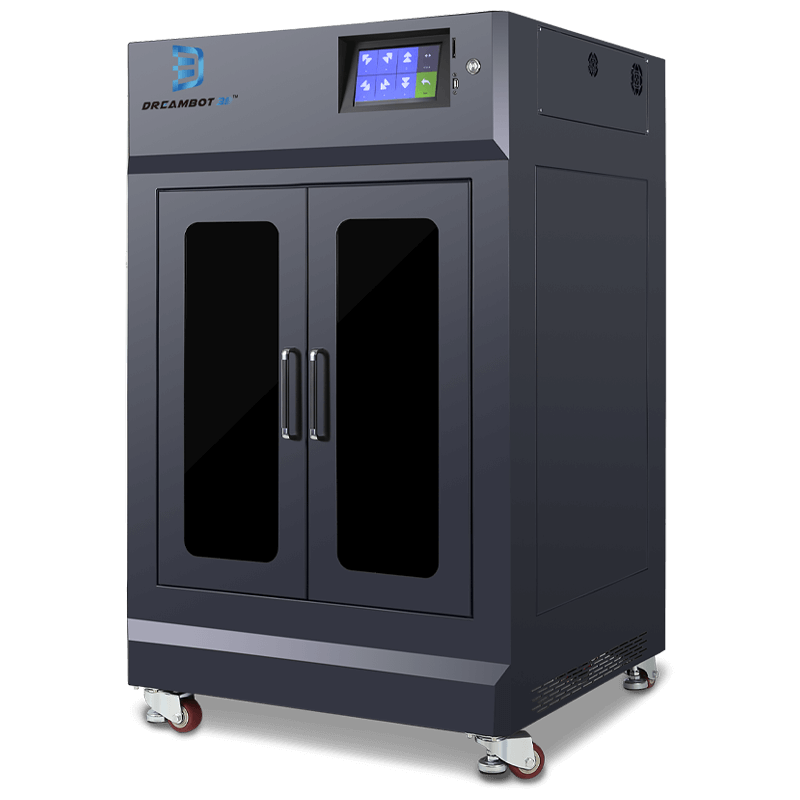

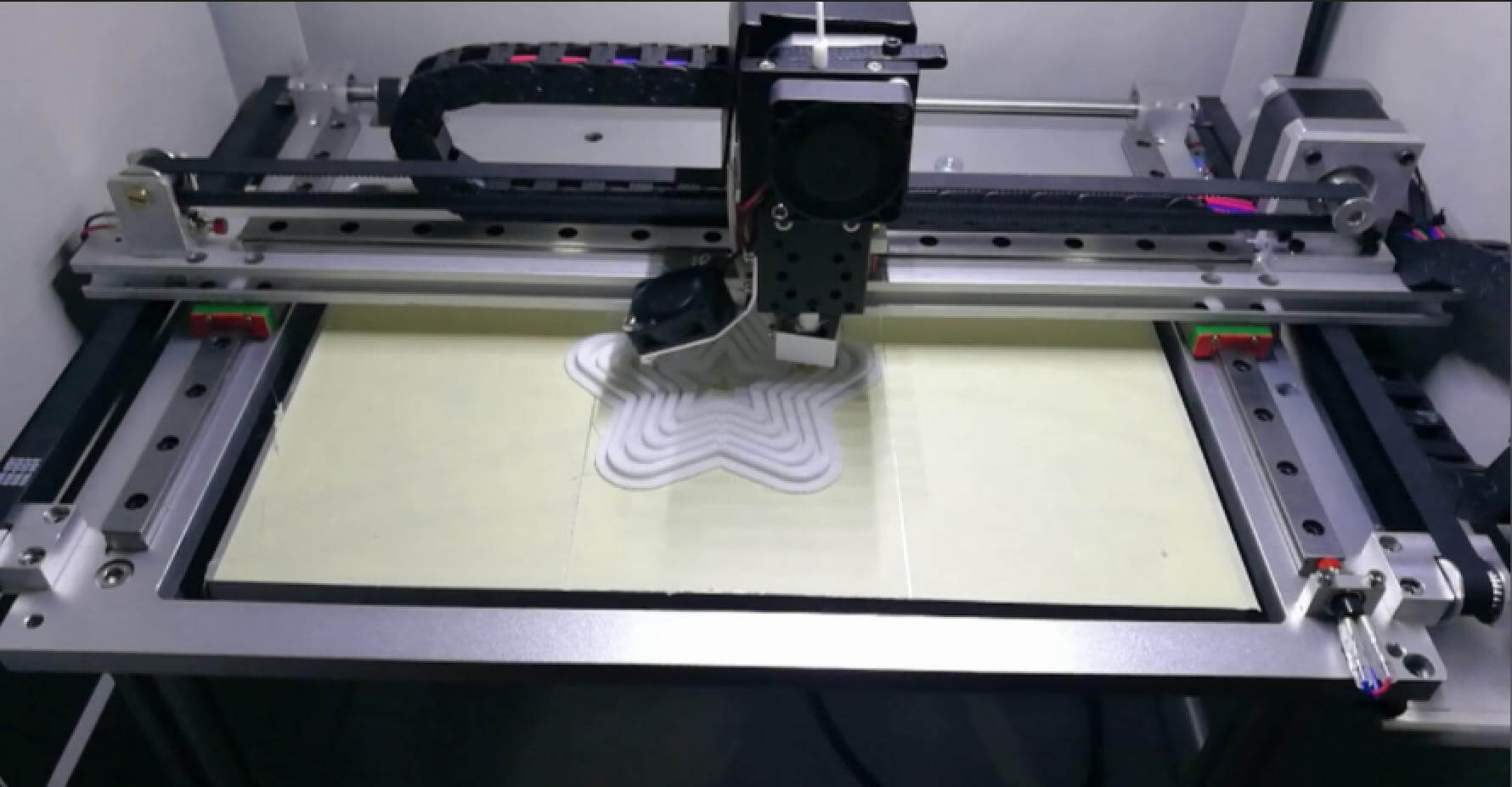

400x400x400mm 3D printer

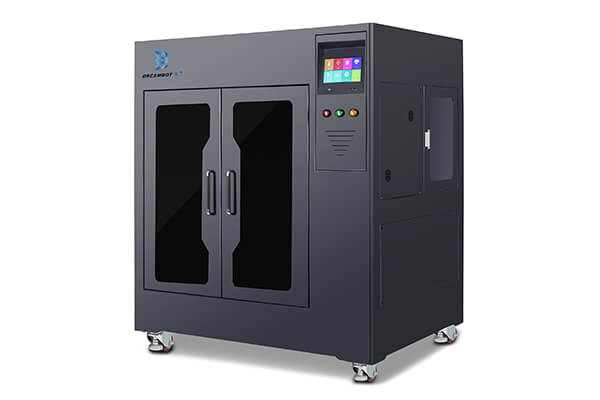

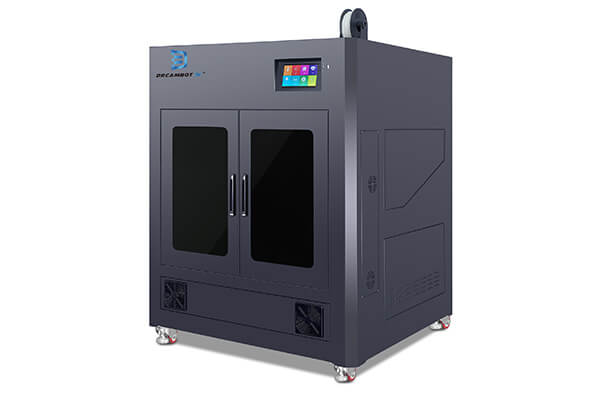

L-400 FDM 3D Printer

- Using FDM process principle, it can support industrial-grade printing size up to 400x400x400mm. Its high precision can reach 0.05mm

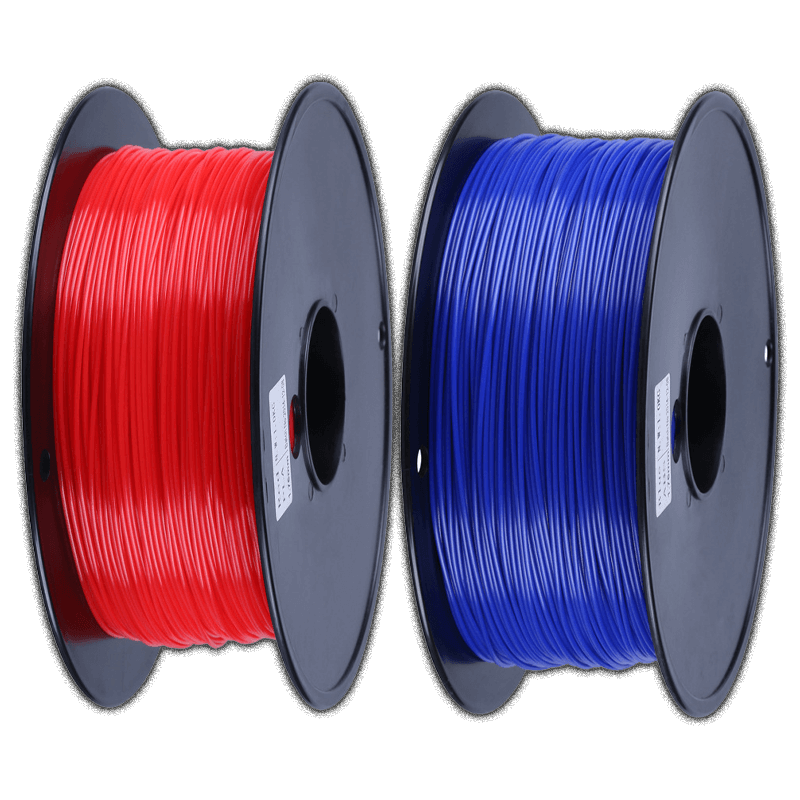

- Industrial-grade FDM 3D printers are used in a variety of materials: PLA, ABS, PC, Nylon, Carbon Fiber, etc.

- Adopts PLC intelligent control and can print offline. Can continue printing after power failure

Dreambot3D 400x400x400mm 3D printer

The Dreambot3D L-400 400x400x400mm 3D printer is used to create 3D physical objects from a digital model. The process of printing with a 3D printer makes it easier for designers to create complex designs knowing fully well that the printer is able to print precisely and accurately.

You can print multiple prototypes in a matter of hours rather than days or weeks, thereby allowing you to move through design cycles faster and more efficiently.

Our L-400 400x400x400mm FDM 3D printer has allowed industries such as dental, medical, manufacturing, consumer goods, etc, to easily create lighter and most effective component parts at a faster rate.

| Technical parameters | Model | L5-400 | L8-400 |

| Photo | / | / | |

| Max printing volume | 400x400x500MM | 400x400x500MM | |

| Printing platform | The platform moves down when printing | Fixed at the bottom | |

| Technical principle | FDM fuse manufacturing technology | ||

| Print head | High-precision extrusion system (double nozzles can be customized) | ||

| Nozzle diameter | 0.2, 0.3, 0.4, 0.6, 0.8MM | ||

| Consumable diameter | 1.75MM | ||

| Printing materials | PLA, TPU, 95A, water-soluble materials, wooden PLA; customizable ABS, PC, PETG, nylon, carbon fiber, metal filling materials, glass fiber addition materials, etc. (not available for 300 size machines) | ||

| Positioning accuracy | X axis 0.0011, Y axis 0.0011, Z axis 0.00125MM | ||

| Printing layer thickness | 0.05-0.3MM | ||

| Printing speed | 20-150MM | ||

| Printing platform | Heating aluminum substrate + black crystal glass platform | ||

| Platform temperature | 30-50℃ (30-120℃ optional) | ||

| Platform calibration | Automatic pre-calibration leveling | ||

| Nozzle temperature | 75-280℃ | ||

| Movement noise | 50 dB | ||

| Connection method | U disk, SD card (both as a gift) | ||

| Screen control | 7 inch full color touch screen (support all languages) | ||

| Chassis structure | 3MM thick sheet metal, fully sealed chassis | ||

| Filter function | 2 air filter devices | ||

| Lighting | LED lighting | ||

| Mechanical transmission | Double linkage gantry type machine tool linear navigation | ||

| Physical parameters | Dimension | 70.5×64.5x100CM | 70x72x137CM |

| Package Size | 75x70x115CM | 95x77x152CM | |

| Net weight | 73KG | 98KG | |

| Gross weight | 100KG | 130KG | |

- L-400 400x400x400mm 3D printer allows you to print even without a computer. Your digital object saved on the U disk or SD card is automatically saved. Hence, you don;t have to worry about losing your designs.

- The material alarm system present in the dimension 3D printer makes it possible to know when the printing material is used up. Printing then continues from where the material stopped. This guarantees no blank spaces when each layer is being printed, which helps to prevent wastage of resources.

- The dimension 3D printer has a glass door that helps control airflow within the printer itself. The feature is important such that the material is not cooled before forming into layers.

- The anodized aluminium template in the L-400 400x400x400mm 3D printer allows remarkable printing for all materials, especially engineering materials.

- The stable frame design of this 3D printer makes the printing operation and performance accurate. No form of interruption for constant adjustment takes place.

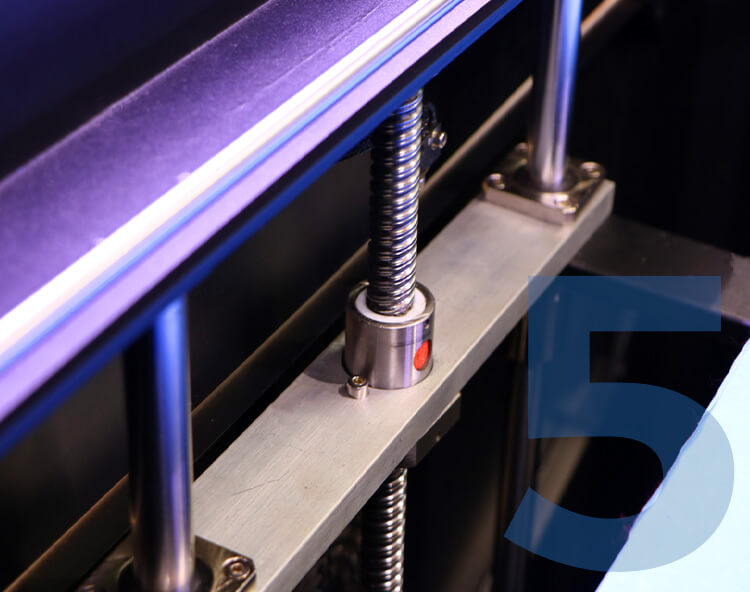

- The precision ball screw known as the Taiwan ball screw makes the positioning accurate and more stable during the process of printing when compared to a T-shaped screw. This gives a detailed and accurate design printing experience.

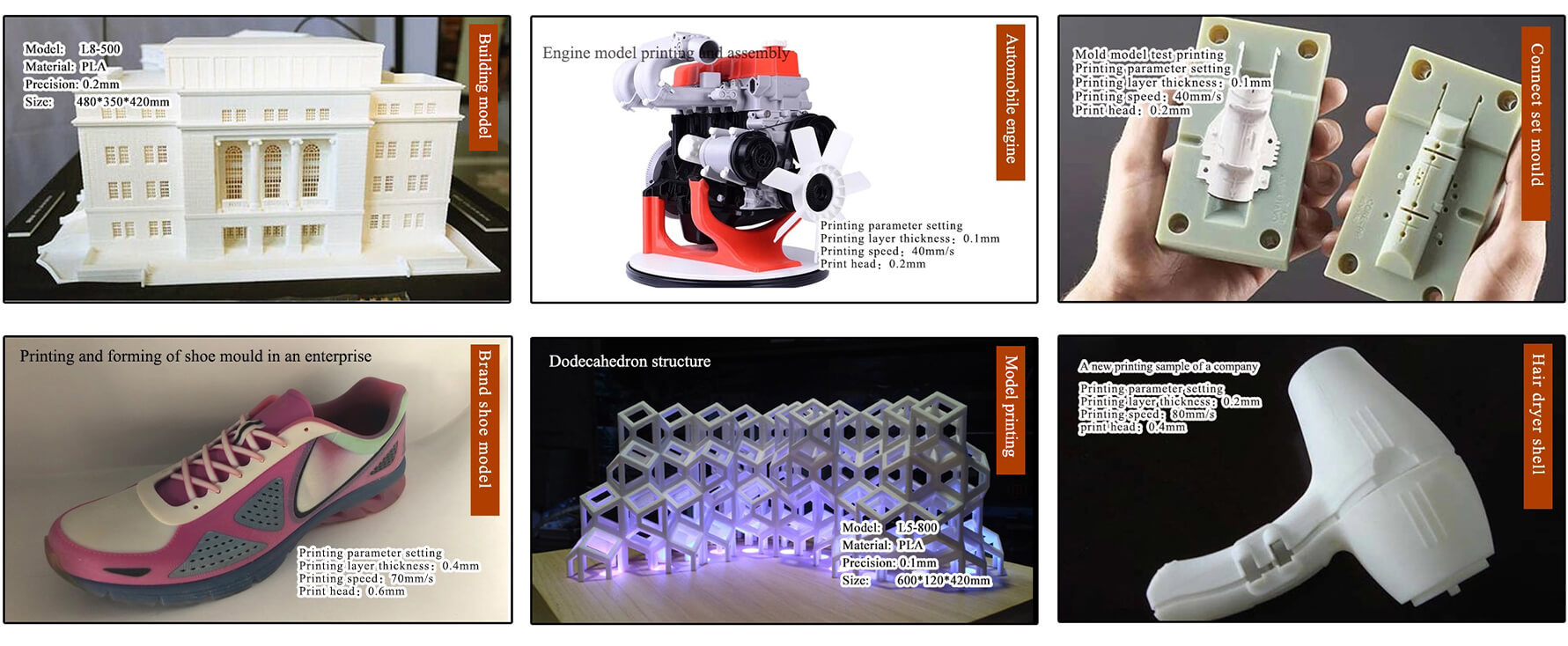

Test your part

We provide sample testing service, allowing you to check the working quality of our 3D printer before placing an order

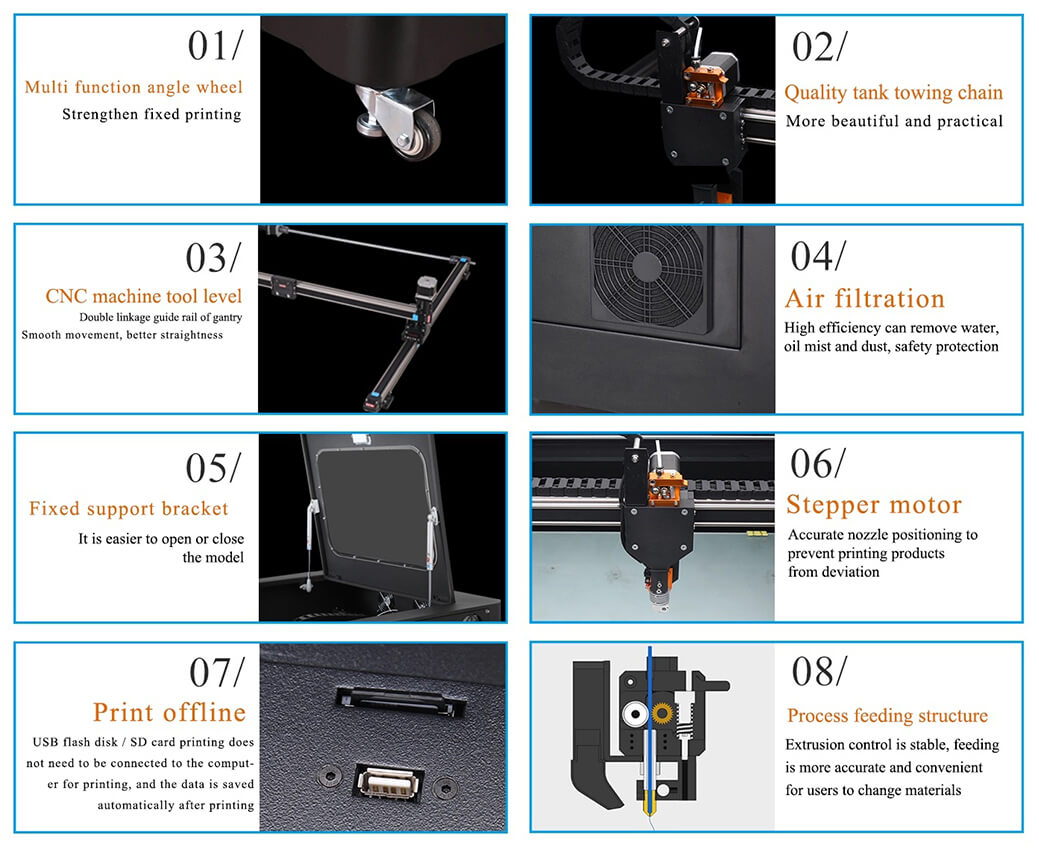

6 points why choose us

Automatic resume printing

Full enclose stable frame

The whole machine case is thickened by CNC cutting, with accurate hole position, better assembly stability, and higher positioning accuracy of printer operation.

Allow offline printing

Use U disk or SD card to print without connecting to a computer to print. After starting to print, the data is automatically saved and the U disk or SD card can be removed.

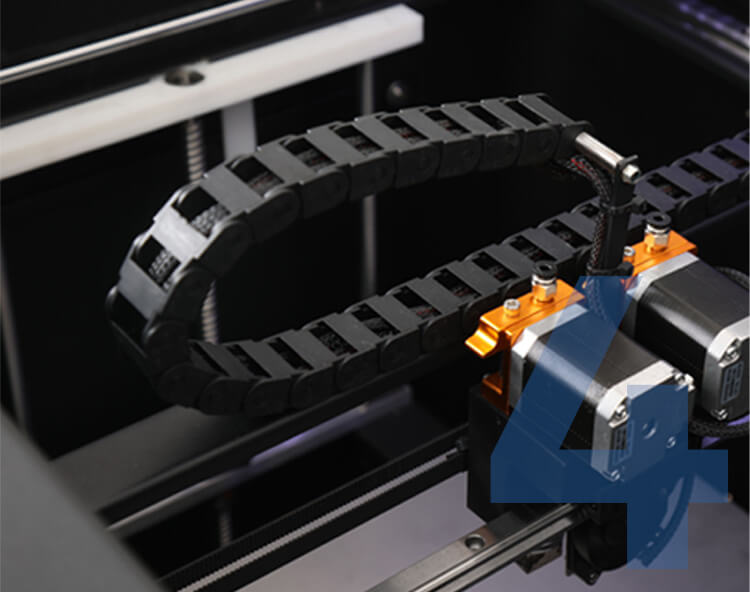

Drag chain wiring design

The wire is installed in the inner casing of the drag chain to effectively ensure that the wire will not be damaged for a long time when the printer moves at high speed.

Precision ball screw

Using the latest Taiwan ball screw, it has higher straightness, lower friction coefficient, better smoothness, higher positioning accuracy and more stability during printing.

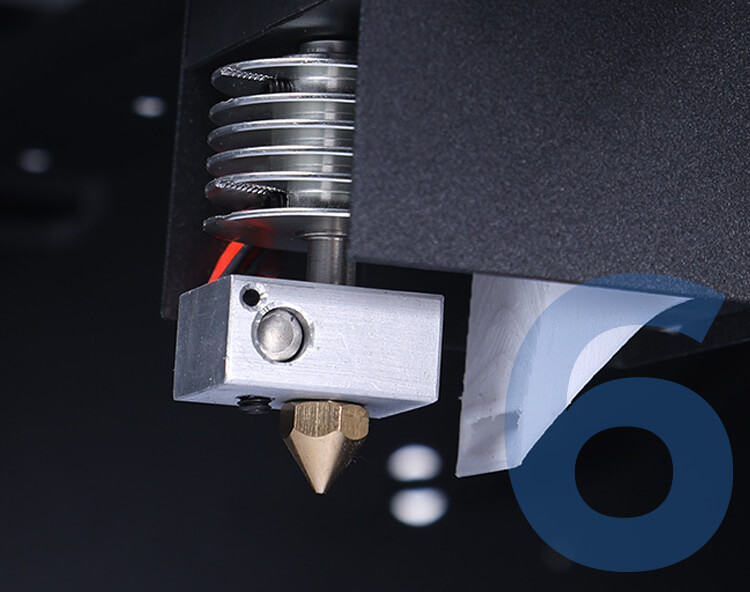

Alloy nozzle

Independently developed a unique bullet nozzle with uniform heating and a patented head assembly, so that it can work smoothly without interruption.

More FDM 3D printers

L-500 FDM 3D Printer

The L-500 3D printer is able to print up to 500x500x500mm sizes. It is suitable for various categories of commercial printing.

L-600 FDM 3D Printer

The object forming size of the L-600 model is 600x600x600mm. This model is suitable for printing core components in automotive and aerospace companies.

L-800 FDM 3D Printer

The L-800 3D printer is usually an option of choice for design and printing of objects within the 800x800x800mm size range. It is also widely used for large industries.

Industrial FDM 3D Printer Buying Guide

FDM 3D Printer Introduction

3D Printing has brought a lot of delight to the research and industrial field, also for recreation. This technology has made it easy and less time-consuming to develop prototypes and exact copies of objects and images. If you are familiar with the world of 3D Printing, you must have known the popularity and efficiency of FDM 3D printers.

For the benefit of the doubt, let us briefly explain the FDM technology if you are new to the world of 3D Printing. FDM 3D printers aid the manufacturing of 3-dimensional objects through a computer-aided manufacturing process. Fused Deposition Modelling (FDM) uses additive manufacturing 3D printing technology, which relies on material extrusion.

FDM uses a simple set-up, which includes a building platform, heated nozzle, and coiled thermoplastic filaments for building objects layer by layer. Each layer you print is placed on top of another layer, which goes on until you finish printing your object. FDM 3D printing is fun, and there are available for domestic usage to industrial 3D Printing. You can find 3D printers from as low as 200x200x200 to 400x400x400mm 3d printer to 1000x1000x1000 3d printers used for weighty industrial purposes.

We understand that there are a lot of 3d printers out there and a lot of advertising, and it can be pretty confusing for you to make the right decision when picking the right 3d printer that you need. This guide will help break down the 3d printing language and provide all the essential information you need to know about industrial FDM 3d printing.

1.1, Principle Of FDM 3d Printer

FDM 3d printers have a unique mechanical process that makes them different from other 3d printers like SLA. FDM 3d printers are widely used because of their effortless set-up. The FDM simple components are made up of different parts like the heated nozzle, the build platform, and the coiled thermoplastic filaments. These three components are necessary; let us take a look at how each works.

Before you begin printing, you need to upload the digital design you want on your 3D printer, pick options, and create slices or layers. After this, your 3d printer creates an extrusion path which the print head or nozzle follows. Finally, the filament is let loosed and fed through your heated nozzle after the software has determined the path.

The nozzle melts the filament into a semi-liquid and lets it out onto the building board. The melted filament is placed layer by layer until you get your required result. The melted filament becomes solid immediately after leaving the printer head and bonds with the layer beneath it.

1.2, What Materials Can Be Printed By FDM 3d Printer

The material for your 3d printer depends on the object you are printing and the type of FDM machine you are using. Thermoplastics are the most common materials used for industrial 3D Printing. This is because they are malleable and can be melted by the printer head. Also, since FDM 3d printing machines use a layer-by-layer printing system, the thermoplastic filaments make it easy for each layer to stick to the layer beneath it.

These thermoplastics include Nylon, Carbon fiber, PLA, ABS, PC, PETG, PVA, HIPS, TUP, and ULTEM. Each filament material is made up of its unique characteristics, making it better for some applications than others. When choosing the material for your 3D Printing, you must consider strength, flexibility, durability, ease of use, the complexity of print, heat resistance, and complexity. Our 400x400x400mm 3d printer can print all materials because of its anodized aluminum template.

Some of these materials are stronger than others, and your filament requirement will determine which one you pick. If you are printing concept prototypes, you will go with the soft and easier materials since your prototype will not face physical pressure. If you want to print an object for functional testing, on the other hand, you will need a tougher and hard-to-print filament material. Let us briefly look at the different properties, cons, and pros of the printing materials mentioned above.

Nylon: Nylon is also known as Polyamide, and it is a commonly used material in the 3d industry. It is commonly used because of its flexibility, durability, abrasion resistance, chemical stability, low coefficient of friction, and it takes up coloring agents very quickly.

Nylon is the best option when you are printing any object that will experience a lot of mechanical wear and tear. This material is best used for creating tools, functional prototypes, and mechanical parts such as hinges, buckles, and gears. Since your FDM machine carries out layer to layer printing, Nylon’s layer to layer adhesion is impressive and excellent. Although nylon filament requires an extrusion temperature of 250-degree Celsius, some FDM printers allow for lower printing temperatures at 220 degrees Celsius.

Although Nylon comes with many advantages, it also has its perks which you need to be mindful of. Nylon filaments absorb moisture quickly, and this is a blessing because it is easy when applying other coloring agents and dyes. But this hygroscopic nature is also a disadvantage. Absorbing moisture can lead to quality print issues. You will need to store your nylon filaments in airtight packaging to guard against this. The closed-door chassis of our 400x400x400mm 3d printer helps against absorbing moisture while printing.

You need high temperatures when printing with Nylon; this leads to high stringing and warping, affecting your object’s outcome. Also, you will end up using a lot of power to heat your print bed and nozzle. Using nylon filament is very tricky, and it will require you to use many tricks to surmount these difficulties, but the end product is satisfying.

PLA: Polylactic Acid (PLA) is the most widely used material for FDM 3D printing because it is easy to use and cheap. Some of its characteristics include low-temperature Printing, less prone to warping, flexibility, does not emit fumes, heat stability, and sub-par durability. In addition, it is ideal for a lot of applications because it also comes in different shades and styles.

It is easy to use and very ideal for beginners. PLA is a toxic-free material because it is made from lactic acid monomers. It can also be made from renewable sources like potato starch, sugar cane, and corn starch. In addition, it requires low heat printing temperatures, which means that you will not encounter warping and stringing.

PLA filaments absorb moisture quickly, which means that you have to store it in an airtight container. If you use a PLA filament that is not well dried, it will affect the quality of your final print. This material is best used for printing prototypes and display items.

HIPS: High Impact Polystyrene (HIPS) is made from polybutadiene and polystyrene, which gives this filament material its strength and flexibility. This filament can absorb more impact without breaking, and it is not expensive. Some of its qualities are heat stability, good impact strength, flexibility, prints at high temperatures, and prone to warping.

This filament is best used for Printing moving parts with high-impact applications and support structures. It is easy to absorb dyes and colors, and it works with several adhesives. However, HIPS filament is not commonly used in 3D Printing as the primary material.

Instead, it is used as a supporting material, especially when working with ABS. It is used as a supporting material because of how easy it is to dissolve it in limonene, a cheap and easily obtainable solvent. In addition, it is best used for ABS because HIPS prints at nearly the same temperature as ABS. This means that you can print both filaments simultaneously using a multi-extruding printer without changing the temperature setting in the middle of the printing.

HIPS is prone to warping and stringing, it is very soft when hot, and it emits toxic fumes, which means you need to use it in a well-ventilated environment. Another good thing about it is that it has been declared food-safe by the FDA, making it a good material for printing food-related objects.

Carbon Fiber: this is a thin filament material made from bonded carbon in a crystalline formation. This filament material is solid, abrasion-resistant, durable, lightweight, and exceptional rigidity. It most times enhances the strength of polymers used in sporting goods, automotive, and aerospace industries.

It is best suited for scenarios where weight is an essential factor. This filament is resistant to chemical degradation and corrosion, and its volume is not affected when exposed to extreme hot or cold temperatures.

One of the difficulties with using this filament is that the carbon fiber particles do not melt during the nozzle’s extrusion. This can make your nozzle clog frequently. Also, these carbon fiber particles work as abrasives that can wear down your nozzle. Therefore, it is advisable to use hardened steel for your nozzle when working with this material. The 400x400x400mm 3d printer on our catalog is a perfect 3d printer for this material because of the high heat temperature of the nozzle.

ABS: Acetonitrile Butadiene Styrene (ABS) is a polymer made from three monomers; butadiene, acrylonitrile, and styrene. These three monomers give it the qualities of durability, chemical stability, high-temperature printing, rigidity, soluble in acetone, and it emits fumes during Printing. You can use this material for outdoor items and functional parts like brackets and hinges.

It requires a high temperature for Printing of about 220 – 250 degrees Celsius, and our 400x400x400mm 3d printer is compatible with this filament. Although it gives its objects high durability and strength, it makes printing complicated. Its rapid cooling creates a high tendency for the object to warp. This means that you need to use a heated printing bed to control the temperature of your building platform.

You need a well-ventilated area when using this material because of the toxic fumes that it produces. Also, because of the complexity of using this material, many things might go wrong when printing, especially if you are new to the 3D printing world. You will need to understand the fundamental of 3D Printing for you to perfect the art of Printing with ABS.

PC: Polycarbonate or PC, as commonly called, is the strongest material used for 3D Printing. It has superior strength, good optical properties, high impact resistance, heat-stable, and high tensile strength. It is best used for safety equipment, electronic display screens, and construction equipment.

This filament transmits visible light in a far more superior way than other filaments. This material also exhibits some amount of flexibility that is not found in PLA and ABS filaments. You can use this for creating some other objects like bulletproof glass and riot gear. This filament is tricky to work with because of its printing temperature.

Printing with this filament requires a temperature that is higher than that needed to print ABS and Nylon. This requires you to print your PC filament on a heated bed with a slightly higher setting. This filament is not recommended for beginners because it is challenging to work with.

PETG: Glycol-modified Polyethylene Terephthalate (PETG) is one of the commonly used plastics in the world. It is a variation of polyethylene terephthalate, and it is highly valued in the 3D printing industry for its mechanical strength. Its qualities include; high-impact resistance, high strength, heat-stable, clear, chemically stable, and prone to damage by UV.

It is used to produce mechanical parts, protective components, and objects that come in contact with food. Its laminating and printable characteristics make it an excellent material for store fixtures, electronic devices, credit cards, and signages. In addition, it is a perfect material for medical containers because of its heat stability which can withstand steam sterilization.

This material is challenging to work with, it degrades quickly when constantly exposed to sunlight, and it is not a good material to use for support structures.

TUP: Thermoplastic Polyurethane (TPU) possesses a desirable combination of rigidity and elasticity. This material is very flexible, abrasion-resistant, impact-resistant, stable against solvents and oils, it cannot be polished or sanded, and it is prone to deformation in the extruder. This material is used to produce inflatable rafts, footwear, mobile device cases, and sporting goods.

Although it is recommended, TPU does not require a heated bed when printing. This material exhibits minimal shrinkage and warping, and it does not produce fumes while printing. However, you will need to store this material in an airtight atmosphere because it is hygroscopic and quickly absorbs moisture.

1.3, How Does FDM 3D Printer Develop From Desktop To Industrial Level

Most desktop 3D printers use the Fused Deposition Model, and they are similar to their industrial-level printers. They all use the extrusion technique, printing objects layer by layer, but their capabilities differ. FDM 3D desktop printers are cheap and easy to use by almost everyone for little prototypes. FDM 3D industrial printers, on the other hand, are huge 3d printers used for industries like R&D for the production of bigger and stronger prototypes.

Although 3d desktop printers can produce low-quality prototypes like the design for architecture classes, they are not suitable to handle high-grade materials, large format 3d Printing, and high precision requirements. To produce precise and quality parts for industries like aeronautics and automotive industries, you need industrial 3d printers, ranging from 400x400x400mm 3d printers to 1000x1000x1000mm 3d printers.

3D desktop printers use materials such as PLA and ABS because the printer head can comfortably extrude these materials at temperatures of about 220 to 280 degrees Celsius. However, if you are dealing with tougher materials like carbon, PC, and Nylon, it is advisable to use an Industrial 3d printer to handle the high extruding temperatures.

Also, a large industrial 3d printer has a greater production capability when compared to 3d desktop printers. This is because the industrial-grade 3d printer helps you complete your task faster, and they have a larger printing area which means the production of larger parts.

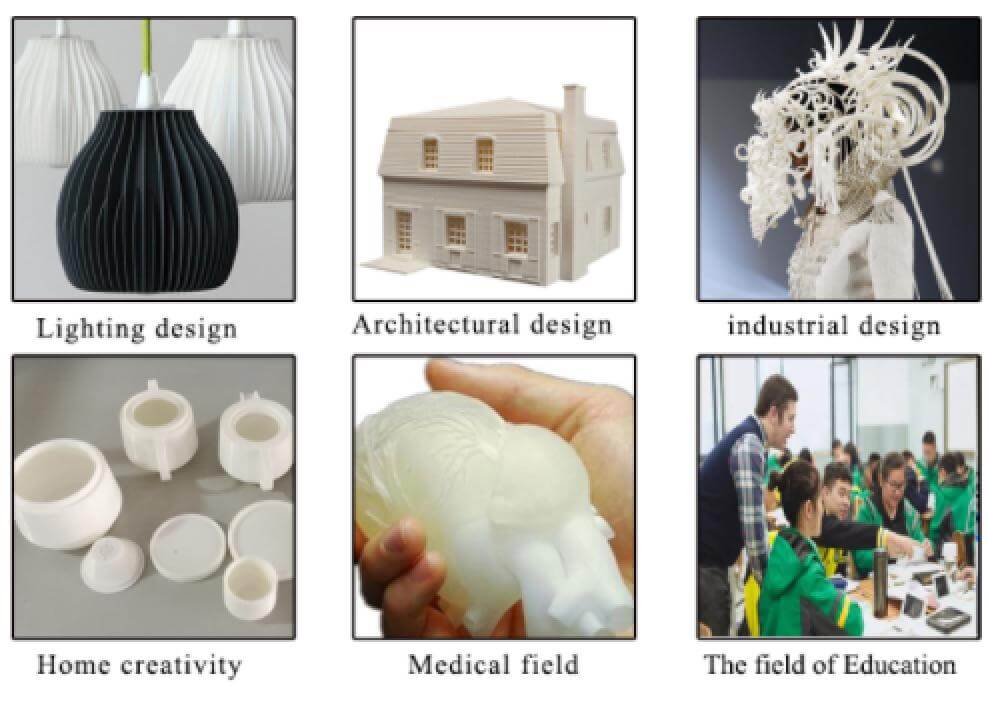

Application Field Of FDM 3d Printer

FDM 3D printers are built to tackle different needs such as prototyping, design, and creating complex geometries. Before buying an Industrial 3d printer, it is essential first of all to know where and how it will be used; this will guide you in your decision.

Although all FDM printers work with the same principle, they differ when used in different industrial applications. However, FDM 3d printing is a fast and cost-effective remedy in all fields it is used in. Therefore, the application of these FDM 3d printing is increasing in different industries. The following are the different fields where FDM 3D printing technology is being utilized.

2.1, For Industrial R&D

FDM 3D printing technology has earned its respect for not only being used to produce gifts and toy prototypes or used just for a hobby. This technology has established itself as a strong force in producing strong, durable, functional products employed in end-use applications.

Research and development are essential aspects of any field, be it medicine, automotive, or aerospace. However, before any final product is produced, many prototypes are produced to understand and demystify the whole idea and concept. Hence prototypes help to move innovative products from ideas to marketable merchandise. Industrial 3D printing machines have helped lower the cost of making prototypes and speed up early-stage prototypes.

This FDM 3d printed prototypes can help you de-risk the possibilities of designs before a company commits considerable resources to these products. In addition, FDM 3D printers are fast, and they produce complex models that will be expensive or impossible when you are using the traditional subtractive methods.

If you want to speed up your research and development process and reduce the cost and expenses of your early-stage prototyping, you can look at our 400x400x400mm 3d printer and industrial 3D printer cost on our website.

2.2, For Molds Making

Injection molding is an essential aspect of the manufacturing world of plastic products. Although the injection molding method was the most used before the emergence of FDM 3d printing, this method is time-consuming and expensive, especially when dealing with complex molding features.

The emergence of 3D Printing has made the process of mold making less expensive and time-consuming. Here are some of the benefits of using FDM 3D printing for your mold making.

Not Limited By Mold Size: when using the traditional mold-making process, it is difficult to make changes once you have arrived at the final version. But with FDM 3d printers, you can make changes immediately you notice defects with the first batch of your printed mold.

All you need to do is make changes to your CAD, and your next mold will come out just the way you need it. You do not have to wait for weeks and months for adjustments or pay more money for changes to be done. You will get what you need without extra expenses that you did not budget for.

Manufacturing Cost Reduction: 3d Printing offers you the opportunity of manufacturing accurate molds, thereby reducing your expenses with regards to mistakes. Also, this method is cost-effective regarding materials, unlike the traditional means of production that produce a lot of scrap materials. Therefore, if you are using expensive materials, they will be utilized without waste.

3d Printing offers you a lot of flexibility regarding designs that have to change after production has begun. Therefore, you can easily change and adapt to the new designs without wasting time and resources.

Shorten Mold Production Cycle: if you are working with time and deadline, you need a machine that helps you deliver within the deadline. 3d Printing reduces the set-up time for mold making and quickly updates the existing design tools. The 400x400x400mm 3d printer is an example of a printer that prints faster, hence helping you reach your deadline.

This means that your business can frequently update and improve its mold design and outcome. This brings about more innovation at a faster rate, keeping in touch with the needs of the market and industry.

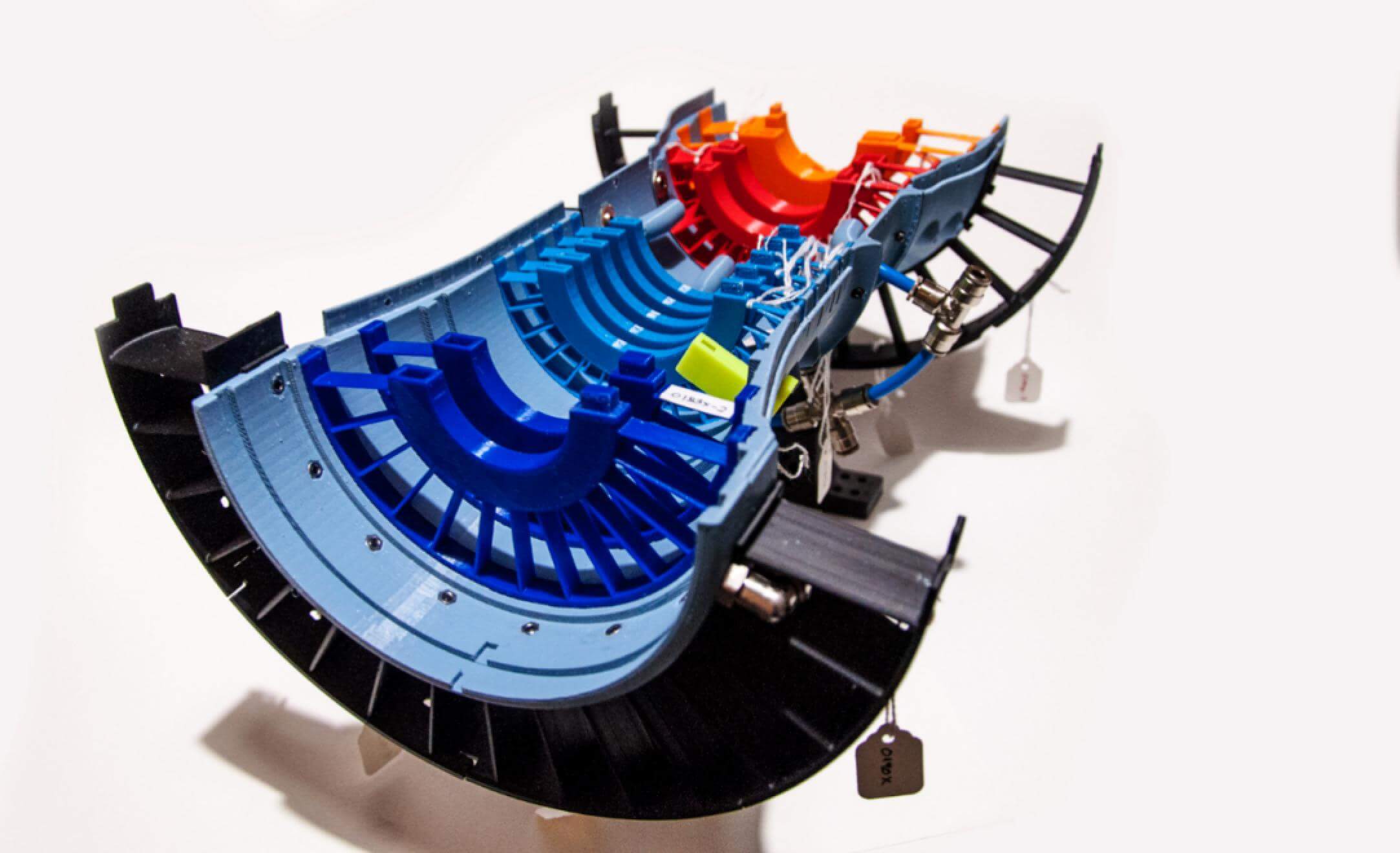

2.3, For Aerospace Printing

FDM 3D printing is a blessing to the aerospace industry because of its ability to manufacture intricate parts that are more lightweight and resilient than traditional techniques. 3d Printing helps to reduce the cost of buying metal parts for the production of titanium aircraft.

With the traditional method of producing aircraft, you might have to buy metal raw materials of between 12 to 25kg raw materials to produce a part of just 1kg. this means that a lot of the expensive raw material bought is wasted. With 3d Printing, you only use the necessary materials, thereby significantly reducing the waste of raw materials.

Making use of 3D-printed parts can reduce the operational costs of airlines. The production of lighter airplane parts has been made possible using 3d printing technology, and these parts are durable and strong. Reducing the overall weight of the plane leads to less fuel consumption, reducing the expenses of airline companies.

Large industrial 3D printers have made it possible to manufacture parts quickly; this means that airplane parts can be produced at the point of need. This solution takes away the difficulty of predicting the demand for spare parts. Printing parts at the point of need also eliminates the problem of having a physical inventory of parts.

With the variety and reliability of 3d printed materials, aircraft structural and complex engine components can be manufactured with ease. This means that these products are not only used for prototypes and design display; they are manufactured for end-use. These commercial 3d printing machines are driving innovation in the manufacturing and design of aircraft components. You can check our website for any industrial 3d printer cost, such as our Dreambot3D3D 400x400x400mm 3D printer.

2.4, For Car Parts Printing

The automotive industry is one industry that has greatly benefited from the 3d printing industry. With the help of a professional FDM printer, many car parts have been designed, manufactured, re-designed according to various needs and requirements. This has helped in creating aesthetically appealing final car products.

The ability to print car parts on demand could save the automotive industry a reduction in production and storage costs. Furthermore, manufacturing complex internal structures can now be easily produced with industrial FDM 3D printers like 400x400x4000mm 3d printer. This is proving to be more economical and less time-consuming.

Many complex car parts were time-consuming to fix and assemble; this has been made easier by single or two-part assemblies. In addition, 3d Printing produces lighter car parts and components; this reduction in the weight of the car enhances lower energy consumption and better performance. You can check our catalog for an industrial 3d printer price.

2.5, For Medical

FDM 3d printing plays an essential role in the medical field and has aided medical research, tools, and processes. For example, 3d Printing has helped save lives in the medical field by developing medical devices and helping surgeons better understand health conditions through physical modeling of the internal organs. These are the following areas that 3d Printing is being used in the medical field.

Research And Learning: with 3d Printing, medical researchers are advancing the manufacturing of medical devices and implants. Surgeons are looking for better ways to repair broken bones by using custom-sized screws made from 3d technology. The materials used for these 3d products are biocompatible, which means that they naturally bind with the human cells.

Amputees who need prosthetic limbs do not have to wait for weeks and months to be attended to. 3d printing technology has sped up creating effective, comfortable, and cheaper prosthetic limbs for amputees. 3d Printing also helps to train medical students for actual future operations.

They provide visualization and models for the complex internal system and organs of the body. Therefore, medical students can easily practice with these printed organs, increasing their knowledge and skills for actual future occurrences.

Medical Equipment: lab and medical equipment can now be printed faster, easier, and cheaper with the help of FDM 3d printer technology. This means that hospitals do not have to wait for weeks and months to receive medical equipment and devices.

The high precision of industrial 3d printers like Dreambot3D’s 400x400x400mm 3d printer makes it easy to manufacture efficient medical tools that make the surgical process easier and more comfortable for surgeons.

2.6, For Various Models Making

FDM 3d printers can be used to produce concept models, display designs, and prototypes for many industries. The following are areas that rely on FDM 3d printing for making detailed and perfect outcomes.

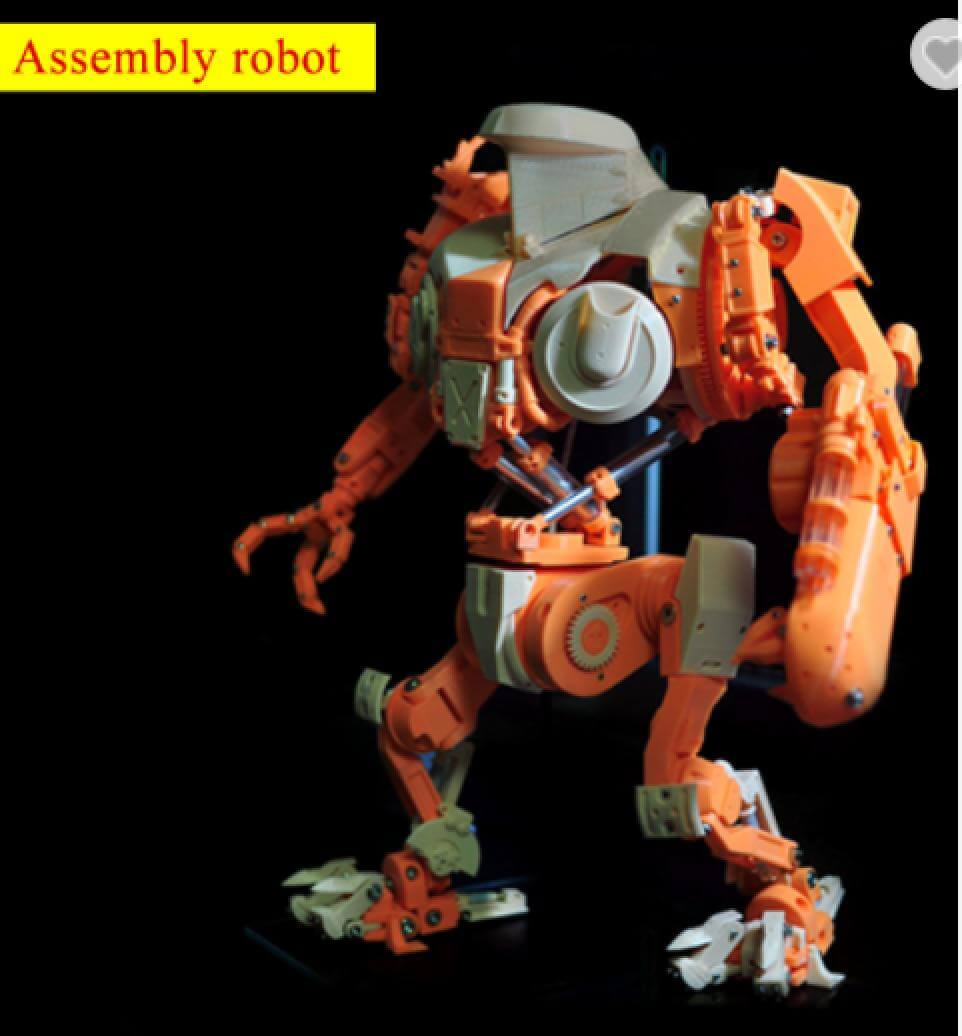

2.6.1, Anime Figure

Anime figures are things we love, be it cartoons or movies. And our love for these figures springs from the distinctness and details of anime characters. So while the finished product might look enticing and exciting, creating anime figures requires a lot of precision, details, and flexibility.

Imagine if you have to produce the design, prototype manually, and the end product; it will surely be time-consuming, hectic, and expensive. FDM 3d printer makes this task less stressful and makes you yield a better result at a faster rate.

Creating anime figures requires you to develop creative ideas that you might want to apply as your work goes on. With 3d printers, you can change your initial design and prototype quickly without wasting resources and wasting time. In addition, with FDM 3d printing, you can work on the character details of each anime figure perfectly.

Also, with the variety of 3d machines and materials, you can create quality anime figures for your movies and cartoon at a minimal cost. You can produce your anime figures at a cheaper rate, faster, and with more quality materials. With the 400x400x400mm 3d printer, you can print in hours rather than days and weeks.

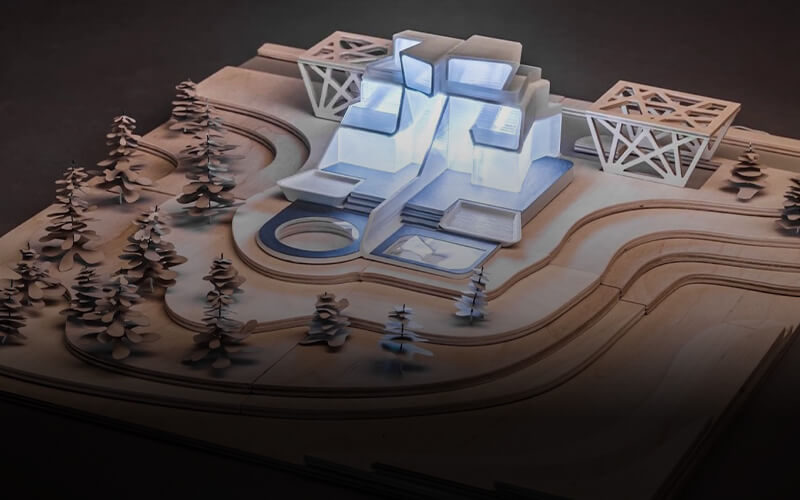

2.6.2, Architectural Models 3d Printer

Architecture is one field where satisfaction is gotten from what one can see and touch. If you are an architect working on a project, you can satisfy and impress your client by physically showing them what you intend to build. So, this is one field that uses a lot of prototypes to display designs before the end product is produced.

With 3d Printing, you can plan, create, and win more clients for yourself. The FDM 3D technology helps you create a scale model of the desired project, impress your client, and help you achieve your goal. There are two applications of 3d printing technology when it comes to architecture.

3d printers can help you create a low-cost architectural model, which can help as a study model during your creation process. Secondly, you can create detailed and realistic architectural models which you can use to promote a project by showing the final and expected outcome. This second use creates a striking model for your clients and the audience you wish to reach.

3d Printing enables you to produce architectural models that are low cost yet with high precision. A 400x400x400mm 3d printer can help you pay attention to details and achieve precision for an architectural model that is essential in convincing your clients.

The clarity and efficiency of 3d printed objects can help you notice any flaws in your architectural model, which you can easily make adjustments to. If you are looking for the right FDM 3d printer, you can check our catalog for any 3d printing machine price.

2.6.3, Mannequin

Mannequins are very important in the fashion world, helping designers to produce fashion pieces, and also advertising these fashion materials. Our top industrial 3d printer can produce both small and large mannequin models.

3d printers help you produce mannequins with precision, and this makes your mannequins represent your product the way you want rather than purchasing random mannequins in the market. Also, using the traditional production methods can take a lot of time because of the unavailability of printing materials.

With the availability of 3d printing machines and materials at a low cost, you can print as many mannequins as you want within a shorter time. Our mannequin FDM 3d printer is one of the fastest FDM 3d printers in the market. You can check out our catalog for the 400x400x400mm 3d printer or a specific printer that matches your need.

2.6.4, Gun

Printing guns with your 3d printer can raise legal and moral concerns, which is not allowed in some countries. In addition, while it is possible to print some gun parts, you still need some non-3d printed parts to complete the gun set-up. This makes it a little tricky if you aim to print and possess an unregistered firearm.

The FDM 3d printer does not create a complex functional gun in one piece. Instead, each component of the gun is printed separately and assembled. This process is complicated and can be time-consuming. But with the technological advancement of industrial 3d printing machines like 400x400x400mm 3d printer, this is changing.

Many 3d printing machine manufacturers are beginning to make FDM 3d printers that can manufacture gun parts like AK receivers, Glock frames, and pistols like a songbird, which were difficult to print in the past. However, printing these gun parts is expensive, and it cannot be achieved with cheap 3D printers.

Although the aim is to enable people to print these guns with cheaper FDM 3d printers and filaments, one will still need metal parts to complete guns like Glock frames and AK receivers.

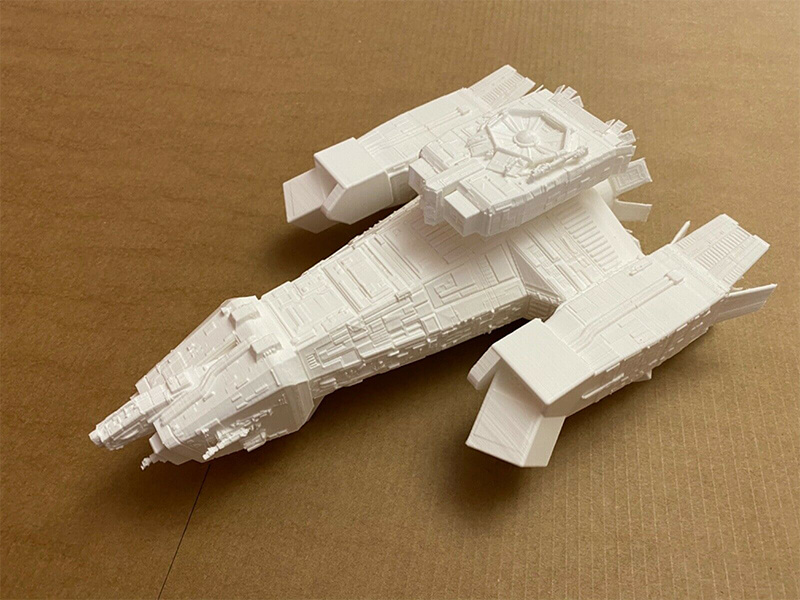

2.6.5, Ship Models

Ships and their working mechanisms can sometimes appear complex to us. With 3d Printing, these complexities can be broken down to us through the Printing of ship models. Also, it has helped engineers come up with better and innovative technologies for the marine world.

We have witnessed simple boats, ships, and water vessels; the FDM 3d printing can help us come with models for the simplest boats to more complex ships and water vessels. In addition, you can 3d print ships as artifacts for your collection.

Engineers also use 3d ship printing to produce prototypes for research and development. Again, it is cost-effective, and it is an easy way to print complex ship designs faster.

2.6.6, Airplane Models

The aerospace industry is one of those that employed the usage of 3d Printing a long time ago, and they have spent good resources trying to improve this technology. However, airplanes are complex machines and require technical know-how, research, and resources.

3d Printing has been used to produce models and prototypes of these complex machines in the innovation and production of new aerospace products. FDM 3d printing has been used to carry out research, prototypes, and concepts of new airplane technology.

This 3d Printing has helped in the production of better airplane structural and complex engine parts. The positive thing is that the aerospace industry is not only using 3d Printing for models and prototypes. It is now using it in the production of end-use aircraft parts that are durable and reliable.

3d airplane modeling has sped up innovation and development of the aircraft industry, and it has been cost-effective. So if you love planes, you can comfortably print any plane model that you want and add it to your art collection. You can check our website for any FDM 3d printer price, especially or industrial 400x400x400mm 3d printer if you are interested in owning a 3d printer.

2.7, For Cosplay Props Making

One of the advantages of 3d Printing is the helps it gives to detailing. With 3d Printing, you can easily print detailed models than if you were using the traditional methods. And one of the essential things in cosplay is the details attached to each character. So 3d printing has made it easier for cosplay fans to recreate and produce popular items from their favorite movies, shows, games, and more.

Most of these cosplay items involve making costumes to recreate specific characters. This means that your build volume will be significant because you are printing big pieces. To effectively print these large pieces, you will need an industrial printer because your small home printer might not accomplish this task perfectly.

While it is possible to make your props and costumes by hand, it is tasking and time-consuming, especially if you need to get the details right. Using an FDM 3d printer will reduce the time, energy and give you a detailed product that meets your desires. If you are interested in getting a 3d printer, you can check our catalog for an FDM printer price. Our 400x400x400mm 3d printer is one of those industrial printers which might help you easily print large volume costumes and cosplay products.

2.8, For Drone Manufacturing

Drones are a very fashionable tech item these days, and many people are getting more access to these items. Thanks to 3d Printing, getting a drone is a lot easier than it used to be. Also, if you have used a drone, we all know the accidents that we frequently make during our first attempts to fly these machines.

It is easy to lose parts from these accidents, and ordering new parts can be difficult and can take a lot of time and resources. With FDM 3d printing, you can print the different parts that you need for your drones. So apart from printing spare parts, you can design custom-made drones.

This means that you can add your design and concept and watch your imagination come to reality. The parts of the drone that you might not be able to print are the electronic, motor, and battery. You might have to purchase these parts. But you can print other parts and assemble them by yourself. The 400x400x400mm 3d printer creates lighter and effective parts at a faster rate.

Factors Affecting Efficiency of FDM 3D Printer in Manufacturing Industries

The benefits of using FDM 3d printing for industrial manufacturing are enormous. It is cost-effective, faster, fewer errors, waste reduction, and efficient. But there are some difficulties with this technology that one must consider before deciding to use 3d Printing. Knowing the issues and difficulties will assist you in finding a better way to address them.

Expertise: Using FDM 3d printing technology requires those familiar and well trained to use these machines, especially when operating large machines. Knowing the technology will yield a more efficient outcome. If you are hoping to use these 3d printers for manufacturing, you need to be able to operate them.

There is no need to have machines but no technical know-how on how to use them. The problem is that there is a lack of expertise in using this technology for industrial-scale manufacturing. If there is no expertise, then it means that the efficiency of manufacturing will be significantly affected. That is why our 3d printers, such as the 400x400x400mm 3d printer, are user-friendly and easy to operate, especially for new users.

Materials available for your industry: while it is true that FDM 3d printing applies to most industrial manufacturing, the materials for these various industries differ. The filaments used for prototypes and display models are different from the filament materials used for other fields like automotive, aerospace, and the medical field.

This means that you can not just use any material; you need to get the exact materials for your industry to yield better results. Using less quality materials or materials for other fields will affect the efficiency and outcome of manufacturing.

Software Development And Capabilities: Before you print any object, it has to be created by software design, and then you download this software and print what you want. In as much as it is easy for almost everyone to download the file for Printing, creating the software in the first place might be difficult.

It will be easy to download already made 3d designs; if you are hoping to create something unique, you need to know about using computer-aided design software, and not many people are trained in this area. This means that to create unique designs, we have to rely on those with computer design software.

Post Processing Needs: using an FDM 3d printer machine for industrial manufacturing can make detail-oriented prints challenging to achieve. This means that you will need to carry out a lot after-processing to achieve the detailed result you need.

If you are mass producing, it can be challenging to carry out after-processing for many printed products. This is one of the factors that might affect the efficiency of your manufacturing industry.

Main Components and Parts of FDM 3D Printer

To get the satisfying and efficient result of your FDM 3d printer, there are outstanding components and parts that make this particular 3d technology different from other 3d printers. First, let us look at some of the core and fundamental parts of the FDM 3d printer.

The Extruder: the extruder can also be referred to as the printer head. This printer head is directed by the computer, directing the nozzle’s path and movement as it moves across the build platform. This printer head movement creates the object according to the calculated path as set up by computer-aided design software.

The heated nozzle draws the object by melting the filament and extruding it onto the building platform. The nozzle extrudes this melted filament layer by layer, and when each layer has been printed, the height of the nozzle increases by an increment as it prepares for the next layer.

The print head can be categorized into two sections; the cold end and the hot end. The cold end is the part that locks the filament and gradually pushes it towards the hot end. As the name implies, the hot end possesses the hot temperature that melts the filament and deposits it on the printer bed.

Some FDM 3d printers come with dual extruders like our 400x400x400mm 3d printer. This means that you can simultaneously print with two different filaments. These double extruders can either be attached to the same print head or connected to different print heads.

Print Bed: this is the component where your printed model rests while printing. The FDM 3d filaments are deposited on this flat surface layer by layer. The print bed can be made with different materials like glass and metal. Each of these materials has its various advantages,

For example, the glass flatbed material is superbly flat, meaning that layers can be added easily and easy to clean, and inexpensive. Aluminum, on the other hand, heats up faster than glass. Our 400x400x400mm 3d printer is made up of heating aluminum substrate plus a black crystal glass platform

Also, there are different kinds of print beds; there are heated and non-heated print beds. A non-heated print bed might be ideal for lower materials like PLA, but it might require you to use heated print beds for advanced filament materials. The type of print bed used helps to enhance adhesion and the stability of your first layer.

Motion Controllers: the motion controllers are fed with instructions by the motherboard. They receive the instructions and do the movement, and these motion controllers move around three axes; XYZ. The X-axis and Y-axis movement is controlled by the belts connected to the motors. The stepper motors are responsible for the mechanical movement of the print head. These motors rotate in steps; that is why they are called stepper motors. The stepper driver controls them, and they connect with the X, Y, Z-axis. Our 400x400x400mm 3d printer has accurate nozzle positioning, which prevents printing products from deviation.

Threaded rods are another set of motors that help the print head move upward and downward. The Z-axis is dependent on the threaded rods for its movement. These threaded rods are connected to the stepper motors.

Print Material: this refers to the filament used for Printing. FDM 3d printers use polymers as filament materials, and a variety of them are used for different objects and industries. These filaments are heated to different temperatures, causing them to melt, and are deposited on the print bed to print the required object.

These different types of filaments have their advantages and limitations. It is necessary to know what you want to print before you purchase any filament. Also, when you buy a printer, you need to be sure of the filament that is compatible with your printer. Not all FDM 3d printers are compatible with multiple filament materials. Our 400x400x400mm 3d printer is compatible with a wide variety of filaments

Motherboard or Controller board: the control or mainboard is the component of the FDM 3d printer responsible for the smooth processing of the machine. We can call the mainboard the brain of the 3d printer because it is responsible for the fundamental operation.

The control board receives the instructions sent from the computer, and it directs the motion component. The mainboard also interprets sensors and signals, so your control board needs to be of excellent quality to achieve high performance.

Frame: The frame of your 3d printer helps keep all the components together. The frame maintains the stability of your machine, and it is made with different materials. The common materials used for frames are acrylic and metal.

It is essential to buy an FDM 3d printer with a robust frame; it makes your printer more durable. Also, there are open and closed frame designs. You will find some printers with semi-closed frames. One of the advantages of the closed frame over the open frame is that it maintains consistent temperature around the print space. Our 400x400x400mm 3d printer has a fully sealed chassis.

User Interface: Most 3d printers these days come with a user interface, an LCD controller that allows you to use your 3d printer without a computer. This display can help you control the printer’s settings, and the 3d printer can work as a stand-alone.

This means that the printer also comes with a space for an SD card for your FDM 3d printer to read the software instructions. Our 400x400x400mm 3d printer comes with a free U disk and SD card.

How To Choose A Suitable FDM 3d Printer For Your Industry

We have stated earlier on how FDM 3d printing machines can be used in different industries and the many benefits they possess. Therefore, before buying any machine, it is advisable to consider what you intend to do and which 3d printer will be best to help you achieve your aim.

Some FDM 3d printing machines are best suited for some tasks than others, and before you invest your resources, there are many things you need to consider before you purchase a 3D printer. We will look at some of the essential things to watch out for when selecting a 3d printer for your industry.

5.1, Your Application Industry

Your application field is an essential element to consider before buying any FDM 3d printer. It could be a professional field, or it could be for hobby purposes. Your application industry will determine the size of the printer, the speed, and the type of filament materials to purchase. For example, the 400x400x400mm 3d printer is an industrial-grade printer that helps you print your industrial objects.

If you aim to use FDM 3d printing to produce little objects like toys, little models for things like planes, ships, and cars, you will go for the machines that suit your need. If, on the other hand, you hope to produce large objects like parts for automotive, ships, airplanes, and medical equipment, you will go for large industrial FDM 3d printers that will best suit your needs.

You are using FDM 3d printing to achieve your aim in both cases, but you are reaching out to different audiences and expectations. You can take a look at our catalog to help you pick the best 3d printer, and if you are not sure of your choice, you can reach out to us through our contact.

5.2, Print Size Requirements

An FDM 3d printing machine for toys would differ in size from the printer for industrial products like medical equipment parts and spare parts for the automotive and aerospace industry. If you are printing bigger objects, you need a bigger 3d printer to help you print easily. A machine like Dreambot3D’s 400x400x400mm 3d printer will be best for printing large and industrial-grade objects.

If you use a smaller machine to print more significant objects, you might need to print them in parts and then assemble them, which might take more time and energy. For effective FDM 3d printing, it is necessary to be aware of the unit of measure for your CAD file. This file will determine how small or big your print size is going to be.

Also, the weight and size of your printed object will determine which FDM 3d printer to use. Different filament materials will produce different results on the size, weight, and dimension of the object printed, regardless of whether you used the same CAD file for both filament materials.

5.3, Printing Material Requirements

If you have been paying attention, you will know that your industry will determine the type of filament material you need. We use FDM 3d printing because of its efficiency, attention to detail, and the ability to recreate designs and models with metal and thermoplastic materials.

This is not a case where one shoe fits all. The different filament materials are best suited for different industries. You can use PLA for toys, display designs, and models, and it will be perfect. But you cannot use the same material for printing automotive parts and things like glass shields. Some filaments are more durable and stronger than others, so to get the best result, it would be essential to know what materials best suit the object you wish to manufacture. The 400x400x400mm 3d printer is compatible with many filament materials.

FDM 3d Printer Buying Guide

Buying a suitable FDM 3d printer is a considerable investment, especially if you seek to buy an industrial FDM 3d printer which will cost you a good amount. So, it is good to go over many details that others might take for granted before you commit yourself to buy any 3d printer.

If you are new to the world of FDM 3d printers, it might not be easy at first for you to know the factors that matter the most. However, we understand your plight; that is why we have put together some factors below for you to consider when buying an FDM 3d printer.

6.1, Check The Brand Reputation

The advancement of technology has made the 3d printing industry flourish. New brands are storming the market daily, which means that we have many brands that we could pick from. However, if you plan to purchase an FDM 3d printer, you need to consider if the brand or manufacturer meets your budget, expectations, and requirements for your industry.

Since many FDM 3d printers are flooding the market, it can be very easy to make a mistake by going for a product that will bring you stress later on. So it would be best if you carried out a lot of research about the different brands in the market before committing yourself to any brand product. Look out for reviews and ratings from buyers, critique, and reviews from professionals in the FDM 3d printer industry. This will offer you a better insight into the FDM 3d printer brand to patronize.

Experience matters in cases like this when you are looking for an FDM 3d printer Brand. Some of the new brands have no experience in the 3d printer industry compared to others. A brand that has been in the industry for a longer time might be more dependable than a new brand, although this might not always be the case.

It can also be helpful to look at 3d printing machine manufacturers that bring innovation and are in touch with modern technology. The 3D printing industry has undergone a lot of innovation since its foundation. So, it would not be nice to go for an FDM 3d printer manufacturer who has done nothing to improve its quality in line with modern technology. Our 400x400x400 3d printer is one of those 3d printers that have features in line with modern technology.

6.2, Safety Configuration Of The Machine

We know that it is very common for people to buy machines and equipment and not bother about asking or reading the safety manual. The truth is that we take safety measures for granted, yet these are the essential things that we need to educate ourselves about. If you are thinking of buying an FDM 3d printer, it is essential to read about the safety conditions.

Check if the machine has proper safety conditions and how it works. This protects you from a whole lot of future complications as you use your 3d printer. As we mentioned earlier, buying a 3d printer is a big financial investment. Therefore, it is necessary to make sure that what you buy will not bring unnecessary spending.

It is not good to assume that there will never be a time when you will have complications during Printing. If you are familiar with the world of 3d Printing, you will acknowledge that there might be times when there are minor complications. So, it is necessary to analyze the printer’s safety configuration before you commit yourself to purchase an FDM 3d printer.

One of the outstanding safety configurations of our printers, like the 400x400x400mm 3d printer, is that there is a material alarm system attached to it. So, if your material finishes, you will be notified, and after fixing your material, your Printing will pick up from where it stopped.

6.3, Resolution Requirements Of The Machine

We are sure you are looking to purchase a 3d printer because of its ability to pay attention to details and produce the exact object you need. Hence, it is necessary not to neglect the resolution requirements of the machine because it is responsible for the precision and clarity of any printed FDM 3d pattern or model.

This resolution requirement is different from one industry to another. For example, you cannot use the resolution required for the cosplay industry for the automotive industry. Therefore, it would be best to know what models, patterns, and specific industry you intend to use your FDM 3d printer and buy a machine that corresponds with that industry.

If you are new to the world of FDM 3d printing, this might all sound strange and hard to comprehend. This is why we at Dreambot3D are here to help you; we pride ourselves on catering to our clients in ways that will benefit you. We know that each one has a different need, and we are here to help you surmount the challenges you might face.

6.4, Consider Whether The Price Of The Machine Is Acceptable

The price of the machine is something essential to consider before you commit yourself to buy one. There are costly and cheap FDM 3d printers out there in the market. However, as earlier stated, the costliest machines might not necessarily mean that they have formidable features not found in other cheap machines.

To determine if the price of a 3d printer is acceptable, you need to consider factors like customer review, track record of the brand, and the brand’s value. You also need to consider your personal preference and the features you need. If the features and designs of the FDM 3d printer go in line with your industry and taste, then it is safe to say that the price tag is acceptable.

This means that you might find a machine that will meet your criteria, and it might not be expensive as you think. If the machine is cheap but meets all your expectations, then you can also purchase it. But do not purchase a machine just because it is cheap, it might not meet all your requirements, and it might not have quality as well. So, the machine’s price you decide to settle for will largely depend on if your needs and requirements are met.

6.5, Consider The Supplier’s After-Sales Service Capability

Most times, people think when you buy a piece of equipment, everything is over. This is a wrong notion; buying a machine is one part of the equation, having and enjoying the after-sales benefit is the other part of the equation. For example, when you buy an FDM 3d printer, you need to be sure that the company or manufacturers will be willing to offer after-sales service to maintain the quality of the machine.

Complications and accidents can happen while using the machine, and we also need to learn the culture of servicing our machines from time to time. This will elongate the life of the 3d printer, and it will serve you better. Hence it would be best if you were sure that the company or the manufacturer you are buying from has a track record of responding to after-sales service.

You will find brands that offer good after-sales service, some might offer you few days in a week, and some brands attend to you all through the week. It is necessary to choose a brand that you can rely on when you need help. Hence do your research, check reviews, and ask the opinions of others who have dealt with the 3d printer brand that you hope to pick.

We at Dreambot3D pride ourselves in the excellent after-sales services that we offer to our clients. If you buy our 400x400x400mm 3d printer or other 3d printers, our support staff and technicians are available all around the clock to help you with your needs. We manufacture the machines, and hence we know all about them; we will help with after-sales services that help maintain the quality of your FDM 3d printer.

6.6, Go For Flexibility

When thinking of an FDM 3d printer, it is nice to go for a flexible printer and have many features that can give you a lot of options. These are the following features that you could look for when looking for an FDM 3d printer.

Ease of Use: it is necessary to buy a 3d printer with features that make the printing experience easy, especially for new users. Different brands these days add features that make it a less tedious job when setting up your FDM 3d printer or constantly monitoring the printing process.

Some of these features like Wi-Fi connectivity, auto-bed leveling, and a heated bed give you a more effortless printing experience that guarantees success. Also, it is good to buy a 3d printer with features that makes the learning experience easier for new users.

Place of Use: The place you use your FDM 3d printer is vital; most persons who use these 3d printers are hobbyists, students, and enthusiasts. They mainly use these printers at home for Printing, and some filament materials produce toxic fumes when printing. These fumes are hazardous to your health, especially if you use them where you live.

If you are using your printer from your home, you can avoid this by purchasing a printer that has a proper ventilation system or enclosures. This ensures that the gases and fumes are released outside the house, making the house safe.

Colors: Here, we are referring to the color of your prints. This is important because you might have to print models that have different colors like props and miniatures. Therefore, it is essential to buy an FDM 3d printer with a dual extrusion that allows you to print objects with multiple colors.

If you want to get different colors, you can use the single-color print, but you will need to post-process your object by painting it. This will take you a long time than having a dual extrusion printer that prints multiple colors. Our 400x400x400mm 3d printer can be customized with double nozzles to help you print multiple colors.

6.7, Pay Attention To Details

While you may be excited about buying a new FDM 3d printer that is fascinating, it is essential to pay attention to details that most people seem to overlook. Paying attention to details will make you get the best printer and avoid any confusion and defects regarding the printer’s life.

For example, although FDM 3d printers print with filament materials, not all filaments can be used in some machines. So, it is necessary to know the type of filaments that is compatible with your 3d printer. In addition, each filament material has a different melting point; you need to be sure that your extruder or nozzle can handle the melting point of your filament.

Also, when buying a 3d printer, it is vital to consider the build volume of the objects you wish to print. Finally, you should know that the speed setting can influence the quality of your output.

6.8, Put Safety First

We should always put safety first when it comes to using an FDM 3d printer. This technology aims to provide a safe environment for working and maximizing a comfortable printing experience. So, it is necessary to take precautions while using your 3d printer, and you need to pick a brand that states what the safety precautions are.

Go through the manual that comes with your FDM 3d printer, and note the best practices and things to avoid while using your printer. The manual should provide information like the best materials to use, the best environment to print in, the best temperature to operate your machine. Then, when the safety instructions are stated, you will be able to use your 3d printer better and wiser.

6.9, Select The Most Cost-Effective

It is important to note that buying a costlier or more popular product does not guarantee that it is the best in the market. Although some brands have lived up to the expectations, some have not. So, it is possible to find a famous brand that might sell costly FDM 3d printers, yet they might not be cost-effective in the future. This does not also mean that choosing the cheapest brand will guarantee you suitable 3D printer filament materials.

Before purchasing any FDM 3d printer, it is necessary to conduct background research about the FDM 3d printer manufacturer. This will help ensure that you get quality products for your money. Furthermore, if you are purchasing a 3d printer for industrial purposes, it means that you will significantly rely on it. So, it is necessary to buy a 3d printer that is reliable, cost-effective, which can save you from stress and disappointments.

If the FDM 3d printer has quality but is expensive, it is better to go for it than going for something cheaper, which might give you a less quality outcome or cause more problems for you in the long run. Whether cheap or costly, endeavor to buy a 3D printer that helps you achieve your goal and delivers a quality outcome.

6.10, Why Is Dreambot3D’s FDM 3d Printer So Prominent?

We have been speaking in general about FDM 3d printers; it is time to give you a reason why we are the best FDM 3d printers in the market and why you need to patronize us.

User Friendly: our 3d printers are user-friendly, especially if you are a new user. Our controls and operating system are set in a way that you can easily learn and follow as you use the machine.

More affordable: we know that buying a 3d printer is a significant investment, and it might require you to spend a good amount of money. We have a range of affordable FDM 3d printers that you can pick from. The features and quality of our printers make it worth the prices for them.

Allow Offline Printing: With our SD card feature, you can comfortably print whatever you want without connecting to the computer. All you need to do is insert your SD card into the printer with the design you intend to print, and you will comfortably print your material.

If the SD card refuses to respond, you can format it and try again. But in the case that you are facing more issues, you could always reach out to us, and we will be willing to help you. You should check out our 400x400x400mm 3d printer, which is equipped with this fantastic technology.

Automatic Resume Printing: there are moments when you experience a power failure or other situations when you are printing, and you have to stop Printing. Well, you do not have to worry about picking up from where you stopped. Our printers are built in a way that allows you to pick up from wherever you stopped while printing without complications and issues. It is an added advantage, especially if you live in places that have frequent power cuts.

Full Enclosed Stable Frame: we mentioned earlier that One of the advantages of the closed frame over the open frame is that it maintains consistent temperature around the print space. This gives you a stress-free and more satisfying output as you print.

Our FDM 3d printers come with an enclosed frame to better the printing experience. Also, the frame of the 3d printer is stable and firm and helps the long life of the 3d printer.

Indicator Light: Our FDM 3d printers are reliable, making them more convenient for you to use. Our 3d printers are equipped with indicator lights to make you aware of the operational status of your machine when printing. These lights can easily be replaced when used up, and they are located at the top part of the machine.

Stable Frame Design: our 3d printers are built with a sturdy frame design to give you accuracy and stability during the printing process. Even if you are printing at high speed, the sturdy frame design of the printers makes your Printing accurate, and it is easy to assemble. Our 400x400x400mm 3d printer has a stable frame that makes the printing experience accurate.

Automatic Recognition System For Broken Material Detection: there are times when you might be using a machine without knowing that one or two components have broken down. And the more you continue to use the machine in this state, the more the situation worsens.

Our FDM 3d printers are infused with an automatic recognition system that immediately notifies you when something is wrong with any component. Even if you are printing, the machine pauses the printing process to notify you to attend to the broken component.

FAQ Guide

What Does FDM Mean In 3d Printing?

FDM 3D printers aid the manufacturing of 3-dimensional objects through a computer-aided manufacturing process. Fused Deposition Modelling (FDM) uses additive manufacturing 3D printing technology, which relies on material extrusion.

What Should I Know Before Buying A 3d Printer?

Before purchasing a 3d printer, you need to research the brand reputation, the price, safety configuration of the machine, the resolution requirement, material requirement, the after-sales service policy, and your application industry. These areas will inform you of the right 3d printer to purchase. Next, check our catalog for our 400x400x400mm 3d printer; it gives you all the features and specifications of this 3d printer.

Why Guard Bands Are Used In FDM?

A guard band acts as a narrow frequency range that separate ranges of two wider frequency. It ensures that two communication channels that are used simultaneously do not experience interference.

Is SLA Stronger Than FDM?

Generally, FDM parts are considered to be stronger than SLA parts. This is because FDM parts have high impact resistance and are less likely to break or degrade over time, and they can be left outside under harsh weather conditions. On the other hand, SLA parts have a vulnerability with regard to SUV rays. If left outside in the sun, they will deteriorate rapidly.

What Is A Good Size 3d Printer?

The size of printer that you decide to settle for will depend on your print size requirement for your industry. For example, if you are making small toys and models, you can always go for a 200x200x200 3d printer size which does not handle a lot.

But if you are hoping to use your printer for industrial purposes, you should consider a 400x400x400 3d printer upwards. So, the size of printer that you settle down for will depend on what you intend to use it for.

How Durable Are 3d Printed Items?

Generally, 3d printed items are durable, but some are more durable than others depending on the materials you use for Printing. For example, filament materials like polycarbonate and PEEK are solid and durable and print things like riot shields and bullet-proof glasses.

Although PLA is one of the most used materials for Printing, it is not as strong and durable as PEEK and polycarbonate. It has a low melting point and can quickly weaken when exposed to high temperatures. So, the durability of your 3d printed items depends mainly on the materials used.

How Much Does An Industrial 3d Printer Cost?

As we stated earlier, buying an industrial 3d printer is a serious investment that one should not take for granted. An industrial 3d printer can cost you from $10,000 to $100,000. The prices of these machines differ depending on the unique features and the size.

So, before you commit yourself to buy a 3d printer, you need to decide what you want to use it for, what features you need for your industry, and your budget. These factors will help you decide the best range of 3d printers.

What Is The Best Industrial 3d Printer?

When looking at the best industrial 3d printer, it is good to consider the brand reputation, application requirement, price, after-sales services, safety configurations, and materials requirement. Hence it is safe to say that our 3d printers are the best industrial ed printers in the market.

Our machines are made with quality materials. We pay attention to your particular needs. Even our prices for industrial printers benefit medium and small businesses that cannot afford the more significant 3d printers. Our 400x400x400 3d printer is an example of a quality and effective industrial machine; it prints industrial-grade size, has high precision, is compatible with many filament materials, and is affordable. You can check our catalog for more of 3d printer price.

Is A 3d Printer Worth Buying?

A 3d printer is worth buying, especially for creators, experimenters, makers, product development, and industrial manufacturers. 3D Printing has brought a lot of delight to the research and industrial field, also for recreation. This technology has made it easy and less time-consuming to develop prototypes and exact copies of objects and images.

What Industries Use 3d Printers?

Many industries utilize 3d printing technology. These industries include jewelry printing, space industry, aircraft, ship, automotive, construction, medical, engineering, architecture, plastic, and cosplay. 3d Printing has made it easy for the rapid development of prototypes, design models in these industries leading to growth in innovation. If you belong to any of these industries and are interested in 3d Printing, you can begin with our 400x400x400mm 3d printer, an industrial-grade printer.

How Long Does It Take To 3d Print A Car?

The speed of your 3d printer and the car design will largely determine how long it will take you to 3d print a car. But it could take you between two days to one week to print your car. So while Printing is one thing, assembling the printed car is another factor.

This is because you will print the car in parts, not as a whole. This means that you will have to assemble these parts after Printing, which could take you between 3 to five days.

What Is 3d Printing Most Commonly Used For?

3d Printing is most commonly used for the production of digitally designed objects like design models and prototypes. However, it is also used to print end-use products and designs.

What Can You Make With A 3d Printer?

With a 3d printer, you can make models of planes, ships, automotive, and architectural designs. You can print toys and cosplays, and you can also print industrial objects like spare parts for cars, aerospace, and ships. Some have gone as far as using 3d Printing to fabricate walls, bridges, and houses. You can also use it for medical, dental, and consumer goods. The 400x400x400mm 3d printer is effective and fast for producing parts, consumer and dental goods.

How Much Are Commercial 3d Printers?

The price of commercial 3d printers varies depending on the size and various added unique features. The price for commercial 3d printers ranges from $1000 and above. You will need to decide which one has the features you require and suit your budget.

Will PLA Melt In The Sun?

The sun reacts to different plastics at various degrees; some plastics are easier to melt under the sun while others take longer. In addition, PLA is biodegradable, this means that it can break when exposed directly to excess sunlight.

Conclusion: Why Our FDM 3D Printer Is The Best Choices

If you are working in the R&D industry, you know the need to print many prototypes for your work. With our 3D printer, you can print multiple prototypes in a matter of hours rather than days or weeks. Printing your prototypes faster will guarantee you the opportunity to achieve your design cycles faster and more efficiently. We help you deliver your work on time, and this takes a lot of pressure off your shoulders that you might encounter from your clients.

Our 400x400x400 3d printer is compatible with various materials such as ABS, PLA, Nylon, PC, and Carbon Fiber. Plus, this printer can be customized with a double nozzle, making things easy when you are printing multiple colors.

We provide you with 3d printers that can enable your pint offline, and they enable you to pick up your Printing where you left it in the course of interruptions. Our products are easy to use, especially if you are a new user, and we are always ready to listen and help you out. Check out our catalog for more of our products, and contact us if you need any help.