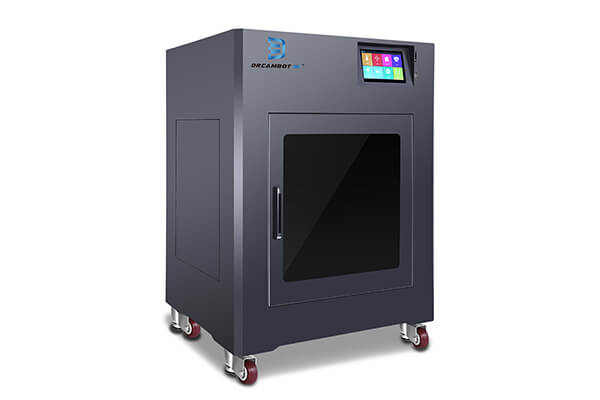

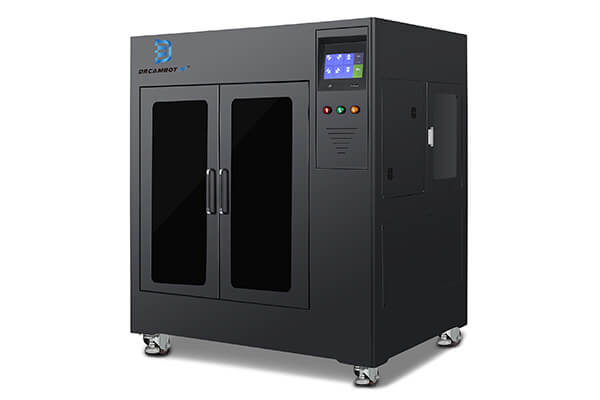

600x600x600mm 3D printer

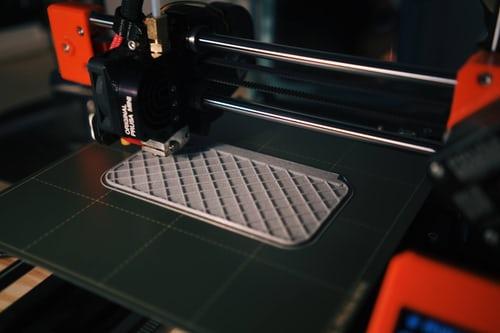

L-600 FDM 3D Printer

- Using FDM process principle, it can support industrial-grade printing size up to 600x600x600mm. Its high precision can reach 0.05mm

- Industrial-grade FDM 3D printers are used in a variety of materials: PLA, ABS, PC, Nylon, Carbon Fiber, etc.

- Adopts PLC intelligent control and can print offline. Can continue printing after power failure

Dreambot3D 600x600x600mm 3D printer

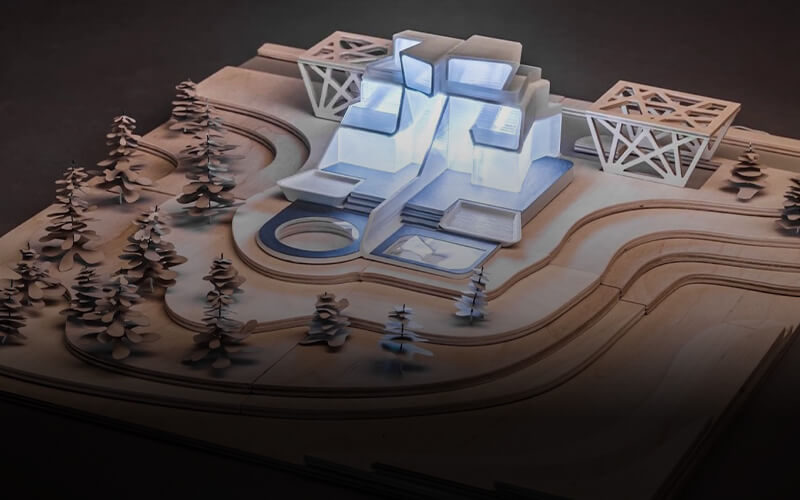

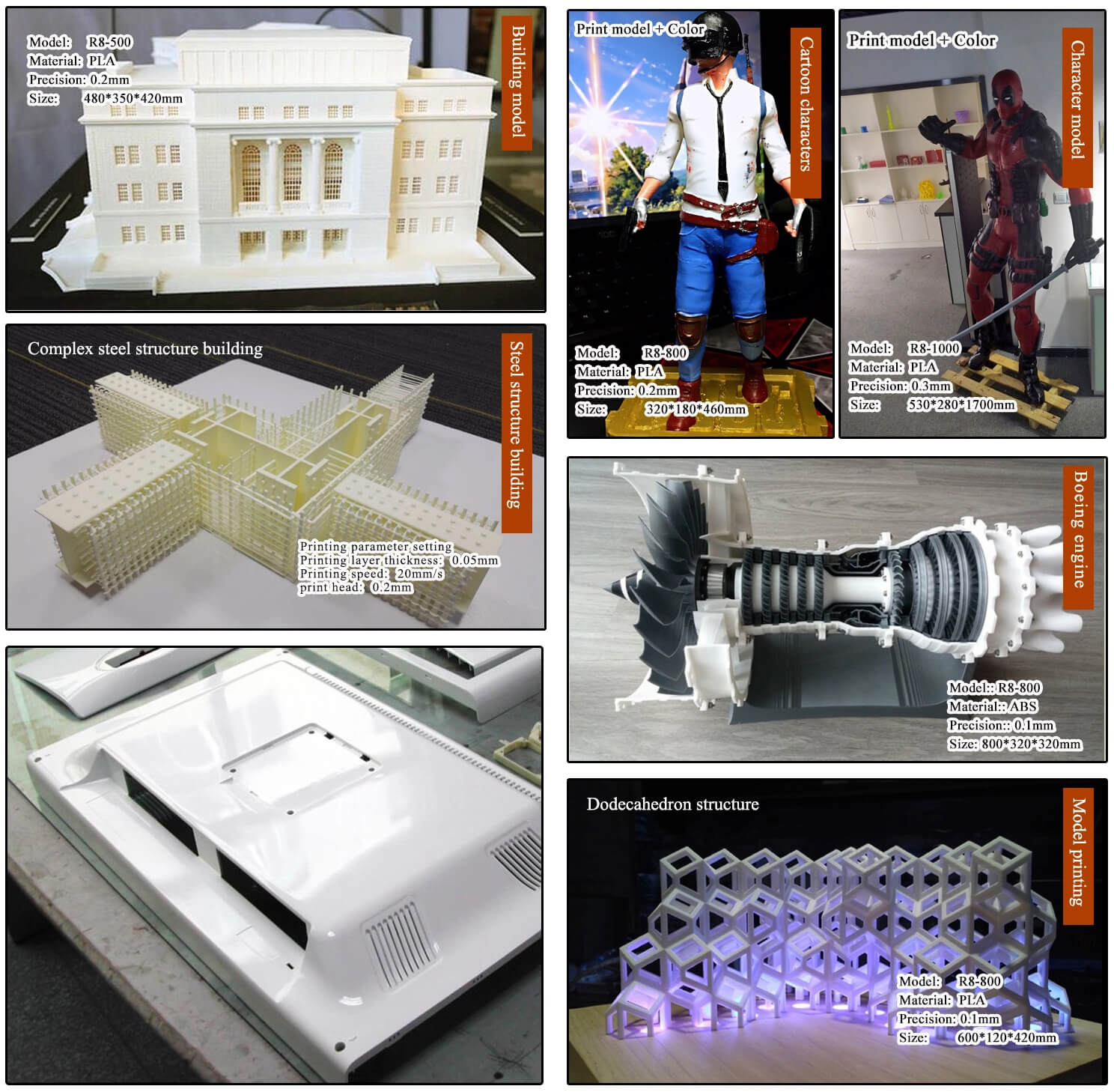

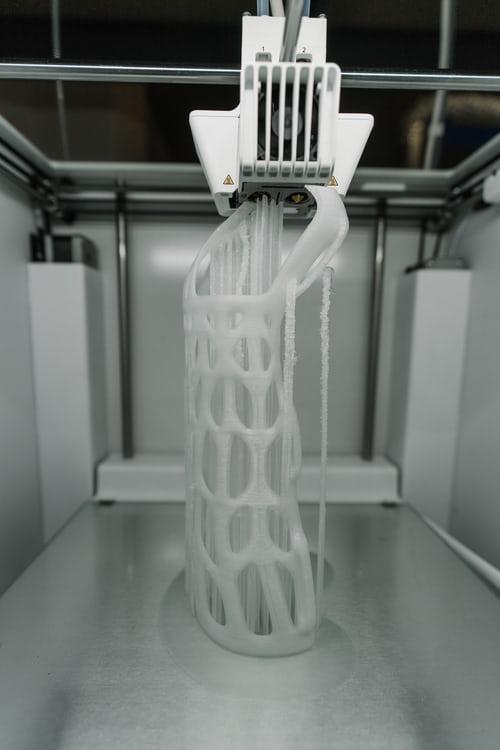

The Dreambot3D 600x600x600mm 3D printer is widely acceptable for printing 3D solid objects in many applications. Among which are the manufacturing, architecture, medicine, custom art and design. As an artist or designer, you can no longer be limited in your creations, because the dimension 3D printer brings them to life.

The 600x600x600mm 3D printer comes in handy when you need to print accurate and timely 3D objects. The FDM 3D printer price is very affordable and makes creating 3D objects easier.

The 3D printer consumes less time in creating multiple 3D objects.

| Technical parameters | Model | L5-600 | L8-600 |

| Photo | / | / | |

| Max printing volume | 600x600x800MM | 600x600x800MM | |

| Printing platform | The platform moves down when printing | Fixed at the bottom | |

| Technical principle | FDM fuse manufacturing technology | ||

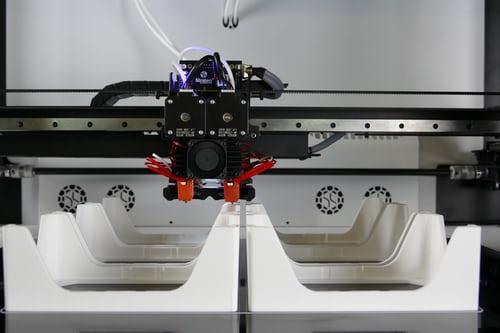

| Print head | High-precision extrusion system (double nozzles can be customized) | ||

| Nozzle diameter | 0.2, 0.3, 0.4, 0.6, 0.8MM | ||

| Consumable diameter | 1.75MM | ||

| Printing materials | PLA, TPU, 95A, water-soluble materials, wooden PLA; customizable ABS, PC, PETG, nylon, carbon fiber, metal filling materials, glass fiber addition materials, etc. (not available for 300 size machines) | ||

| Positioning accuracy | X axis 0.0011, Y axis 0.0011, Z axis 0.00125MM | ||

| Printing layer thickness | 0.05-0.3MM | ||

| Printing speed | 20-150MM | ||

| Printing platform | Heating aluminum substrate + black crystal glass platform | ||

| Platform temperature | 30-50℃ (30-120℃ optional) | ||

| Platform calibration | Automatic pre-calibration leveling | ||

| Nozzle temperature | 75-280℃ | ||

| Movement noise | 50 dB | ||

| Connection method | U disk, SD card (both as a gift) | ||

| Screen control | 7 inch full color touch screen (support all languages) | ||

| Chassis structure | 3MM thick sheet metal, fully sealed chassis | ||

| Filter function | 2 air filter devices | ||

| Lighting | LED lighting | ||

| Mechanical transmission | Double linkage gantry type machine tool linear navigation | ||

| Physical parameters | Dimension | 90x86x129CM | 90x93x159CM |

| Package Size | 95x92x144CM | 105x97x174CM | |

| Net weight | 117KG | 144KG | |

| Gross weight | 150KG | 170KG | |

- Alarm indicators when there seem to be any omission, such as the broken material indicator, the indicator light and the material alarm makes the 600x600x600 3D printers are beneficial for small businesses or individuals who are new to 3D printing technology.

- The Dreambot3D 600x600x600mm 3D printer makes a high printing accuracy of up to 0.05mm. What you design is exactly what is printed, no quality reduction.

- The Dreambot3D 600x600x600mm 3D printer is assembled on a stable frame design which is also thickened by the CNC cutting and forming. This solid 3D printer makes printing positioning very accurate.

- The two-way cooling unit is part of the unique feature of the dimension 3D printer that protects the printer from excessive heat. Hence, the 3D printer does nor break down due to repeated object printing.

- The built-in memory module of Dreambot3D 600x600x600mm 3D printer makes it possible for printing to continue even after power interruption. No layer is skipped to cause a printing defect.

- The touch screen system only allows you to use a USB or SD card. There is no requirement for any computer. This allows you to print your objects anywhere and anytime.

Test your part

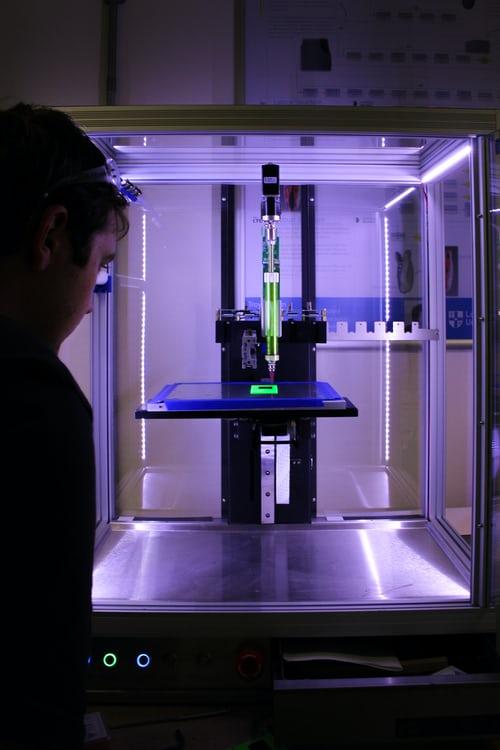

We provide sample testing service, allowing you to check the working quality of our 3D printer before placing an order

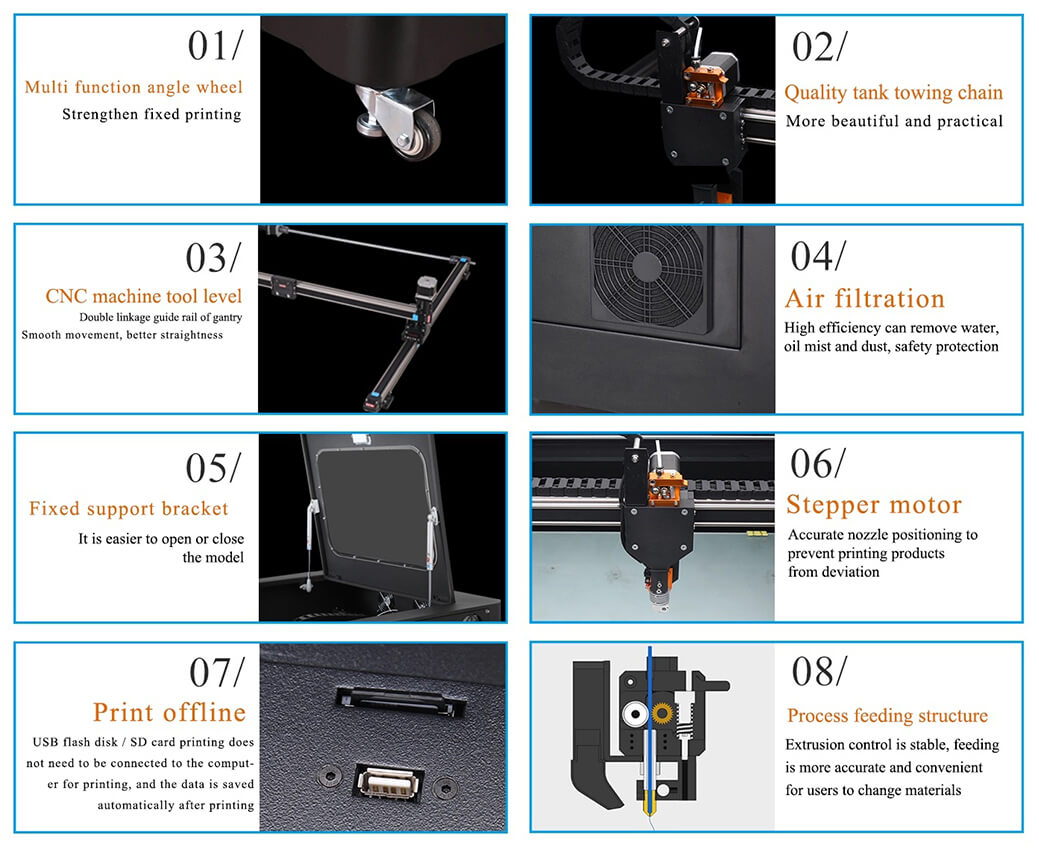

6 points why choose us

Automatic resume printing

Full enclose stable frame

The whole machine case is thickened by CNC cutting, with accurate hole position, better assembly stability, and higher positioning accuracy of printer operation.

Allow offline printing

Use U disk or SD card to print without connecting to a computer to print. After starting to print, the data is automatically saved and the U disk or SD card can be removed.

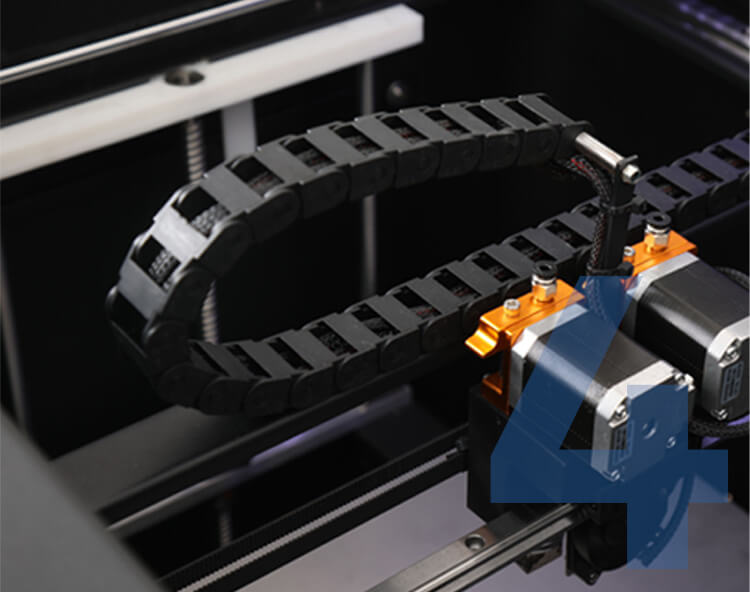

Drag chain wiring design

The wire is installed in the inner casing of the drag chain to effectively ensure that the wire will not be damaged for a long time when the printer moves at high speed.

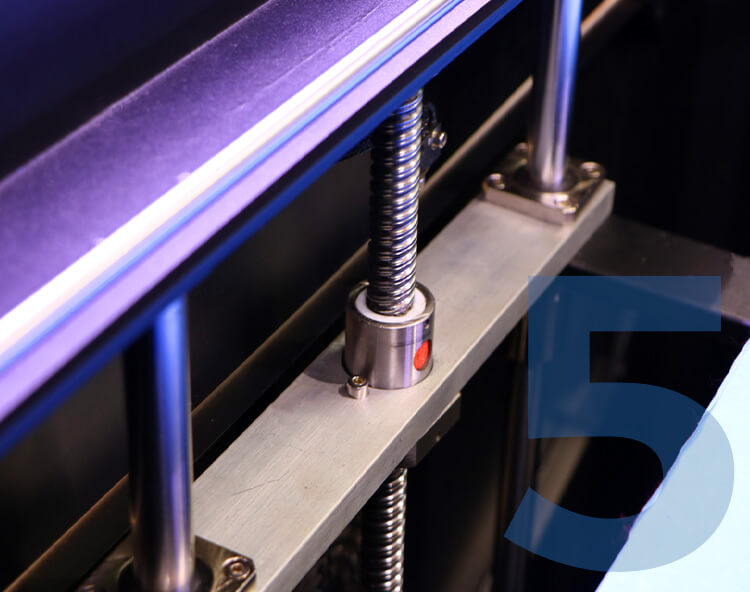

Precision ball screw

Using the latest Taiwan ball screw, it has higher straightness, lower friction coefficient, better smoothness, higher positioning accuracy and more stability during printing.

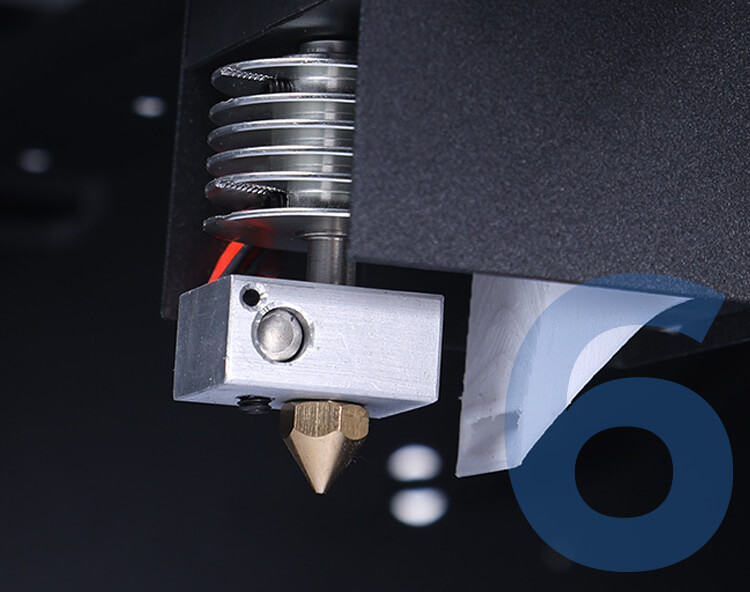

Alloy nozzle

Independently developed a unique bullet nozzle with uniform heating and a patented head assembly, so that it can work smoothly without interruption.

More FDM 3D printers

L-300 FDM 3D Printer

The L-300 3D printer meets the printing needs of small printing businesses as well as personal hobby. Capable of printing objects up to 300x300x300mm

L-500 FDM 3D Printer

The L-500 3D printer can be used for big 3D print projects or a small business looking for a professional sizable 3D printer.

L-1000 FDM 3D Printer

The L-1000 is mostly used for wider printing applications, whereby multiple 3D printing is done at once. It is able to cover 1000x1000x1000mm print sizes.

Industrial FDM 3D Printer Buying Guide

Industrial FDM 3D printers are now widely in use in heavy industry, manufacturing, and auto industries, producing unique, on-demand parts with the help of both durable and lightweight engineering polymers. In addition, hobbyists, designers, architects, researchers, educationists, and other professionals have adopted these printers to help them perform various tasks involving converting CAD files into 3D models.

These printers can print at the very least 30 centimeter-long parts, have a build-in chamber capable of maintaining the temperature at 80°C, produce an extruder temperature of at least 350°C, and allow easy automation. They are, therefore, reliable, ensuring that they ensure close parameter control during the printing process.

FDM 3D Printer Introduction

Every FDM (fused deposit modeling) 3D printer works by selectively depositing molten material with precision layer by layer to form an object. An FDM 3D printer could be small and fit for home operations or a large-scale 600x600x600 3D affair. However, the 600x600x600 3D printer that falls in the industrial category is large enough to print substantial, commercially usable objects.

FDM 3D printers are the most widely available worldwide, representing the first 3D printing technology users interact with regardless of their scale of operations. They make use of different types of thermoplastic polymers, which are widely available and easy to use. This chapter seeks to address the intricacies of how FDM 3D printing works to help designers know its capabilities and limitations to work with it successfully.

1.1, Principle of FDM 3D Printer

FDM 3D printing is an elaborate process that starts with 3D CAD (computer-aided design) models using software like AutoCAD, CATIA®, Inventor®, Solidworks®, and so on. The model then goes through the slicing process, which involves preparing the model in a format that an industrial FDM 3D printer can interpret. When the model is ready, a manufacturer loads a spool of printing filament into the printer, turns on the machine, which starts feeding the extrusion head and the nozzle with molten printing material. After melting the filament, the nozzle releases the material onto the table or bed, creating the desired object.

Therefore, FDM 3D printers can only work with the presence of the following primary conditions:

Printer Platform: The printer platform or bed usually consists of a hard surface like plastic, ceramic, and metal. Its primary purpose is to hold the object that being printed as the nozzle deposits the molten material. In that case, a 600x600x600 3D Printer has a large bed capable of producing larger objects.

Nozzle/Printer Head: An industrial FDM 3D printer has a nozzle that moves with the power of a lead screw or belt on a mechanical chassis in the X, Y, and Z dimensions as it creates the additive part. It also has the stepper, a fourth motor for pushing the thermoplastic material through the nozzle. A computer controls all the head and raw material movement, ensuring precision during the depositing process.

Raw Materials: The raw materials used in FDM 3D printers is primarily thermoplastic, which can repeatedly melt on exposure to heat and re-solidify when it cools. However, some machines may use a blend of metal, especially where the additive part requires it. Material for FDM 3D printing is wound on a spool. It uncoils when fed into the printer nozzle; as the printer nozzle melts and releases the material, the spool rolls, releasing more filament for a continuous printing process.

A 600x600x600 3D printer can keep the nozzle temperature at a level close enough to the material’s glass transition temperature. Because of that, the material extrudes at a semi-liquid state, returning to a solid-state almost immediately. That’s how the top industrial 3D printers ensure greater dimensional accuracy every time it produces an additive. Thermoplastic FDM printing materials include urethane, polystyrene, ply-lactic acid, polycarbonates, nylon, and acrylonitrile butadiene styrene. Different manufacturers have 3D filament of distinct quality, giving users various materials from which they can choose. Of course, the choice of materials depends on the industry and the product, prototype, or additive part one intends to make.

FDM 3D Printing Process: The FDM 3D printer works by extruding the thermoplastic material through the hot nozzle. It deposits the material on the printer platform and continues to do so as the thermoplastic solidifies, building the object layer by layer upwards. The previous layer fuses with the succeeding one at every stage until one gets the object in question. The average 600x600x600 3D printer, like the Dreambot3D 3D, initially prints the object’s outer edges followed by the interior trims and, lastly, the inner part of the layer before solidifying.

In some cases, a professional FDM printer incorporates struts or support structures to hold thin overhanging sections. That happens throughout the printing process to ensure that the object comes out just right. However, the props aren’t permanent and require prompt removal once the printing process is over. Instead, they are made from the material as an object and released via a second extruder that deposits soluble thermoplastic struts to avoid drooping overhangs. It is the 3D printing machine manufacturers who determine whether a device has two extruder nozzles or not. When placed in a solvent, the thermoplastic dissolves, leaving the desired object.

Printer Parameters: FDM 3D printers have several adjustable parameters, including build platform temperature, nozzle temperature, layer height, build speed, and cooling fan speed. The operator adjusts the build platform temperature, nozzle temperature, cooling fan speed, and build speed, ensuring that the printing process works as well as possible.

On the other hand, the designer is in control of the layer height and build size. An industrial 3D printer machine has a build size ranging from 600x600x600mm to 1000x1000x1000mm. So one can buy a 600x600x600 3D printer if they need one for use on an industrial scale. Regardless of its size, an FDM 3D printer has a height of 50 to 400 microns, which is also adjustable. A smaller layer height has smoother parts and helps accurately capture curved geometries. However, a more significant layer height least to faster object printing.

Warping: FDM 3D printing may result in warping due to the molten material cooling and solidifying. That mainly because different sections of the object cool down at different speeds causing dimensional change at different rates. There is a general internal stress build-up with differential cooling, pulling underlying layers upwards, causing warping in the object. However, one can prevent warping by closely monitoring the build platform and chamber temperatures. Increasing how tightly an object adheres to the build surface can also help. Warping worsens when dealing with things with expansive plat areas, thin protruding features, sharp corners, and the use of certain materials. When it comes to materials, the one that’s most prone to warping is ABS.

Layer Adhesion: One of the essential principles enabling FDM 3D printing is the adhesion between the layers deposited on the additive part as it’s being printed. As the molten thermoplastic filament extrudes through the nozzle, it sits and adheres to the previous layer, which is already drying. The pressure and temperature are so high that it re-melts the last layer, enabling bonding of both layers. Layer adhesion is essential since it determined how quickly and effectively one can print 3D quality products.

The inter-layer strength between any two successive layers is always less than the material’s base strength. Since FDM printed additives are anisotropic (have a lower z-axis strength), the design process usually incorporates part orientation. The depositing of a material layer over another also means the finished object has a wavy surface when dry. It also means there must be post-production inclusion of features such as thread and holes.

Support Structure: In FDM 3D printing, the support structure is beneficial for propping up overhangs with an angle of more than 45 degrees. One can use either bridging or support, where bridging involves stretching the material between two points. That removes the need for support and is useful where the bridge is 5mm long or less. Anything more than that requires extra support to hold the material in position. Support often involves some form of post-processing, which consists of removing the support from the printed object. Since it utilizes additional materials, support makes FDM 3D printing slightly more expensive.

Infill and Shell Thickness: Large format 3D printing doesn’t lead to the production of outright solid objects. Instead, it involves tracing the outer perimeter to create a shell, which is then filled with a low-density material called the infill. For example, with a 600x600x600 3D printer, the infill setting can start anywhere from 25 percent of the object’s total density with a 1mm shell thickness.

1.2, What Materials Can Be Printed By FDM 3D Printer?

An FDM 3D printer can print several materials for industrial purposes, with each of them coming with unique strengths, weaknesses, and features. Because of that, each of these materials is great for printing different types of industrial additives. This chapter introduces you to some of the best materials for a professional FDM printer.

Nylon (Polyamide): Nylon is a synthetic, durable, flexible, corrosion-resistant, and low-friction thermoplastic used for making 3D printing filament. Nylon is suitable for creating objects with delicate and complex geometrical representations. It is one of the primary filament materials for FDM 3D printing because it’s easy to dye. However, nylon is hygroscopic and has a short shelf-life of 12 months. It also shrinks when cooling, resulting in less precise prints.

ABS (Acrylonitrile Butadiene Styrene): ABS is another popular thermoplastic for making 3D printer filament. It is excellent for manufacturer and engineering 3D printing and is suitable for using any 600x600x600 3D printer. The popularity of ABS emanates from its wide availability, mechanical strength, relatively long lifespan, and a wide variety of colors. However, ABS requires heating of the printer bed, experiences warping due to its high melting point, and is non-biodegradable.

PLA (Polylactic Acid): PLA is a bioactive and biodegradable thermoplastic polyester made from corn starch and other natural, environmentally friendly materials. It is excellent for printing additive parts, prototypes, and other products. PLA filament makes it possible for a 3D printer to deposit materials more accurately, resulting in a fine surface. It is available in many colors, is biodegradable, and allows improvement of strength through baking. Besides, the material works well with the fastest FDM 3D printer with a lower printing temperature and minimal or no shrinkage. However, additive parts printed using PLAaren’t durable and can be affected with exposure to UV light. In addition, at 140°C, PLA tends to get warped or”cooked.”

PET (Polyethylene Terephthalate): PET is a thermoplastic polymer produced by combining two monomers for making various products, including clothes, bottles, and prototypes. It is mainly food-safe, flexible, moisture-resistant, tough, shock-resistant, paintable, recyclable, and capable of producing excellent, smooth layers. Unfortunately, even though PET is easy to use, it makes objects whose details are hard to notice. It also has medium heat resistance, limiting the number of application in which you can use it.

PETG (Polyethylene Terephthalate Glycol): PETG is slightly different from PET because of the addition of glycol, which is the”G” in its name. It is a modified material that’s inherently more durable and stronger than PET, making it great for use during large-format 3D printing. It produces nice-looking, smooth layers while making food-safe, moisture-resistant objects. Since PETG has good stress and heat resistance, it is suitable for use in printing mechanical additives. Even though it shrinks less, the material can break down with exposure to UV rays and softens at only 170°F (80°C). It also tends to change color from the original translucent to semi-transparent during the printing process.

TPU (Thermoplastic Polyurethane): TPU is a rubber-like material for producing semi-flexible parts using some of the top industrial 3D printers. It is technically a block copolymer and polyurethane plastic with a structure featuring chain or soft and hard segments, giving it characteristic flexibility. TPU is flexible, abrasion-resistant, robust, semi-transparent, and wear-resistant. However, it can be challenging to use during printing, hard to glue together, and hard to use for 3D printing.

PC (Polycarbonate): PC is an ABS alternative with a carbonate-filled structure that makes it strong enough for use with a 600x600x600 3D printer in construction, aircraft, and medical applications. It is also a preferred material for fabricating electronic covers, glasses, and bottles. PC filaments use an FDM 3D printer relatively quickly and can be retardant, transparent, and sterilized. However, it is sensitive to UV light, requires high temperatures to print, and absorbs moisture.

ASA (Acrylonitrile Styrene Acrylate): The original purpose of creating ASA was to serve as an ABS alternative for making high-quality parts and additives. It is a strong, UV-resistant, and heat-resistant material, making it suitable for use with an Industrial FDM 3D printer for objects meant for outdoor use. ASA is a strong, UV-resistant, weather-resistant, stress-resistant, durable material that can be smoothened using acetone. A significant disadvantage of ASA is its propensity to yellowing when used outdoors. It is also mildly hygroscopic and requires high printing temperatures.

1.3, How Does FDM 3D Printer Develop From Desktop To Industrial Use?

The FDM 3D printing technology is the most popular, featuring in both desktop and industrial printers. Recently, machines that initially existed as desktop printers have gained industrial use. A desktop FDM 3D printer can quickly develop to industrial use with minor improvements in its accuracy, printing materials, production capabilities, and cost.

Accuracy: Desktop FDM 3D printers have a 1 percent standard accuracy, 0.10mm to 0.25mm typical layer thickness, and 0.8mm to 1mm minimum wall thickness. Therefore, it produces relatively high dimensional accuracy and relative minimum feature size to their industrial counterparts.

On the other hand, an industrial FDM 3D printer is highly accurate in producing parts thanks to calibration algorithms that kick in before and during printing. The heated chamber minimizes the effects of rapidly cooling thermoplastic material while the machine works at higher printing temperatures. Unlike desktop 3D printers, which have a single extrusion nozzle, most industrial machines have dual extrusion mechanisms. That makes it easier to remove water-soluble materials for a smoother surface, great for printing more complex parts.

Materials: The most preferred material for a 600x600x600 3D printer is the easy-to-print PLA. Even though less durable, PLA makes it possible to print finely detailed additive parts. A great PLA alternative is ABS, which is strong, pliable, and stable against high temperatures. However, since most desktop 3D printers lack heating chambers, they end up producing warped parts. PETG is an ABS alternative that’s easy to print, strong, and durable.

Top industrial 3D printers use engineering plastics like ABS, PC, and TPU, whose properties give them more excellent biocompatibility, chemical resistance, thermal stability, and high-impact strength. In addition, some materials for industrial FDM 3D printing have material properties close to those of injection molded parts and can work well with mold printing.

Production Capabilities: A desktop FDM 3D printers have a medium build envelop of 200x200x200mm, enabling them to produce only smaller objects. It also takes a lot of time to print just one additive part and cannot qualify as the fastest FDM 3D printer. On the contrary, an industrial FDM 3D printer can print a large order of elements within no time. It is typically a 600x600x600 3D printer with a massive printing area for producing more significant spare parts at once or printing several models simultaneously. It is also reliable, making similar parts repeatedly.

Application Field of FDM 3D Printer

FDM 3D printers have wide application in additive manufacturing in different industries and not just in making prototypes. Its field of application is so vast that it applies in making tooling aids, product prototypes, and end-use additive parts. This chapter explores the current applications of Industrial FDM 3D printers in different sectors and for various purposes.

2.1, For Industrial R&D

FDM 3D printers are helpful in industrial research and development (R&D) since they help produce prototypes of various kinds of products. It starts with a CAD file that’s then converted to a 3D printer readable format. Then, using any acceptable materials, a 600x600x600 3D printer produces the prototype by piling molten material layer-by-layer. Therefore a commercial 3D printing machine is necessary at the product development stage, creating prototypes for testing, market research, and development. It is helpful for engineers, designers, and other professionals involved in industrial R&D.

2.2, For Molds Making

Large-format 3D printing helps design and make molds that can help produce functional prototypes and products. It saves on the costs one would have incurred using CNC machining to create expensive steel or aluminum molds. An excellent industrial 3D printing machine can accurately make molds with a perfect surface finish. Such devices use materials with excellent wear and temperature resistance capable of producing low-run injection molds. 3D printed molds enable quick mold design verification, reducing the financial risk of acquiring expensive metal molds. A substantial 3D printer ensures fast turnaround times, low production quality applications, molds that require changes, and relatively small parts.

2.3, For Aerospace Printing

The aerospace industry is one area where Dreambot3D 3D, the best 3D printer for industrial design, would get greater use. For these purposes, materials like metal and thermoplastic filament produce additive parts for aircraft and rocket engines. FDM 3D printing is fast and affordable, and fantastic for printing parts in low volumes. It allows the in-house production of antennas and circuit boards, eliminating the need to hire third parties for high-value projects. Aerospace companies can also use the top industrial 3D printers when making jigs, fixtures, and other tooling equipment. The production of spare parts is also another function in which these machines can come in handy.

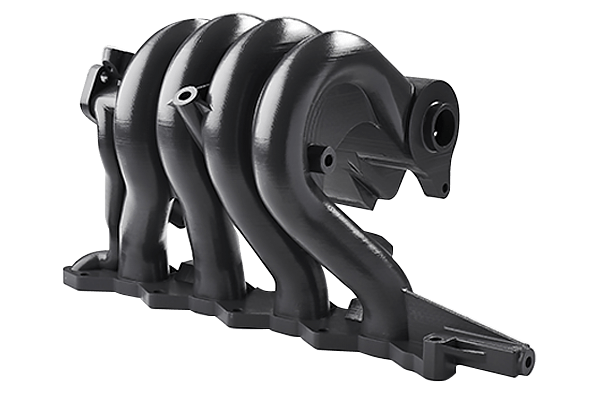

2.4, For Car Parts Printing

Car parts printing is one of the major applications of industrial printers, creating functional prototypes and tools. Large-format 3D printing quickens the product development process, making it possible to test and validate car parts. In addition, it eliminates tooling, increases design flexibility, and promotes customization of spare parts to a particular motor vehicle. Besides, it is more affordable, barring the initial 3D printing machine cost.

An FDM 3D printer plays a vital role in producing highly complex additive parts by infusing complex geometries into the products. It is excellent for making prototyping new products linked to the automotive industry. That’s in addition to producing tooling aids like jigs, fixtures, and injection molds while customizing them for improved functionality. Finally, a professional FDM printer would come in handy for making spare and end-user parts quickly and more efficiently.

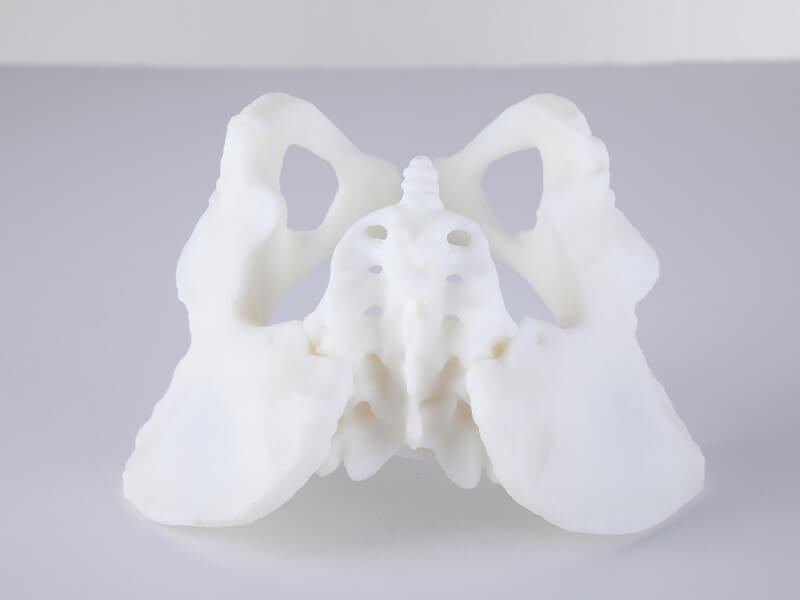

2.5, For Medical

It is not uncommon to find an industrial 3D printing machine solely dedicated to producing customized implants and dental appliances. The machine is being used to optimize the design for medical devices by reducing the cost of prototyping. As a result, medicine and dentistry designers can work more quickly and avail affordable patient-specific devices than traditional manufacturing.

Thanks to the advances made in digital dentistry, it is now possible to combine intraoral scanning with 3D printing to create bite plants, bridges, and crowns matching a patient’s anatomy. 3D printers are also helpful in speeding up dental implantology by creating helpful surgical guides.

A 600x600x600 3D printer can also come in handy when producing 3D-printed prosthetics and implants such as hip joints, knee joints, spinal implants, and cranial reconstruction implants. With suitable materials, the machine can also create artificial living tissues good enough to mimic natural tissues. In the future, these machines could play an important role in regenerative medicine. Also known as bioprinting, the technology already has several applications, including the production of bone, skin, cartilage, cardiac patches, blood vessels, and simple tissues & structures.

2.6, For Various Models Making

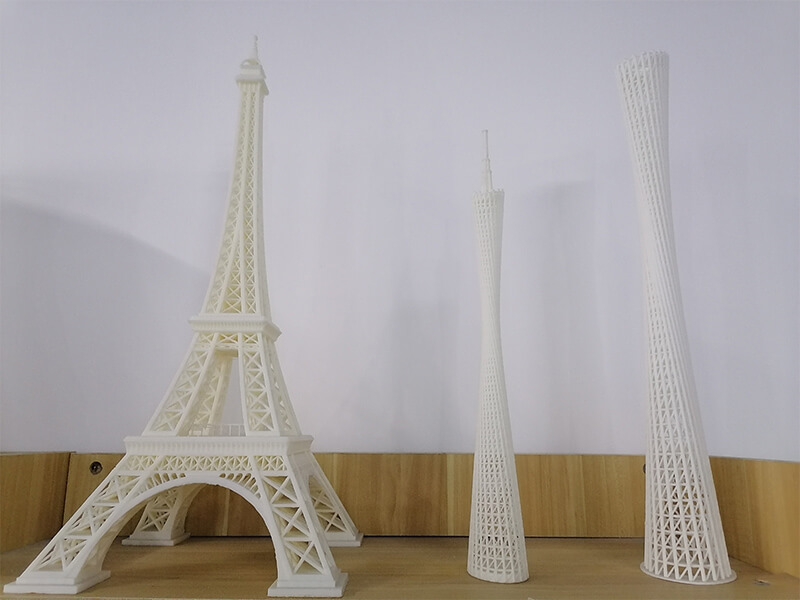

The decreasing industrial 3D printer cost has led to more affordable anime figures, architectural models, mannequins, gun, ship, and airplane models from metals, plastics, and ceramics. Manufacturers then use these models to test whether the designs can work in producing real-life products. For example, they can push the structural integrity of a construction project long before it is actualized.

2.6.1 Anime Figure

Anime figure 3D printing is now easier, thanks to the advent of the industrial-grade 3D printer. It is now possible to print various anime objects and toys with relative ease and at a lower cost. With multiple websites offering ready 3D anime figure designs, all one needs is a good FDM 3D printer. Also, one can scan real-world models and use a 3D printer to produce new ones. Thanks to the affordable 3D printing machine price and availability of downloadable anime figure designs, just about anyone can build these models. The material could be ABS, nylon, PLA, PET, or PTU, depending on what individuals hope to achieve.

2.6.2 Architectural Models 3D Printer

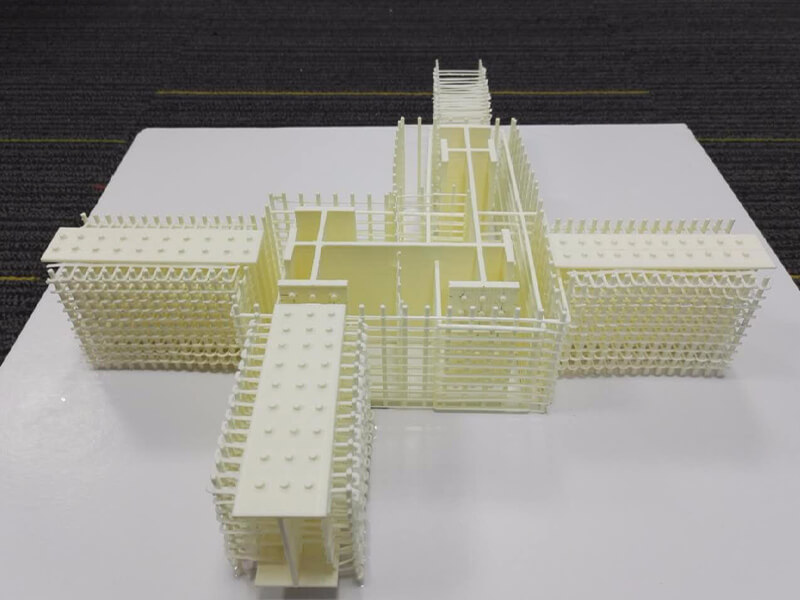

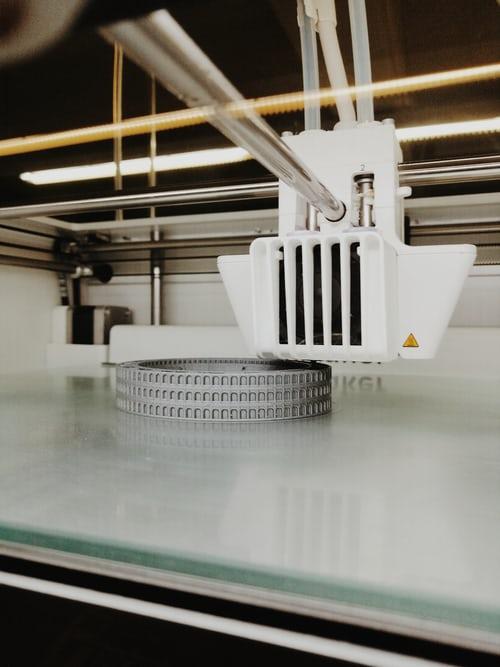

An architectural model’s 3D printer can help architects avoid using drawings, blueprints, and digital 3D models of construction projects. Instead, they help in producing 3D-printed architectural models faster, easier, and more accurate. All one needs is to craft the 3D design using CAD software, preparing it for 3D printing, and finally printing the model. The reducing industrial 3D printer cost makes a lot of sense to print and test architectural models before implementing them in real life. An architect can also better showcase their work in 3D models than mere drawings or digital 3D models.

2.6.3 Mannequin

Mannequin printing is another growing area where top industrial users gain applicability, especially using the massive 600x600x600 3Dprinter. It removes the need for the lengthy traditional mannequin manufacturing that takes eight weeks to produce one model, speeding up the production process several times. Here, an FDM 3D printer is important given the ease with which it interprets 3D CAD designs and converts them into valuable mannequins. As a result, it is possible to create bespoke figures designed to meet specific customer needs. In addition, like in many of the other FDM 3D printer applications, designers can test prototypes and make quick changes, making the process cost-effective and less time-consuming.

2.6.4 Gun

Despite the controversy surrounding the topic, individuals and firms are now using top industrial 3D printers to produce gun models. As a result, users get gun blueprints from various sites and print guns for their use instead of getting established gun manufacturers and dealers. Examples of firearms whose blueprints are available for printing include the Liberator .380, Grizzly .22 Caliber Rifle, Reprringer Pepperbox .22 Revolver, Browning 1911 Metal Replica the ZigZag .38 Revolver. In most cases, the individuals and companies involved have test-fired the guns and found them to be as good as those manufactured in the old conventional ways.

2.6.5 Ship Models

It is possible to use large format 3D printing to create fast, cheap, and customizable ship models without relying on conventional production methods. Thanks to the speed of the industrial FDM printer, prototyping a ship has become faster and more affordable. Designers can test various versions of the ship model without spending too much money on it. A commercial 3D printing machine can produce cheap additive parts with a relatively fast turnaround from building ship models. Furthermore, the printed models can be great for naval architects displaying to potential customers, helping convince them to buy into the idea. In this regard, it works better than paper sketches or digital 3D files of the design.

2.6.6 Airplane Models

Aviation enthusiasts, hobbyists, and designers can print airplane models using a 600x600x600 3D printer. It could be anything between solid models, multipart models, or R/C planes. Solid airplane models are often printed in a single or, at most, two pieces. Multipart models, on the other hand, are designed for printing in multiple parts. R/C places are fully functional airplanes, which can fly with the help of remote control. Instead of mechanical engines, they have an electronic circuit and battery-powered motors that help them fly.

In recent years, 3D printing machine manufacturers have come up with big enough printers that print out the different parts of the R/C airplane in readiness for the eventual assembly. The thickness of the outer skin is the same as the nozzle diameter of the 3D printer. However, firewalls, wing roots, and joint areas are usually thicker to provide extra strength. Printing airplane models are possible for CAD designers or laypeople using digital 3D files downloaded from the internet.

2.7, For Cosplay Props Making

Cosplay or costume play has been growing in popularity since the 1980s, with enthusiasts ready to do everything to acquire their favorite costumes. As a result, many are prepared to spend up to $1,000 on cosplay props based on video game characters, comics, and anime figures. An easy and less expensive way is to use a professional FDM printer to create life-size cosplay props for periodic industry festivals. Several 3D printing machine manufacturers have developed versatile, high-quality, and accurate printers that make cosplay support manufacturing relatively easy. The machines can print life-size helmets, armor, outfits, and other futuristic figures and devices for adorning during comic conventions.

2.8, For Drone Manufacturing

Drones have become so common that they are now commonplace in the security, cinema, aerospace, military, and agriculture industries. However, drone manufacturing no longer relies exclusively on traditional manufacturing processes, with the FDM 3D printer gaining center stage. In this regard, a 600x600x600 3D printer is helpful in two ways – enabling fast prototyping and producing parts for a finished drone. Even though industrial 3D printer costs might be high, using it to print a quadcopter is more cost-effective. It also makes it easier to customize the project to the user’s needs instead of buying a generalized ready-made drone. Furthermore, when used for product development, a 3D printer hastens to prototype and does it more affordably.

Factors Affecting Efficiency of FDM 3D Printer in Manufacturing Industries

The top FDM 3D printers are efficient, producing objects faster and more efficiently. However, an FDM 3D printer may work at different levels of efficiency, depending on the variation of certain factors. This chapter discusses the factors affecting the efficiency of FDM 3D printers in manufacturing industries. Knowledge of these factors makes it possible to institute the necessary controls to keep the printer working more efficiently.

Printing Materials

The choice of materials and their amount is the most significant factor in determining the cost of printing and the lead times. Thus, one should be careful when selecting printer materials like ABS, nylon, PLA, PET, or PTU. ABS provides good strength and temperature resistance, even though it is susceptible to warping. Nylon also has high power and resistant to chemicals and wear, even though it absorbs a lot of ambient moisture. Although PLA isn’t so strong, it is easy to print with and provides outstanding visual quality. PETG is strong, fire, and chemical-resistant. It is also food-safe and easy to print with.

The best 3D printer for industrial design utilizes differently-priced materials based on their chemical, mechanical, and physical properties. Apart from the printer, the filament material determines the build process and speed one can attain. Thus, some materials are more efficient than others, making it possible to build objects faster. Even though most of the filament materials for FDM printers are thermoplastics, some are fast to print, given their little or no shrinkage. Others require more careful handling and a controlled environment, such as a heated chamber.

Orientation and Supports

A 600x600x600 3D printer may print objects faster and at a lower cost if the supporting angle isn’t too high. At higher orientation (more than 45 degrees), support becomes necessary, prolonging the printing process and consuming more materials. Thus, it is possible to get more printing efficiency using self-supporting angles. It is not only faster but also costs much less. In the same way, the part orientation determines the amount of support an object requires. Under normal circumstances, it is essential to re-orient the design to reduce the number of materials supporting the structure. With that, it is possible to reduce the cost of printing an object. However, that doesn’t mean basing your design totally on the x-y plane in a cost-saving bid. That only results in the additive part losing the original mechanical integrity and feature definition.

Layer Height

FDM 3D printers often print objects with a 50 to 400-micron layer height. It refers to the preset height of materials deposited in each layer as the printing process continues. A large industrial 3D printer can produce smoother, geometrically accurate additive parts when the layer height is at the lowest level. It is crucial to choose a smaller layer height if the object has holes or curved surfaces. Visual appearance is more important than functionality, and there won’t be any finishing after 3D printing. However, the printing process isn’t fast enough.

With a more significant layer height, it is possible to print objects faster and more cheaply. Therefore, you can increase the efficiency of an FDM 3D printer by increasing the layer height. Most printers in this category, such as the Dreambot3D 3D, use a layer height of about 200 microns. Apart from being faster, a higher layer height produces parts with better mechanical properties. Therefore, it is suitable for sand, paint, or acetone-smooth the finished product.

Wall Thickness

Every 600x600x600 3D printer comes with settings for determining the wall thickness of the object. A thicker wall is more robust and slower to print than a thinner one. However, it also consumes slightly more materials and is more costly. That’s because a thick wall consists of several nozzle diameters and takes time to print. In most cases, the wall thickness consists of two nozzle diameters or 0.8mm for the top industrial 3D printers.

While thinner walls lower the build time, they may result in flimsy features, exposing the object to warping or unexpected fragility. That’s why designers must seek to establish a balance between the layer and wall thickness for the desired performance and detail without additional printing time or material cost.

The Infill

FDM printed objects are like wooden doors, which often feature a low-density core. After printing the outer shell, it is necessary to finish the additive part with a low-density infill. The infill density can be as low as 20 percent for those looking for a less robust model and between 50 and 75 percent for those who consider strength necessary. A lower infill density is easier and faster to print but not so strong. On the other hand, a higher infill density makes the model stronger, even though it might take longer to print.

Labor or Workforce

A large industrial 3D printer might not produce 3D objects with finality. Some additive parts might require substantial post-processing work and finishing. Anything that involves coating, painting, or smoothing costs more in terms of materials and labor. That may diminish the overall efficiency of the project because of the additional time and cost. By analyzing the project needs and determining the need for finishing, you will be better prepared to manage and deliver more efficiently.

Machine Build Size

FDM 3D printers have a build size ranging from 200x200x200mm to 1000x1000x1000mm. The lower limit represents mostly desktop printers that can print either smaller objects or bigger ones bit-by-bit. For larger, small objects, a printer with a smaller build size is very efficient. However, if the object is industrial-scale, you have to print different parts separately, which might take too long. Thus, a smaller 3D printer is less efficient when printing larger objects. In that case, a 600x600x600 3D printer is good enough to print larger objects quickly and at a lower cost. It is, therefore, more efficient than a 3D printer with a smaller build size.

Main Components and Parts of FDM 3D Printer

Understanding FDM 3D printer components and parts ultimately result in printing objects of the highest quality. Undoubtedly, an FDM 3D printer has different parts that work together to give you better quality prints at the desired speed. In-depth knowledge of these parts is necessary for maintaining the 3D printer and giving it a longer life. It is also essential when it comes to upgrading and modifying the elements as required. This chapter discusses the different parts and components of an FDM 3D printer in greater detail.

Build Area/Volume

The build area/volume is the space occupied by the objects as the 3D printer prints them. Therefore, its description is volume, indicating the maximum printable size of a 3D object for that particular printer. For example, the Dreambot3D 3D has a build area of 600x600x600mm, meaning that the main printable additive parts for this specific printer measure 600x600x600mm. The build area is measured in the x-y-z dimensions, like the case of the 600x600x600 3D printer.

Motherboard/Mainboard/Control Board

The motherboard is the component responsible for maintaining the machine’s smooth operation. It is the 3Dprinter’s brain, directing the motion components based on the instructions it receives from a computer. It also interprets sensor signals and translates them into the necessary actions. As such, an industrial-grade 3D printer would require a high-quality controller board to achieve the highest possible performance. A machine with the best parts but a flimsy motherboard wouldn’t function as well as expected.

Frame

The frame is essential for holding together all the other components of a 3D printer and maintaining the machine’s stability. It is, therefore, the primary determinant of a 3Dprinter’s durability. A good 600x600x600 3D printer requires a strong metal frame to hold its many components together. However, some 3D printing machine manufacturers use wood, acrylic, and other materials to make their printers. Therefore, choosing a machine with a stable metal frame is a must for anyone looking for a durable 3D printer.

Even so, a metal frame may significantly increase the FDM 3D printer price, putting it outside the affordable range. 3D printer frames can be open or closed, with the latter offering better results by maintaining a consistent temperature in the print space. However, there is a compromise, especially when it comes to printers with a semi-closed frame.

Print Filament

Every 600x600x600 3D printer requires a suitable filament, in the form of a spool with a string wound around it, to produce the object in question. Printing can only happen by slotting the spool into the machine. An FDM 3D printer heats and melts the material before depositing it onto the print bed or the object being printed. The printer deposits the material layer-by-layer as the object forms progressively. 3D printer filaments come in various material types like PLA, ABS, PETG, and nylon, with each having its advantages and disadvantages. That’s why it is essential to check that a commercial 3D printing machine is compatible with the types of material you intend to use.

Motion Controllers

They are called 3D printers because they work along the x, y, and z axes. After receiving instructions from the motherboard, the motion controllers make movements as they print the object in question. The following 3D printer components play an essential role in the activities any machine makes:

Belts: The motor has straps connected to it for making x-axis and y-axis movements from side to side. Since the belt movements affect the precision and print speed, they determine the quality of results one can get from an FDM 3D printer. When the belts sit tightly, they ensure the best possible results.

Stepper Motors: The purpose of the stepper motors is to enable all movements happening in the printer. A stepper driver controls their activities along the x, y, and z axes, and they drive the print bed, print head, and the lead screws while making rotations in steps. That’s the reason for the name”stepper motors.”

Threaded Rods: Connected to the stepper motors are threaded rods to enable the print head to move upward or downward. Several top industrial 3D printers may have the movements of their prints beds relying on the threaded rods. Therefore, most movements along the z-axis depend on the threaded rods. In some printers, movements along the x-axis and y-axis also depend on these rods. However, since they are too expensive, a majority of 3D printers use belts.

End Stops: End stops make it possible to mark endpoints along the three axes while the various components move. Their work is to identify each component’s range of movement.

Print Bed

A print bed is a flat surface on which objects sit while they are created. The extruder nozzle deposits the molten filament onto the print bed layer-by-layer until it finishes building the entire additive part. It is one of the most significant 3D printer parts, determining the surface finish and quality of the final object.

Depending on the preferred filament material, a 3D printer might have a heated or non-heated printer bed. For example, PLA filament works best on a non-heated bed, while other materials need a heated one. Heating is essential for maintaining the stability and adhesion of the first layer of the object being printed.

Prints beds might feature different materials depending on the needs of the 3D printing machine manufacturers. The most common materials are aluminum and glass. While an aluminum printer bed would heat up faster, one made from glass is flatter, providing a better finish and is easy to maintain. With an aluminum print bed, the industrial 3D printer cost can be way too high. Some printer beds have automatic calibration, while others require manual manipulation to work correctly.

Power Supply Unit (PSU)

The power supply unit (from its name) supplies power to all parts of a 600x600x600 3D printer to ensure the smoothest possible operation. It could be attached to the frame or sit separately together with the controller box. In the best 3D printer for industrial design, the power supply is so compact that it doesn’t interfere with the machine’s overall design. The strength of a PSU determines just how much heat a 3D printer can produce and, therefore, the material it can use. To print using high-end materials, one must select a printer with the highest temperature range.

Extruder/Print Head

The extruder is the 3D printer that extrudes molten filament, depositing it on the print bed. A print head is made up of the cold end and the hot end. The cold end locks the filament and gradually pushes it towards the hot end. In turn, the hot end has a nozzle that heats the filament by maintaining a temperature higher than the material’s melting point. After melting the filament, the hot end deposits it on the print bed layer-by-layer until the object is formed. The following are the different parts that combine to make up the print head:

Filament Drive Gear/Extruder Drive Gear: This part pushes the filament from the cold end to the hot end.

Heat Sink: The heat sink works with the heat sink fan to keep the material solid until it gets into the nozzle.

Thermocouple: The thermocouple is a temperature sensor that makes it possible for the extruder to maintain the temperature at the right level. It is situated in the hot end part of the printer head.

Heater Cartridge: This is the part of the extruder that heats the filament, melting it.

Nozzle: The tip of the extruder that releases the melted filament to the print bed. Every 600x600x600 3D printer comes with its nozzle size, even though the most common is 0.4mm. The size determines the quality of the printed object you get from a 3D printer. While a smaller nozzle produces finer details, the larger ones print quickly but with relatively poor results.

Cooling Fan: The deposited melted filament needs cooling down for setting before another layer is deposited. Thus, the cooling fan kicks in to ensure that happens and fast.

A typical 600x600x600 3D printer has one extruder, even though some come with two of them. The advantage of a dual extruder is how it enables simultaneously printing using two different filaments. For example, dual extruders might be attached to one print head or work using two distinct print heads.

Feeder System

The top industrial 3D printers use two major feeder systems – the Bowden and direct feeder systems. With the Bowden feeder system, the cold end and hot end are located in two different locations. Therefore, it has a filament tube that directs the filament to the hot end, increasing the print speed more dramatically because it makes the extruder lighter. On the other hand, the direct feeder system has the cold and hot-ends connected directly. That is common in printers that rely on flexible filaments.

Connectivity

Every professional FDM printer provides several connectivity options, including a USB port, Wi-Fi, and so on. Thus, it can connect to a computer via a simple USB cable, Ethernet, or through a Wi-Fi network. In addition, with Wi-Fi, it is possible to connect the printer to a laptop, tablet, or smartphone. The purpose of all of these connectivity options is to transfer the 3D design file to the printer for eventual printing. Besides, some printers have slots for SD cards to transfer files without using any other device.

User Interface

It is hard to find a large industrial 3D printer that doesn’t have an LCD user interface. The LCD screen controls the printer settings without the need for an additional device (such as a computer). That’s what enables a 600x600x600 3D printer to work independently using files from a simple SD card. In addition, one can use the interface to check the printer parameters and initiate the filament loading and unloading. The small screen is also valuable for initializing the auto-leveling system before and during the printing process.

How to Choose A Suitable FDM 3D Printer for Your Industry

With so many top industrial FDM 3D printers available on the market, it helps if you know how to choose the right one. Having narrowed your search down to FDM printers would help determine other factors such as the industry, print size, and printing materials requirements. Here are the three most important considerations you ought to make.

5.1, Your Application Industry

The application industry in which one intends to use an FDM 3D printer is essential in determining the machine to purchase. The top industrial 3D printers are most commonly used for research & development, mold making, aerospace printing, car part printing, medical & dental, model making, cosplay props making, and drone manufacturing. Therefore, it is essential to buy a reliable FDM 3D printer capable of creating great prototypes for research and development. That’s because of the necessity of testing the market with a good enough prototype to compete with existing products.

A professional 600x600x600 3D printer is also necessary for mold making, aerospace printing, car part printing, medical & dental, and drone manufacturing. However, if the printer is making cosplay props and models, it is possible to compromise a little bit on the quality. That’s because the products from these applications do not necessarily require high-end filament materials like metal.

5.2, Print Size Requirements

The print size is the most significant volume of an object an FDM 3D printer can build. Most industrial 3D printers define their print size in cuboid volume, while others (delta 3D printers) have it in cylindrical terms. A good example is the 600x600x600 3D printer, which can print industrial-scale objects. Such a large print size is suitable for printing many smaller additive parts or one large one. However, the additive part is larger than the printer’s print size; it becomes necessary to make it into smaller pieces and join them with screws or glue later on.

Therefore, it is necessary to have a print size that’s a little larger than the size of the most extensive object. For example, if you print jewelry, then a 75x75x75mm print volume is just enough to print several things. On the other hand, printing drone parts require a giant machine with a 600x600x600mm print size or more.

Remember that a machine’s print size is a significant determinant of a 3D printing machine’s price. For that reason, the 600x600x600 3D printer is several times more expensive than a smaller machine. But when all other factors are held constant, the printer is worth it when printing practical industrial-grade prototypes. Also, an increasing size leads to the consumption of even more materials.

5.3, Printing Material Requirements

Different types of 3D printers require additional materials to produce objects of various kinds. For any industrial FDM 3D printer, PLA or polylactic acid is the most common material. Apart from being great for most of the available printing applications, PLA produces consistent results all the time. Those in the plastic or chemical production industry may use materials with better properties. Even so, it should be a thermoplastic with a melting temperature of between 200°C and 300°C. Another great option is ABS, which works well for producing injection molds but is difficult to print and shrinks a little too much.

Most 3D printing filaments have a diameter of 1.75mm or 3mm, which necessitates checking what a particular machine needs. In the same breath, you may want to choose a filament in a given color. Some 3D printing machine manufacturers have filaments that go with their machines, making it easier for users to select suitable materials. Where manufacturer-provided materials aren’t available, then you have to buy from other sources. That would mean changing the printer settings every time you use a different material. Printing with the wrong material may make your printer develop unnecessary issues.

A 600x600x600 3D printer may also use materials like nylon, which is more vital than PLA. The major downside of nylon is its tendency to absorb too much moisture, compromising its quality. There is also PETG, which is a solid industrial-grade filament. When starting, stick to a maximum of two materials to learn how to use them. However, if your industrial application demands materials with specific physical or chemical properties, you have no option but to comply.

FDM 3D Printer Buying Guide

It is not enough to know how to choose an FDM 3D printer. Knowing how you can purchase one is also essential. Some things to consider may include the brand reputation, the machine’s safety configuration, resolution requirements, FDM 3D printer price, after-sales service, flexibility, safety, and cost-effectiveness.

6.1 Check the Brand Reputation

The number of 3D printing machine manufacturers has been on the rise over the last few years. While there are old players in the industry, some are still relatively new. To know whether an FDM 3D printer manufacturer is correct, check their brand reputation based on reviews from past users of the machines. Some of the most prominent players in this industry include HP, Envisiontec, 3D systems, MarkForged, Stratasys, and Dreambot3D. A reputation manufacturer would provide machines of the highest quality.

6.2 Safety Configuration of the Machine

A printer’s safety configuration is one of the most important considerations when buying an FDM 3D printer. Several printers have an automatic shut-off feature that enables them to detect when being opened and pausing to keep their users safe. Some printers also have flexible steel plates for removing printed objects before they cool down. Apart from protecting users, a good printer should keep tabs on the task’s progress to resume when power is restored. That way, it won’t be necessary to start printing the model from scratch.

6.3 Resolution Requirements of the Machine

Each 600x600x600 3D printer comes with a different resolution, referring to the smallest feature a machine and material can print. FDM 3D printers have a resolution of between 50 and 500 microns. A micron represents 0.000001 meters, 0.001mm or 0.00004 inches. For printers meant for exacting designs, the resolution can be as low as possible. Machines with a more precise resolution are great for making microscopic machinery and parts and prosthetic devices.

6.4 Consider Whether the Price of the Machine is Acceptable

The FDM printer price varies from one manufacturer and model to another. A good 600x600x600 3D printer may cost anything from $10,000. However, the cheaper FDM 3D printers are not as robust, feature lower resolution, and may not provide industrial-grade printing. Still, few of these machines can operate 24 hours a day, seven days a week, 52 weeks a year. If you are looking for the best 3D printer for industrial design, you should be prepared to pay anything between $60,000 and $1 million. With that expensive price range, you get a fully-fledged industrial-grade 3D printer.

6.5 Consider the supplier’s After-Sales Service Capability

Whether a manufacturer of FDM 3D printers offers after-sales service is another important consideration before purchasing a machine. Examples of after-sales service include manuals, setup instructions, white papers on the best use of the device, and training videos. While these can be found online, some manufacturers offer installation and repair services for their clients online. Apart from that, the manufacturer should provide support around the clock to meet the needs of international clients. Another important consideration for a 600x600x600 3D printer is the warranty period, which should be long enough. So, it is essential to purchasing a 3D printer from a company that provides setup assistance, training, documentation, online help, and a service contract for support and repairs.

6.6 Go for Flexibility

Going for a flexible 600x600x600 3D printer is one of the best choices one can make. Flexibility essentially implies a printer that can use different types of materials and print varied objects. For example, a good FDM 3D printer should utilize ABS, PLA, PET, PETG, or nylon materials without discrimination. That way, it is possible to fall back to a particular material when the main one isn’t available. The printer should also be operational across different industries and print differently sized objects.

6.7 Pay Attention to Details

Before purchasing the best 3D printer for industrial design, it is essential to pay attention to details to avoid missing any details. Some of the critical things to consider are the connectivity options like Wi-Fi, USB, and Ethernet. A good 600x600x600 3D printer should have connections that work perfectly for the user. Another thing to check includes touchscreen control, which helps during setup, configuration, and customization of the build process. The type of extruder, monitoring mechanism, build plate, stands, and raw material control also matters. Failure to pay attention to details may miss an important feature that may render the printer virtually unusable.

6.8 Put Safety First

FDM 3D printers have various safety issues, including mechanical hazards and emissions. For example, a heated print bed can present a severe mechanical hazard due to high temperatures of up to 100°C. That’s also true for the heated extruder block and nozzle, which can reach 270°C. At the same time, the extruder motors might also heat up quite considerably. Apart from the heat, another mechanical hazard comes in fast-moving components and sharp tools for removing finished printed objects.

Additionally, a 600x600x600 3D printer may release ultrafine particles (with 0.1 microns, or less, in diameters) into the air. The ultrafine particle emission rate depends on the type of filament used, with PLA having the lowest emissions. On the other hand, ABS has the highest ultrafine particle emission rates. Also of great concern are the volatile organic compounds that result from melting thermoplastics. The speed and type of mixture also depend on the kind of materials used.

It is essential to buy an industrial-grade 3D printer with the lowest mechanical risks and minimal emissions. For example, a good printer should have its print bed secured so that it becomes hard to accidentally touch the heater block, nozzle, motors, heated print bed, moving parts, or sharp object removal tools. At the same time, a printer that utilizes materials with little or no emissions is the best.

6.9 Select the Most Cost-Effective

Some 3D printing machine manufacturers build FDM printers that solely rely on their branded filaments. Unfortunately, using such machines can be too expensive since it limits the user to just one type of printing filament. Therefore, before purchasing a 600x600x600 3D printer, it is essential to ask about the overall cost of producing a model using it. That way, you will avoid ending up with a printer that isn’t cost-effective enough to serve your needs.

6.10 Why isDreambot3D’s FDM 3D Printer So Prominent?

Dreambot3D3D Technology Company is one of the foremost 3D printing machine manufacturers in the world. Its industrial FDM 3D printers have a 0.05mm accuracy, resulting in smooth, accurate models all the time. They rely on different materials, including nylon, PLA, ABS, TPU, PC, PET, PETG, and PC.

Besides, the company’s machines are approved by some of the best professional certification global bodies. A single Dreambot3D 600x600x600 3D printer is suitable for multiple industries, including education, industrial design, automotive, aerospace, medical, manufacturing, and dental. Other popular industries are mannequins, electronics manufacturing, and crafts and sculpture. Dreambot3D’s FDM 3D printer stands out because the company focuses only on the FDM technology and not any other. Therefore, it has perfected its printers, making them stand out from the crowd.

FAQ Guide

How does an FDM 3D printer work?

An FDM 3D printer works by converting CAD files into 3D-printed objects. It melts filament via a nozzle and deposits it onto the print bed layer by layer until it finishes forming the desired object. In some printers, the print bed is heated to hold the thing firmly in place as one is printing it. A layer of molten material can be anything between 0.1mm and 0.5mm thick, based on the settings chosen by the user.

Is FDM stronger than SLA?

Yes, FDM (fused deposition modeling) is more potent than SLA (stereolithography) because it uses a wide variety of high-quality materials like PLA, nylon, ABS, PET, PETG, and so on. In addition, the materials are more robust than the liquid resins on which SLA 3D printing relies. Consequently, FDM is excellent for additive, prototype, and spare part production.

What are the advantages of FDM?

One of the advantages of FDM is its affordability in terms of the industrial 3D printer price and the cost of printing materials. Also, the technology makes it possible to design and print precise, high-quality objects all the time. Since they are more durable, FDM 3D printed things serve various purposes in different industries. The printers are easy to print and great for beginners who want to learn how 3D printing works. Apart from being faster, FDM is also the most common 3D printing technology, printing large objects.

What is the difference between FFF and FDM?

FFF (fused filament fabrication) and FDM aren’t very different since they rely on the same printing process. Stratasys is the company that first invented the process and registered it under the FDM trademark. However, after the expiration of the FDM trademark in 2009, a new, low-cost process called FFF paved the way for affordable 3D printers.

What is FDM used for?

FDM is used for different kinds of applications, including product research and development. It produces prototypes for testing the market before the production of the final products. An FDM 600x600x600 3D printer is also helpful in making prosthetics, architectural design, industrial design, pre-surgical models, props & cosplay, and household items. Other industries where this technology has gained popularity are aerospace, drone making, and car part manufacturing.

What is the primary use of FDM 3D printing?

The primary use of FDM 3D printing is in industrial applications requiring durable models with precise dimensions. It can be either in prototype printing or making additive parts that go into actual products.

Is rapid prototyping the same as 3D printing?

No. Rapid prototyping isn’t the same as 3D printing. While 3D printing is a popular method for manufacturing additives, rapid prototyping refers to only one application of the technology. Furthermore, rapid prototyping may rely on other technologies different from 3D printing. 3D printing is a recent additive manufacturing that costs much less than SLA, which was complex and more expensive. Because of the issues with SLA, most companies adopted rapid prototyping as an alternative additive manufacturing process. However, machines and materials used for this process were prohibitively expensive, curtailing its widespread use.

How many hours will a 3D printer last?

A 3D printer can last for anything between 7,500 printing hours to 15,000 printing hours when working for four hours daily for ten years. But, of course, the actual longevity depends on the brand and the build quality of a particular 3D printer.

Will 3D printing replace traditional manufacturing?

No, 3D printing won’t replace traditional manufacturing. Instead, the two technologies are likely to keep complimenting each other as they experience more and better advances. For example, 3D printing to produce prototypes quickly is expected to improve product development and manufacturing speed in general. However, 3D printing might gain some use in making final use products but without replacing manufacturing.

Is 3D printing cost-effective?

Yes. 3D printing is cost-effective since it utilizes inexpensive materials to produce various products. It also cuts out the need for having different machines to manufacture products. Even though 3D equipment might be expensive to buy, it helps users avoid paying another company to print for them.

Is it worth buying a 3D printer?

Yes. It is worth buying a 3D printer, whether you are a hobbyist, designer, or manufacturer. Hobbyists can quickly print objects of desire, such as models, for their enjoyment. On the other hand, designers can quickly develop prototypes of various products for testing on the market. Later on, they may change the design in line with the prevailing reception in the market. Similarly, manufacturers can create injection molds using a 600x600x600 3D printer and create various products.

What is the most accurate 3D printing technology?

The most accurate 3D printing technology is material jetting with a ±0.05mm to ±0.1mm dimensional tolerance. However, the objects created from material jetting are not as durable as those from FDM.

Is 3D printing cheaper than manufacturing?

Yes. 3D printing is cheaper than manufacturing when printing 407 units at most. Unlike manufacturing, where the design is fixed, 3D printing makes it possible to change design details unlimited times. However, where more than 407 units are required, manufacturing is infinitely less expensive.

Is 3D printing suitable for mass production?

Yes. 3D printing is suitable for mass production since it helps one avoid traditional tooling methods. As a result, it reduces prototype and end-user product lead times. Users can also change the product design details quickly, reducing the time required to make a prototype. Furthermore, where there’s a need for low-volume production, 3D-printed molds can drastically cut the printing cost and time. Therefore, 3D printing is excellent for mass production, both as a prototyping method and production method.

What can be made with a 3D printer?

Several items can be made with a 3D printer. The only condition is that the idea must be conceived as a CAD file before being printed. Examples of things to make with a 3D printer include surgical instruments, flutes, acoustic guitar, 3D figurines, iPhone case, guns, electric bikes, hanging lights, robotic arms, coffee cups, joystick, fabrics, pen holders, LED lamps, candy dispenser, and ratchets. A 3D printer is excellent for printing prototypes, additive parts, and finished products of various kinds on an industrial scale.

Conclusion – Why Our FDM 3D Printer Is the Best Choice

Our 600x600x600 3D printer is much better than a hobbyist’s tool. It is excellent for designers, architects, medical technologists, and other professionals looking for a professional FDM printer. It is a reliable machine that produces 3D prints of the highest quality, making it great for industrial use. With such a massive build volume, you can print larger objects without, first, breaking them down into smaller parts. It works with several CAD software, helping you get the most out of your work regardless of the device you use.

The Dreambot3D 3D printer comes with an intuitive user interface for changing and monitoring settings during the 3D printing process. It uses different materials such as ABS, PLA, TPU, PC, PVA, and nylon, making it highly flexible. Besides, the printer has a 0.05mm high-precision, PLC intelligent control, print memory on power failure, and the ability to print offline. Connectivity methods include the U-disk and SD card, making you able to print without a laptop or computer.