The Tokyo Olympics 3D-printed 98 podiums with 24.5 tons of discarded plastic

Tons of Scrap Plastic and Improve Atheletes’ Performance

Tokyo 2020 was slated to take place between July 23rd, 2021 and August 8th 2021. The Tokyo 2020 Olympics featured 33 sports with hundreds of athletes from all over the world. We wish all Chinese athletes the very best in all the Olympics competitions.

Looking at the Olympics Games, the 3D printing technology had a great impact on the entire event. The podiums, track shoes, bicycle handlebars, gun grips were some of the noteworthy items that the 3D printing machine was able to design and print with high precision, strength, accuracy and quality. Let us examine the contributions of 3D printing technology in the Tokyo 2020 Olympics

- The 3D Printing Medals Podium

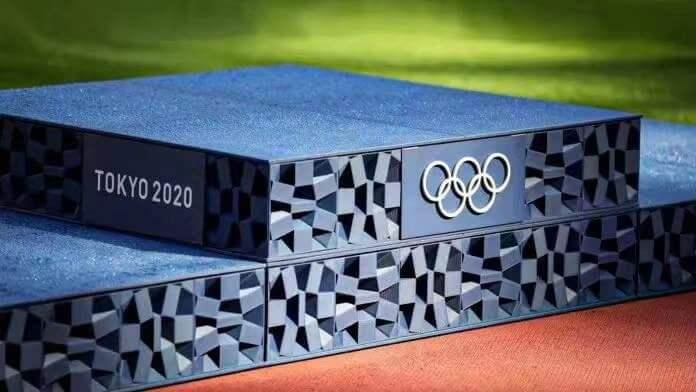

The Tokyo 2020 Olympics podiums were made from 24.5 tons of waste plastics and printed with the industrial 3D printing machine. The Japanese public donated household plastics through over 2000 collection boxes situated in departmental stores and schools across Japan. 400,000 plastics equivalent to bottles of washing powder were gathered over a period of nine months.

These bottles were recycled and made into filaments. The filaments pigments resulted in the vibrant colours of the podiums, which is impossible to achieve through painting. The filaments in turn were used by the industrial 3D printing equipment to print all 98 podiums used throughout the game.

The podium was designed by Asao Tokolo based on the concept of the Olympic logo. Each of the podiums is shaped like a diamond and has a number of small cube modules that are linked together to form three plinths. Each podium cube weighs only 1.5kg.

After the Olympic Games, the Tokyo 2020 Organizing Committee and P&G plan to recycle 65% of the plastic material and give them other functions such as packaging materials for P&G products. The design team also has plans for the podiums after the Tokyo Olympics.

They plan to use the podiums as display or rework. This is only possible because the design concept is sustainable 3d printing recycling. The winners at the Tokyo 2020 Olympics and Paralympics were crowned on the 3D printed podiums. The 3D podiums can be flattened for the Paralympics teams.

- Adidas “4DFWD”

Ever since Nike’s Zoom Superfly Elite shoes were credited to have helped Shirley Ann Fraser win two medals at the 2016 Rio Olympics, major competitor, Adidas has caught up in the 3D printed software race. Over the years, Adidas has worked with Carbon to create a Futurecraft 4D range of sports shoes.

The Futurecraft 4D sports shoes are designed for easy movement, stability and comfort for every athlete and nonathlete. Adidas and Futurecraft started working together in February 2018 to create the sporty AlphaEdge 4D LTD. This is followed by a partnership with the British fashion brand Stella McCartney.

The Stella McCartney brand and Adidas collaborated to produce a limited edition of the Stella McCartney X Adidas shoe. The two new shoes that were released after the McCartney and Adidas collaboration were the AlphaEdge 4D Colour: Core Black and White Carbon and White Carbon.

The second was the Addidas 4DFWD midsole designed with Carbon DLS using 3D printing technology. The 4DFWD was created by combining athlete data with the unique technology of 3D printing.

These companies are working together using software and robotics to create a Futurecraft partner, that will be the perfect fit for every athlete’s foot. The upgraded 4DFWD midsole allows athletes to reduce the peak of breaking force by 15%.

The Adidas 4DFWD was created to improve athlete’s running experience and enjoy the precision performance in every step. Adidas 3D-print-optimized next generation running shoes will first be made available to athletes and medalists starting from August 12, 2021, before it is made available for fans and consumers all over the world.

- New Bike Design and Titanium Handlebars

Prior to the 2020 Olympics event, the 3D printer manufacturer, Renishaw had collaborated with Lotus Engineering and Hope Technology to design new track bicycles for the British cycling team. Engineers used the RenAM 500M to create a prototype of the HB.T bicycle parts.

The evaluation of bike and rider was carried out in the wind tunnel and testing was carried out to maximize strength and minimize weight. Even though carbon fibre was used in designing the final version of the bike, it is possible to use additive moulds for the bicycle parts, which helps in the innovative development and unique front fork and handle design of the bicycles.

Nottingham Metron A.E LTD created the 3D printed titanium handlebars from 3D-printed titanium (Ti6AI4V) and extensions such as shallower and longer parts were printed in Scalmalloy. Titanium and Scalmalloy and the handlebar are different components.

- 3D Printing Gun Grip

The French specialist sports equipment customization company, Athletics 3D, used a Zortrax M300 Dual 3D printer and a Zortax Apoller to print gun grips that helped the French gas gun competitor, Celine Goberville to win a medal in the 2020 Tokyo Olympics. Athletics 3D used the Zorax M300 Dual and Apoller to create a pistole grip for Celine’s personal requirements.

The gun grips were smoothened in the Zortex Apoller SVS device. Athletics 3D used the Zortax M300 Dual printer and a combination of Z-Ultrat and Z-Support to design a custom-made 3D gun grip. A smart steam smoothing device and the Zortrax Apoller were used to achieve the surface glossiness of the grips.

Share