wax 3D printer

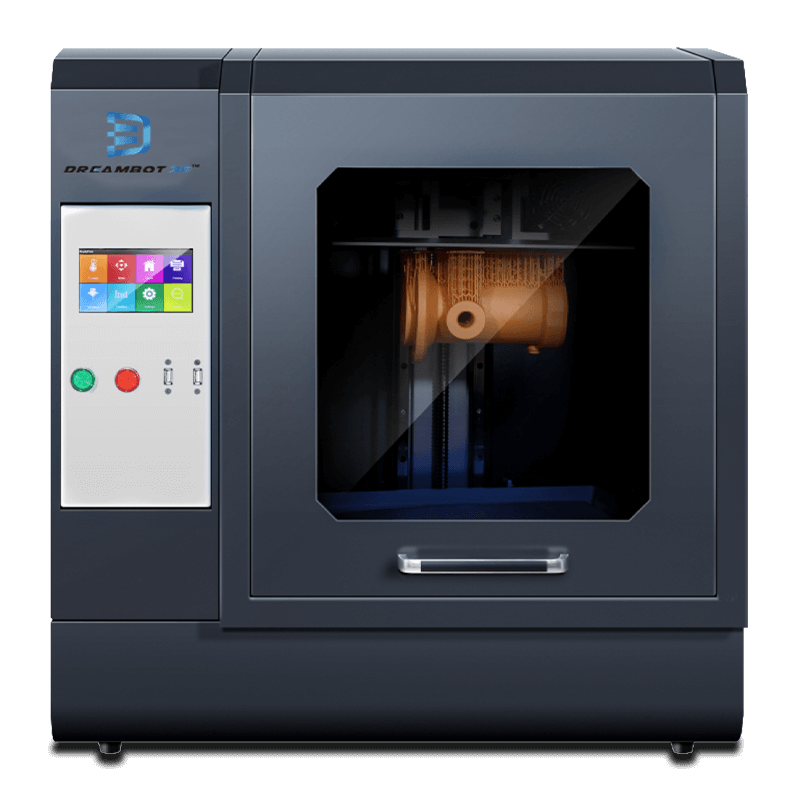

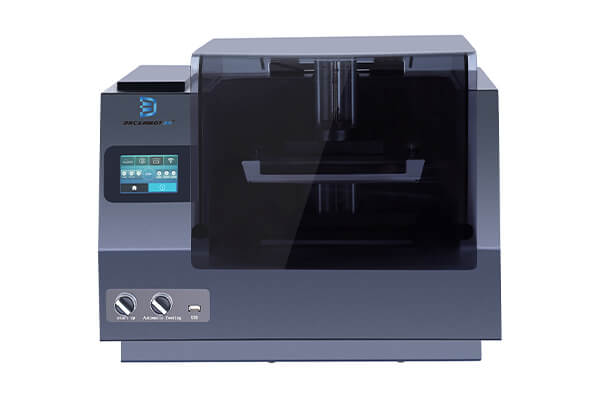

DB-293 LCD 3D Printer

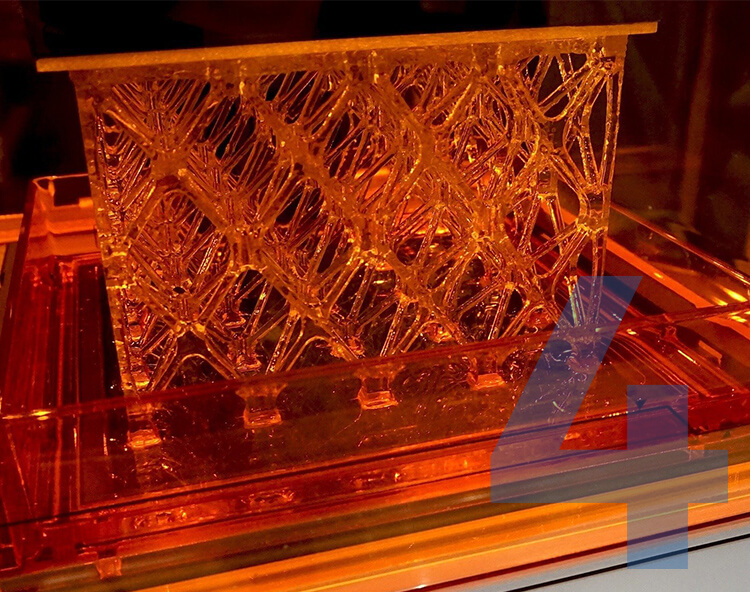

- Stereoscopic light curing 3D printer with LCD technology, high quality of finished products

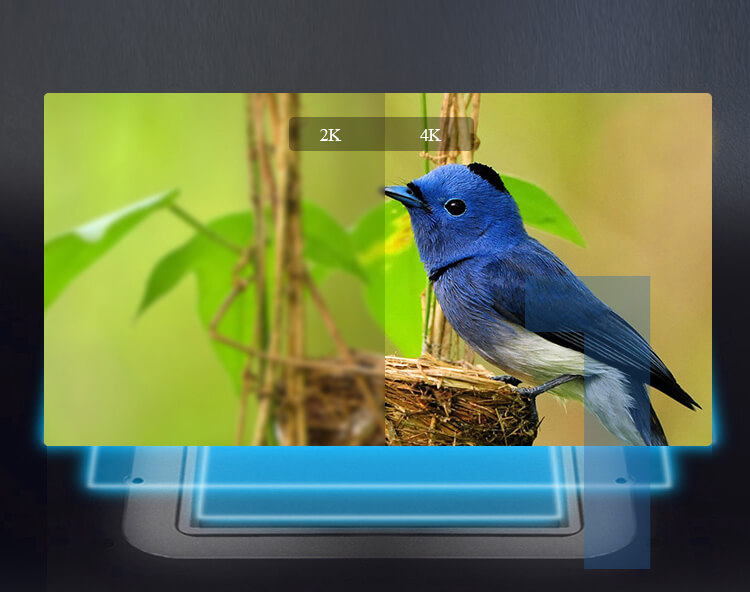

- 4K high-definition pixel printing greatly improves the smoothness of the model surface.

- Dreambot3D wax 3d printer(DB-293) has obtained CE, FCC certification and quality assurance.

Dreambot3D wax 3D printer (DB-293)

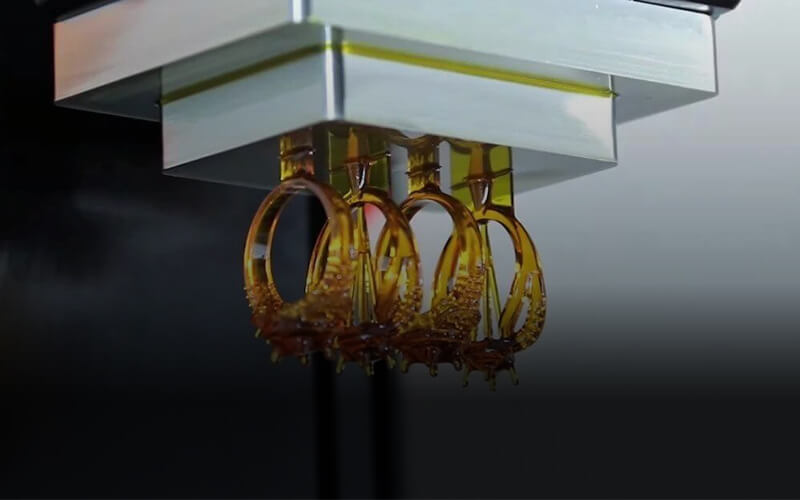

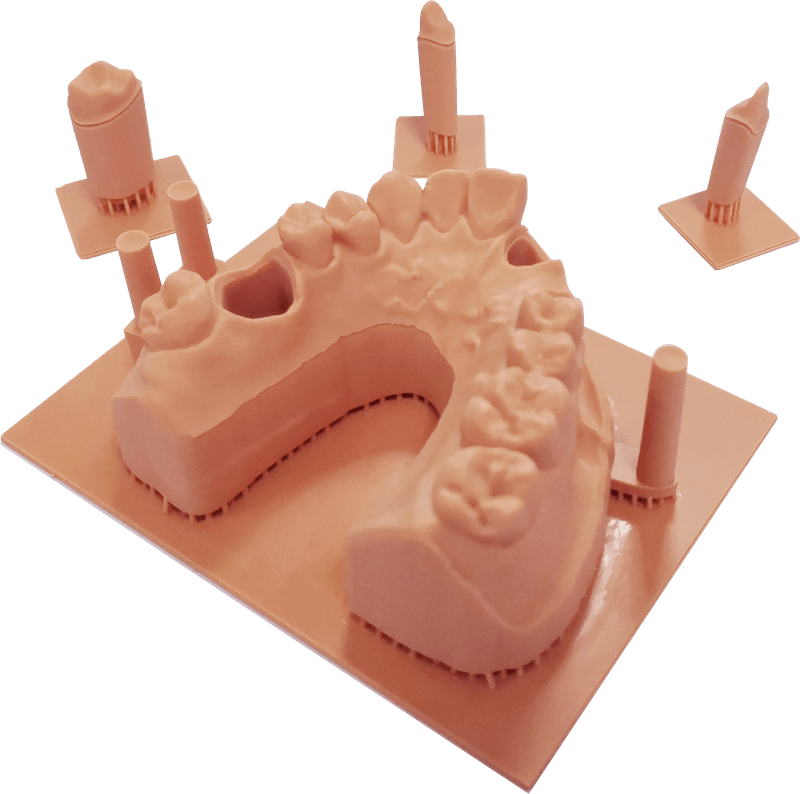

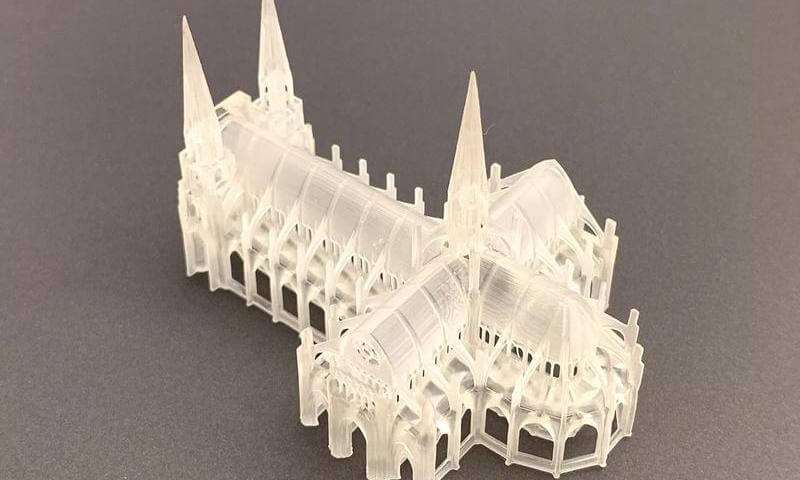

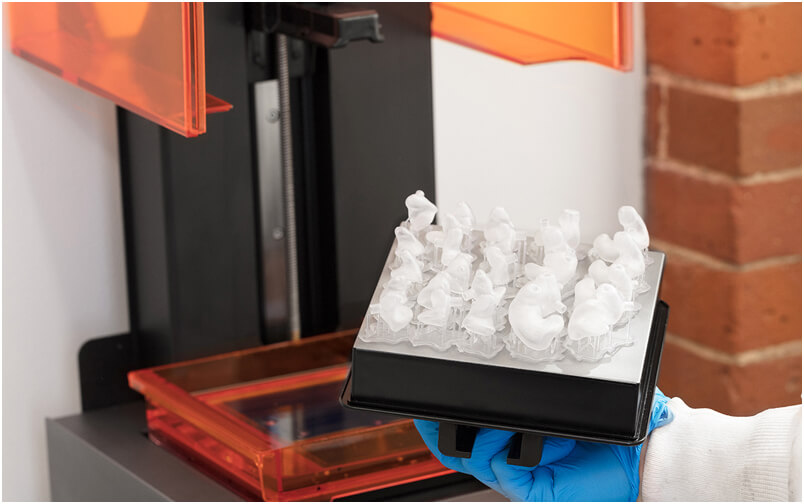

The Dreambot3D wax 3D printer(DB-293) is popularly used to create 3D wax molds most especially in the jewelry industry. The wax 3D mold is able to print exactly what has been designed in an accurate and detailed fashion. This wax 3D printer is equally used by designers, professionals, personal hobby, etc.

All sharp edges, organic shapes, crisp details, and fine filigree all appear on printed wax mold. Giving your jewelry all details and precision. The printing process is fast which contributes to the overall fast processes of the jewelry making industry. The Dreambot3D wax 3D printer(DB-293) price is very affordable.

| Parameters | DB-293 | |

| Technical parameters | Max printing volume | L293 W165 H400 |

| Voltage | 100-240V AC50-60HZ | |

| Power | 250W | |

| Printing technology | LCD surface forming | |

| Printing layer thickness | 0.025-0.1mm | |

| Printing speed | Max 20nm/h (Z axis) | |

| Pixel | 4K Monochrome LCD Screen | |

| Support function | Automatically generated, editable | |

| Curing wavelength | 402-405nm | |

| LED array | Parallel UV LED light source | |

| Resin support | Castable resin/non-casting resin | |

| Operating temperature | 10-30℃ | |

| Relative humidity | 30-90% | |

| Storage temperature | 0-30℃ | |

| Operating parameters | Printing software | CHITU |

| File format | STL /SCL | |

| Adaptation system | Windows Linux Mac OS OSX | |

| Transfer method | USB / network cable | |

| Physical parameters | Dimension | 670x430x640mm |

| Package Size | 730x520x870mm | |

| Net weight | 48KG | |

| Gross weight | 55KG | |

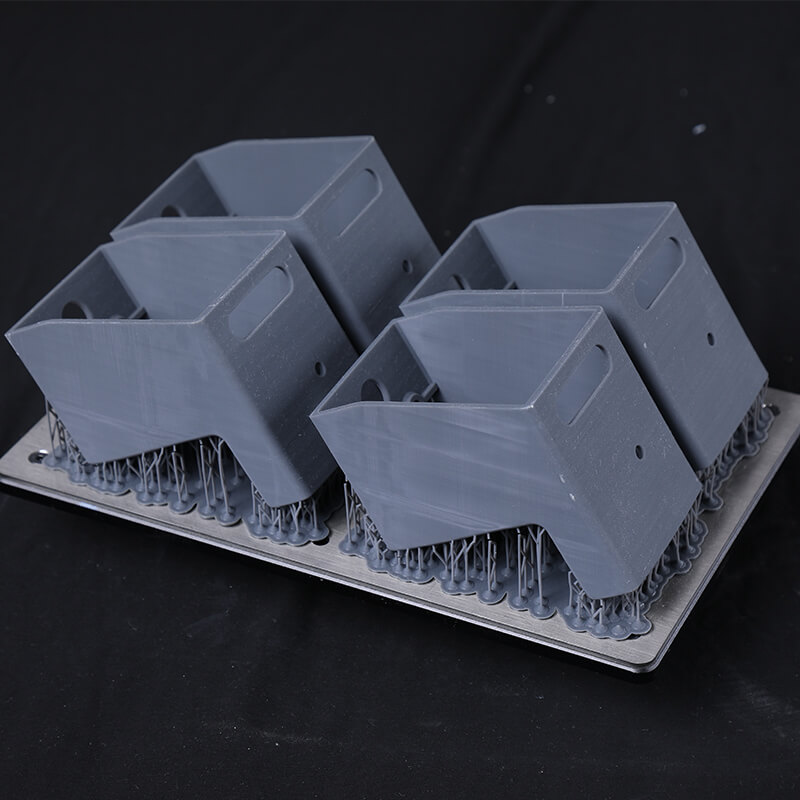

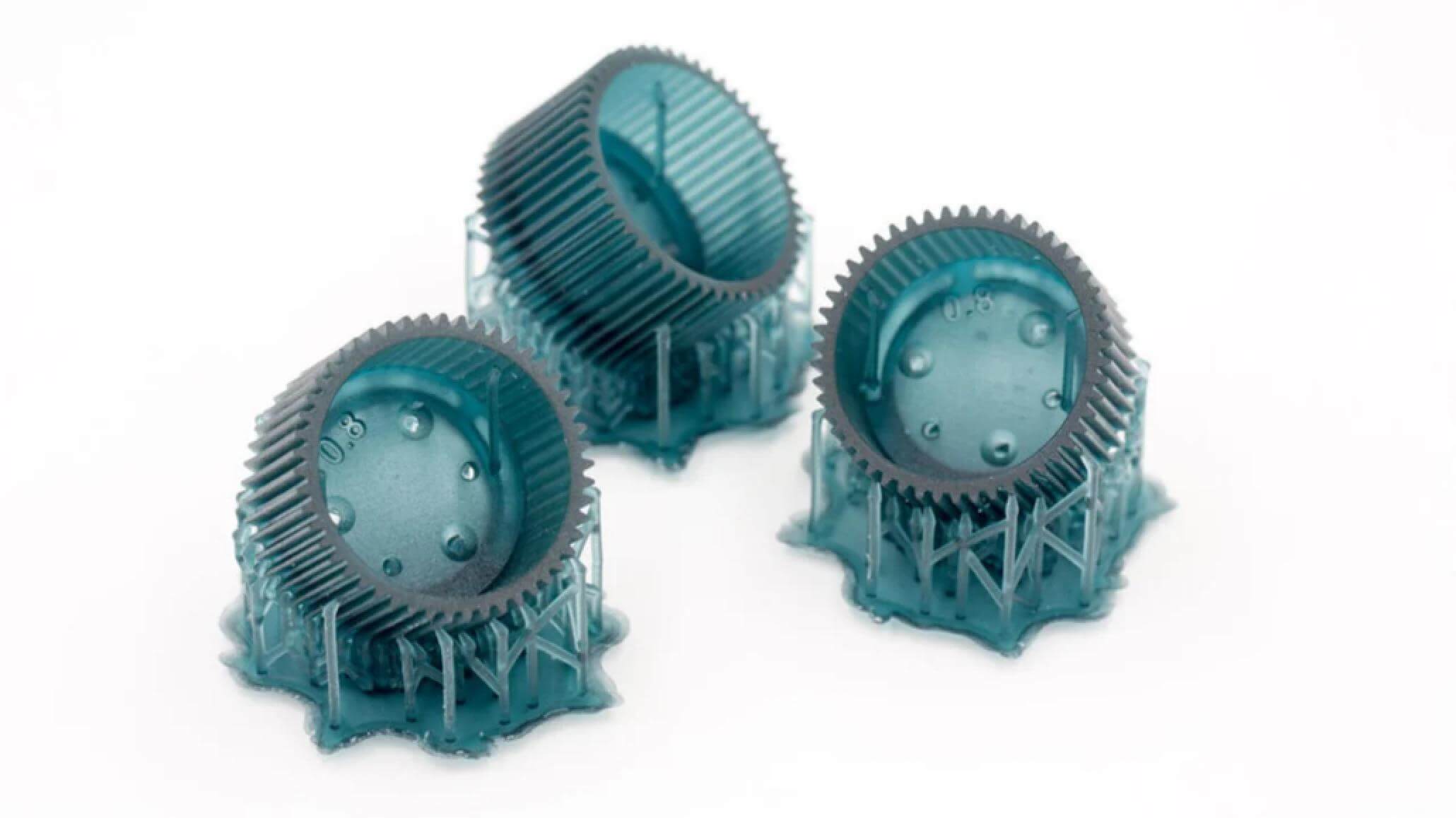

- The Dreambot3D wax 3D printer(DB-293) and its consumables makes it possible to create detailed and unique 3D models either for casting jewelry or any other purpose.

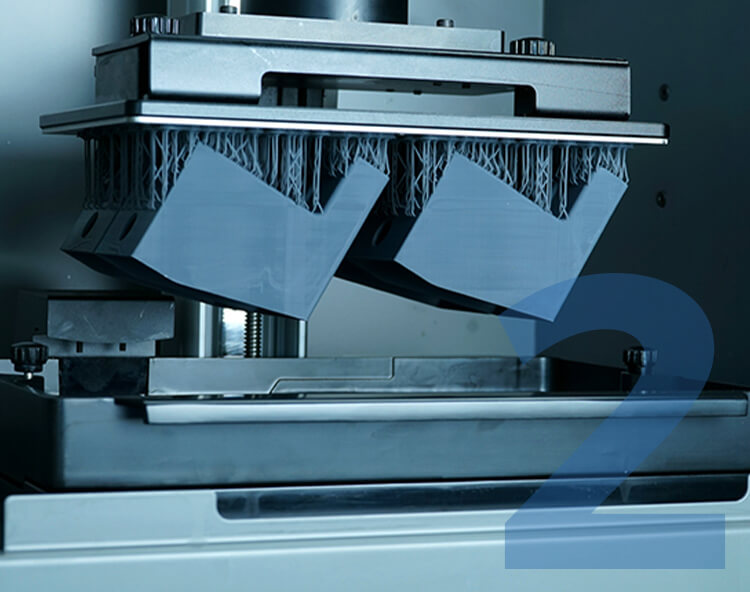

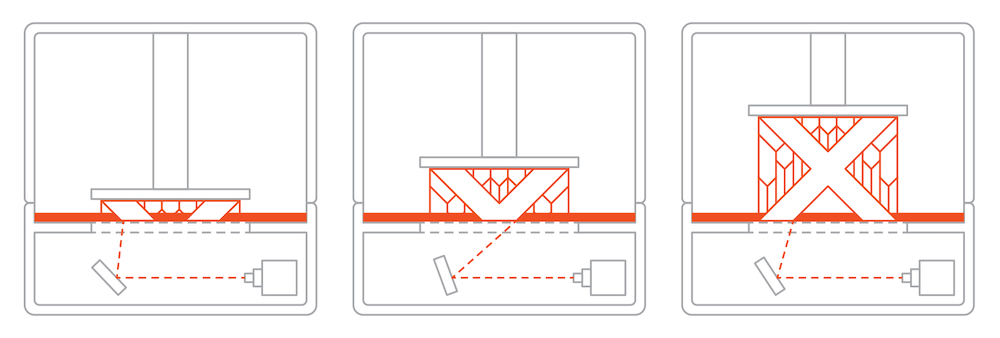

- The resin is cured layer after layer under the ultraviolet light to form a 3D product. This ensures that no part of initial design is left out including the complex angles.

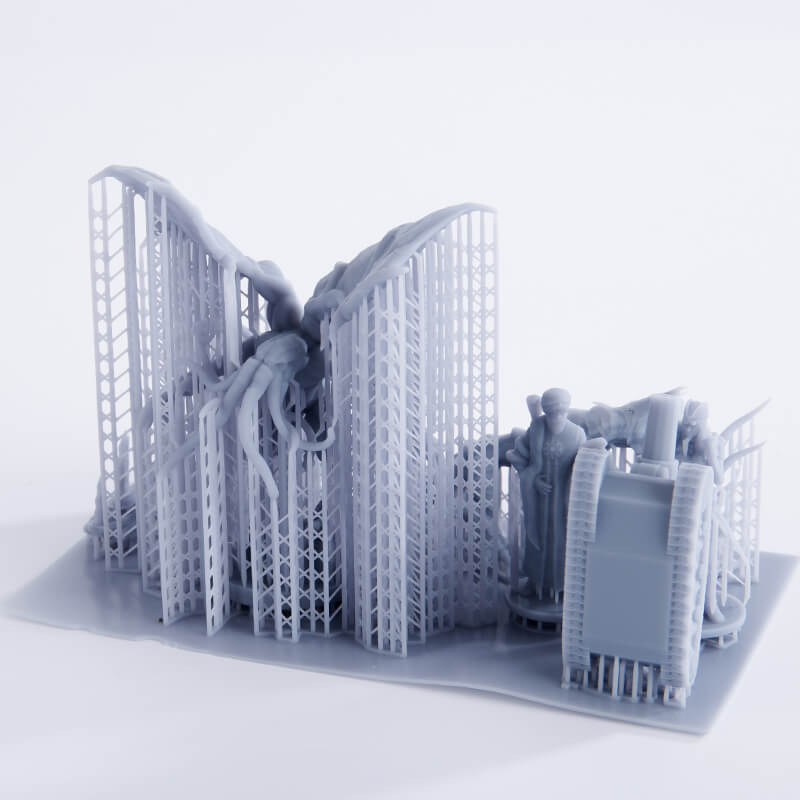

- The wax printing machine is fast, gives all your 3D objects a smooth surface, highly stable, the cost of operation is low.

- The wax printing machine is used in engineering design, artistic designs, handicraft, toys, dental and other small batch productions.

- The wax 3D model uses 3D software modelling such as UG, 3DS MAX, solidworks, ProLE, rhino, CAD, etc.

- The layer of thickness is between 0.02 to 0.1mm. The surface of the finished product is smooth and shows every detail.

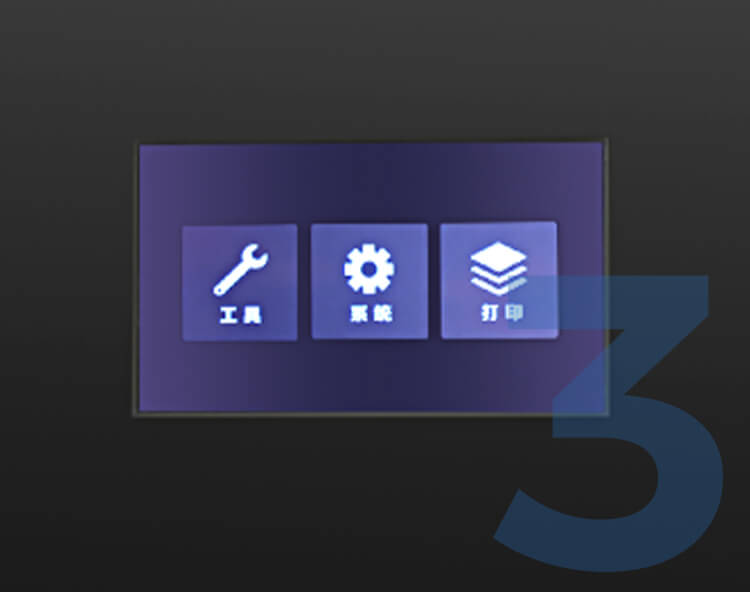

- The Dreambot3D wax 3D printer(DB-293) comes with a touch colour screen with an easy to navigate interface. You can switch between Chinese and English. There is no need to connect to a computer.

- The transparent cover allows you to observe the printing process.

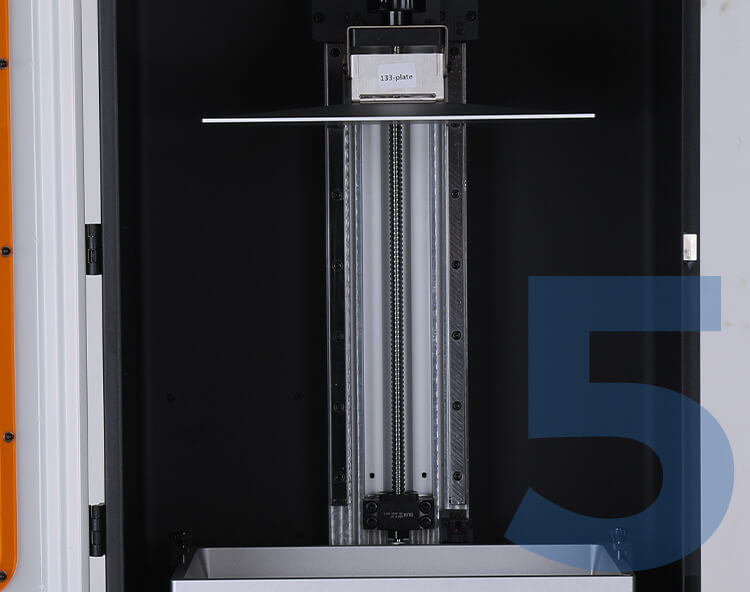

- The z-axis guide rail and the industrial grade ball screw helps to ensure the smoothness of the printing surface and high precision printing.

Test your part

We provide sample testing service, allowing you to check the working quality of our 3D printer before placing an order

6 points why choose us

4K resolution printing

Large size printing

PLC control system

Extremely speed printing

Industrial grade ball screw guide

Reinforced structure

More wax 3D printers

ME-215 LCD 3D Printer

The ME-215 3D printer prints objects at 0.03 to 0.1mm thickness. It is suitable for small printing use because of its compact size.

DB-345 LCD 3D Printer

The DB-345 can be used for medium and large 3D printing. The printing layer thickness is between 0.025 to 0.1mm.

DB-550 LCD 3D Printer

The DB-550 is mostly used for large 3D printing applications. The printing speed makes it suitable for busy production processes.

wax 3D printer buying guide

It’s a common notion that LCD 3D printers or the 3D printing technology is only meant for printing or creating models of numerous objects using resins. If you share such beliefs and you are about to explore this buying guide, we beg to differ at this early stage.

LCD 3D printers don’t only make use of resins when printing materials, wax and metals can also serve as suitable replacements; depending on your industry and the type of object you want to create a 3D model of.

3D printing with wax is suitable for creating a 3D mold out of CAD file. 3D printing technologies create the finished object with no casting or further steps needed.

Without prior design skills, using wax for 3D printing can keep you at the task all day—if you yet to print 3D models using a wax 3D printer, stick with an online instructional video, or better still, seek expert advice from renowned professionals.

With that being said, this buying guide is designed to give you a detailed overview of what wax 3D printing entails, the most suitable 3D printer for wax 3D printing, application field, materials that can be printed on using wax 3D printers and a detailed guide on all the questions and considerations you need to keep in mind when scouting for a sustainable LCD 3D printer for your wax casting needs.

What is An LCD Printer?

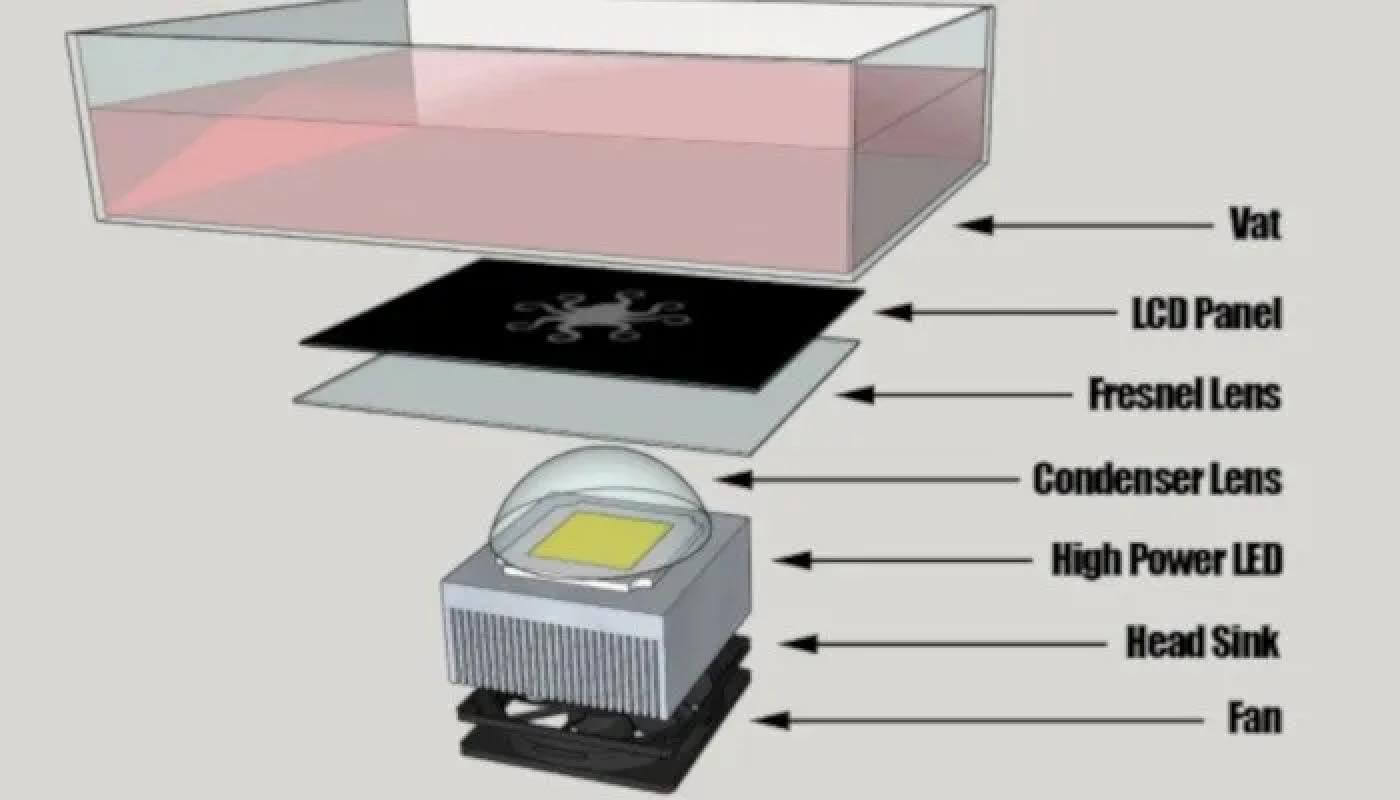

Liquid crystal display printers or LCD printers as they are popularly known are 3D printers use to create 3D models or designs of numerous objects in education, automotive, aerospace, medicine, dentistry etc. LCD printers generate their light source through an array of UV LCDs.

These printers are used to create 3D patterns or images of CAD models using materials such as resin, wax or metals. The images or 3D models obtained using LCD 3D printers are composed of dots.

LCD 3D printers compatible with wax 3D modelling are generally referred to as wax 3D printers. Wax resin 3D printers are widely used in jewellery casting. They are used to design 3D models and patterns for customised artefact and pieces of jewellery.

Most LCD printers are compatible with materials such as resin, wax and metal. However, it’s important to note that the printing process involved in using wax is quite different, and the materials used are not actually pure, natural wax.

1.1, What Does LCD Mean and Where Does it Come From?

LCD means Liquid Crystal Display. LCD is a flat panel display technology commonly used in TVs, computer monitors and 3D printers. It is also used in screens for mobile devices, such as laptops, tablets, and smartphones.

LCD displays don’t just look different than bulky CRT monitors; the way they operate is significantly different as well. Instead of firing electrons at a glass screen, an LCD has a backlight that provides light to individual pixels arranged in a rectangular grid.

Each pixel has a red, green, and blue RGB sub-pixel that can be turned on or off. When all of a pixel’s sub-pixels are turned off, it appears black. When all the sub-pixels are turned on 100%, it appears white. By adjusting the individual levels of red, green, and blue light, millions of colour combinations are possible.

LCD technology is amongst the few defying the conventional sense and science of reasoning. LCD is capable of existing as both liquid and crystals. That’s LCD’s are not entirely solid neither are they entirely liquid. LCD molecules tend to hold better in such a state.

1.2, How Does an LCD 3D Printer Work?

Wax 3d printing essentially means melting the thermoplastic plastics, and then spraying the finer “threads” at the nozzle, and then spraying up layer by layer, and layering up layer by layer. In essence, 3d printing is just a combination of layer by layer “planes” to make it three-dimensional.

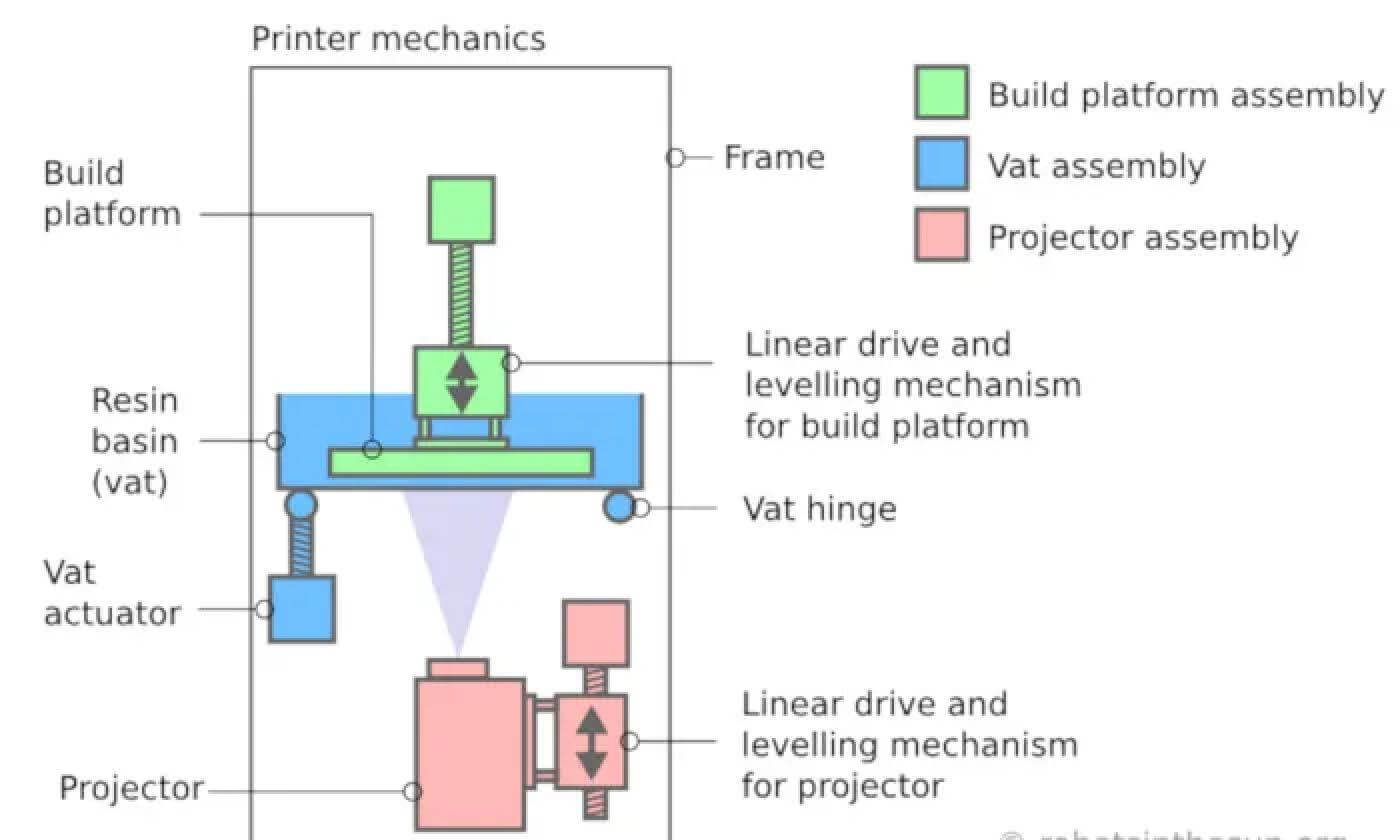

LCD 3D printers display image by sending light from a metal-halide lamp through a prism or series of dichroic filters. This dichroic filter separates light into three polysilicon panels. In simple terms, a liquid 3D printer uses an array of UV LCD as its light source. The printer shines light directly from the flat LCD panel in a parallel fashion onto the build area.

As the light travels through the light source, the individual pixels open up to allow light to pass or close to block the light. This combination of open and closed pixels creates room for the liquid polymer 3D printer to produce multiple colours and shades on the projected image.

The light emitted from an LCD 3D printer isn’t expanded—that’s, it doesn’t spread beyond its projected frame. When using these 3D printers, you can design patterns and images of multiple variations; rest assured you wouldn’t experience pixel distortion halfway. Note that unlike most other resin printers, the LCD 3D printer print quality depends on its LCD density.

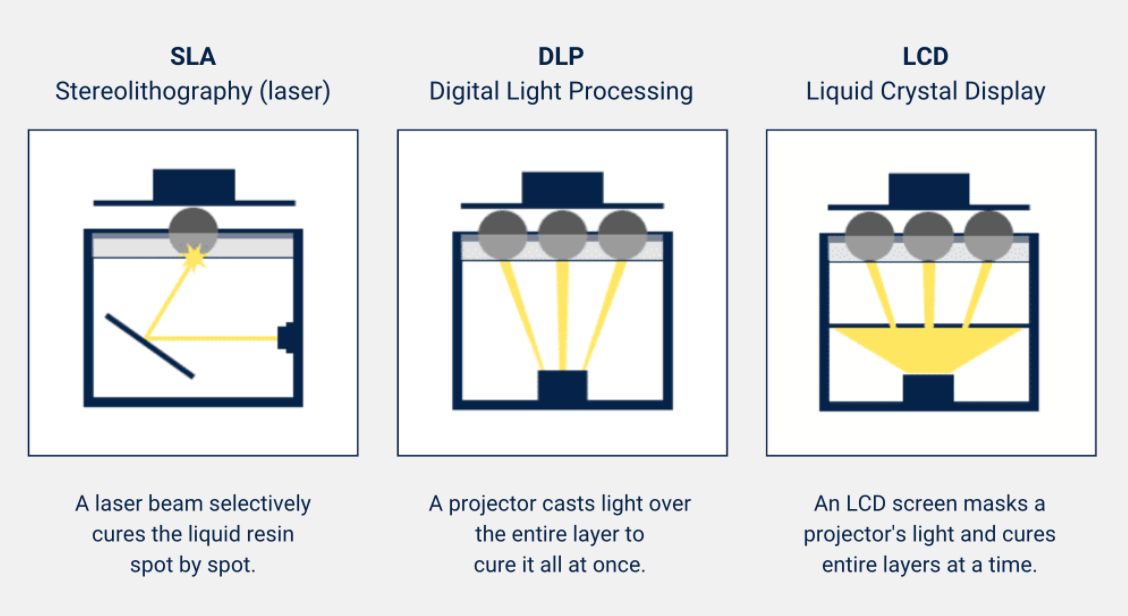

1.3, LCD vs DLP vs SLA; All You Need to Know

With detailed info on the 3D wax casting process and how an LCD 3D printer helps you obtain smooth, durable and accurate surface finish for your 3D models, its high time we focused on helping you choose the right LCD machine for your design and prototyping task.

While it’s obvious that this buying guide is optimised to guide you through the buying processes of an LCD 3D wax printing machine, we believe it’s necessary we highlight some of the other notable wax 3D printers available in the market and why our resolution to stand behind the LCD 3D printers holds firm.

A simple google search would expose you to DLP and SLA wax 3D printers. And just like LCD printers, SLA and DLP 3D printers possess multiple 3D variants built to help simplify the wax printing process. However, the durability and efficiency DLP and SLA 3D printers provide to hobbyist and professionals in the industry can in no way be compared to that of LCD wax 3D printers.

DLP

Digital light processing 3D printers make use of projectors to create 3D models and patterns of a given object making use of projectors. DLP projectors are shone through a lens to a DMD. The DMD directs the light to the bottom of the resin tank making room for the lights pixel/reflection to cover a wide area.

DLP wax 3D printers are quite fast and can complete bulky tasks within a limited amount of time. However, the number of pixels on a DLP projector is the same regardless of the size of the print. In simple terms, using a DLP 3D printer to create wide 3D models or patterns can leave you with end products whose edges are filled with tons of distorted pixels.

SLA

Stereolithography Wax 3D printers popularly known as SLA 3D printers are amongst the first variants created. Stereolithography (SLA) uses an additive manufacturing process that belongs to the Vat Photopolymerization family.

In SLA, an object is created by selectively curing a polymer resin layer-by-layer using an ultraviolet (UV) laser beam. The materials used in SLA are photosensitive thermoset polymers that come in a liquid form.

SLA printers are seen as the innovation behind most of the reputable 3D printers available in the market today. Just like DLP printers, the laser beam generated by SLA printers are projected from below the tank, but unlike DLP, SLA printers require a manual tracing of each layer with the laser.

LCD

Liquid crystal display printers, also known as LCD 3D printers make use of LED lights to create 3D models of a designated CAD design. The liquid 3D wax printing process involves flashing entire layers at once to imprint patterns on the material housed in the resin tank without the interference of an external object or material.

Unlike SLA and DLP, the light emitted from LCD printers isn’t expanded; it doesn’t spread beyond its projected frame. That’s when using an LCD 3D printer; you can create wide or narrow models rest assured issues of pixel distortion wouldn’t arise at any point in time.

Also, the LCD lost wax 3D printing method involves flashing the entire layer of the object at once, so you don’t need to worry about the modelling defects that come with manually tracing each layer of the laser.

Difference Between LCD, DLP, and SLA Wax 3D Printers

Cost: on a levelled scale, LCD wax 3d printers are regarded as a cheaper option that DLP and SLA. Just like SLA and LCD, DLP printers come in different sizes and shapes, but unlike the other two, the credibility of most DLP printer is based on its gigantic nature, size or shape.

SLA wax 3D printers on the hand are quite outdated are not held in high regards by most professionals.

If you are looking for a cost-effective 3D resin printer, then the LCD wax 3D printer should be your preferred pick.

Resin Curing Method; DLP printers make use of projectors—quite sustainable but prone to leave distorted edges. SLA printers make use of a laser beam—not in any way durable due to the need to manually trace each layer of the laser. LCD wax 3D printers make use of LED lights—quite durable, not prone to distorted edges and do not require manual tracing.

Printing Speed: in terms of printing speed, LCD and DLP wax 3D printers are exceptionally fast. However, the same cannot be said for SLA.

Print Quality: in comparison with DLP and SLA, LCD wax 3D printers creates models with a smoother and more accurate surface finish. LCD wax 3D printers should be your preferred pick if the print quality is of utmost importance.

Overall, LCD 3D printers are fully equipped to help you cater to your day to day printing needs while allowing you to enjoy the professional privileges you require to excel in the 21st-century market.

For more information on the remarkable opportunities you get to enjoy from making an LCD wax 3D printer your preferred pick, ‘Get in Touch’ You can obtain a detailed overview of the product from our support team.

Application Field of LCD Printer

We settled the usage and product difference between numerous wax 3D printers in the previous chapter focusing on the dominance of LCD 3D printers above DLP and SLA.

With that info in mind, let’s consider some of the leading industries where 3D printers are widely used and its impact thus far.

Note that while our focus is firmly fixated on the impact LCD wax 3D printers are providing to hundreds of hobbyist and professionals worldwide, we didn’t in any way limit the application field info to only industries where LCD 3D printer usage runs rampant;

The sections below comprise of industries where LCD, SLA and DLP printers play a vital role, and the day to day influence the 3D wax printing machine has on its customers.

2.1, Used in the Jewelry Industry

The fair mention of the term ‘wax 3D printers’ sparks interest firmly associated with the jewellery industry. Many jewellers and goldsmith believe this notion holds based on the fact that one of the most appreciated jewellery making methods goes by an identical term ‘lost wax casting’.

As to whether 3D printers are enjoying widespread usage in the jewellery industry in comparison to the other fields listed out, it’s impossible to say—there are no stats to justify the figures.

However, there is a notion that every individual, whether affiliated with the jewellery industry or not can attest to the fact that the introduction of wax 3D printers heightened the design and creation process of artefacts and pieces of jewellery within the industry and beyond.

Back in the days when there were no CAD models to create or replicate designs easily, jewellers and goldsmiths had to design models manually. That’s they had to somehow design and structure a model/mold similar to that of their client’s using molding tools.

Designing molds or models without a well detailed computerise interface made the design and creation process a complex and highly complicated job.

Wax 3D printers didn’t just make the design and development process smooth and efficient; its introduction also helped demystify the complex nature of the job, helping jewellers and goldsmith create formidable prototypes and designs within short periods. Wax 3D printers also made jewellery customization cost-efficient.

Today, amongst the many 3D printers available, LCD printers are regarded as a prioritised pick by most experts in the jewellery industry. The ever-evolving change and unique designs LCD wax 3D printers bring to the table daily have helped clear a lot of misconception and contradictions surrounding the usage and efficiency of 3D printers in the industry.

If you are a jeweller or goldsmith looking to enjoy greatly improved detail and precision that provides fascinating models from master designing your 3D model to post-processing your finished piece, we recommend you explore our catalogue—we possess numerous variants of LCD wax 3D printers flexible enough to cater to your dynamic printing needs.

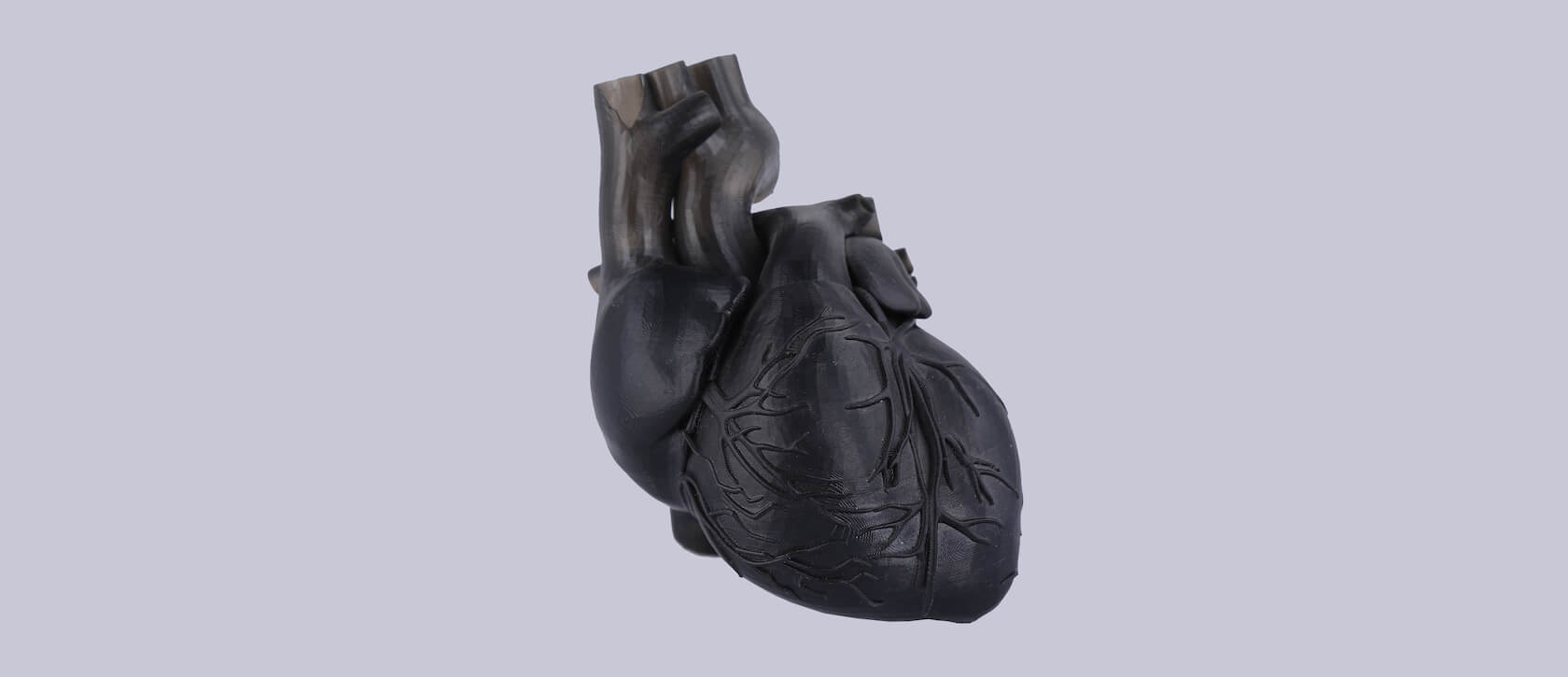

2.2, Used in the Medical Industry

Whether you are a dentist trying to treat a patient with a decayed tooth, a surgeon trying to explain the complex processes and procedures involved in the surgical operation you are about to carry out or a doctor whose day to day task revolves around counselling and prescribing—wax 3D printing machines are essential to productivity and ease of work.

3D printing in healthcare makes it possible for medical professionals to provide patients with a new form of treatment in several ways. 3D printing is used for the development of new surgical cutting and drill guides, prosthetics as well as the creation of patient-specific replicas of bones, organs, and blood vessels.

To help you further understand the impact of 3D printers in the medical sector, let’s focus on niche-specific medical services.

Dental Sector: dental procedures are extremely complex. Every dentist knows how important accuracy and repeatability is to the profession. And since it is impossible to hide tooth problem or shove it under the desk to avoid visiting a dentist, deploying sustainable measures to demystify the complexity of the process is essential.

LCD wax 3D printers serve as a viable machine for creating biocompatible materials. These materials are used to replace or restructure a worn-out tooth. Biocompatible materials consist of intraoral parts such as night guards, surgical guides, and digital dentures.

While a dentist can opt for any 3D printing machine in creating models of specific biocompatible materials, it’s important you note that the process needs to be streamlined, production speed and scalability also needs to be considered, so the procedure is easily repeated with accuracy. And when it comes to accuracy, LCD wax 3D printers take the front role.

Surgery: how many times have you found yourself awed by the names and description most surgeons attribute to simple and in some cases, casual medical procedures? You are not alone. Yeah, surgical operations are complicated, but its common belief that surgeons can help demystify its complexity by using simple and self-descriptive terms.

However, while the industry might be plagued with complex terms, the need for a detailed and descriptive explanation of the procedures involved in every surgical operation is still paramount. LCD 3D printers can customize pre-surgical planning models, identify patient-specific anatomical features, shape implants during surgery, and help communicate complex surgical procedures to patients.

Medical Equipment: hundreds of equipment are used in the medical industry on a daily. Most of this equipment were prototyped and designed using 3D printers.

LCD wax 3D printer is widely used to create 3D models of most of the equipment used in the medical industry. LCD printers built its reputation on the precision and accuracy it provides. If you are in search of a viable 3D printer to design or prototype any medical equipment—place a call today.

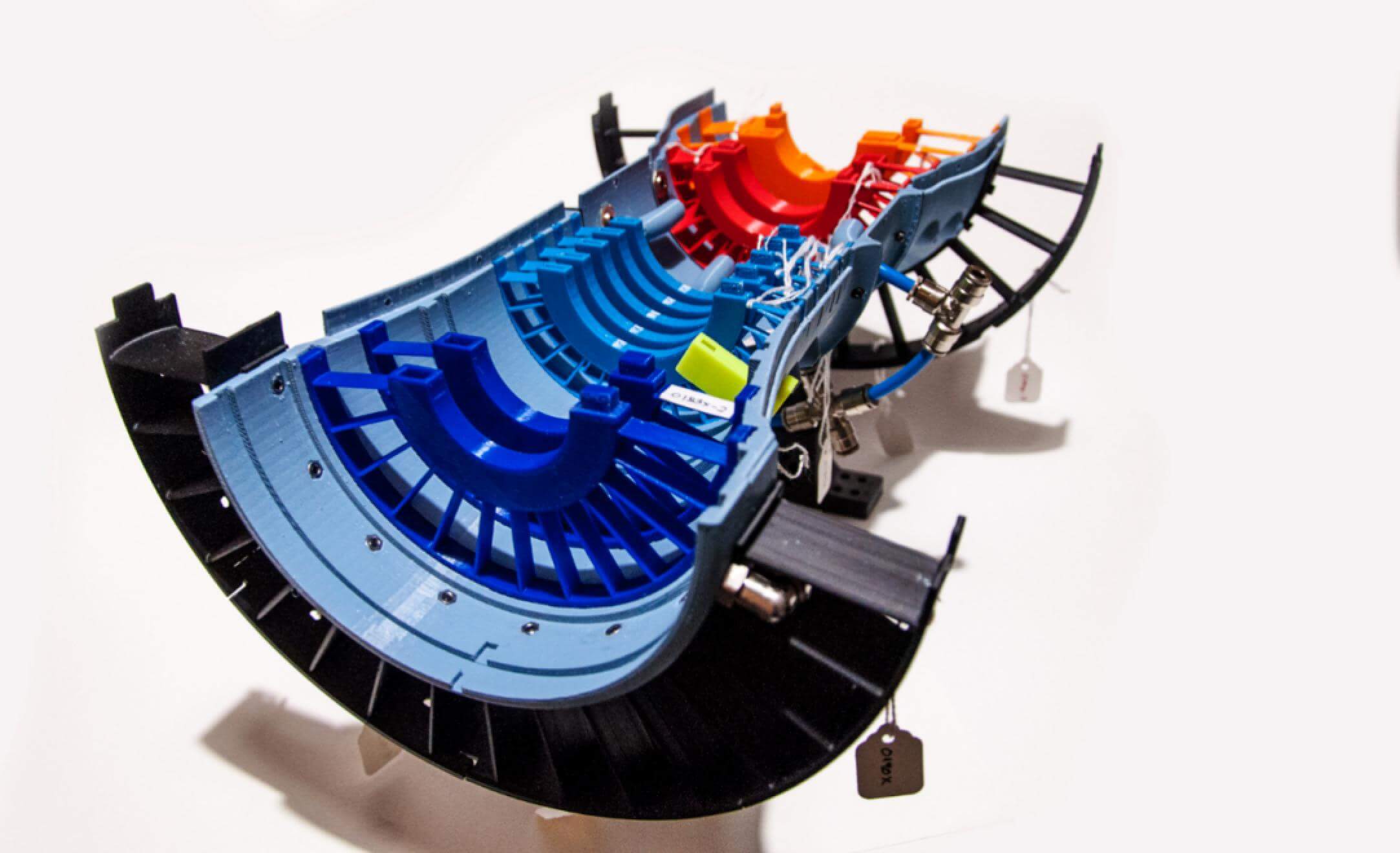

2.3, Used in Production and R&D

From design iteration to manufacturing and distribution, 3D printers play an important role all round. Every product found in the market today was once at its designing and framing phase. Be it a cup or a laptop, sewing machine or mannequins, these products where at one point just ideas yet to be actualised.

3D printers help bring ideas to life. It helps experts in the R&D industry gain a better understanding of the object they are trying to create and also help design prototypes using 3D models to streamline a smooth and efficient production process.

Every manufacturing industry has an R&D team powering their innovations, so it’s okay to say that wax 3D printing machines are essential in almost every industry around the globe. To further demystify the importance of LCD wax 3D printing machines in the R&D industry, let’s lay special emphasis on its usage by shoe companies to create shoe soles and molds.

Unlike in many other R&D industries, shoe companies mainly make use of manual tools in designing or creating customised shoe models for clients. While this is quite effective for the hobbyist looking to satisfy the needs of a small client base, renowned companies like Adidas and Nike can’t toe the same line.

The introduction LCD 3D printers in the design and creation of shoes soles and molds help streamline a fast and efficient manufacturing process. With an LCD wax 3D printer, strict adherence to instructions, well-designed prototypes and a detailed finished product is guaranteed.

LCD wax 3D printers are viable printing machines not just to experts in the shoe and sole production lines, but also to manufacturers of electronics, fabrics, plastic and so on. Nonetheless, if you are looking to join the manufacturer’s bandwagon in the R&D industry and you are yet to find a suitable LCD 3D printer for the job, don’t hesitate to contact our support service—we are available round the clock.

2.4, Used in Education Industry

Learning never ends, not just because we exist in a world governed by a constant flux of change, but also because our ability to create and recreate is limitless. You might be wondering, how are 3D printers influencing the educational sector?

Of what importance are wax 3D printers to students at a primary level who are yet to understand the basic of algebra? How can an LCD 3D printer positively influence the workload of a teacher trying to make a class of over 200 students navigate the dynamics of the quadratic equation?

We know a lot of thoughts are running rampant in your mind at this moment. Still, all we ask is that you stick with this buying guide, the impact LCD wax 3D printers are having in the educational industry would be communicated in simple and detailed terms in a bit.

3D printers are renowned for their ability to make even the most complex information look simple. From how the tumour on the right hand can affect the lungs to how the genetic makeup of a kid can be traced back to his father, 3D printers demystify them all.

3D printers provide a real-time descriptive analysis of otherwise complex situations, hinting not just the average joey on the remarkable possibilities such a situation can lead to but also telling the story is a simple yet detailed manner.

Visuals from LCD wax 3D printers are used to make learning fun on a primary level. A well-designed 3D model can help a student transcend time and space in ways conventional teaching methods deem impossible.

With 3D models, learning becomes interactive, perceptions are heightened, and the teaching spectrum is made accessible to the bourgeois folk.

2.5, Used to Make Various Models

3D printing is a process whereby three-dimensional objects are assembled from a digital file. That’s 3D printing involves creating real-time representations of CAD models and design.

3D printing is a powerful technology. It allows you to bring to life anything you have in mind. With 3D printing technology, you can now see, hold and feel whatever is in your imagination. For those new to 3D printing and are eager to 3D print their first project, you can start with the small stuff and work your way up.

With a wax 3D printer, you can create a 3D print of anything and everything. While a lot of folks feel 3D printers are quite expensive and its usage is associated mainly with individuals in the R&D or jewellery industry, this is a myth—and we beg to differ. 3D printers are machines suitable for use by anyone and everyone under the sun.

However, you must note that the ability of your 3D printer could limit the things you can 3D print. 3D printers come in different range and size and are suitable for home, office and enterprise use. The wax-resin 3D printers widely used by experts and hobbyist in different industries include LCD, SLA and DLP.

Amongst the three printers listed out, LCD wax 3D printer is our preferred pick. The printing accuracy, precision and unrivalled modelling sequence it brings to the industry are seconded to none.

LCD printers are extremely responsive machines capable of giving you an out of the box printing experience. LCD wax 3D printers are cost-efficient, user friendly and serve as an ideal gift for kids.

So, whether you are looking for a small 3D printer your child can use in creating fun models of household items, or you are a hobbyist trying to make the best out of your craft; know that we have an LCD wax 3D printer for you.

All you need do is get in touch with our support representative, and we guarantee, a 3D printer will be sitting dock at your doorstep within 3 to 5 business days.

Which Resins can be Printed on LCD 3D Printers

There are multiple resins in the market but very few 3D printers can handle the dynamic features they come with. This chapter is detailed to provide deep insight on all the 3D resin printers available in our collection and their compatibility with numerous resins.

3.1 For Transparent Resin Printing

If you have encountered issues with the quality of print or smoothness of the finish product while trying to create patterns on semi-transparent materials during the resin printing process, you don’t have to settle for the notion that it’s unavoidable.

With our DB-345 LCD 3D printer, you get to enjoy an efficient cooling process free of bubbles. Our DB-345 LCD wax 3D printer comes with a 15.6-inch 4K high-precision screen and possesses a printing speed of 20mm/h—that’s you get to enjoy HD pixel printing and complete complex task within a short period.

Exclusive UV Heat Dissipation Chanel: LCD printers, as you already know, make use of UV light to imprint patterns. Using an LCD resin wax printer for an extended period can result to overheating or malfunctioning.

At Dreambot3D, one of our primary goals is to help our customers enjoy an impeccable printing process for long hours. We built our DB-345 LCD 3D printer with an exclusive heat dissipation channel that helps regulate our liquid printing machine’s temperature, enhance print quality, and keep the LCD machine operating far longer than its warranty certifies.

4K High-precision Screen Exposure Imaging Display Technology: no one likes a complex machine. No matter how proficient a device is, complexity in its controls can hinder functionality.

We are well aware of this fact, and to ensure our customers are enjoying the all-round proficiency our DB-345 LCD 3D printer offers, the machine comes with an interactive panel that supports real-time human interaction. That’s you get to communicate with the DB-345 LCD 3D printer at an intelligent and humane level.

High Precision, Smooth and Delicate Surface Finish: Precision in design and finish is of utmost importance not just to the day to day hobbyist but also to the final consumer. A machine that doesn’t guarantee a finished product of high accuracy doesn’t only hinder sales; it can chase away existing customers.

At Dreambot3D, we love it when our customers provide feedback with a subtle yet priceless smile on their faces. The DB-345 LCD 3D printer is optimized to provide high precision with a smooth and delicate surface finish to all prints.

3.2 For Flexible Resin 3D Printing

When it comes to flexible resin 3D printing, the most viable option is LCD 3D printers. There are numerous models and variants of LCD wax printers available in the market. We know you wouldn’t fancy scouring multiple catalogs to find the right liquid 3D printer for flexible resins.

To hasten the process, we recommend trying out our DB-345 LCD 3D printer. The DB-345 is suitable for transparent as well as flexible resin 3D printing.

If you are an expert or hobbyist in the shoe production industry and you are looking to write shoe molds, you would definitely value the productive influence of the ME-345 LCD 3D printer. Here are some of the perks you get to enjoy from using our DB-345 LCD wax 3D printer.

USB plug-and-play stand-alone offline printing: many printing companies shy away from LCD printers because of their reliance on computer plug-ins. Not anymore; the DB-345 LCD 3D printer is built to stand alone.

Whether you are offline and need to create a 3D model using flexible resins or are always finding it hard to configure your LCD printer to easy printing, the DB-345 got you covered. The machine is built to operate in offline mode with a transparent cover that allows you to observe your prints first-hand.

More Uniform Illumination: the DB-345 LCD wax 3D printer relies on light-activated resins to build objects. This LCD printer uses a large-format light source and directs the UV light into areas layer by layer to solidify them.

That’s you get to design 3D models or imprint patterns on materials systematically and uniformly. The Stereo-light curing 3D printing also provides an incredible surface finish with fine adhesion to details.

Reduced Resonance: having a noisy machine doesn’t just attract lousy neighbors; it also limits your workflow. At Dreambot3D, we know how important time is to productivity and wouldn’t for any reason create machines that hinder workflow.

The DB-345 LCD wax 3D printer comes with an all-metal integrated shell built to make printing more stable and improve accuracy. Our DB-345 LCD wax 3D printer is also built with a touch-screen interface that supports man to machine interaction. You can interact with the machine via Chinese or English.

3.3 For High Hardness Resin 3D Printing

For high hardness resin 3D printing, we recommend you check out our ME-345 LCD 3D printer. The ME-345 wax LCD 3D printer uses cutting-edge light-curing 3D printing technology, which places liquid photosensitive resin in the printing area and selectively irradiates it with ultraviolet light.

The material is cured layer by layer under the action of ultraviolet light to form a three-dimensional product. The printing size is large, fast speed, smooth surface, high stability, low cost of use, widely used in engineering design, artistic handicrafts, dental care, and small-batch products.

Here are some of the Extraordinary Perks you will love the ME-345 LCD 3D printer for:

Humanised Operation Interface: yeah, there is no doubt that the ME-345 wax 3D printer is big and bulky. A machine this big is certainly going to leave a lot of customers confused about its operational sequence.

Like always, Dreambot3D R&D team considered this factor. The ME-345 3D printer is equipped with a new UI interactive interface that supports humanized interaction. You can operate the machine via a man-machine communication sequence that supports English and Chinese.

Uninterrupted Workflow: creating 3D models might not require the endless hassle and stress individuals operating on a 9 to 5 basis experience daily, but that does not in any way means the workflow doesn’t get tedious at times.

Our ME-345 wax printing machine is designed to support the alternate use of multiple work platforms. That’s you can quickly replace a 3D model you are working on with another without interrupting the workflow. The LCD 3D printer can function for 24 hours non-stop without affecting the overall work quality.

Automatic Detection and Feeding: the ME-345 LCD wax 3D printer comes with a 2*1kg material box that automatically detects and replenishes low-volume reminders to ensure sufficient material, constant material, high stability, simple operation, plug-in and use, and clean flow. With this 3D printer, you get to enjoy a fast, efficient, and detailed printing process void of excessive waste.

3.4 For Castable Resin 3D Printing

With our focus fixated on proffering the most durable LCD 3D printer for creating smooth and efficient 3D printings using castable resins, we believe it’s high time we introduced the ME-192 3D printer.

The ME-192 3D printer goes with the hashtag ‘born to be extraordinary and create the future.’ This tag gained traction around the ME-192 due to the remarkable features it possesses.

Unlike most of the other LCD 3D printers stocked in our store, the ME-192 3D printer provides a more delicate and detailed printing and is backed by an LCD Light-curing printer with nine high-end configurations and smart black technology.

Higher Printing Accuracy

Every expert of hobbyist in the jewelry or shoe molding industry know how important a fast 3D printing machine is to the production line. The ME-192 LCD resin printer is backed by a 4K black and white high definition screen that allows users enjoy a flexible operating sequence.

With the ME-192, you get to enjoy a printing process backed way faster than that of the average industrial LCD 3D printer. The ME-192 printer can print as fast as 40mm/h without affecting print output, quality or accuracy.

CNC Machining: if you have been in the jewelry casting line for a long time, you would definitely look at the good old days of hand-made cast with a smile thanking technology for the remarkable advancement it has brought thus far.

With our ME-182 LCD 3D printer, you don’t have to design or structure any model manually. The ME-192 is an automated printing machine. Designs are modeled via pre-programmed sequences.

Larger Molding Area: if you have been looking for a wax 3D printing machine with room for you to enjoy creativity without boundaries, then you need look no further.

The ME-192 LCD wax 3D printer comes with a large molding area that can complete bulky printing tasks at once. The large molding area is backed by a more stable slide rail performance helping retain precision and balance regardless of the size of the castable resins inserted in the molding area.

Our latest invention, the ME-500 printer broke remarkable boundaries with the exceptional screen size it possesses. Purchasing our ME-500 LCD 3D printer grants you access to a large screen machine of up to 24 inches.

With the ME-500 at your disposal you can print 3D models of choice rest assured you wouldn’t have to contend with a small interactive screen that’s not flexible enough to touch nor bold enough to read.

3.5 For Photosensitive Resin 3D Printing

Photosensitive resins are a mixture of photo-initiator, monomer polymer, and prepolymer; this material can be cured under ultraviolet light focusing on specific wavelengths.

The model printed with photosensitive resin material has a smooth surface, high printing accuracy, and high molding quality. Photosensitive resin 3D printing is compatible with the SLA, DLP, and LCD 3D printers.

Focused on LCD 3D printers known to handle all the challenges of photosensitive resin 3D printing proactively, we present the ME-345 LCD 3D printer. ME-345 has a larger printing space, high-volume product mold, low costs, and a short production cycle.

High-Resolution Surface Effect: Purchasing the ME-345 LCD 3D printer grants you access to materials such as ABS resin material tray, spare film kit, and post-processing cleaning box.

With such a supporting list backing up the Tiny XY spot (0.008mm²) and fine layer thickness selection (0.02mm), the ME-345 printer is optimized to provide a printed product with clear details smooth surface finish is guaranteed.

Feel the Fun of Printing: are you tired of a boring printing process? Use this Dreambot3D 3D printer to step up your game. ME-345 uses cutting-edge light-curing 3D printing technology, which places liquid photosensitive resin in the printing area and selectively irradiates it with ultraviolet light.

The material is cured layer by layer under the action of ultraviolet light to form a three-dimensional product. The printing size is large and can design multiple 3D models at high speed.

3.6 For Heat Resistant Resin 3D Printing

While most of the machines available in our store can serve as durable options for heat resistant resin 3D printing, we recommend the ME-192 LCD 3D printer. The ME-192 is built with a layer thickness accuracy is 0.02-0.1mm optional, and the single spot area is only 0.01mm². The surface of the finished product produced by the 3D printer is smooth and delicate, showing the beauty of details.

Support Wireless Transmission Printing: with the ME-192 3D printer, you can enjoy a wireless transmission printing process. While a computer’s presence in designing and creating a CAD model is still essential, the machine can function perfectly via wireless transmission of the design. That’s you don’t have to always connect the 3D printer to a computer each time you want to finalize a heat resistant resin printing task.

No need for Levelling Design: the ME-192 is not only popular for the unique surface finish it provides, but it’s also regarded as a more convenient option. The machine leaves room for you to access a new generation of leveling-free designs and enjoy one-time leveling. The machine is firmly fixed by 4 screws operating via a self-leveling core.

Shortens Production Cycle: when using a heat resistant resin material for printing, and the molding accuracy is high, and the processing of accessories with complex structures is difficult. 3D prints can be molded at once, and the molding strength of the accessories, which is high, can be directly applied to the product. That’s with a ME-192 LCD wax 3D printer at your disposal; you get to finalize hefty printing tasks within a short period of time.

3.7 For Conductive Resin 3D Printing

When it comes to conductive resin 3D printing, any LCD 3D printer can efficiently handle the task. In order not to keep you second-guessing yourself each time you come across a durable 3D printer for the job, we recommend checking out our DB-345 printer.

Our DB-345 LCD 3D printer comes with standard version configurations. That’s if you have ever used any LCD 3D printer before, you wouldn’t have a hard time navigating your way around the control sequence. With the DB-345, you are guaranteed a printing thickness accuracy that fully reflects the products’ details. Some of the bonus you get from purchasing our DB-345 printer include

High-definition printing: the DB-345 LCD 3D printer leaves room for every bit of the printing process to be shown in detail. The machine is built to accurately reflect the model’s subtle structural changes and add a qualified delicate texture till the physical model is created.

Life-Time Technical Support: at Dreambot3D, it’s not just about producing an innovative machine at low cost; it’s about satisfying an individual’s needs. Purchasing our DB-345 machine grants you automatic access to lifetime technical support—that’s you can contact our support team on a 24 hours basis, 365 days a year rest assured someone would be active to tend to your every need.

Years Warranty Policy: While all our machines are tested multiple times during the research and development phase, we are well aware that issues can arise at any time during or after shipping. Regardless of when and how such problems occur, we got you covered. Using our DB-345 machine to cater to your conductive resin printing needs entitles you to a 1-year warranty policy.

How to Buy a 3D Printer — Questions You Should Ask

In the previous chapters, we highlighted most of the information you would need to make an informed decision—stating the basic difference between the available wax 3D printers, their industries and the type of resin materials they can be used on.

We believe that since you are still reading, you have made up your mind about purchasing an LCD 3D wax printer; although we are yet to confirm if the variants listed in chapter 3 were appealing enough to make you pay a visit to our store.

However, since it’s impossible to finalize the wax 3D resin printer buying process without knowing and asking the right question, we detailed this chapter to walk you through the process.

The following sections contain all the internal and external factors you need to consider when trying to buy a wax 3D printer. Be it in-depth analysis of the material to be printed on to the size of print, brand and safety configuration; this chapter covers it all.

4.1, Before Buying, You Should Consider Your Own Needs

In this buying guide, we tried as much as possible to ensure we don’t leave any information to chance. From the basic comparison of the refreshing printing experience SLA, DLP and LCD printers provide to individuals in diverse industries to their durability, efficiency and printing style, we have covered it all.

But even at that, we still have little to no influence over your buying decision. When it comes to buying 3D printers, it all boils down to your own needs. We might be able to pinpoint all the features, attributes and specification that makes a 3D printer worth your funds, but that doesn’t in any way overrule personal requirements.

If you are wondering how you can identify your personal needs and if there are factors to put into consideration when trying to pinpoint your needs, stick with us, we will highlight such questions in a bit. But first things first, we need to be certain you know how to prioritise needs over wants.

For instance; LCD wax 3D printers with high screen resolutions are more expensive than other models. While having a high screen resolution printer is good for business, its usage, efficiency and durability can come into question when trying to differentiate needs from wants.

If you are in the jewellery or architectural industry, we recommend you prioritise high screen resolution wax 3D printers as a need, but if you are a hobbyist looking to print day to day household items, screen size and resolution won’t count for much.

Now to the big question, how can I identify my personal needs and what factors do I need to put into consideration when trying to identify my needs? To get accurate answers to the above-listed factors, detail out your answer to the following questions.

On a scale of 1 to 10, which feature or services is the most prioritized for the LCD wax 3D printer I am looking to purchase? Are you of the notion that a machine capable of providing a smooth and efficient finish overrides all other features? Are you encountering overheating issues with your current machine and desire an LCD wax 3D printer offering an exclusive UV heat dissipation channel?

While we can go on and on about the basic questions to consider when trying to pinpoint your needs, the final decision all comes down to your prioritised wishes and desires for the printing task at hand. Detailing out your own needs takes you a step closer to the ideal wax 3D printer.

4.1.1 What is the Thing to Be Printed

The ideal goal of most individuals seeking 3D wax resin printers is to enjoy a printing process backed by greatly improved detail and precision that provides fascinating 3D models. While this goal is very much archivable, it’s important to note that the thing to be printed goes a long way in determining the viability of your print.

LCD wax 3D printers can be used to print materials of different size and shapes. Its usage spans across multiple industries and its durability are second to none. Before settling for any 3D wax printer, try as much as possible to get a detailed overview of the type of resins that can be printed on using the preferred 3D printer.

Bear in mind that not all LCD 3D printer manufacturers provide customers with the basic information as to the type of resin that can be printed on using their printer—carrying out personal research or putting a call through to a support rep might be required.

However, as we stated in chapter 3, all our wax 3D printers are compatible with multiple resins. At Dreambot3D, providing our clients with industrial-grade printing machines of superior quality is a key priority.

If you’ve opted for any of the wax 3D printing machines available in our collection and still sceptical as to whether the machine can handle the type of resins you regularly use in creating prints, we recommend you book a call through to our support team.

4.1.2 What is the size of the Print?

Over the years we have been in business, we have had the opportunity of interacting with consumers from different countries and region. One of the most highly influential factors most hobbyist or professionals who have walked through our door to purchase a wax 3D printer ignore is the size of the print.

Yeah, it’s practically impossible to determine the exact size or specification attributed, or that would be required in most of the prints you make—especially if you are a business owner looking to satisfy the needs of clients from different parts of the world—but totally ignoring the print size a wax 3D printer can create is unacceptable.

LCD 3D printers garnered renowned usage ahead of SLA and DLP not just because of its printing speed or the remarkable finish product its capable of providing, but also because of its ability to perfectly create sustainable 3D models on wide materials.

Before buying any LCD wax 3D printer, try to know the type of resin it can print on and whether it’s durable enough to print perfect models on wide materials without leaving distorted edges.

4.1.3 What are the Special Needs for Printing Materials

While most LCD wax 3D printers can be used to print resins of different types, all resins do not possess the same features and do not provide the same finish. The finished product you obtain from printing with an ABS resin is quite different from what PLA resins offer.

When buying an LCD wax 3D printer, take into consideration the special requirement of the printing material. To ensure you are buying an LCD printer that can cater to the dynamic makeup of different resin materials, proffer suitable answers to the below questions;

Do the LCD wax 3D I am about to purchase possess a user-friendly system not susceptible to print fails? What’s the heat dissipation performance of the wax 3D printer like? Would a printer with a higher screen resolution help me create a 3D model with my PLA resin fast or can I settle for one with the basic screen resolution and still enjoy the unique printing experience I desire?

Every printing material possesses special needs and features that if not thoroughly considered, can affect the efficiency and durability of your 3D printer. If you are having a hard time navigating your way around the internal factors necessary to purchasing an LCD wax 3D printer, contact our support team today; we will get you up to speed within the shortest possible time.

4.2, When Buying Consider External Conditions

You now know the internal conditions that can affect your buying decision; let’s talk about external factors. Note that the internal considerations discussed earlier are based on personal preference; that’s those are factors you may or may not want to consider.

However, the eternal wax 3D printer buying factors we are about to discuss is based on the reliability of the machine; not putting these factors into consideration can affect the efficiency of your production line.

4.2.1 Determine Your Ideal 3D Printer Style

A simple Google search would expose you to countless variants of LCD wax 3D printers. Most of the printers are optimised with different features and specifications geared towards tackling dynamic printing needs. Your ideal 3D printer style is dependent on the type of specifications and requirement you desire from a wax 3D printer.

Are you looking for a lost wax 3D printer that’s not messy, smelly or slow? Or a printer built with fewer settings to adjust? Or maybe an extremely responsive wax 3D machine that prints with highly improved detail and precision?

It would be best if you determined the ideal printer style you are in search of before scouring the catalogues of renowned manufacturers or you might end up purchasing a durable wax 3D printer not optimised to provide the accuracy and precision you desire.

Note that regardless of what the features or specification of your ideal wax 3D printer might be, Dreambot3D got you covered.

4.2.2 Resolution Requirement of the Machine

Most LCD wax 3D printers are built to ensure consistent temperature throughout the building process, but not all can give you the surface finish you desire. Wax 3D printers vary based on resolution, shape and size, and the pricing and buying process are hugely dependent on these features.

While it’s nice to have an LCD wax 3D printer with high screen resolution in your production line, note that these printers are quite expensive and sometimes these machines are viewed as wants instead of needs—that’s quite luxurious but not necessary.

To be on the safe end, try to vet the resolution requirement of wax 3D machines needed to run your production line efficiently. Knowing the resolution requirement of your machine can help you save cost and land the most lucrative LCD wax 3D printer for your printing needs.

4.2.3 Choose a Reliable Brand

In every industry, there is always a brand with a logo that needs no introduction. The 3D printing industry is no different. While an internet search would expose you to hundreds of formidable brands, bear in mind that you will also come across a handful with wax 3D machines void of the sustainable solutions you need to keep your printing line functional.

When buying a 3D printer, ensuring that you are banking with a reliable brand is necessary. This helps you authenticate the viability of your purchase. However, try to avoid purchasing a wax 3D printer solely based on the brand name or reputation.

There are a lot of industrial-grade 3D printer manufacturers not possessing a portfolio or track record comparable to that of the top dogs. Still, the semi-assembled LCD wax 3D printers they offer are seconded to none.

Simply put, the brand you are purchasing a wax 3D printer from matters, but the basic features and requirement you desire from a 3D printing machine should take precedence irrespective of the brand name.

4.2.4 Consider Weather the Price of the Machine is Acceptable

LCD 3D wax printers are quite expensive. A good LCD printer requires an investment well above a thousand dollar. Budget and pricing is a basic factor that must be considered before you kickstart the buying process.

While most of the renowned LCD machines available are quite expensive, you wouldn’t want to compare the price tag with that of SLA or DLP printers of the same size. LCD 3D printers are 1/5 or even 1/10 the price of DLP/SLA 3D printers of the same magnitude and size.

Note that its quite important that you don’t make the mistake of basing the efficiency or durability of a 3D wax printer on the price tags attached. There are lots of LCD 3D printers offering high-quality printing services at cost-efficient rates.

If you run a big production line or you are a hobbyist looking to purchase a remarkable wax 3D printer, and you firmly stand by the belief that your budget is sizable enough to purchase any printing machine of choice—we recommend you explore our catalogue armed with the basic features and specification you require from a preferred LCD printer.

On the other end, if you are on a low budget and require something substantial to cater to your day to day printing needs, please put a call through today—our support representative will guide you through the buying process.

4.2.5 Consider the Supplier’s After-Sale Service Capability

It’s easy to forget that you are meant to check out the after-sales service of the wax 3D printer manufacturer you want to purchase from during the buying process.

The mind can easily get clouded with features and specifications and forget that the reliability of your purchase is hugely dependent on the technical support your manufacturer offers you after the purchase.

Every reliable wax 3D printer manufacturer backs its sales services with 24 hours support. Check out your suppliers track record, if possible, ask questions from previous clients; till you are certain the after-sale support service provided can keep your production line running all year long, we advise you abort purchase.

4.2.6 Safety Configuration of the Machine

We might have listed the safety configuration of the machine you are about to purchase as the last thing to explore when looking to buy an effective LCD wax 3D printer, but that does not in any way mean this can’t be the first thing to checkout immediately a reputable 3D printer is thrown your way.

What’s the safety configuration of the machine you are about to purchase like? Hope the configuration is simple enough to operate and viable enough to keep your printing machine running regardless of whether prints fail or not?

Endeavour to ask your supplier detailed questions regarding the wax 3D machine’s safety configuration before making a purchase.

Conclusion

There is nothing left to explain. From how LCD wax 3D printers affect the day to day workflow of the average joey to how it’s revolutionising the medical and educational sector; we’ve covered it all.

With a detailed analysis of all the questions you should consider when buying an LCD 3D printer covered in chapter 4, we believe you are well equipped to make an informed buying decision. Dreambot3D offers numerous variants of industrial-grade 3D printers optimised to suit dynamic printing needs.

Our commercial-grade wax resin 3D printers allow you enjoy convenient printing operation void of barriers. Our machines are duly assembled to provide users with the three-dimensional modelling glory they desire. Wondering how you can have one of Dreambot3D photocuring LCD wax 3D printer delivered to your doorstep, put a call through today.

FAQ Guide

Can 3D printers Print wax?

Yes, 3D printers that can use wax can print two wax types at the same time to produce supportive bracing as well as the 3D printed object itself. They do this by printing the wax at two different temperatures; the wax that melts at the higher temperature, about 70 degrees Celsius, is used for the object itself, and the wax that melts at a lower temperature creates the supportive material that bridges gaps in the wax patterns until the initial wax hardens. Then the supportive wax is melted off.

What is the best 3D printer for jewellery?

LCD wax 3D printers are the go-to printers for goldsmith and jewellers in the jewellery industry. Unlike SLA and DLP printers, LCD offers a smooth and efficient printing process. Using an LCD wax 3D printer to handle your jewellery modelling needs also guarantees a silent printing process, longer lifespan and stable performance while printing.

What is a thermal wax printer?

Thermal wax printers use heated pins to ‘burn’ images onto heat-sensitive paper. These printers are commonly used in calculators and fax machines; and although they are inexpensive and print relatively fast, they produce low-resolution print jobs. Thermal wax printers use thermal wax ribbon to melt coloured wax on paper for a photo print. Jack Kilby invented it. However, since the usage of 3D printers became dominant in most industries, thermal wax printers are regarded by most jewellers and hobbyist as an outdated trend. If you are looking to enjoying a smooth and efficient printing process, its best you make use of a 3D printer.

What wax is used for lost wax casting?

Lost wax casting is a custom term used mainly in the jewellery industry. This is a process whereby a duplicate metal structure is cast from an original sculpture. Lost wax casting is an ancient technique and has been used even before 3D printers came into the picture. Through this technique, a mold can be created from a prototype that was made using wax. For traditional jewellery makers, lost wax casting is a beneficial method for producing high volume of custom pieces. Note that in recent years, 3D printers have developed enough to perform crucial roles in many applications, undermining the efficiency and durability of lost wax casting.

Can you use candle wax for lost wax casting?

Yes, you can use candle wax for lost wax casting. Although, not in all industries. While candle wax might serve as durable casting material for plastic, it’s not a recommended casting material for metals. If you haven’t used candle wax for lost wax casting before, it’s advisable you seek advice from an expert before engaging in the task. Its recommended you make use of 3D printers and suitable 3D printing materials when carrying out any casting activity.

What do you mean by lost wax technique?

The lost-wax technique comprises of all the steps involved in a lost wax casting process. Lost wax technique is a process used in metal casting that consists of making a wax model, coating it with a refractory to form a mold, heating until the wax melts and runs out of the mold, and then pouring metal into the vacant mold. If you want to enjoy a fast, efficient and smooth lost wax casting process, its important you make use of 3D printers when making designs and patterns for the wax models.

Are resin printers loud?

Depends on the type of resin printer you are making use of. Most of the industrial-grade LCD wax resin 3D printers used in many production lines would rarely attract nosy neighbours. However, it’s important to note that resin printers come in multiple variants from different manufacturers; the machining process involved in the design and development phase goes a long way to determining how loud your resin printer would be.

Are resin printers stronger than FDM?

No, in terms of mechanical build and end product, FDM printers produce are more durable. However, a detailed search can expose you to numerous resin 3D printers capable o withstanding FDM in strength and durability, but to keep the catch, you would need a high budget.

How strong is 3D printer resin?

The durability of a 3D printer resin is measured based on its tensile strength. The standard 3D printer resins are not as tough as most of the materials used by FDM printers. However, just because the resin is tough, it doesn’t mean that prints made from these resins will be twice as strong than if printed with a standard resin. Other factors, like model design and print settings, play important roles in the final print’s strength. Nonetheless, comparing tensile strength is a straightforward way to determine which material is stronger.

How expensive is 3D resin?

3D printing is an expensive venture. Before diving into it, weighing the cost of the basic materials required is essential. The cost of a 3D resin varies based on geographical location, type of resin and the quantity required. Nowadays, the standard price for a 1-litre water bottle of liquid resin is around $50. This price is for a very low-end resin product. For professionals who want to get the best quality possible, a premium resin could cost as much as $500 per litter.

How much is a 3D resin printer?

The price tag attributed to resin 3D printers varies base on brand, size, screen resolution, print quality and lots of other features. The price of our LCD 3D printer is around US$800 to US$10,000, depending on the size and configuration selected by the customer, you can contact us for details.

What do I need to know about resin 3D printing?

Resin 3D printing is the name given for a class of additive manufacturing technologies that helps in curing liquid photopolymers for building an object by each layer. Resin printing isn’t the official term for the entire group, people it’s easier to call that because the machines will require resin materials. There are several kinds of 3D printing technologies existing in the market that use liquid resins. The common factors among them are –

- All of them use a photopolymerization principle for creating objects.

- All of them work specific to a code.

- All of them use resins as materials.

- All of them use materials that need to be stored in a vat.

Can you reuse 3D printer resin?

You can reuse uncured resin just fine, but you’ll need to filter it out properly to ensure the larger pigments of cured resin aren’t put back into the bottle. If you do this, you might be pouring back hardened resin back into the vat, which isn’t good for future prints. Once the resin is slightly cured, you can’t practically reuse it for your 3D printer. Note that you can leave uncured resin in your 3D printer vat/tank for several weeks if you keep it in a cool, dark area. Giving your 3D printer extra can prolong how long you can leave uncured resin in the vat for, though when it comes time to 3D print, you should gently stir the resin, so it is fluid.

What is resin 3D printing?

3D printing using resins is also an additive process, just like FDM printing. This means that the process relies on a layer-by-layer building process where one-layer forms molecular bonds with the succeeding layer. This process repeats until the whole model has been recreated. 3D printing uses plastic resin as the raw material, in contrast to the filament used in FDM technology. The liquid resin used in 3D printing is typically composed of either epoxy or a combination of acrylic and methacrylic monomers. When exposed to UV radiation, these monomers quickly form molecular bonds with each other and turn into a solid polymer.

What are resin 3D printers good for?

3D printers are good for printing 3D models used in the design and prototyping phase by experts in numerous industry. These printers can be used to create 3D models of any object. From household items to artefacts, jewellery and sculptures, these printers play a huge role in the day to day activities of professionals in numerous industries.

Should I get a resin 3D printer?

If you want to create a 3D model of a household item, pattern or design of a machine or looking to heighten efficiency and productivity in your production line, then Yes, you should buy a resin 3D printer. 3D printers are quite expensive and are regarded as a high-value consideration by many. Before jumping into conclusion as to the type of resin 3D printer to buy, we recommend you explore our buying guide.

What happens if you touch uncured resin?

In the early days of handling uncured UV resin, not much will happen as a reaction when it comes into contact with your skin. Still, after repeated exposure and use, you can build up a high sensitivity to photopolymer resin. It is similar to how you don’t feel any effects of respiratory issues until years later. Some people have said that after years of handling resin and it coming into contact with their skin, they are now sensitive to even the smell of resin where it starts to give them headaches.

How dangerous is resin 3D printing?

If you’re wondering what might happen to you if you don’t adhere to safety recommendations when working with resin – it depends on the resin you use, what safety advice you aren’t following and how fast you act to remedy an accident. Generally, not wearing gloves while working with resin, for example, can cause mild skin irritation. Washing your skin with plenty of soap and water usually solves it. You may not experience a reaction the first few times resin comes into contact with your skin at all. Still, in some cases, the skin’s resistance to resin exposure decreases over time, leading to more severe reactions such as skin burns and blisters.

Are resin printers faster?

The process of printing with resin is considerably faster compared to printing with a filament. In an FDM printer, the extruder needs to move around the print bed to deposit the molten filament along with the specified patterns. This is a slow process because of the weight of the extruder and the controlled manner in which the filament has to be extruded. Resin printers have no such issues. In SLA printing, a single rapidly reorients to point the laser to the liquid resin along with pre-defined patterns. DLP and LCD printing is even faster because they cure a whole layer in a single step. For this reason, fast-paced industries prefer using resin printers.

How does a resin printer work?

Resin 3D printers make use of liquid resin. The LCD printing process occurs in a large tank and begins with a layer of liquid polymer spread over a platform. Since this piqued polymer is UV-sensitive, an array of UV LCD serves as its light source, hardening the area that forms one layer of your 3D print. The rest of the layer stays liquid. The platform is lowered, and the next layer is drawn directly on top of the previous one. When the object is complete, it is raised out of the tank via the supporting platform – much like a submarine rising to the water’s surface – with the excess liquid flowing away.

Do resin 3D printers smell?

Resin printers produce foul-smelling fumes, carry unknown health risks, and require tedious clean-up of unused resin. However, Resin 3D printers left on their own do not smell, but when used to create patterns or models in an environment not well ventilated, issues or irritation can occur. LCD 3D printers make use of resins, which naturally give off fumes. Particles emitted from consumer-grade 3D printers could negatively impact indoor air quality. To avoid such issues, it’s important you make use of your printer in a well-ventilated environment.

Is resin poisonous?

Depends on the resin. If you are using epoxy resins, you can print rest assured issue of poisoning wouldn’t occur while if you are making use of plastic casting resins, taking due precaution is essential. To be on the safe end, try to check out the toxicity status of every resin before using it in your production line.

Are resin printers safe?

There are few studies on the safety of 3D resin printers. While some argue that the fumes are perfectly safe, others claim that the liquid resin can cause allergic reactions, if left on exposed skin. Simply put, liquid resin isn’t something children should use or be exposed to.