resin 3D printer

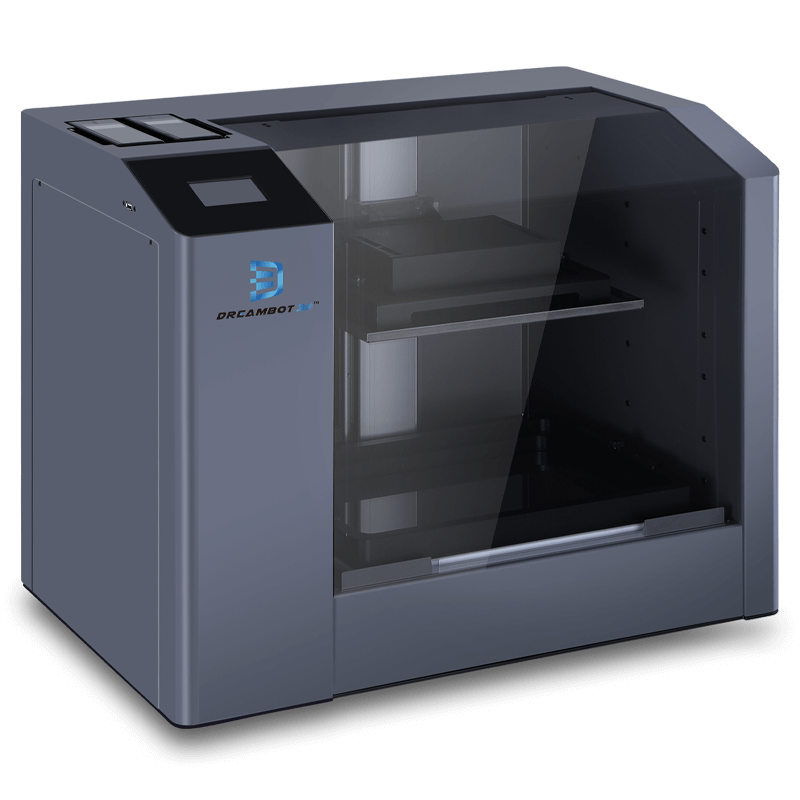

ME-345 LCD 3D Printer

- Stereoscopic light curing 3D printer with LCD technology, high quality of finished products

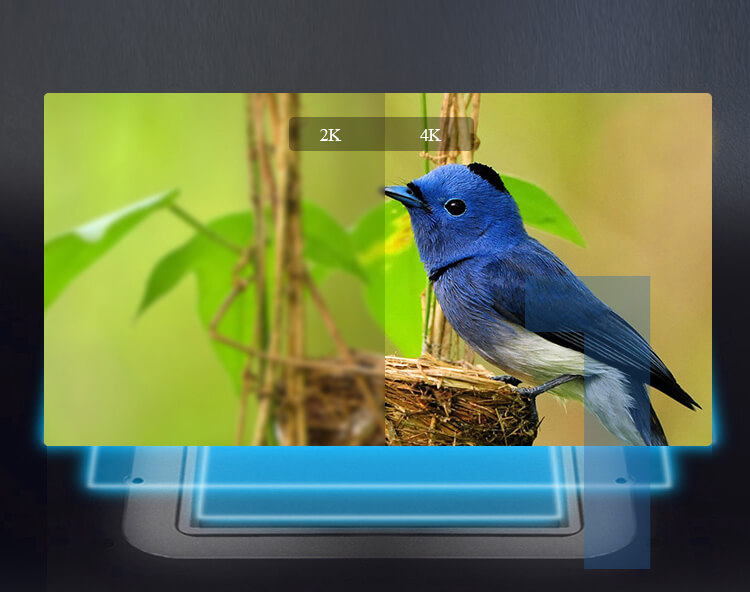

- 4K high-definition pixel printing greatly improves the smoothness of the model surface.

- Dreambot3D resin 3d printer(ME-345) has obtained CE, FCC certification and quality assurance.

Dreambot3D resin 3D printer(ME-345)

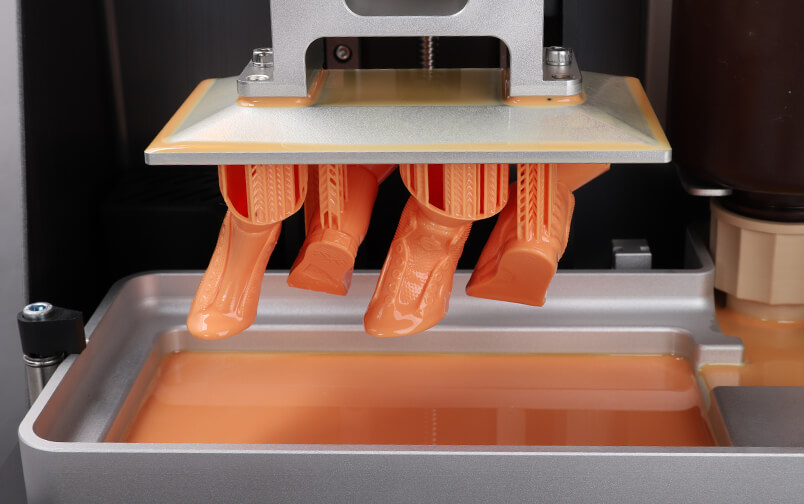

Dreambot3D Resin 3D printer (ME-345) uses an ultraviolet light source to cure liquid resin into solid 3D objects. The curing takes place layer by layer while the 3D object is being formed. The resin 3D printer is commonly used among hobbyist, jewelry businesses, toy making industries as well as those that do not require very large printing.

The Dreambot3D resin 3D printer (ME-345) only prints high definition and accurate 3D objects. All objects printed are always uniform, no wrapping or skipping of layers occurs. The resin 3D printer serves both personal and commercial purposes. You make use of the printer anywhere so far the location is highly ventilated.

| Parameters | ME-345 LCD 3D Printer | |

| Printing Parameters | Printing style | RESIN LCD 3D Printer |

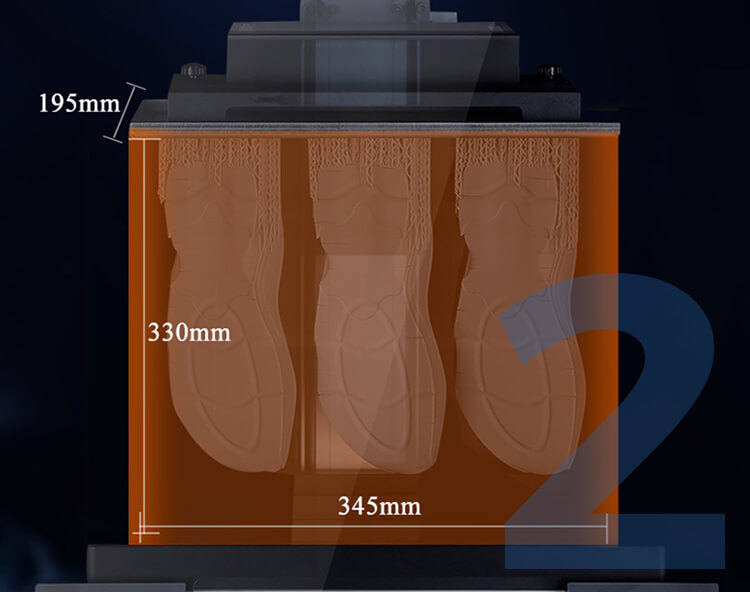

| Max printing volume | 345*192*335mm | |

| LCD size | 15.6 inch | |

| LCD panel | 4K LCD screen panel | |

| Printing accuracy | X Y axis 0.075mm, Z axis 0.02mm | |

| Printing speed | max 20nm/h (Z axis) | |

| Resin support | 405nm resin | |

| LED array | Parallel UV LED light source | |

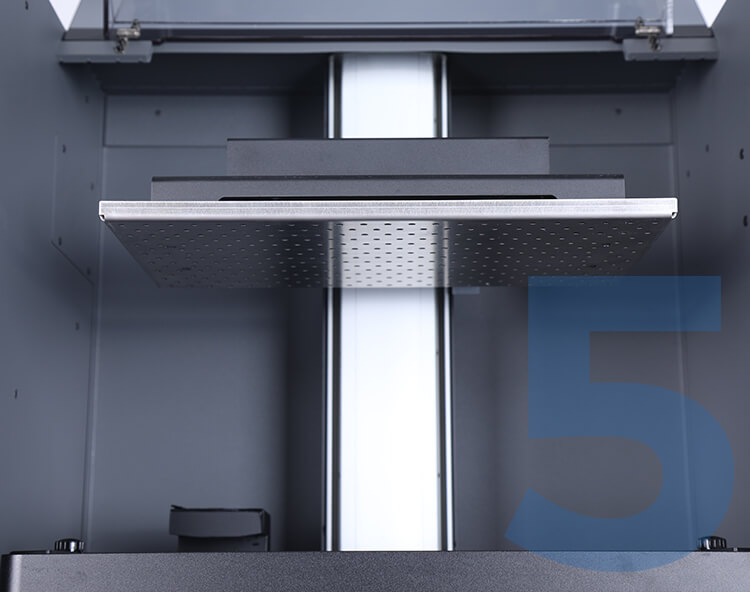

| Z axis | Dual Linear Rail, Ball Screw, 100% Aluminum CNC Structure | |

| Touch screen | 5 inch High Resolution Touch Panel | |

| Software Parameters | Operating systems | Windows Linux Mac OS OSX |

| 3D Modeling software | CAD Solidworks 3Dmax UG Maya Rhino Proe 3Done Skatchup ect | |

| 3D Slicing software | Linux | |

| Input format | STL OBJ AMF ect | |

| Connect mode | USB,Network Connect | |

| Physical Parameters | Printer dimensions | 745*455*585mm |

| Package size | 870*580*710mm | |

| Gross weight | 55kg | |

| Structure | CNC Sheet Metal (full enclosed style) | |

- The Dreambot3D resin 3D printer (ME-345) is an exceptional printing technology that makes use of ultraviolet light to create 3D objects at a speed of 30mm/h.

- The printing thickness is between 0.01 to 0.05mm, therefore giving your printed objects accurate, detailed and precise printing. What you design is exactly what you get.

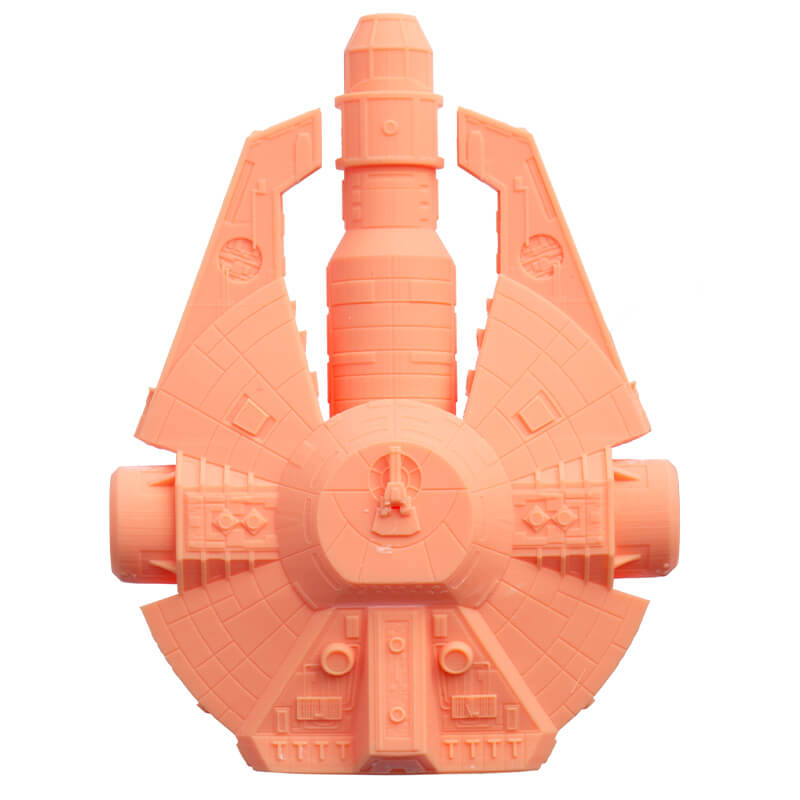

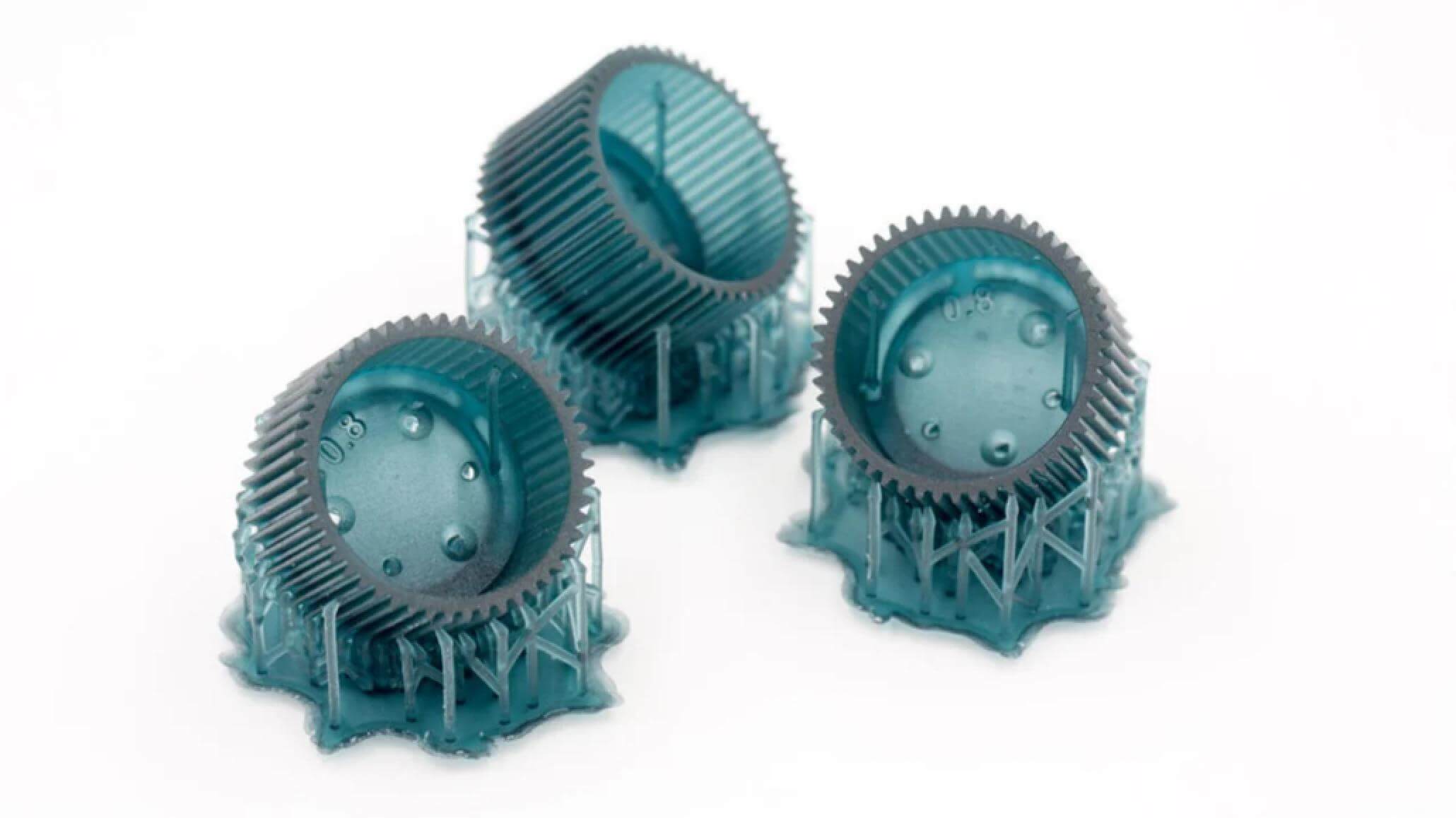

- The Dreambot3D resin 3D printer (ME-345) is widely used in industries such as toy making, pharmaceutical, advertising, jewelry, etc, due to its outstanding features.

- Our resin based 3D printer makes use of consumables such as dental mold resin, rigid resin, high temperature resin, elastic tree, ABS tree boat, high hardness tree, etc. These resins make printed objects more colourful.

- The resin 3D printer (ME-345) has a powerful air cooling system that keeps the printer temperature in check. The large area under the built in screen has multiple fans for heat dissipation. Therefore, you don’t have to worry about overheating that is usually caused by repeated use.

- Also to prevent overheating is the overall chassis structure formed by CNC machining of aluminium profiles. The powerful cooling fan sucks air into the chassis so that the air convection in the chassis reduces the heat generated during printing.

- The thickness of each layer is about 0.02 to 0.1mm. This shows that there is detail in each printed layer.

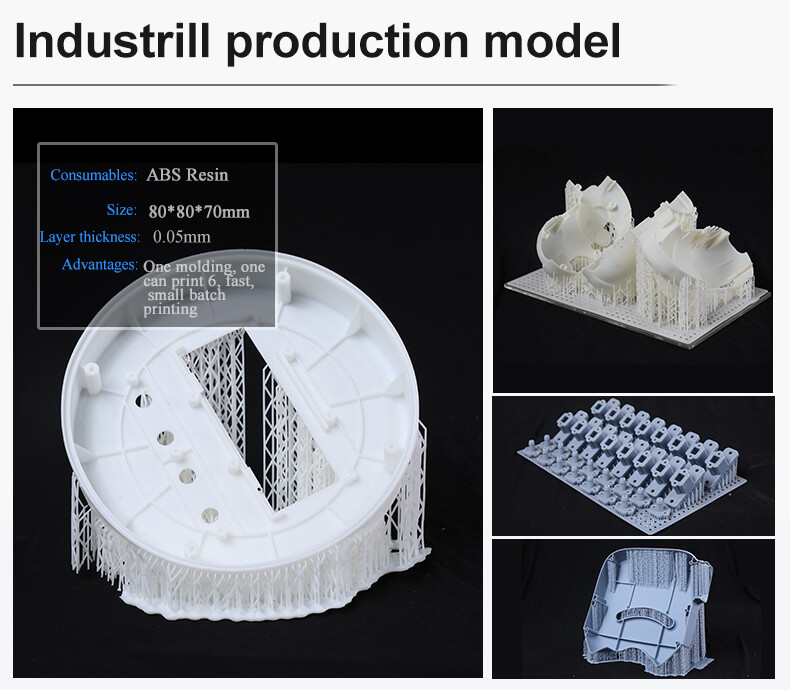

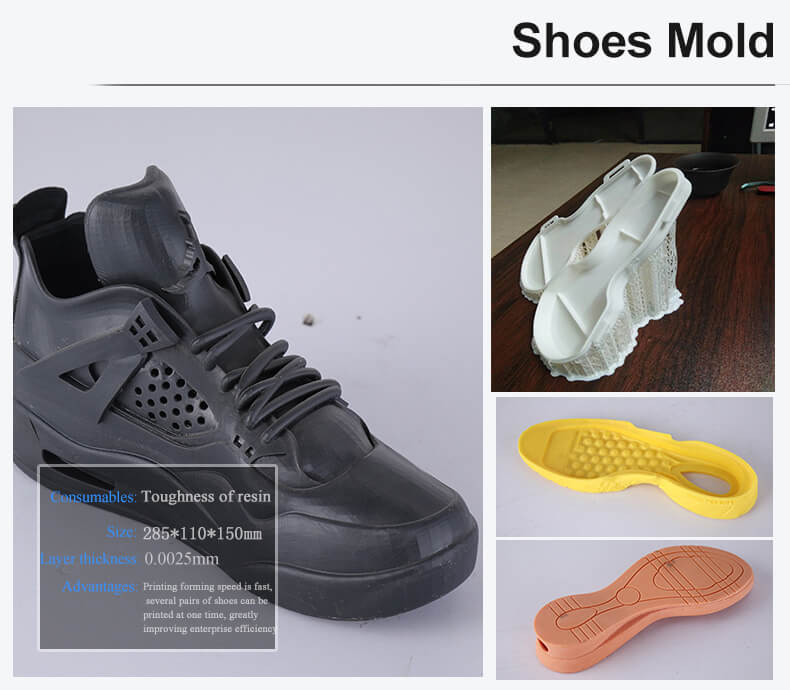

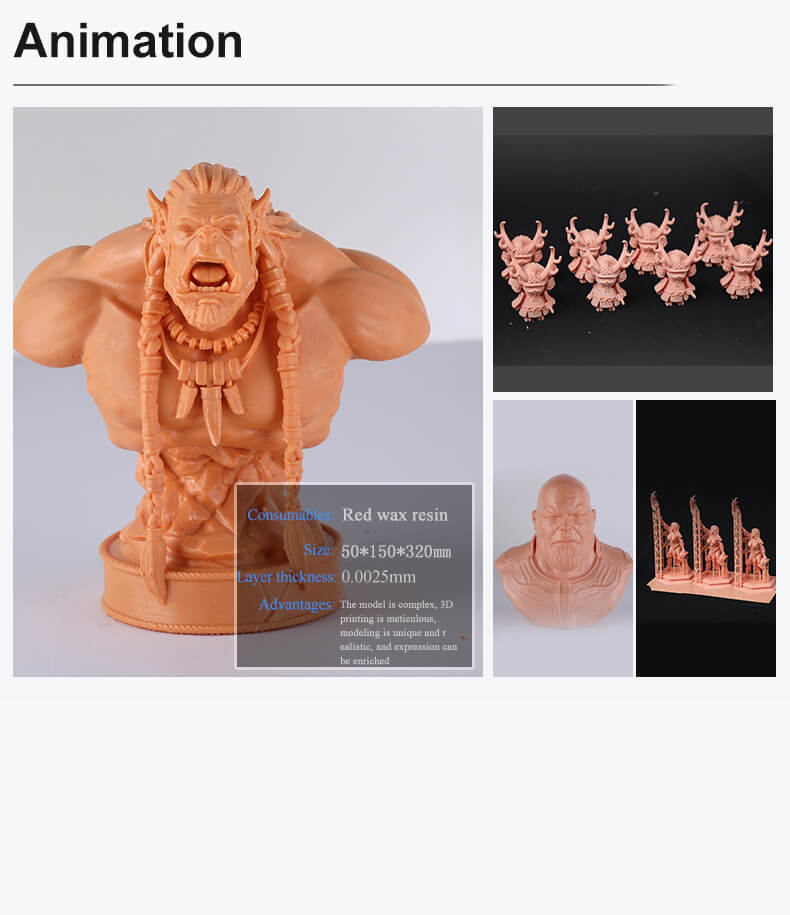

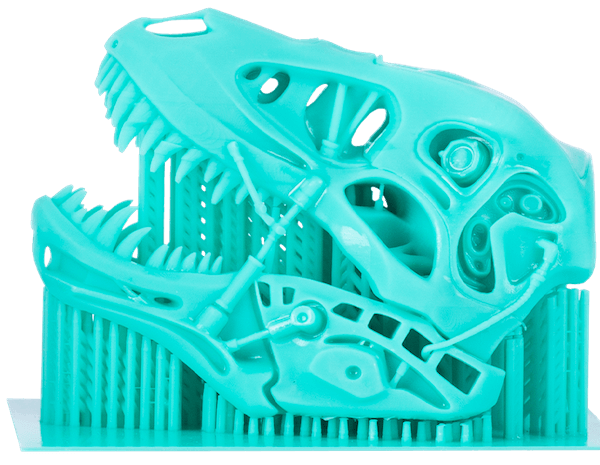

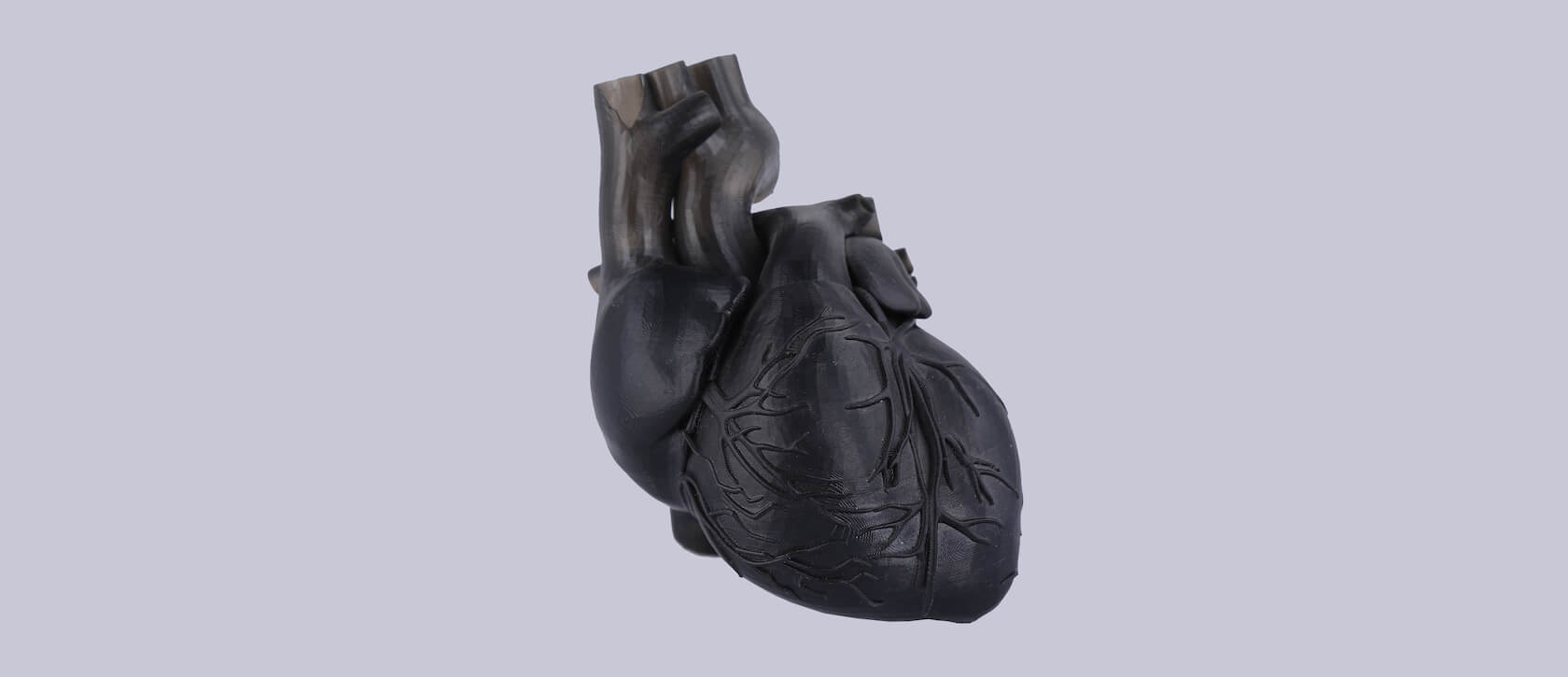

Application of resin 3D printer

Test your part

We provide sample testing service, allowing you to check the working quality of our 3D printer before placing an order

6 points why choose us

4K resolution printing

Large size printing

Our newly developed industrial-grade LCD 3D printer can support print sizes up to 345x195x330mm.

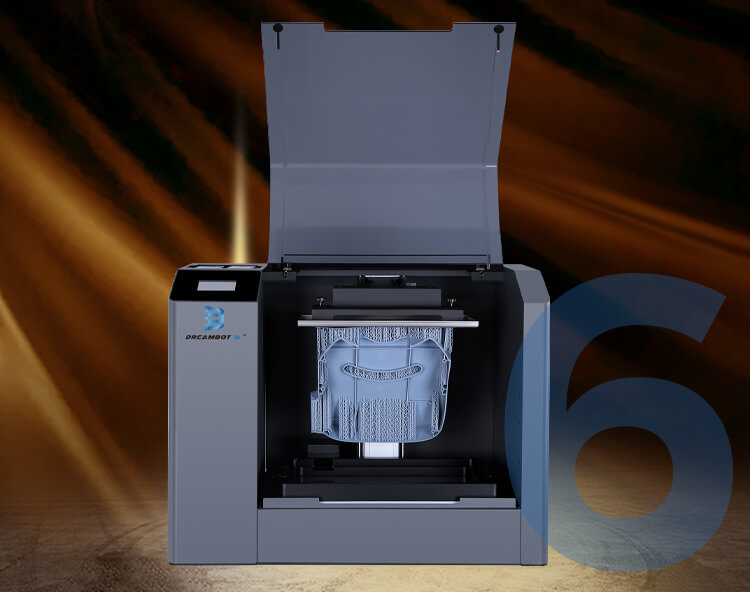

PLC control system

Automatic detection and feeding

With the automatic detection function of 2 * 1kg material box, it can replenish materials to ensure sufficient materials.

Industrial grade ball screw guide

Reinforced structure

More resin 3D printers

ME-192 LCD 3D Printer

The Dreambot3D ME-192 is used for redefined 3D printing. It is applicable for printing 0.025-0.1 mm thickness.

DB-293 LCD 3D Printer

The DB-293 uses a stereo light curing for 3D printing that has an incredible surface finish and fine details for any range of printing.

DB-550 LCD 3D Printer

The DB-550 is used for large 3D printing. It is suitable for use in industries or businesses that require more complex and large printing.

Resin 3D printer buying guide

With time, 3D printing and LCD 3D printers have become very popular to offer the user isotopic, watertight and higher accuracy prototypes and different types of parts.

Those parts are made of advanced and high-quality material with smooth surface finish and delicate features. There was a time when such machines were considered costly machines, and not all could use the machines.

However, things have changed a lot, and now you can buy the best printer under your budget.

The rapid advancements in the 3D printing industry continue to change the way most businesses use to do the production and prototyping. The technology is getting more accessible and affordable; engineers, designers, and beyond are using resin 3D printing in their workflows.

On the other hand, the market is now full of different types of 3D printers that can effectively help you to get your project done. So, this is where you may face a little confusion as you don’t know which one will be the best for you.

Don’t worry at all as we have given detailed information here that will help you choose the right 3D printers, especially a resin 3d printer. Now you might be wondering about what resin 3D printing is?

What do you mean by resin 3D printing?

In simple words, this is a part of the family of additive manufacturing technologies. This process effectively and accurately cures liquid photopolymers with layers to create a solid 3D model. It may be noted that this is not the official name, but as the machines work utilizing resin, they are called resin 3D printers. Here are some things that define resin 3D printing.

- The machine functions based on the code that is uploaded in the form of a digital model.

- To create objects, they use photopolymerization principles.

- This printing is done by using daylight or UV resins.

- Resin or printing material is stored in a resin tank or vat.

Photopolymerization is the liquid material’s chemical reaction, and this process changes the properties when it comes in contact with UV, laser, or any other light sources. In the scientific term, it is described as light-activated resins, and in the world of 3D printing, it is called resin.

Before going deep into this, let’s start with the most basic question, i.e., what do you mean by an LCD 3D printer.

What is an LCD 3D printer?

Before getting deep into this matter, let’s know what resin 3D printing is and then discuss how LCD 3D printers work.

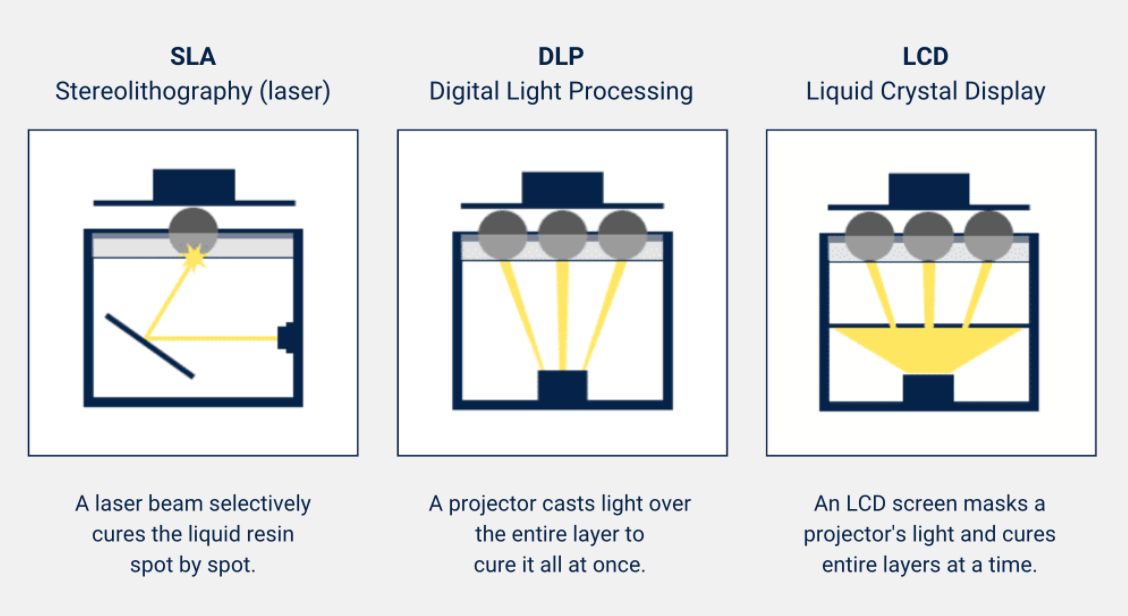

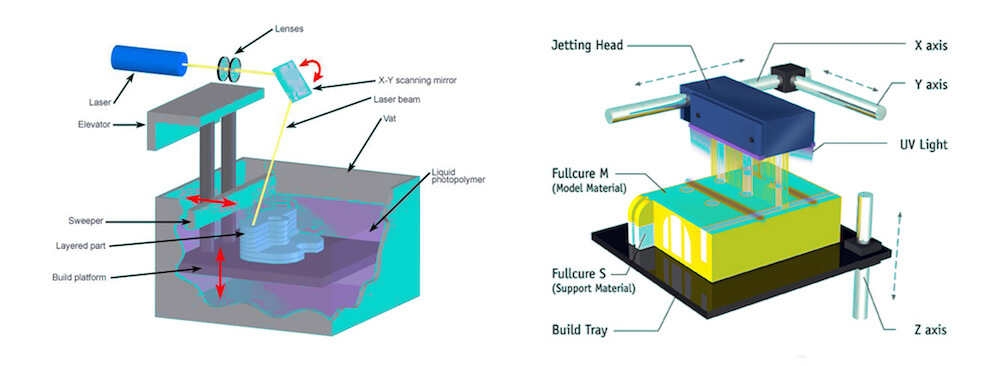

Now, speaking about resin 3D printing, it is also known as Polymerization. It comes in three different primary types, and these are LCD, DLP, and SLA. Despite the fact SLA printing technology is getting outdated, some 3D printers come with this SLA printing technology.

Even though this article will primarily focus on LCD, FDM, and DLP printing technology, it will be better for you to know how SLA printing technology works.

When choosing the fastest resin 3d printer a few years back, SLA printers were considered the best option. This is the eldest method. SLA- Stereolithography utilizes laser technology, and the laser is directed by galvanometers. Here the laser cures the resin. You can consider the Galvanometers as mirrors that guide laser beams through the transparent tank to the 3D printing platform.

Now, coming to the DLP- Digital Light Processing, this printing technology uses a digital light projector for resin curing to make accurate 3D models instead of a laser. Here, the light is directed by a DMD- Digital Micromirror Device. In the 3D printers, DMD is a significant component that combines thousands of tiny mirrors.

The DLP printing technology printer creates layers that include voxels. These are the 3D equivalent of pixels. The reason behind this is that the pro screen of the projector is also made of pixels.

Talking about LCD 3D printers, they are the same as DLP 3D printers. Under the LCD 3D printing, the machine flashes the layers at the vast, but the UV lights come from LEDs and then projected onto an LCD. A screen will work as a mask, and the screen will only reveal the pixels required to form the layers.

It may be noted that LCD is a robust technology, and it produces high-resolution 3D models, and you can even use cheaper 3D printing material to create detailed and complex 3D models. You will find that most of the top resin 3d printers also use LCD printing technology.

Some benefits of LCD 3D printers

- Delicate and detailed printing.

- Can anti-alias edges for 4 to 8 times to eliminate horizontal lines.

- To ensure continuous 3D printing, the machines create robust heat dissipation.

- You don’t have to level the machine to use it. So, this is good for beginners.

- The precision level is high, and you can see all the details correctly.

- The machines will offer a stable power supply during the printing process.

- When it comes to manufacturing complex 3D models and structure, you can always trust LCD 3D printers.

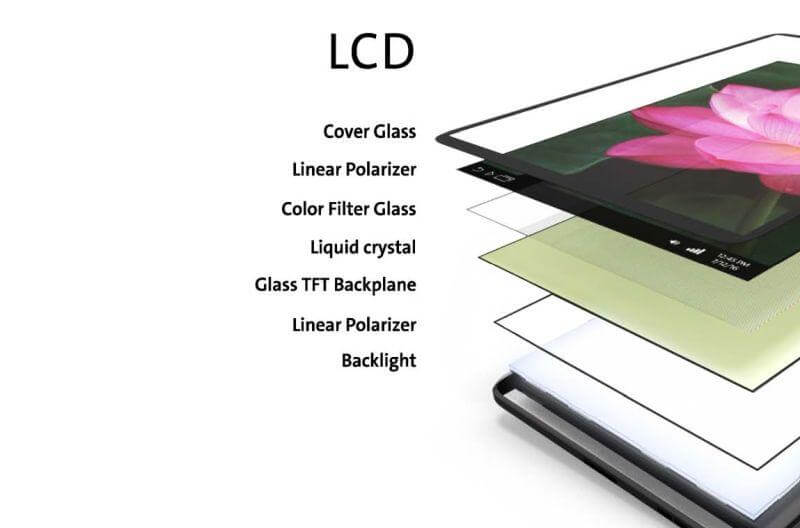

Now, let’s understand what an LCD is and its evolution

1.1, What does LCD mean and where does it come from

Speaking about LCD- Liquid Crystal Display, it is basically a flat-panel display, or you can say electronically modulated optical devices that utilize light-modulating technology and combine the liquid crystal properties with polarizers. Here, the liquid crystal will not directly emit light. They use a reflector to create images in monochrome or color.

This plays a significant role in human lives. Liquid Crystal’s first application was observed in 1968.

LCD’s background

In 1888, the Austrian botanic physiologist Friedrich Reinitzer invented the liquid crystalline from carrots and published the findings at the Vienne Chemical Society. Charles Mauguin, in 1911 experimented with liquid crystal between plates in different thin layers.

After going through many processes, in the year 1962, Richard Williams from RCA Corporation started his research about the NLC- Nematic Liquid Crystal properties. After achieving massive success in this, Williams filed an LCD patent in the same year. The LCD patent was granted after five years, i.e., in 1967.

After one year, in 1968, RCA Corporation makes the LCD technology official, and during a press conference, the company said that very soon everyone can expect to see a thin television in their homes hanging in a room.

With time, the LCD technology went through many improvements, and in 2011, Toshiba launched its 6.1-inches LCD panel that produced a resolution of 2560p x 1600p.

There are a lot of LCD technologies that have been developed; however, we are waiting for further research. Few examples are cholesteric LCD, blue phase mode, photo-alignment technology, and more. All these technologies will take the LCD panels to a new level.

How LCDs work?

While making LCDs, there are three critical facts that you need to consider. These are:

- You should use polarized light.

- LCD’s basic structure needs to be controlled by altering the applied current.

- The liquid crystals of the panel should control the operations to change and transmit the polarized light.

When you apply an electrical current to the liquid, the crystal molecule will remain to untwist. This action will cause the angle of light, which passes through the molecule of the polarized glass. Besides, this also creates a change in the top polarizing filter’s angle. A little amount of light is allowed to go through the polarized glass affecting the LCD’s particular area.

When it happens, that area will become darker. All the LCD panels function by blocking light.

Due to the advantage of a lower level of power consumption, LCDs are now being used for various gadgets and electronic devices, such as computers, TVs, video games, monitors, smartphones, and more.

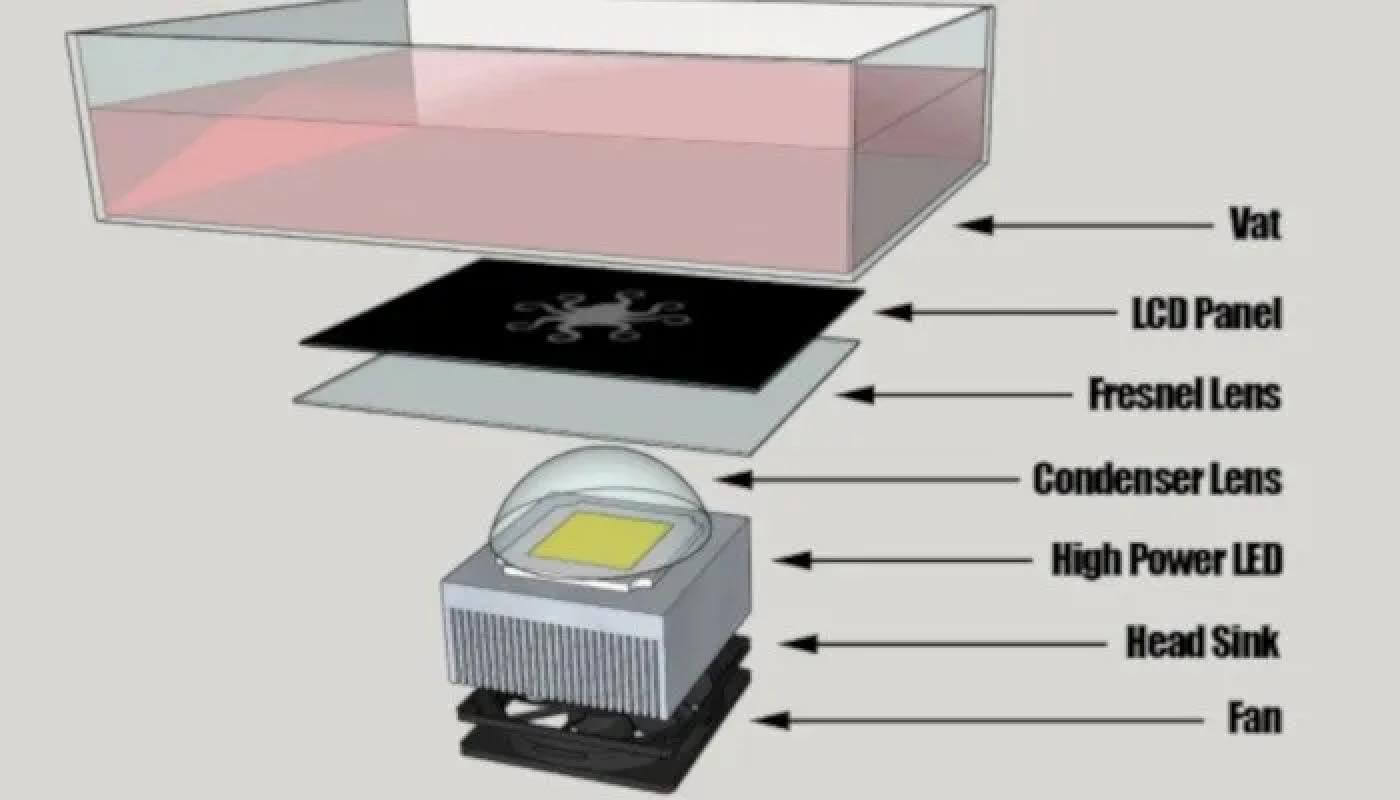

1.2, How does an LCD 3D printer work?

All the LCD 3D printers utilize an array of UV LCDs and work as the light source for the 3D printing process. Here the light coming from the flat LCD panels focus directly, in a similar way, onto the platform.

As the light can’t be expanded, the distortion will be less. The printing quality of the LCD printers, or you can say a resin-based 3d printer depends on the level of LCD density. If the amount of the pixel is more, the print quality will be better.

What this means is that the print quality of an LCD printer depends on its LCD density. The more pixels it has, the better the print quality. Now, let’s have a close look at how LCD or high-resolution resin 3d printer works.

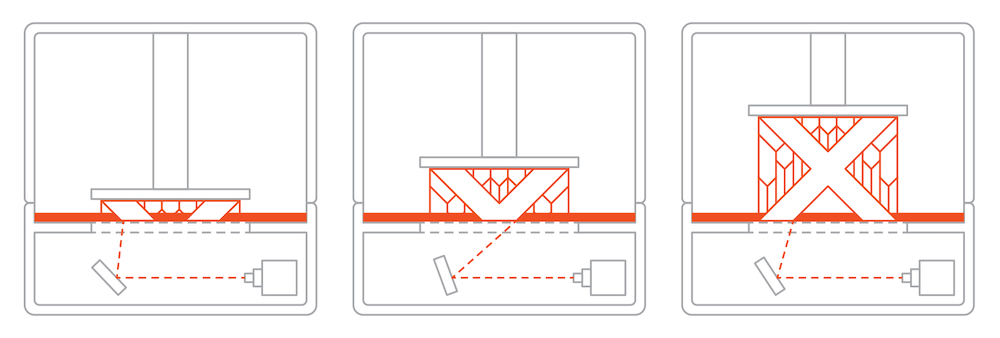

- First, the resin tank, located on the top of the printer, is filled with high-quality resin material. Remember to check the printing material supported by the 3D printers. It is advisable to choose a resin 3D printer that can support different types of materials. For example, you can go for LCD or FDM resin 3d printers from dreambot3d that support PLA, TPU, 95A, water-soluble materials, woody PLA, customizable ABS, PC, PETG, nylon, carbon fiber,glass fiber addition materials, etc. If you go for ME-125 and ME-345 printers, you don’t have to out resin manually as they support automatic feeding function. So, it is advisable to use these two printers.

- Once done, the printing machine will descend the build platform down or up, to form a thin layer of resin touching the build platform.

- After that, a light source will slowly draw the resin’s pattern in the resin and let it layers to solidify. The machine can make one layer at one time.

- The platform will let the uncured resin come through and create a new layer above the plate.

- If the unit has a roller, it will move across the building area to ensure a perfect resin level on the build platform.

- These steps will be repeated until the entire 3D model object is formed.

Once done, the 3D model will be removed from the printing machines for post-processing. Now, have a look at the post-process steps involved in resin 3D printing work.

- Washing- After the printing works, it is necessary to remove the resin leftovers that are uncured. For this, you can put the printed 3D model into water, alcohol, or let it dry on paper towels.

- UV-Curving- Here, the 3D prints are exposed to a UV-lamp or sunlight to make them stable. During the printing process, every layer is exposed to UV light for a few seconds. So, the post-curing of the 3D object is mandatory.

To make the washing and curing process easier for you, we also offer the best washing and curing machines.

- Removal of support- Under this process, all the supporting structure from the 3D models are removed. Resin 3D printing, to create perfect 3D models required supporting structure to hold the objects and stick the object to the build platform for better stability. Such supporting structures are very easy to remove. However, be careful when cutting them as you may cut down too much volume of the objects.

- Sanding- By using wet sanding or dry sanding tools, taps are removed from the areas where the supporting structures touched the object.

- Finishing- In this process, parts are covered suing particular types of coatings or compositions. This will further strengthen the parts and eliminate all the visible imperfections.

- Painting- Here, the 3D models are painted with different compositions and colors.

After going through all these processes, you will get a high-quality and durable 3D model of your product. Check out the3d printer resin price and get your first resin 3D printer now.

1.3, LCD vs. DLP vs. SLA: All you need to know

The factors that can significantly affect your buying process related to top resin printers is the printing technology. You will come across three major printing technology processes; these are SLA, DLP, and LCD. Are they all the same? Which one will be better for you? Keep reading to get your answers.

What do you mean by SLA?

SLA is the short form of “Stereo Lithography Apparatus.” Under this printing technology, the laser beam perfectly outlines the first layer’s shape of the 3D model that you want to print on the resin’s surface. In most cases, the liquidized photosensitive resin is used for this.

After that, the production platform comes down to a certain distance, and the cured layer is immersed in the resin. After making the prototype using the resin, it is cured, polished, and colored to get the desired 3D model.

What do you mean by DLP?

DLP stands for Digital Light Processing. Under this process, the image signal is processed digitally before projecting out the light. The principle of DLP printing technology is to pass the light source emitted by the printer’s UHP bulb.

It is done through a condenser lens, and the machine makes the light uniform using a rod. The processed light will be let to pass through the color wheel located in the printer, separating the light into three colors. After that, the color is projected from the DMD chip lens, and the reflections are imaged on the screen. This process offers better accuracy than SLA.

What do you mean by LCD?

As discussed above, the LCD stands for Liquid Crystal Display. As the name suggests, it is a liquid crystal printer or projector. The LCD panel is made of RGB color- Red, Green, and Blue and the color are transmitted by a mirror and a lens of magnification.

In the case of LCD, a UHP or metal halogen lamp works as a light source. Now, have a look at the advantages of these three printing technologies.

SLA processing advantages

- It offers a higher level of processing accuracy and can cover around 0.1mm.

- It can easily manufacture different types of complex shapes (for example, hollow parts) and serviceable (for example, jewelry, handicrafts, and more) parts. Besides, this printing method is perfect for delicate parts and toys, for instance, radios, walkie-talkies, mobile phones, mice, and various high-tech electronic industry housings. In some cases, SLA processing is used to created auto models, parts, and medical equipment.

- The speed of manufacturing parts will be breakneck. This can process 0.1 to 0.15mm layered scanning.

- The surface quality of the 3D models created through this process will be okay. It can produce fine details along with a thin-wall structure. The post-processing method is also easy. The workload level related to post-processing will be very low.

DLP projector benefits

- In terms of a technical point of view, this technology has three essential characteristics. These are a miniaturization of printing machines, a higher level of native contrast, and a secured optical path.

- The chip utilizes a mechanical process. The lens’s movement level is right, and you will get the expected native contrast ratio.

- Almost all the DLP projectors work based on reflective principle. This is quite good in terms of eye protection.

- On the other hand, it also utilizes a semiconductor structure and a closed optical path to lower the risk of dust entering the machine.

Advantages of LCD

- Better accuracy- Using LCD 3D printing technology, it is easy to get maximum accuracy of 100 microns. This is something much better than SLA technology and DLP printing technology.

- Cost-effective- If your camper this with the DLP and SLA technology, you will find the price-performance ratio very impressive. Besides, as this doesn’t include any projection module or laser galvanometer, the printing machine structure is simple, and you will find it easy to maintain and use.

- Faster printing- It utilizes surface forming light source printing method that a DLP printer uses. It can also print multiple 3D model parts simultaneously, and the speed level will remain the same.

- General resin- As it has a 405nm backlight, an LCD 3D printer will support all the DLP resins along with photocurable resins.

Which printing technology can offer the best 3D printing quality?

The resin 3D printing quality ultimately depends on the types of 3D printers and printing materials you are using. If you are looking for high-performance LCD 3D printers under your budget, you can go for dreambot3d’s ME-192, ME-345, ME-215, DB-293, DB-345 and DB- 550.

In the case of an FDM 3D printer, dreambot3d offers L5-300, 400, 500, L8- 400, and 500 FDM 3D printers that work really great.

If you value performance, cost, and reliability, it would be better for you to go with a well-known brand known for resin 3D printing products, such as dreambot3d. This brand is famous for manufacturing and supplying quality FDM and LCD 3D printers. Their printers support all types of printing materials, including resins.

Application fields of LCD 3d printer

This is the time of Industry 4.0, and most of the companies are now implementing high-quality 3D printers or a resin bath 3d printer to enhance their business activities.

The use of LCD and FDM technology is considered the most effective and advantageous solution in different industries, such as tooling, production, spare part production, and more.

On the other hand, this has also emerged as the fastest and cost-effective way to produce different prototypes covering complex geometry.

The adoption level of 3D printing has reached a critical stage as the businesses that have yet to implement additive manufacturing in their supply chain are now gradually doing this.

LCD and FDM 3D printing were ideal for manufacturing and prototyping during its early years; it has now transformed into an advanced production technology.

If you look at the current demand for LCD to FDM 3D printing, you will find it industrial. It has been forecasted that by the end of 2026, the global 3D printing market will cross USD 41 billion.

This printing technology is all set to transform all the primary industry, revolutionizing how people work, play, and live.

The cost of these machines is now getting down, which has boosted the adoption rate. It is not just limited to a single industry. For a few years, LCD or FDM 3D printing has developed at a higher rate and is now performing a significant role in different sectors or applications.

Some of the most critical industries under this are architecture, medicine, design, manufacturing, custom art, robotics, and more. Do you know what the real reason behind such growth of 3D printing is? It is due to the rapid development of customized product designing, prototyping, 3D modeling, automotive parts, and more.

The possibilities with an LCD 3D printer or a resin 3D printer is quite impressive. It is all set to influence the entire industries, covering healthcare, consumer products, construction, aerospace, automotive, and more.

In this section, you will explore the current scenario of 3D printing across different industries. Besides, you will get to know how it is being used across those sectors. This guide will give you an in-depth knowledge of how 3D printing technology can be used to drive innovation and business growth.

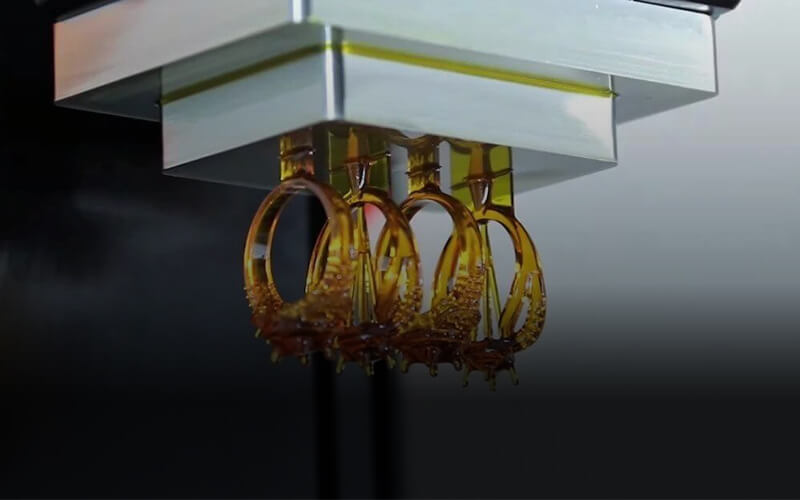

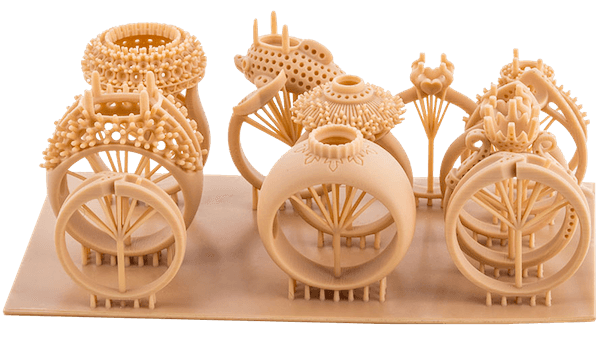

2.1, Used in the jewelry industry

The jewelry manufacturing industry has dramatically embraced the LCD and FDM 3D printing industry. It can be said that it is one of the first industries to use 3D cast printing in the investment casting method.

In this industry, 3D printing is widely used to make creative patterns for investment casting and to directly print different jewelry pieces. Instead of costly metal printers, most jewelers are now using wax. Here the jewelry pieces are printed using wax.

Utilizing CAD- Computer Aided Designing, jewelers can 3D print master patterns for jewelry, and then it is cast in precious metal to craft jewelry.

Resin 3D printing has dramatically impacted this industry and successfully eliminated different traditional and time-consuming steps. One of the most useful ways resin 3D printing has affected the global jewelry sector is method tooling and prototyping.

3D printers are now used to craft the primary 3D models that can be used to create real pieces of jewelry. All these applications have witnessed an enormous development in many areas of the jewelry industry.

3D printing is widely used to form patterns for investment casting. Using this, you can even print jewelry directly. The oldest method of wax mold is gradually getting replaced by this technology.

By using this, multiple intricate patterns for the jewelry can be made at once, and you will take less time for this. In a single print, you can come up with multiple designs.

How customers and jewelers benefit from this?

- A new method in the segment of customized jewelry

Earlier, designing and producing customized jewelry was an expensive privilege. Now using 3D printers, jewelers have started offering highly personalized creations.

On-site digital designing amalgamated with the feature of 3D printing has changed and shortened the gap between the customers and designers. Within just a few days, one can now get a customized piece of jewelry.

- Freedom to design

With advanced LCD and FDM 3D printing machines from dreambot3d, you can now create designs that will be difficult to hand-draw in the traditional way. This has also improved quality. By using high-quality resin and rugged LCD 3D printers, you can now capture all the elements with an excellent sharpness level.

- More comfortable and faster mass production

These machines are making jewelry customization easier and are helping in the mass production of the designs. An advanced FDM or LCD 3D printers can create master models that can be used to produce RTV- Room Temperature Vulcanization molds.

2.2, Used in the medical industry

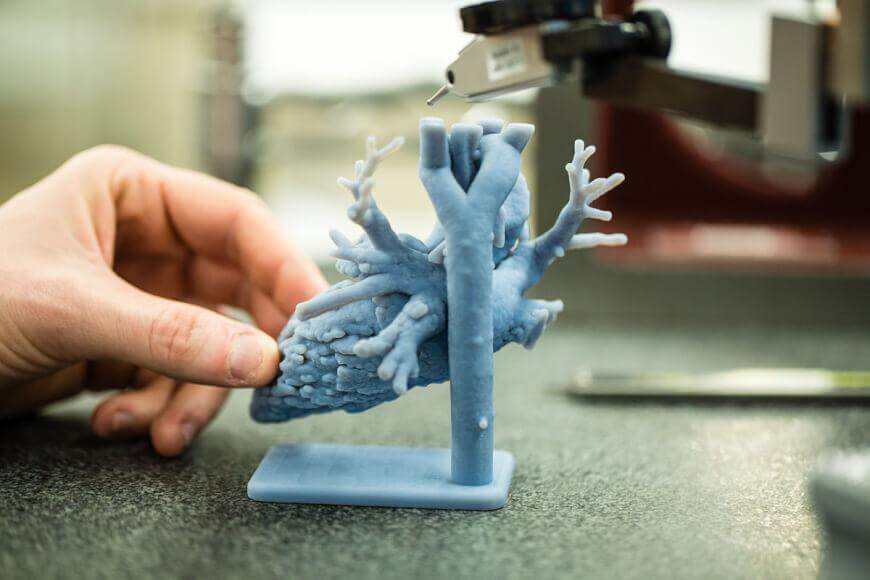

It is a fact that around 13 percent of global 3D printing revenue comes from the medical industry. How? Well, starting from the surgical guides to prosthetic solutions, you will find a massive number of medical applications for 3D printing technology.

The level of flexibility that this technology offers has allowed medical experts and hospitals to come up with patient-specific medical devices at the best prices.

This industry is already primed for 3D printing technology

Some of the most crucial parts of the global medical industry are image processing and detailed scanning. Using laser scanning, you can take detailed images of a particular area, and on the other hand, MRI imaging and CT scanning are used to get bones and tissues’ cross-sectional images.

Advance medical imaging software has converted such medical images into a complete model that can be used for 3D printing. Medical devices that were perversely considered as theoretical now can be developed within a few weeks or months.

Some typical medical 3D printing applications

Resin 3D printing has been used for years to produce replacement limbs, detailed models of organs, hearing aids, bones, surgical implants, blood cells, and more.

- Prosthetic- 3D printing, also known as additive manufacturing, has completely changed the global prosthetic industry. From prosthetics to operational replacement limbs, such printing machines can be customized to create things without spending a lot of money.

- Surgical guides- Whether it is medical surgery or dental surgery, both the tasks require a high level of precision. When you can have a well-developed 3D printed guide, it can help your staff to adequately line up holes and incisions with the patient’s anatomy. The LCD and FDM printing technology have made it faster to create such guides.

- Implant- 3D manufacturing has the features to craft delicate mesh structures without any additional cost. This is a feature that is required for surgical implants. When you have the device’s organic structure, the risk of rejection can be significantly reduced after completing the surgery. With 3D resin printing, you can manufacture customizable implants. As a result, you will get sterile, robust, and well-suited implants.

- Models- Using 3D printing, you can create correctly scaled models of structure and anatomy. This way, nurses and doctors can efficiently study the subject from different angles to come up with a perfect solution. It has been proved that 3D printing is the best and cost-effective way to create anatomical 3D models.

Surgical implants require organic and complex structures to be entirely accepted by natural tissue. Only through 3D printing is this possible. It is forecasted that by the end of 2025, 3D printing in the medical sector will be worth around USD 4 billion.

In 2016, it was recorded at USD 713 million. On the other hand, it is also projected that from 2017 to 2025, the compound annual growth rate would be around 18 percent.

2.3, Used in production and R&D

Whether it is the production industry or the R&D sector, 3D printing plays an important role. R&D-Research &development is a crucial part of different industries and markets.

For keeping up with the growing customer demands and surviving the competition, firms and manufactures will have to make sure that their products can match the changing market demand and trends.

R&D helps form a robust foundation for the product innovation life cycle. When you utilize it properly, you will enjoy the better market expansion.

3D printing was earlier developed as a way for quicker and error-free prototyping. At large volume, the traditional production process may look cost-effective. What about the condition where the products are not going to be produced in bulk?

This is where you can go for 3D printing as it can be a cost-effective solution during such a situation. The advancement in RP-Rapid Prototyping has increased the materials and printing process, for example, FDM, SLS, DMSL, and more.

On the other hand, advancements in technology also helped the companies witness reduced production cost and increased productivity. With this, you will be able to match the growing demand of the market. Have a look at some significant advantages of 3D printing in this industry:

- You can develop and market your products faster

Forget about those traditional methods of conducting research and producing products. With 3D printing, it will take just a few hours to create perfect 3D models of your products, and you can analyze every aspect of it.

With this, you can come to a conclusion and make the right decision about whether the product will be profitable or you should make some changes. The faster you develop the products, the quicker you will launch the products in the market.

- Cost reduction

If you failed to detect the products’ identified risk element, you would suffer a considerable loss. Some parts of your products may not work correctly. With 3D models, you can create functional parts of your products and understand how it works.

Besides, using resin-based 3d printing, you can automate the process of 3D model making. Feed the design into the computer, and the machine will print the designs.

- Reduced risk

It is quite essential to make sure your product has no issue before sending it for final production. You can lower the chances of risk related to product rejection, money, marketing cost, and more. When you have an accurate prototype of the product, you can create the right products.

- Easier to developed complex geometrics or parts

Some components of products may have complex geometries that can’t be crafted manually. Using high-quality resin and other 3D printing materials, you can create lightweight and durable parts.

2.4, Used in the education industry

Every year, more colleges, universities, and schools are implementing 3D printing technology into their syllabus. This is something that has been helping students and teachers to enjoy a better teaching style.

Besides, as the machines are easy to use, students can easily create different prototypes for learning. 3D printing works by beginning with a CAD model and then crafting a three-dimensional subject that can be used physically.

Here are some examples, how students, schools, colleges can use the power of 3D printing.

- History students can now print historical artifacts in 3D models for examination or analysis purposes.

- Graphic students can print 3D models of mountains, rivers, regions, and their artwork

- Geography students will be able to create 3D interactive models of topography, demographics, or maps.

- Mathematics students can now print different geometrical shapes and other 3D models to solve problems faster.

- Chemistry students can now 3D print the molecules.

- Biology students will be able to print viruses, cells, organs, and other biological artifacts in attractive 3D models.

These are some significant ways through which 3D printing is gradually bridging the gap between digital worlds and physical worlds. On the other hand, the cost of LCD and FDM 3D printers are also going down.

However, they are a technical element for the students but are now useful and essential educational tools. With this, both learning and teaching can be made better.

This way, students can visualize and conceptualize their designs and give that a physical shape using a resin 3D printer.

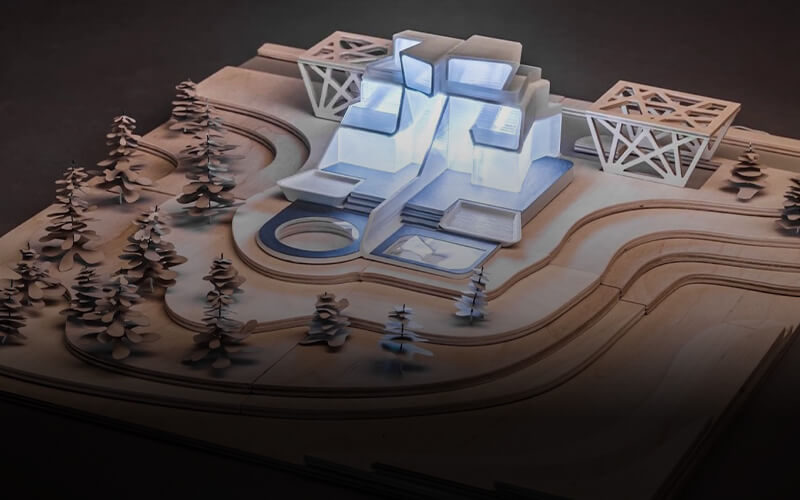

2.5, Used to make various models

When it comes to conducting a better product presentation to create a robust effect on the customers, investors, and other stakeholders, most companies are now using 3D models. Such models depict the product’s real attributes, and one can know how the product will look and work after the completion of the development.

You will get to see the things that are impossible with a 2D model. Now, you might be thinking that it will take days to create a perfect 3D model of your product. When you have the FDM and LCD 3D printers developed by dreambot3d, you can get it done within a few hours. However, that will depend on the type of product you want to manufacture.

With 3D printing, you can make your product model look more vivid and realistic. You can literally offer your clients and customers a perfect virtual project. What’s more? You can detect the possible issues and make the necessary changes to ensure that the product is all set to impress your customers.

Film, prototypes, constructions, and architects have now adopted 3D printing technology as an essential part of communicating and visualizing their products and services.

With this, they can craft colorful and clear physical 3D architectural models from their data. 3D printing technology offers the level of accuracy and details that is not possible through old designing methods.

The future potential application of resin 3D printing is increasing. Different industries are now trying to develop new business models and opportunities using this printing technology. So, you should not take it lightly. It’s time to take your business to a new height with advanced FDM and LCD 3D printing machines.

Which resins can be printed on an LCD 3d printer?

Earlier, when the LCD 3D printers were introduced, the options related to resins were very limited. However, now things have changed a lot. You can use different types of resins for different purposes. However, before talking about it, let’s look at how the 3D printer resin really works and how it is made.

LCD 3D printing process starts with a huge tank filled with resin. A liquid polymer layer is spread on the build platform, and that polymer is sensitive to UV light. By applying laser, certain parts of the liquid resin are hardened.

The process is repeated until you get the final 3D model. During the process, the support structures are automatically generated. Once done, the model is raised out, and support structures are removed manually.

How does the 3D printer resin work?

FDM uses the solid filament spool, and the 3D printers used resin, which is one type of liquid solution. Resin is a perfect combination of different oligomers and monomers.

Oligomers are the short chains made of carbon atoms and different functional groups. They remain in liquid form. The primary objective is to build longer chains utilizing the oligomers and monomers, which gradually become a hard-plastic material from a 3D model.

Resins are very versatile and widely used in different industries. In fact, you can also use resins as an epoxy material. Besides, it can also be molded and converted into the desired structure and shape. Resin also has the feature to get blend in and camouflage.

In general, resins can be categorized into thermoplastic and thermosets based on if the hardening reaction of resins can be reversed or not. Some of the famous examples of thermoplastic resin are polycarbonate, polyethylene, and polystyrene. On the other hand, some standard thermoset resins are polyester, polyurethane, epoxy, and vinyl ester.

Speaking about the thermoplastic resins, these resins can be melted and hardened through the cooling process. Due to the molecule chain structure, they create a robust bond between molecules.

Further, these resins are processed through non-reversible reactions for creating hard end 3D models coming to the thermosets. It is done through a process named Polymerization.

Apart from this, you will also find other different types of resins, and each of them has its own properties.

3.1, For transparent resin 3d printing

This is a low-cost resin that you will get in the market for 3D printing. It is generally created from liquid resin processed by a laser.

The material is easy to pain, smooth, and translucent. Besides, with transparent resin 3D printing, you will enjoy a higher level of details, and on the other hand, the pose processing techniques involved in this are also comfortable.

When it comes to enjoying excellent quality at a reasonable cost, transparent resin 3D printing will be a perfect option. The support you will get with this type of resin is commendable as you can use transparent resin without any assistance.

Apart from being cost-effective, the material will also offer fantastic surface quality. You can use this resin for visual models, figurines, and model trains having controlled functionalities. It is a fact that transparent 3D printing is challenging, but when you have the best resin 3D printer, essential guides, and the right material, you can quickly get it done.

While doing transparent 3D printing, it is essential to keep in mind that it will reflect more light if you choose a more intricate design. On the other hand, the transparency level will be a little low. As per the experts, for better transparency, you should lower the light refraction level.

For the best result, you also need to consider a few other things, i.e., flow rate, layers thickness & height, print platform temperature, extrusion temperature, printing speed, and diameter of the printing nozzle. Talking about some useful features of transparent resins:

- The shrinkage level is relatively low.

- UV stability level is good.

- You will enjoy non-yellowing characteristics.

- With this, you will enjoy high gloss finishing.

- Using suitable pigments, you can pigment this resin.

- It offers a lower level of viscosity.

- You will get 3D models having a smooth finish, transparent surface, and high-quality.

- With 3D printers, you can achieve complex structures that are mostly impossible to achieve using traditional processing technology.

Are you looking for the best 3D printers for creating high-quality transparent 3D models? If yes, you can get in touch with dreambot3d that manufactures world-class LCD and FDM 3D printers. Besides, they also offer the necessary help and video tutorials to complete the 3D printing process successfully.

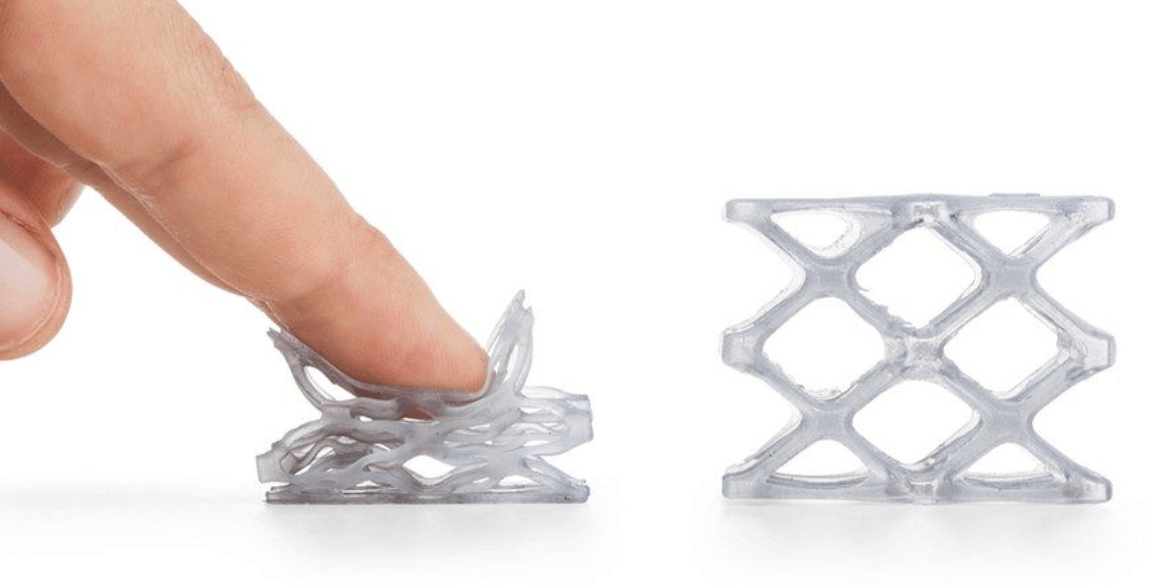

3.2, For flexible resin 3d printing

The 3D printing industry is now going through a massive revolution, and the things and complex modern 3D models which were impossible to print can now be printed easily. All thanks to advanced 3D printing machines and flexible resin.

Such resins can be bent, twisted, and stretched, but they don’t lose their original shape. If you are still using the standard printing procedure, then it’s time to go on and use flexible resin 3D printing to offer your customers better products.

With flexible 3D printing, you can use rubber-like tires, products, gaskets, phone cases, and more. Not only can you use such resins for functional and ergonomic prototypes, but you can also use this for end-use parts.

Some common characteristics of flexible resin

These are mostly a rubber-like printing material and come with elastomeric properties. However, the elongation level is very low. That means the parts made through flexible resin 3D printing will be compressible, bendable but you can’t stretch them more.

3D model parts that are printed thick are called resilient, and the parts that are thin-printed are called pliable. If you want to make your object impact-resistant, then the parts need to be very thick.

Denser parts will be less bendable. Always go for the latest flexible resins to get more benefits as they are wear-resistant and tear-resistant. On the other hand, the tensile strength of post-cured will be 7.7 to 8.5 MPa, and the tear strength can be around 75.7 lbs./in.

While printing, the flexible resin will feel like rubber or silicone material. Such parts can be appropriately compressed, and they can bounce back to the original shape. As the name suggests, they can’t shatter like a standard filament.

Application of flexible resin

Such resin’s unique compression characteristics make it perfect for printing 3D materials to be used for high-impact applications. This tactile material is perfect for functional prototypes and ergonomic prototype. Besides, you can utilize flexible resin 3D printing for producing end-use parts.

On the other hand, such printing can be used to 3D print gaskets, custom holds and grips, cushioning, stamps, wearable prototypes (shoe insoles), and more. In some cases, this can be utilized for soft-touch materials simulation.

It may be noted that this printing is not suitable for stretchy material simulation, and don’t expect that it will offer you fine details. But the possibilities are endless.

Want to learn more about flexible resin 3D printing and looking for high-quality 3D printers for such printing work? Call dreambot3d now.

3.3, For high hardness resin 3d printing

The photopolymer resins that are used for 3D printing are fragile in nature. They can make delicate details susceptible to cracking and snaping. For that reason, this printing technology is used for aesthetic purposes, such as visual prototypes and artistic models. However, to address such issues, all the companies are now producing tough resins.

Such resin can offer you the properties of ABS plastic. The tough resin 3D printing can demonstrate a higher level of wear-resistant for various parts. You can bend them without worrying about their cracking. Different studies have proved that such resin can support around 55.7MPa of tensile strength and 2.7 GPa of elasticity level.

Due to their nature, such resins are perfect for creating robust 3D models, prototypes, functional parts, along with assemblies that require a perfect combination of strength and compliance. Some amazing properties of tough resins are:

- You can create sturdy and shatter-resistant parts.

- Tough resin is ideal for crafting functional prototypes and different mechanical assemblies.

- You will get professionally designed parts.

- The strength and stiffness level will be awe-inspiring.

- The parts can perform well under changing temperatures.

3.4, For castable resin 3d printing

Now, speaking about casting, it is the photopolymerization technologies used in jewelry and dental industries to fabricate 3D parts that can be cast as metal. Almost all the top resin printers can be used for this.

Here, molds are filled with resin, and once cooled, you will get the rigid structure. Castable resin 3D printing is an ideal option for small-scale manufacturing, creating models, collectible figures, jewelry production, and more.

The key to a perfect castable resin 3D printing is burned out. When the 3D object is cast from the 3D printed parts, the polymer is burned out, offering you a perfectly crafted product.

Some benefits of castable 3D printing

- You can craft intricate designs that were impossible to craft. Just feed the design through the computer, and the machine will get it done.

- When it comes to changing the design, castable printing offers you a lot of opportunities. You can change the design as many times as you want.

- Such printing is cost and time-saving. You can print the design in a single print within a few hours.

3.5, For photosensitive resin 3d printing

For photosensitive resin 3D printing, UV resins are similar to epoxy resin but come with a different chemical structure and setting process.

In standard resin, two parts need to be combined to set, but it is already combined in UV resin; such resin sets faster as the process is activated immediately when the material is exposed to UV light.

UV resins can include stabilizers, plasticizers, pigments, co-initiator, photopolymerization, monomers, oligomers, and more. Some features of such printings are:

- UV resin offers a faster drying time than other types of resin.

- The parts are already combined, so you don’t have to mix it with other resins.

- Your 3D model will only begin to set when you apply light, so you will get more time to work with the products.

Application

The application of such resin is quite simple as you can directly pour the resin on an object that you want to coat. Besides, before using it, you can change the color of the resin. You will enjoy some advantages like a reduced waste, better productivity, lower energy consumption, and more.

3.6, For heat resistant resin 3d printing

Some brands have been offering quality resins that can withstand a higher level of temperature. In general, heat resistant resin supports an HDT – Heat Deflection Temperature of around 290-degree C at a loading of around 0.45 MPa, which is quite suitable for all types of printing systems, including FDM and LCD 3D printers.

Such printing can be used for applications like creating injection molding tools, testing channels for fluids or hot air, and casting and thermoforming tools.

The heat resistant resin 3D printing involves lower power consumption. However, for such printing, you need to use support structures. After setting, you may find a little bit of shrinkage. While printing heavy objects with heat resistant resin, make sure the touchpoint size is large.

Use high-temperature resin for prototyping milli-fluidic devices, kitchen appliances, and encapsulation of cosmetics. Besides, this resin can be used to mount sensors for wind tunnel testing, prototype under the hood components, and more.

Such printing is also used to produce protective masks for coating, soldering electronic test molds, injection molds, to create carbon fibers parts for automotive and aerospace, and to create vulcanized molds for jewelry crafting.

3.7, For conductive resin 3d printing

Utilizing conductive resins, you can develop parts for electrical connections using materials that can’t be solder. These are made of conductive filler and synthetic resin.

These are also used in different applications where the risks of thermal and mechanical cracking are relatively high, and there are concerns about affecting heat sensitive electrical components on the PCB while soldering.

They can be used as a perfect alternative to leaded and unleaded solder. The curing temperature is low, and the resin won’t damage the heat-sensitive components.

Under this printing process, silicon resin, synthetic rubber, epoxy resin, and urethane resin are used for the binder. On the other hand, nickel, silver, and carbon are used for electro-conductive fillers.

Such resins are thermally conductive and can keep the components cool. Some advanced conductive resins offer exceptional smart properties, such as self-curing, self-repair, self-healing, self-protection, and more. So, conductive resin 3D printing is widely used for energy supply, aerospace, technology, building, and automotive industry.

How to Buy a 3D Printer – Question you should ask

Finally, you have decided to buy a 3D printer after going through all the details and learning about the things such a printer can create. It is a fact that such devices offer an endless array of 3D printing possibilities.

But to get the best 3D printing results, you will have to buy a high-resolution resin 3d printer, which is where you may face some challenges.

So, how to pick the right one? Here are some points that you can consider to develop the best option for your 3D printing requirements.

4.1, Before buying, you should consider your own needs

4.1.1 What is the thing to be printed?

First, you need to understand what you want to 3D print. Base on your printing requirements, you will have to buy the right printer. 3D printing gadgets for your desk and printing industrial production parts are two different things. Besides, you also need to think about how often you will use the machine and plan to use the printed objects.

4.1.2 What is the size of the print?

This describes the maximum size of the object that the printer can print. Here the size is calculated by XYZ dimensions. For instance, 20-inches Wide X by 20-inches Deep Y and 10-inches High Z. So, based on your product size, you will have to choose a printer.

4.1.3 What are the unique needs for printing materials?

Here you may need to consider two types of printing materials, such as filaments and resin. When it comes to filaments, you can choose from:

- PETG- Using this, you can create layers that can effectively trap bacteria, moisture, and food. This is a food-safe plastic.

- PLA- This is perfect for indoor application as the moisture level and prolong exposure can damage this material.

- ABS- This is the most durable printing material and can withstand higher stress and temperature levels.

- Nylon- It offers the durability and flexibility to create thin walls. The melting point is high, and the coefficient of friction level is low.

- Carbon fiber- This material is five times stronger than steel but feels very lightweight. It can offer you the strength of aluminum.

- PVA- PVA, when exposed to water, get dissolved. You can make the support structures from PVA and the model from other materials to prevent support removal issues.

The types of resins you can use are as follows;

- Transparent resin- Using this, you can create 3D models with a transparent appearance and smooth surface.

- Though resin- This is an idea for various engineering applications as the models can sustain a higher level of impact.

- Standard resin- For small prototypes and gadgets, you can use this resin.

- ABS resin offers better chemical resistance, low creep, excellent dimensional stability, and better toughness.

- Dental casting resin- Instead of burning, this resin melts, and you will enjoy an easy casting process.

- Jewelry casting resin- It is easier to mix and measure, and you will get accurate results. You can easily create intricate designs with this.

4.2, When buying, consider external conditions

4.2.1 Determine your ideal 3D printer style

Here you may need to choose between an LCD or FDM ED printer. If you are a beginner in this industry and a hobbyist, it will be better to buy an FDM 3D printer as they are low-cost and work great. Such printers also support different printing materials, such as carbon fiber, nylon, glass fiber, woody PLA, PC, ABS, PLA, PETG, and more.

4.2.2 Resolution requirements of the machine

In 3D printers, be it an FDM or LCD 3D printer, the resolution is measured by microns. With resin-based printers, you will get around 100 microns of the resolution, and with FDM 3D printers, the resolutions will be around 25 microns.

With an FDM printer, you can adjust the resolution. However, while buying, choose a machine that can offer 50 and above microns of resolution.

4.2.3 Choose a reliable brand

Only a reliable brand can offer you world-class products. For example, dreambot3d has been manufacturing and supplying quality FDM and LCD 3D printers for years and has a good reputation. Besides, only a reputed company can offer you excellent after-sale services.

4.2.4 Consider whether the price of the machine is acceptable

If you go for a cheaper option, you may not get the quality you are looking for. You can find printers under USD 500 to USD 1000, which will work great. However, make sure that the printer supports advanced features, especially in terms of printing materials.

4.2.5 Consider the supplier’s after-sales service capability

Before finalizing your deal, have a look at the customer service quality of the manufacturer. Does it offer professional support? Ensure the company has a good community on social media platforms so that you can clear your doubt quickly and interact with other users. Besides, ensure that the customer support service is available 24×7 hours.

4.2.6, Safety configuration of the machine

Safety configurations and features available with the machines can completely change your printing experience. So, while buying, keep your eye on things like heated glass beds, filament support, interface, and more. Besides, make sure that it has the features to prevent heat damage or a gas leak during the printing task.

FAQ Guide

What is Resin 3d printing?

Resin 3D printing is done by a resin 3D printer, and the process is also called a stereolithography apparatus, photo-solidification, or optical fabrication. This advanced 3D model printing is widely used to 3D print patterns, models, parts, prototypes, and more in a layered fashion. It is done through photochemical processes where the light or UV light created chemical oligomers and monomers. These are then crossed linked to create the polymer. This polymer is used to create a three-dimensional structure that you called 3D models. Resin 3D printing can be used to develop products prototype in the development of medical models, computer hardware, and other such application. There is no doubt the process is quite fast, but it can be a little expensive for you. As in this process, liquid material or resin is used; you need to combine different support materials for overhanging parts. Once the 3D model is removed from the machine, the support will need to be removed manually. The significant benefits of materials printed through resin 3d printing are finishing works, smooth surfaces, and unlimited possibilities related to post-processing.

How much is a 3d resin printer?

It has been seen that a resin 3d printer can produce amazingly accurate prints, can create parts quickly, and offers different types of materials. Earlier, when first introduced, these machines used to cost thousands of dollars. However, in recent years, the cost of resin 3D printers has gone down. You can find such printers under USD 100, but the functionality and quality of such resin 3D printers can be questionable. Besides, if you go for a cheaper one, you will get limited functionalities. You can only print fewer materials, print speed will be less than 100 mm/s, and such machines will produce more sound. So, always go for better options. A hobbyist and entry-level high-resolution resin 3d printer can cost you around USD 300 to USD 1000. On the other hand, a professional 3D resin printer can come with a price tag of USD 1000 to USD 10,000. If you are running a business, then you will have to buy industrial or business 3D printers. Such printers’ price would be more than USD 10,000. With us, you can buy industrial LCD 3D printers under your budget. Our high-quality machines are priced at around USD 1000 to USD 7000. For more details, you can feel free to get in touch with us.

What is resin 3d Printers right for?

Most of the resin 3D printers use DLP-Digital Light Processing or SLA- Stereolithography 3D printing technology. So, you can use resin 3D printers for making watertight, high-accuracy, and isotropic prototypes and parts using different types of materials with smooth surface finish and attractive features. These are also goofed for commercial and design applications. Such printers are also in medical, educational, aerospace, automotive, jewelry, and other industries.

How does a resin printer work?

The primary technology behind resin 3D printing is Stereolithography. Here are the entire processes. In the first stage, the printer spreads out a thin layer of liquid polymer. As the layer is in liquid form, it will correctly spread out through the build platform, maintaining a perfect thickness level. A UV laser strikes the polymer, and then the resin will convert into a solid form. These steps are repeated multiple times to complete the 3D prints. Once done, the print is raised out of the tank. The print is then removed from the platform and finished manually.

Should I get a resin 3d printer?

Resin 3D printers utilize DLP technology and are getting more common and affordable. If you are looking for something to produce a big 3D printed model, you need to go with the filament printers. However, if you are looking for production quality out of a machine and want to print small models with high-level details, you should prefer to buy a resin 3d printer. The level of resolution and quality that you will get from a resin-based 3D printer will be extraordinary. Give it a try. We have the best LCD and FDM 3D printers that can 3D print resins.

How strong is 3d printed resin?

Resin comes in different types, and for better strength, you can use tough resins. 3D models made of tough resin can offer a tensile strength of 55.7 MPa, and the elasticity modulus level will be around 2.7 GPa. However, if you compare, you will find that LCD resin-printed 3D models’ power is not as good as that of FDM 3D printed models.

What happens if you touch uncured resin?

When treated in the 3D printing process and its material properties, resin, when processed, releases pollutants and irritants. So, you should never expose the bare skin to this liquid printing material. Such material can develop dermatitis, one type of surface rash that can develop into skin allergy if you expose your skin for a long time. Besides, the resin can give off fumes. So, follow all the safety protocols while using uncured resin. However, to keep you safe, you can use out ME-215 and ME-345 LCD 3D printers that come with the automatic feeding function. You will have a lower level of exposure to the resin.

How dangerous is resin 3d printing?

The resin used for 3D printing is quite toxic, not only for human beings but also for the environment. When your body part gets exposed directly to uncured resin, it can cause skin irritation. On the other hand, different studies have proved that the resin molecules can attach to the fish’s nervous systems. Those molecules can break down the neurological processes. So, you should conduct resin 3D printing carefully. Besides, always buy suitable quality printers, like dreambot3d’s FDM and LCD 3D printers.

Are Resin prints stronger than FDM?

The FDM 3D printers create a perfect mechanical bond with better multiple layers, but a resin 3D printer can create chemical bonds by effectively cross-linking multiple photopolymers throughout the layers, creating dens parts and air watertight. Such can create high degrees of lateral strength, developing isotropic parts. You will get a strength level that will not alter with orientation. So, resin prints are better for manufacturing and engineering applications where the properties of the materials matter the most.

Is resin printing faster than FDM?

In the field of 3D printing, you may not find an accurate answer to this, and it all will depend on what you need to achieve. However, an LCD printer is faster than FDM 3D printers. While LCD printers’ maximum speed can go up to 2 mm/h, FDM printing are formed by dots. If your model has a larger singles-side area, you can use LCD printers for better speed.

How long does a resin printer take?

Some factors, such as the parts’ geometry, the overall size of the 3D model that you want to create, and the 3D printing technology you are using, can affect the printing time. An LCD printer can work at 20mm/h speed, and FDM printing is done by dots. So, for faster printing of a model with a larger single-sided area, you can go for LCD printers.

How fast is a resin printer?

Let’s understand this by taking an example. How long does it take to create a 3D model of a house? Some companies have reported that they have managed to 3D print a house within 24 hours, but that depends on the size. A whole villa can be printed within 45 days. However, with dreambot3d FDM and LCD resin 3D printers, you will get decent speed. The printers can offer a printing speed of 20 to 150MM with a layer thickness of 0.05 to 0.3MM. The maximum speed of such printers can reach 200mm per hour.

How expensive is resin printing?

The cost of resin printing will depend on the materials used for printing. 3D printing materials come in powder or filaments. You will get different types of filaments, such as carbon fiber, wood-like or flexible materials, PLA, PETG, ABS, and more. While buying filaments for your office 3D printers, you should consider a price of around USD 20 to USD 70 per kg. Besides, the cost may include manpower cost, 3D printer operation costs, and margin.

Is resin printing more expensive?

Again, this is something that will depend on the material and machine cost. If you consider the material cost, one liter of standard resin will cost you around USD 100 to USD 300. So, resin 3D printing can be expensive than other 3D printings.

Are resin printers faster?

Yes, most of the resin printers are very fast, especially the latest models. For example, FDM and LCD 3D printers from dreambot3d that can print resin offer decent speed. With 0.05 to 0.3mm of thickness, the printer works at a speed of 20 to 150MM. Based on the material types, a printer can take 10 to 20 hours to print a 3D model. dreambot3d also has launched a new black and white screen like ME-192, which is 3 to 4 times faster than the color screens. It will be an excellent product for the company.

Can you reuse 3d printer resin?

You can reuse the resin left in the tank, but you can’t use solidified resin printed products for more 3D models. The reason is, once the product is developed, resin changes its properties that you can’t bring back to the natural state.

Do Resin 3d printers smell?

Like other chemicals, resins have some types of odor. The odor of resin can range from harmless to discreet to noxious and powerful. However, the smell of resin is not harmful. Some resins don’t produce VOCs- Volatile Organic Compounds or fumes.

Is resin poisonous?

When processed through the machines, resins release irritants and pollutants. Besides, if touched with a bare hand, it can cause skin irritation. So, it is poisonous to humans and other living beings. So, always be careful while using resin and prefer to use FDM and LCD 3D resin printers of dreambot3d, designed to offer your safe working environment.

Are resin printers safe?

Yes, resin printers are safe. If you have dreambot3d’s 3D printers, there is nothing to worry about any issue. Thousands of people have already owned a resin 3D printer, and they are doing great. However, it is advisable to follow all the safety guidelines related to using 3D printers while using them.

Are resin printers loud?

A low-cost resin 3d printer can be a little noisy compared to costly 3D printers. They are relatively quiet. However, you may find them noisy if you stay in the printing room for an hour. In most of the cases, the average decibel range can be around 40db to 44db. Fans of the printers can create sounds like your laptop fans. But that is something that can be ignored. So, go for it now.

What do I need to know about resin 3d printing?

Before going for resin 3d printing, here are some basic things that you need to know. This is a form of additive manufacturing technology. This printing utilizes the photopolymerization principle. You need to set the design through the computer to print it. You can use different types of resins, as mentioned above, for 3D printing. Resin 3D printing is all about converting a liquidized plastic into a solid 3D model, and UV light is used in the process. Some significant benefits of resin printing are; smoother surface, great details, high speed, different types of materials, and waterproof printing.