designs possible. However, having a surgical 3D printer with high definition can help you attract, build and grow a formidable client base.

Before making a purchase, explore the resolution of the surgical 3D printer. Try to be as detailed as possible. You can seek advice from experts and professionals with a reputable track record in the medical industry. Endeavor to have a basic idea or information on the surgical 3D printer resolution requirements that would keep your production line running at an optimal level before actualizing your surgical 3D printer purchase.

5.5 Consider Weather, the Price of the Machine, is Acceptable

It’s never a fun experience to have explored all the remarkable features and benefits a 3D surgical printer is offering, weighed it with your production line, and obtained satisfactory results just to find out during checkout that the printer for 3D printing surgical models you want to purchase is far above your budget.

Surgical 3D printers are quite expensive. They require a sizable investment, especially if you are looking for industrial-grade printers. As a professional or expert looking to help individuals from different walks of life obtain formidable surgical models or the finished product they desire, having the best printer for surgical 3D Printing is essential.

Before exploring all the features and benefits of a surgical 3D printer, weigh its price range with your budget. Note that the price of a printer for 3D printing surgical models does not determine efficiency. There are a lot of surgical 3D printers with a high price but not as durable and efficient as counterparts with low price tags.

To hasten your surgical 3D printer buying process in terms of price, it’s advisable you put a call through to a support representative backing up the activities of a brand of choice stating your estimated budget and the type of surgical 3D printing activities you would like to carry out using the machine.

5.6 Consider the Suppliers after Sales Service Capability

Many folks place all their focus on the remarkable features a machine offers and forget to obtain detailed info on what their suppliers after service capability is like. From experience, we can boldly tell you that a remarkable LCD resin 3D printer or an industrial FDM 3D surgical printer with no warranty policy guiding its purchase would do you more harm than good.

Every reliable surgical 3D printer manufacturer attributes a warranty policy of not less than one year to each product available in its collection. If you are about to purchase a surgical 3D printer and a warranty policy of less than one year is thrown your way, abort purchase.

Also, take note of technical support. Twenty-four hours support service is ideal. However, there are a lot of formidable surgical 3D printer manufacturers not offering round-the-clock support. Before finalizing your purchase, try to ensure that the brand you are banking with possesses technical support with a viable track record.

5.7 Consider the Service Life of the Machine

Every 3D surgical printer comes with designated service life. Most manufacturers state how long a machine for 3D Printing in surgery would last base on the equipment and products that went into the design and development phase. To authenticate this claim, most surgical 3D printer suppliers attribute a warrantee to their machine based on the service life.

Most 3D printing machines for surgery come with a one-year warranty. While this is the normal service life most manufacturers offer for a surgical 3D printer, it shouldn’t come as a surprise if surgical printers with six months warranty are thrown your way. In most cases, such printers are relatively cheaper and come with limited benefits and features.

It’s best you ask your supplier’s support representative about the warrantee policy backing up the machine you are about to purchase. Try as much as possible to weigh in on the same scale as your production line and the price tag attached. If the service life of the surgical 3D printer doesn’t seem to be the one that can yield profitable returns within the estimated time, it’s best you abort the purchase.

5.8 Consider the Maintenance Cost of the Machine

One thing you should not forget is that surgical 3D printers for either commercial or industrial use are machines. And like every other machine, they need maintenance from time to time. The maintenance cost of a 3D printer used in surgery is not huge. However, most times, the cost is determined by how you use the machine.

Experts making use of 3D printers in surgery can take hours to create models; within this time, it’s common to find loose mechanical parts and accessories that have degraded from a month of constant use. If not upgraded, the final quality of your 3D printed surgical models will consequently reduce. Therefore, 3D surgical printer maintenance is necessary, and it might come with added costs where some parts like the nozzle may need to be replaced entirely. You must incur a reasonable maintenance cost of your surgical 3D printer to consistently get clean and fine detailed prints.

Surgical 3D printer manufacturers have defied the odds and manufactured machines that are highly versatile, cost-effective, easy to use and maintain while still giving you high detail prints. If you are interested in finding out which surgical 3D printer is best suited for your needs, consider all the factors listed above to get the best 3D printed surgical models.

FAQ Guide

How is 3D Printing Used in Surgery?

3D printer a specialized but fairly affordable device that produces three-dimensional models of an individual’s skull or body part. The 3D models enable a surgeon to visualize, practice, and then perform the reconstructive surgery while saving time and increasing precision.

Facial reconstructive surgery involves intricate anatomy within an extremely narrow operative field. Being able to print out a high-resolution 3D model of the injury allows surgeons to do detailed preoperative planning and preparation that is more efficient and accurate. Surgeons can also use these patient-specific models in the operating room to improve the accuracy of implant placement. 3D Printing in surgery is leaving room for the specialist to create transplantable human organs, bio prints, dental parts, and lots more.

What is 3D Printing in the Medical Field?

Three-dimensional (3D) printing in medical applications refers to a number of manufacturing technologies that generate a physical model from digital information. Medical 3D Printing was once an ambitious pipe dream. However, time and investment made it real. Nowadays, 3D printed surgical models represent a big opportunity to help pharmaceutical and medical companies to create more specific drugs, enabling rapid production of medical implants and changing the way that doctors and surgeons plan procedures.

Patient-specific 3D-printed anatomical models are becoming increasingly useful tools in today’s practice of precision medicine and for personalized treatments. In the future, 3D-printed implantable organs will probably be available, reducing the waiting lists and increasing the number of lives saved.

Do Surgeons Use 3D Printers?

Yes, surgeons make use of 3D printers, and the process and procedures involved are gradually becoming rampant. Some Yale Medicine surgeons now routinely use 3D Printing (essentially producing a solid, three-dimensional object from a virtual digital model) to plan surgeries, design tools specific to an upcoming surgery and that particular patient’s anatomy, and even to print some of the parts used to replace defective ones in the body.

There is more to come. Researchers are exploring ways to use 3D Printing to make patient-specific transplant organs and eyes capable of translating light into electrical signals. And while practical use of these things is still years away, researchers recently printed the world’s first 3D vascularized, engineered heart, using a patient’s own cells and biological materials.

What Can Medical Equipment be 3D Printed?

The flexibility of 3D Printing allows designers to make changes easily without the need to set up additional equipment or tools. It also enables manufacturers to create devices matched to a patient’s anatomy (patient-specific devices) or devices with very complex internal structures. These capabilities have sparked huge interest in 3D Printing of surgical models and other products, including food, household items, and automotive parts.

Medical devices that can be 3D printed include orthopedic and cranial implants, surgical instruments, dental restorations such as crowns, and external prosthetics.

How Does 3D Printing Affect the Medical Industry?

Making prosthetics the traditional way is very expensive because they have to be personalized to the individual. 3D Printing in surgery gives users the freedom to choose, e.g., different designs, forms, sizes, and colors of their prostheses. This makes every 3D printed piece personalized. 3D Printing of surgical models also allows prosthetics to be more widely available at a lower price.

3D Printing allows to 3D print medical and lab equipment. It is possible to 3D print plastic parts of the equipment. This drastically reduces costs and time spent waiting to receive a new medical device from external suppliers. Furthermore, the manufacturing process and further applications are also easier. This makes the equipment more readily available and allows low-income or hard to access areas to get 3D-printed medical equipment more easily.

What are the Uses of 3D Printers in Surgery?

The use of 3D Printing is gaining considerable success in many medical fields, including surgery. Here, the technology was introduced for increasing the level of anatomical understanding thanks to the inherent characteristics of 3D printed surgical models: these are highly accurate and customized reproductions, being obtained from own radiological imaging of patients, and are solid graspable objects allowing for free manipulation on the part of the user.

The resulting tactile feedbacks significantly help the comprehension of anatomical details, especially the spatial relations between structures. In this regard, they proved to be more effective than conventional 2D imaging and 3D virtual models. To date, an increasing number of applications have been successfully tested in many surgical disciplines, extending the range of possible uses to preoperative planning, counseling with patients, education of students and residents, surgical training, intraoperative navigation, and others.

In recent years, 3D Printing in surgery was also employed for creating surgical tools and reproducing anatomical parts to be used, respectively, as templates or guides for specific tasks of the surgery and individualized implantable materials in reconstructive procedures.

How Can 3D Printing Help Humans?

To highlight some of the positive impacts that 3D printing in surgery is having on humans, here is a list of some of the top ways that the technology is making a difference for the environment, health, culture, and more.

Disaster Relief

In recent years, the benefits of using 3D printed surgical models for various disaster relief efforts have become increasingly apparent. Perhaps the most compelling use of 3D Printing for disaster relief was by Field Ready, a tech-oriented NGO, which relied on 3D Printing to make water pipe fittings and washers on the fly after the severe earthquake in Nepal in April 2015. In other words, 3D Printing’s suitability for producing spare parts has the potential to help communities in disaster areas to rebuild infrastructure more quickly.

Affordable Housing

3D printed housing has been touted as a possible solution for low-income housing. Earlier this year, ICON and New Story made headlines for their $4,000 3D printed house. The 3D printing technology used for the build is reportedly capable of constructing a single-story, 600-800 square foot home in under 24 hours and is ultimately intended for producing housing in developing areas.

Affordable, Stylish, and Children Prosthetic

Almost as soon as affordable 3D printing technologies became available, literally dozens of projects have focused on using them to produce prosthetics at accessible costs to people in developing countries or to children. The enable association and community were among the very first of these, but so many other ones followed. Projects like Open Bionics and companies like 3D Life Prints took it to the next level in terms of complexity and reach.

Saving the Coral Reef

In some of the most diverse ecosystems on the planet, coral reefs are also some of the most fragile. In recent years especially, the underwater ecosystems have suffered tremendously from rising water temperatures and are not expected to survive for much longer. The grim reality of coral reefs is uplifted somewhat by a number of recent efforts to use 3D Printing to reinvigorate coral growth and sustain the many aquatic species that live in the reefs.

Can 3D Printing Save Lives?

Yes, 3D printing in surgery is saving lives. Additive manufacturing is saving lives and can help with bone reconstruction. This technology helps to make custom products that can be tailored for each patient, outside and inside their bodies. For example, additive manufacturing is offering new possibilities for jaw reconstruction!

3D printed surgical models are becoming quite helpful in many aspects. For example, we can see that more and more from the customers of our online 3D printing service, to create custom made medical tools, fully adapted to their job and to their specific needs. Indeed, using 3D Printing is particularly helpful when it comes to tools; it makes it possible to make one or several tools.

Is 3D Printing Used in Healthcare?

Yes, 3D printing is used in healthcare. 3D Printing in healthcare makes it possible for medical professionals to provide patients with a new form of treatment in a number of ways. 3D Printing is used for the development of new surgical cutting and drill guides, prosthetics as well as the creation of patient-specific replicas of bones, organs, and blood vessels.

Recent advances in 3D Printing in surgery have led to lighter, stronger and safer products, reduced lead times, and lower costs. Custom parts can be tailored to each individual. This improves the understanding of patients by medical professionals and improves patient comfort level by allowing interaction with products that are designed especially for their anatomy.

What are the Benefits of 3D Printing in Medicine?

The application of 3D Printing in medicine can provide many benefits, including the customization and personalization of medical products, drugs, and equipment; cost-effectiveness; increased productivity; the democratization of design and manufacturing; and enhanced collaboration.

However, it should be cautioned that despite recent significant and exciting medical advances involving 3D Printing in surgery, notable scientific and regulatory challenges remain, and the most transformative applications for this technology will need time to evolve.

When Was 3D Printing First Used in Medicine?

3D Printing was first used for medical purposes as dental implants and custom prosthetics in the 1990s. Eventually, in 2008, scientists were able to produce the first 3D prosthetic leg. In 2012, the 3D Printed a Jaw.

How Can I Improve My Prints?

Eight Tips for Improving 3D Print Quality

- Adjust the bed and set the nozzle height.

- Check the nozzle’s temperature.

- Use different building plates to create different effects.

- Pay close attention to your printer’s adjustment and maintenance.

- Handle the filament carefully.

- Use a slicer.

- Lower the printing speed.

- Don’t forget to post-process.

What is the Most Common Thing That’s Usually 3D Printed?

Out of all the raw materials for 3D Printing in use today, plastic is the most common. Plastic is one of the most diverse materials for 3D-printed toys and household fixtures. Products made with this technique include desk utensils, vases, and action figures. Available in transparent form as well as bright colors — of which red and lime green are particularly popular — plastic filaments are sold on spools and can have either a matte or shiny texture.

Where is 3D Printing Used in Medicine?

3D Printing has many functions in a variety of industries; however, in the medical field, it has four main applications. 3D Printing could be used to replace human organ transplants, speed up surgical procedures, produce cheaper versions of required surgical tools, and improve the lives of those reliant on prosthetic limbs.

How Many Hospitals Use 3D Printing?

At this moment, there is no detailed data on the number of hospitals making use of 3D printers. However, you might want to bear in mind that the number of U.S. hospitals with a centralized 3D printing facility has grown rapidly in the past decade, from just three in 2010 to more than 100 by 2019. As the technology evolves, this point-of-care model may become even more widespread. 3D Printing also has potential applications in other product areas.

What is a 3D Printed Device?

3D printing or additive manufacturing is the process of making three-dimensional solid objects from a digital file. A 3D printer is a device used in 3D Printing. some of the most popular 3D printers include LCD, FDM, and SLA. 3D Printing is the opposite of subtractive manufacturing which is cutting out / hollowing out a piece of metal or plastic with, for instance, a milling machine.

Why is 3D Printing Important?

3D Printing is important because it facilitates a seamless work environment for experts in multiple industries. With 3D Printing, fewer parts need outsourcing for manufacturing. The main advantages of 3D Printing are realized in its Speed, Flexibility, and Cost benefits.

Conclusion

With all the information provided above, we have no doubt that you are, at this point, well equipped to make the right 3D printing machine buying decision for your medical or healthcare facility.

However, to cross the Ts and dot the Is, it’s important we make mention of the many 3D printers for surgery available in our catalog. Dreambot3D provides a one-stop solution for surgery guide 3D printers. Ranging from small 3D printing equipment for surgeons to use in carrying out a specific test to industrial weight 3D machines for creating surgical models, we provide them all.

To get detailed information on the type of 3D printer that would be suitable for your medical line, the basic features, price, and benefits, we recommend you put a call through to our support representative today—they are ever ready to guide you through the buying process.