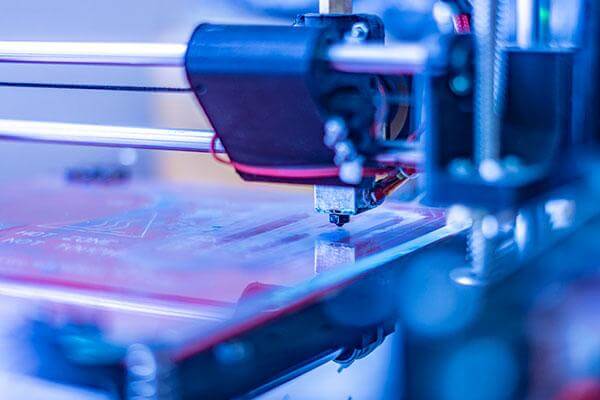

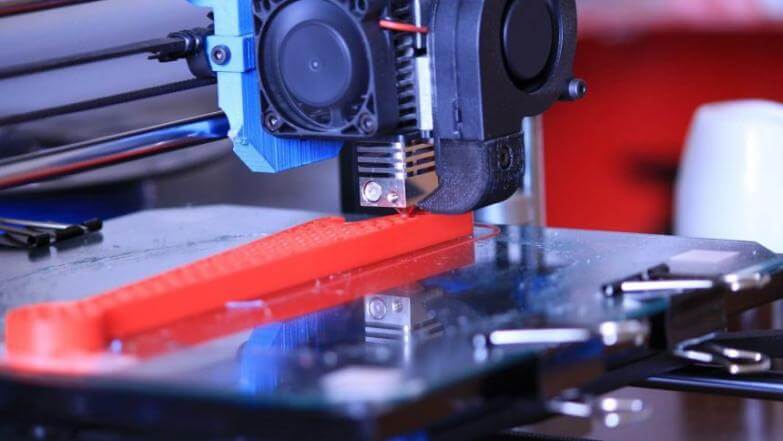

Industrial FDM 3D Printer

Dreambot3d industrial FDM 3D printer is used for printing large pieces or dozens of smaller parts.

The process of printing with the industrial FDM 3D printer is fast, consistent and requires less manual calibration. Dreambot3d industrial FDM 3D printers are used in construction, architecture, automotive, ammunition, robotics, etc.

Contact Us

Industrial FDM 3D Printer

- Dreambot3d industrial FDM printers are designed for speed, detail, repeatability and reliability.

- We have earned quality and standardization certifications through our main focus on quality products.

- Dreambot3d only selects the most popular brand materials in designing our 3D printers.

Dreambot3D industrial FDM 3Dd printers list

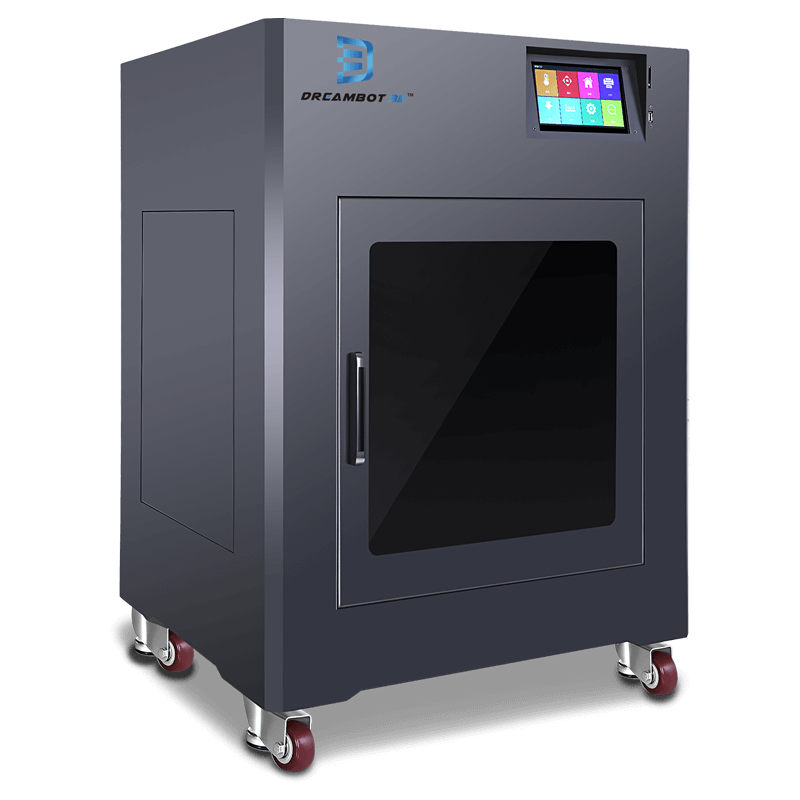

The L-200 3D printer has a printing size of 200*200*200mm. It has a high precision that reaches up to 0.05mm.

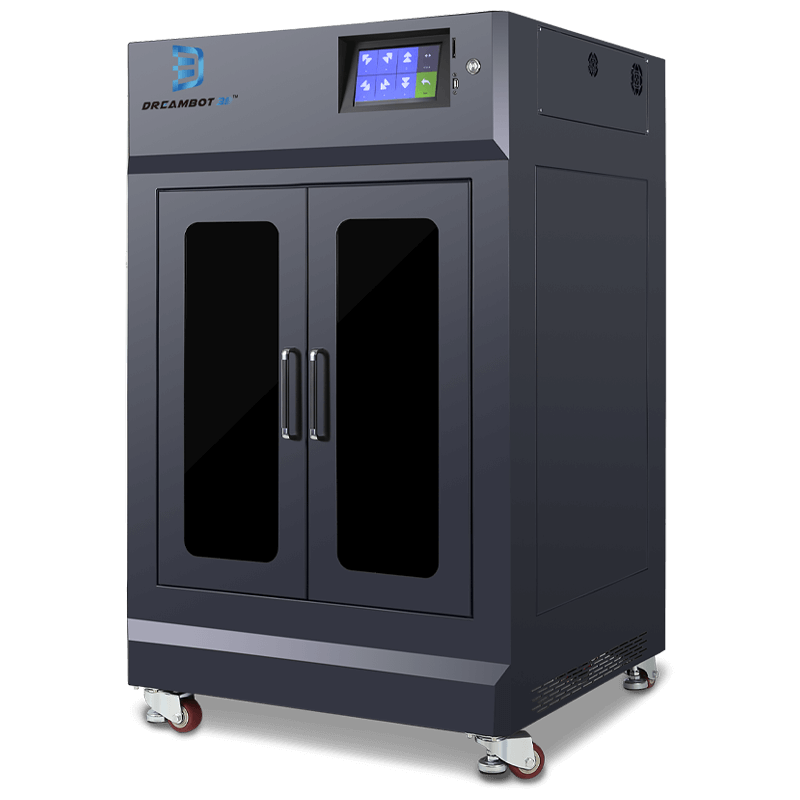

The L-300 FDM printer has a maximum printing volume of 300*30*400mm. It prints at a thickness of 0.05-0.3mm.

The L-400 FDM printer has a printing volume of 400*400*500mm. The printer has a printing speed of 20-250mm.

The L-500 FDM has a maximum printing volume of 500*500*800mm. The printer has a consumable diameter of 1.75mm.

The L-600 FDM printer has a maximum printing volume of 600*600*800mm. It has a maximum speed of 20-150mm.

The L-800 FDM printer has a printing volume of 800*800*800mm. The positioning accuracy is 0.0011*0.0011*0.00125mm.

The L-100 FDM printer has a printing volume of 1000*1000*1000mm. It prints at a speed of 20-150mm.

Test your part

We provide sample testing service, allowing you to check the working quality of our 3D printer before placing an order

6 points why choose us

Automatic resume printing

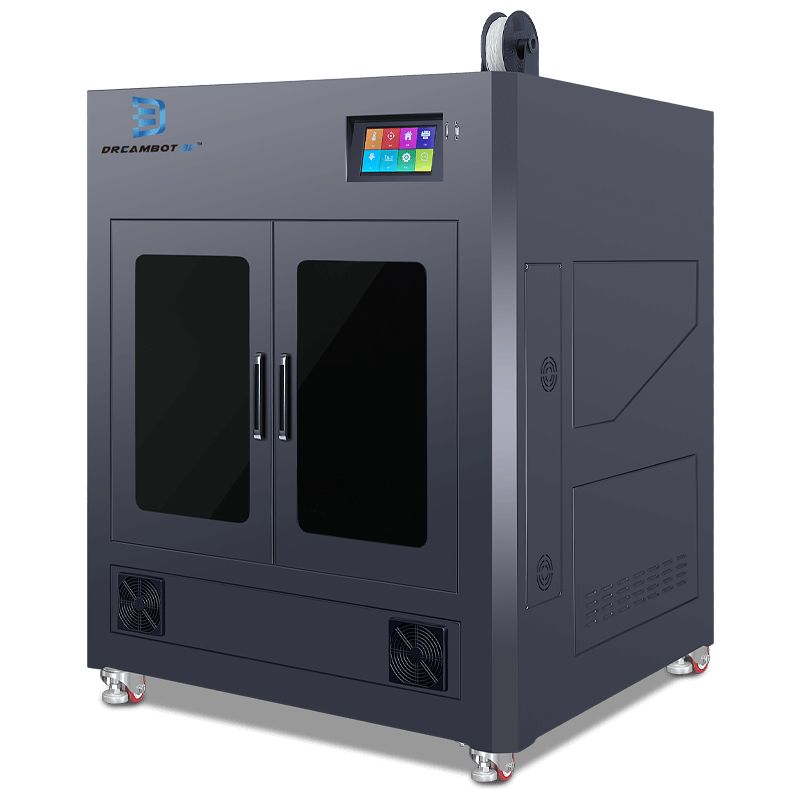

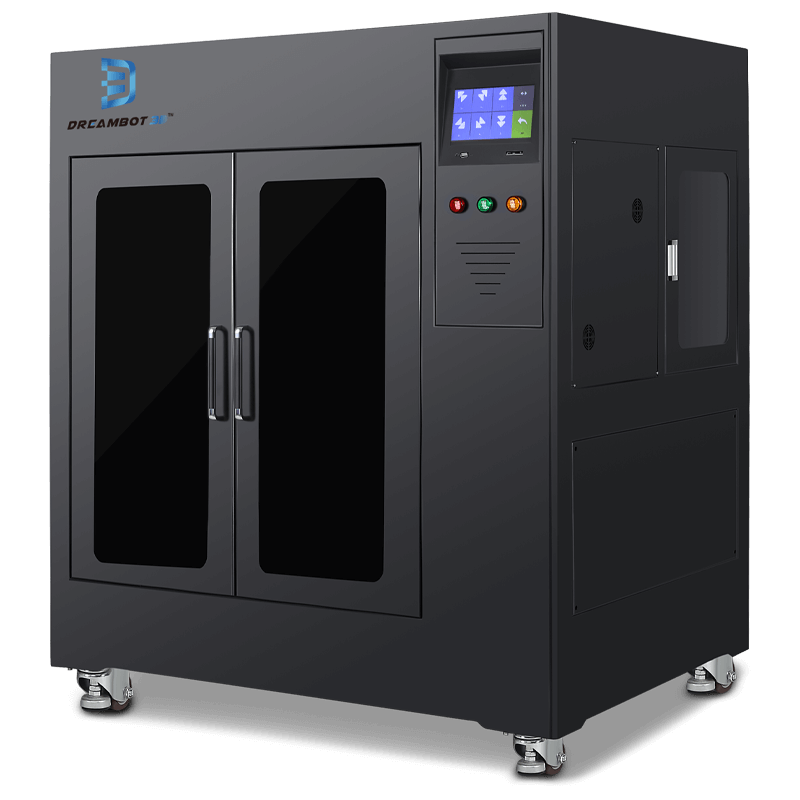

Full enclose stable frame

The whole machine case is thickened by CNC cutting, with accurate hole position, better assembly stability, and higher positioning accuracy of printer operation.

Allow offline printing

Use U disk or SD card to print without connecting to a computer to print. After starting to print, the data is automatically saved and the U disk or SD card can be removed.

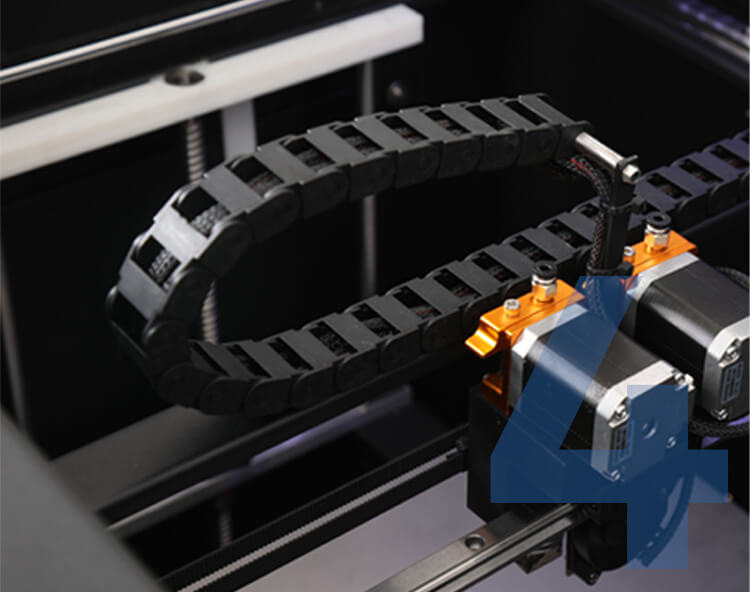

Drag chain wiring design

The wire is installed in the inner casing of the drag chain to effectively ensure that the wire will not be damaged for a long time when the printer moves at high speed.

Precision ball screw

Using the latest Taiwan ball screw, it has higher straightness, lower friction coefficient, better smoothness, higher positioning accuracy and more stability during printing.

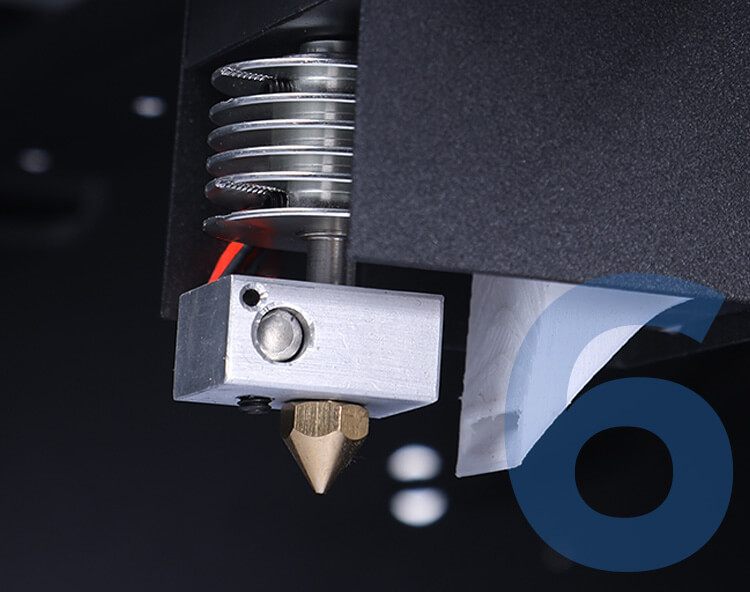

Alloy nozzle

Independently developed a unique bullet nozzle with uniform heating and a patented head assembly, so that it can work smoothly without interruption.

What Our Customers Say

Industrial FDM 3D Printer buying guide

It is a fact that Industrial designers are getting challenged with designing the most efficient and effective manufactured products. For this, they need robust and advanced hardware that can perfectly support their unique goals. When it comes to satisfying the customers, it is crucial to offer them something they really want.

There are many things to do to come up with such a product, and one of the most important things is developing prototypes for evaluation purposes. But if you go for the traditional prototyping method, it will take a lot of time and money. So, what can be the best solution for this? This is where a good quality industrial FDM 3d printer comes to play.

To remain highly competitive in this ever-changing market landscape, retailers, along with consumer-oriented industries, should be able to adapt to the changing consumer demand and the evolving industry trends.

Nothing can meet these needs better than additive manufacturing. This has been proved as the most cost-effective way for product development, evaluation, and production. From consumer electronics to sportswear and toys, prominent players are increasingly implementing industrial design 3d printing as a crucial addition to their existing manufacturing solutions.

In fact, for the fastest and the most realistic product prototypes, manufacturers and designers are leveraging the real power of additive manufacturing or 3D printing using rugged FDM 3D printers, especially the industrial FDM 3d printer.

Different from desktop FDM 3D printers, these are developed to carry out bulk projects or production. So, if you plan to set up a manufacturing unit to serve different industries, then investing in a large-size FDM 3D printer can be a perfect idea.

These machines are gradually creating a solid base in various sectors, including automotive, aerospace, manufacturing, medical, education, model making, and more.

What do you mean by an industrial 3D printer?

As the name suggests, industrial-grade 3D printers are designed and developed to quickly produce large volumes and various products faster. These printers offer a higher level of throughput, multiple material options, and a massive build platform than the desktop 3D printer of a non-industrial FDM3D printer.

As different 3D printer manufacturers produce different FDM 3D printers, how to choose the best 3d printer for industrial use? This can be a little challenging for you. However, to make it a bit simple for you, we have written down all the essential things, including FDM 3d printer price below, going through which, you can make the right decision. Have a look at those points.

FDM 3d printer introduction

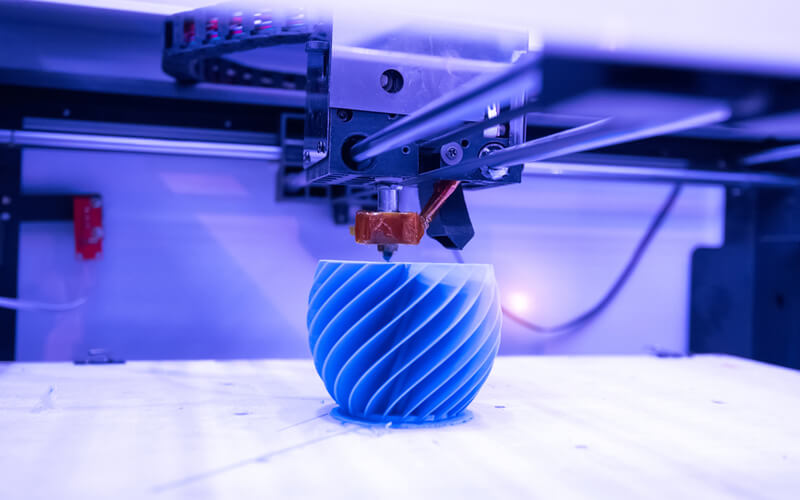

In 3D printing or additive manufacturing, you will get various 3D printing options involving different technologies. However, the 3D printing technology that is quite popular than others is FDM- Fused Deposition Modeling technology.

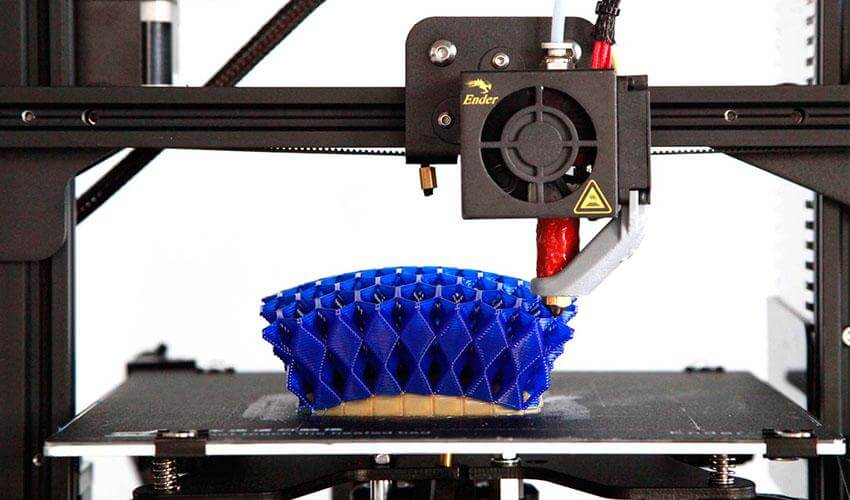

These printers can manufacture various types of parts layer-by-layer by heating and extruding different kinds of printing materials or filaments. In general, these printers use production-grade thermoplastic materials suitable for producing low-volume manufacturing parts, functional prototypes, robust manufacturing tools, and more.

Different industries look for different types of solutions to maximize the object’s efficiency. An industrial FDM 3d printer lets them develop durable and functional prototypes that can easily withstand the other kind of testing.

Speaking more about it, FDM’s printing was first introduced during the 1980s by Scott Crump, the co-founder, and chairman of Stratasys Ltd. After that, Then MakerBot, which is the current owner of Stratasys, developed a similar printing technology named FFF- Fused Filament Fabrication.

These printers come with advanced technology to process different types of 3D printing materials, such as pastes, thermoplastic, exotic 3D printing materials, and more. So, within a few minutes, you can create different types of products using other materials.

How FDM 3D printing technology function?

In simple words, this printing technology works by extruding heated 3D printing materials or thermoplastic materials layer by layer onto the build platform. The entire process involves three major stages. These are:

- Pre-processing stage

Here, a build-preparation software perfectly slices and then positions a 3D CAD file and evaluates the right patch to extrude 3D printing materials and the required support materials.

- The production stages

In this stage, the 3D printer properly heats the thermoplastic to turn the material into liquid form and then deposits the liquid in ultra-fine beads through the extrusion path. If there are any buffering and support requirements, the FDM 3D printer will deposit a removal material that will act as a scaffolding.

- The post-processing stages

This is the final stage of 3D printing, where the producers break the support structure or dissolve it in water. Once done, the part is ready to use.

Most of the FDM 3D printers utilize thermoplastic that is found in the traditional manufacturing methods. This is ideal for different applications that require tight tolerances, environmental stability, and toughness. Some essential aspects of FDM 3D printing are:

- This printing technology is well-developed, simple to use, and clean. You won’t face any complications with this printing method.

- Supported production-grade thermoplastics that you can use with these printers are environmentally and mechanically stable.

- This allows you to give the correct shape to the complex geometries and cavities that will otherwise be challenging to become possible with today’s FDM 3D printing technology.

Who prefers to use industrial-grade FDM 3D printers?

In general, industrial 3D printers are widely used by industrial designers to create prototypes of the design they have in mind. As the designers can be working on different types of products, covering furniture, toys, and card, the FDM 3D printers they are using must have the ability to offer the desired level of flexibility and speed. On the other hand, industrial FDM 3D printers’ different types of material options enable the industrial firms to provide various industries services.

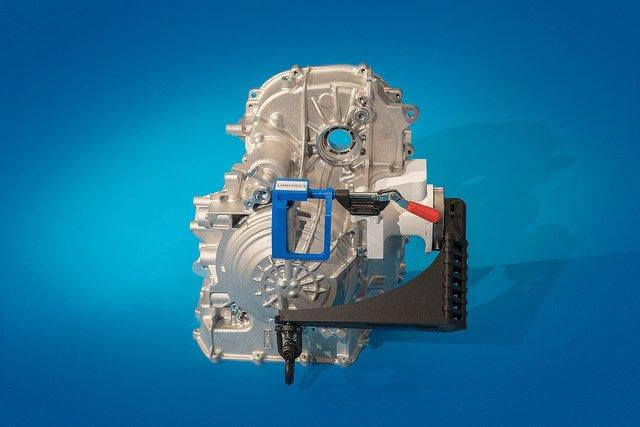

On the other hand, these types of 3D printers are used in the manufacturing process. As the printers come with large build size, they are quite useful in producing 3D printing jigs, fixtures, airplane parts, car parts, packaging solutions, and more. The machine’s higher level of precision and accuracy helps make quality end-use parts, for example, front bumpers and battery covers.

Let’s know how these printers work to create high-quality 3D models. The process is quite simple to understand. You can consider your hot-glue gun for this.

Some benefits of FDM 3D printing for consumer goods

- The enhanced product development process

Before launching a new product, the design of that particular product must be validated, tested, and then approved for the final process. The process takes place during the stage of product development. Two things are considered as vital aspects of the process, i.e., models and prototypes.

The reason is they are quite commonly used for research and testing purposes. FDM 3D printing can speed up the process of product development by facilitating the rapid production of models and prototypes. With this, product engineers and designers can develop and validate different iterations, and you can carry out repetitive testing without spending much time and money.

- Quicker time-to-market

Your ability to accelerate the product development process and time will directly impact how early you can launch your product in the market. In simple words, by testing and validating your products faster, the engineers and designers can speed up the time-to-market.

Some companies have used 3D printing products to conduct pilot product testing. For example, in 2015, PepsiCo manufactured different prototypes of the Ruffles chips brand and tested its size to know which worked best. The best one was used to produce a new potato chip slicer at the plants. So, you can also enjoy such benefits by adopting this method.

- Faster and effective mass customization

As per the experts, the most significant impact of additive manufacturing for consumer goods depends on producing personalized products customized to the consumers’ requirements. In the case of traditional manufacturing, where you manufacture products in masse, the tailored products produced in small batches can be inefficient.

Such limitation has been eliminated with the help of industrial design 3d printing. So, if you plan to run a business to offer customized services to your customers, you should use the FDM 3D printers.

- Mass production

An industrial FDM 3d printer can offer you the ability to manufacture end-use parts in seamless pieces, and there will not need to go for post-production assembly.

- Unlimited printing material options

One of the most significant advantages of using the FDM 3D printers is supporting multiple 3D printing materials. You can now produce prototypes that will feel, look, and behave just like the end-use product. You can even heat-resistant 3D models using these machines.

There are more such excellent benefits that you can enjoy using an industrial-grade FDM 3D printer. Use it to witness the difference in your product quality and production capacity.

1.1, Principle of FDM 3d printer

This section will discuss the significant parts of top industrial 3d printers and the process through which desired 3D models or objects are made. So, let’s start with the parts of an FDM 3D printer.

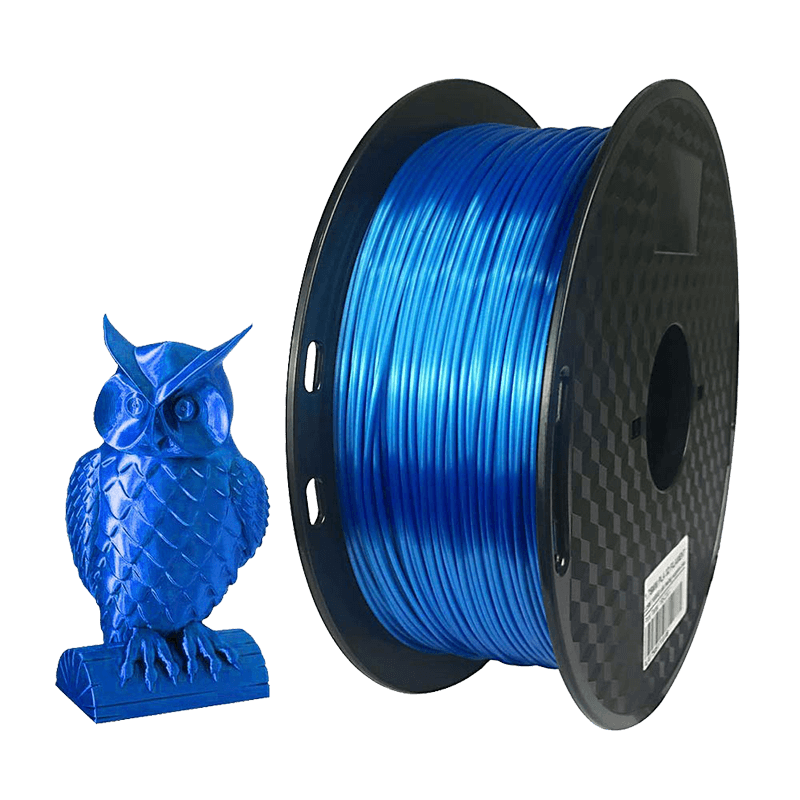

- Filament- In simple words, this is the 3D printing material for your 3D printer. Before using the printer, you need to attach the filament spool to the printer’s back or side and connect it to the extruder.

- Heater- The heater’s objective is to correctly heat the filament to turn it into the liquid for printing.

- Hot end- This particular portion of 3D printers includes a cooling fan, nozzle assembly, and heat sink.

- Extruder- Your printer’s extruder will pull out the filament and will push it towards the heater. Some called it Cold End.

- Build platform- On the build platform, the liquid-formed printing material is deposited using the nozzle. Once applied, the material will stick to it to build the object. Based on the filament you are using and the object you want to produce, the build platform can be heated or non-heated.

The printing process is done using all these parts. Now, let’s know the printing process of an FDM 3D printer.

Printing methods of an FDM 3D printer

As per the experts, FDM 3D printers are like a Cartesian type of 3D printer, a coordinated system that can be found in printers. This technology is responsible for the movement of the print head or nozzle and builds a platform. You will discover three crucial rails, i.e., X, Y, and Z, corresponding to each axis.

When the process begins, the extruder, nozzle, and printhead assembly move correctly in a particular direction, in the X and Y direction. On the other hand, the build platform moves in the “Z” direction. Here is the actual printing process.

To begin with, the filament is attached to the extruder of the machine. You may find filaments in two types of diameters in the market, one is 3 mm, and another one is 1.75 mm. However, one printer will support only one size of filament. The extruder is equipped with a gear mechanism to pull the filament and then send that to the heater.

The heater will convert the tough filament into liquid. Experts suggest that before using the heater, you should know about the melting point of different filaments. For example, ABS’s melting point is 210-degree C to 250-degree C, and PLA melts between 180-degree C to 230-degree C. Talking about Nylon, this material melts at 240-degree C or 467-degree F.

After this, the melted filament will be sent to the nozzle. In nozzle also, you will get nozzles with two types of diameters, one is 0.4mm, and another one is 0.2mm. Remember that the thickness of the printed layer and printing quality will significantly depend on the nozzle’s diameter.

The nozzle will apply the liquid-form of filament onto the build area after reading the product’s design from the digital 3D CAD file. During this, the nozzle will move in the X and Y direction, and the build platform will also move in the Z direction. After done with one layer, the nozzle will move in the same way to create the second layer. The process will keep going until the entire object is made.

After printing work, the 3D object will be removed from the build platform for post-processing. Here are some standard post-processing techniques that can be used for FDM 3D printing for a better idea.

- Support removal

Support removal is the first method of post-processing. In general, there are two types of support materials, i.e., Soluble and Insoluble.

Speaking about soluble, some examples of soluble materials are PVA and HIPS, and these are easier to operate with as they can be easily dissolved in different chemicals like Limonene and water.

Some examples of insoluble materials are Nylon, PC, ABS, PLA, and more. These can be removed using hand, pliers, or flush cutters. Sometimes, these supports can be found challenging to reach.

- Sanding

One of the simplest methods is sanding. The sanding process needs to be carried out carefully in different successive stages, and it can be started from low grit sandpaper with 150 grit, then you can move to 400 grit, 600 grit, and then 2000 grit. The major drawback of sanding is the process is quite a time taking.

- Vapour smoothing

In this process, acetone is used. This technique is generally utilized while using ABS filament. The vapour reacts with the object’s outer layer, and it will start to melt. This process will melt the outer layer lines and offer the object a glossy look. However, you need to use it very carefully, as this can affect the object’s dimensional accuracy. This method is ideal for luxury products, where the aesthetic of the product matters more than dimensional accuracy.

- Priming and painting

Priming is about coating the 3D printed object using a primer. This becomes a base for your printing job. You can do this after the sanding process. Once done with sanding, just apply two separate coats of primer. After that, let the object dry and then paint the object.

- Polishing

For this, you need to use the buffing wheel. For this, you can use the Dremel tool. You can easily buy a 3D printing Dremel toolkit online.

- Hydro graphics

This is considered an exciting technique called water transfer imaging, immersion printing, water transfer printing, and hydro dipping. You can use this method for wood, glass, metals, plastic, and more.

The primary reason behind the massive popularity of an industrial FDM 3D printer is that it can produce different 3D printed parts with a higher level of accuracy than the standard desktop FDM machines. There will be a control of processing parameters, and they initiate calibration algorithms before every point. Besides, some machines also support dual extrusion. So, when it comes to enjoying a better end-product result, you can always trust the FDM 3D printers of Dreambot3D.

1.2, What materials can be printed by FDM 3d printer

Why people prefer to buy industrial 3d printers? The primary reason is these printers can support different types of 3D printing materials. Currently, the global 3D printing industry is enjoying a rapid introduction of new printing materials.

Even though PLA and ABS are considered the primary printing materials, you can now use other materials. So, based on your 3D printed object requirements, you can use materials. Now, let’s have a closer look at the types of printing materials.

- ABS

This is a petroleum-based filament and widely used in different industries for its durability. The melting temperature of this material is 240-degree C. While using this printing material, you need to use a heated build area to stick to the build platform’s surface properly. Once applied, the material will not pull up or away from the surface.

It has been seen that to create a perfect level of adhesion, some people use Kapton tape. This material produces durable and tough objects. Well, it can break, but by combining ABS with carbon fiber, you can make it relatively stronger. The best part is that ABS can be reformed, recycled, and granulated.

- PLA

Polylactic Acid melts at a significantly lower temperature than ABS. The melting point of PLA is 180-degree C. This is a common and classis 3D printing material that is used in almost all the industry. The material is generally made from different renewable sources, for example, sugar cane and starch.

While using this for creating 3D objects, you don’t have to use a heated build platform. It is available in different colors, including translucent and transparent filament. Remember that 3D models made of PLA will not be durable like ABS. Besides, this material is harder to recycle.

- Nylon

In the FDM 3D printing industry, Nylon comes in different grades, and for 3D printing, Nylon 618 is considered the ideal option. Unlike PLA and ABS, Nylon will melt at 242-degrees C. Nylon comes with some similar properties to ABS and can cool quicker.

This material doesn’t release any harmful fumes while printing, but it is advisable to use the printers in a properly ventilated area. Besides, it will be better to use appropriately enclosed FDM 3D printers that you can get from Dreambot3D.

- Carbon fiber

This filament uses carbon fibers along with thermoplastic, which is the base material. This is a strong material, but you can further increase its strength and stiffness by adding ABS, PLA, and Nylon. This material is easy to print, and the products will come with a smooth surface.

- PC

Polycarbonate is a robust material that is widely used in different types of engineering applications. The PC products will show better resistance to temperature and can also sustain physical deformation of up to 150-degree C. It has been seen that the PC can easily absorb moisture from the air. This material is used for its strength and a good level of transparency.

- PETG

This material is a perfect combination of PET and Glycol. The combination offers an amorphous thermoplastic that is durable. The finished products made of PETG will feel and look smooth. The best thing is the material can be sterilized, and you can use it in the food production or food packaging industry.

However, you can witness a little bit of colour alteration during the PETG printing process. Besides, in some cases, the 3D printed objects may come with visible scratches.

- PVA

Even though this is used in the industrial sector in a limited amount, it is an ideal option for low-end FDM 3D printers. You can use this as a support material as it will get dissolved easily during the post-processing stage. However, this is not suitable to manufacture products that need higher strength. As a budget-friendly 3D printing material, this is good for temporary-use products.

- HIPS

High Impact Polystyrene is a plastic filament use as a supporting element in the industrial FDM 3D printers. This material is straightforward to use and can easily get dissolved. It is soluble in a liquid hydrocarbon like Limonene.

- TPU

Another wide use of 3D printing material is TPU. It comes with rubber-like characteristics, and you can use it to make parts with the semi-flexible feature. The object made of TPU can have a semi-transparent appearance. It demonstrates an adequate level of abrasion resistance. Besides, it can offer a decent level of strength.

- ULTEM

This is the best material for professional-level FDM 3D printers. This is one type of resin from the Polyetherimide family. Speaking about some of its characteristics, it offers a better level of performance and heat-resistant.

1.3, Why is Dreambot3D’s FDM 3d printer so prominent?

FDM 3D printing technology is evolving rapidly than other manufacturing methods as it dramatically influences the manufacturing processes, helping businesses perform better. Furthermore, the 3D printing manufacturing line is significantly easier to change than the traditional manufacturing production line.

That’s why this is perfect for the bulk equipment production process. This is why industries like construction, automotive, aerospace, and more have started using FDM 3D printers. This, in turn, has propelled the demand for rugged Industrial FDM 3D printers.

For this, Dreambot3D has introduced some of its robust industrial-grade 3D printers in the global market. If you face issues in finding a perfect Industrial FDM 3d printer, just get in touch with Dreambot3D now. No matter what are your 3D printer requirements, we have different options for you that will come under your budget.

You might be thinking about why you should go to Dreambot3D’s printers? To get your answer, check out the below-mentioned points.

- If you look in the market, you will find FDM 3D printers with a straightforward structure, and they also will have the acrylic outer box. That means those printers are not durable enough to run for years. Besides, it is not safe to use an FDM 3D printer that has a low building structure. But this will not be there with Dreambot3D’s FDM 3D printer. As a leading 3D printer manufacturing company, all the printers come with a very stable structure. In terms of safety, all the 3D printers have integral sheet metal chassis, and the enclosed structure makes it safer to use. The XYZ axis also works stably even when running the machine at a higher speed. If you want to enjoy the maximum accuracy level, you can always trust Dreambot3D’s FDM 3D printers.

- There should be the “Constant Temperature System” to keep the machine warm throughout the process in an industrial FDM printer. This system heats the chassis’ entire printing control to the desired temperature to keep the printing process smooth. Why is this system important? Well, when you will use heat-resistant printing materials, like Nylon, carbon fiber, PC, ABS, and more, they will not be warped and drawn during the printing process. However, not all the printers available in the market have this feature. Dreambot3D has provided this system in its machine to offer you a quality 3D printing experience.

- You might have a costly FDM 3D printer at your company, but if the printer has a complex operating system, it can create challenges for the users as they don’t know how to operate the machine. So, this is where you will need an FDM 3D printer with having easy to use OS and interface. This what the FDM 3D printers of Dreambot3D offer. You won’t take much time to understand how to use the machine and start your project faster.

- What will you prefer, a machine with a 5-inch screen or a large 7-inch screen? The obvious answer will be an FDM 3D printer machine with a large 7-inches color screen. Because you can see the text and the options clearly to smoothly operate the machine. While FDM 3D printers of Dreambot3D come with a large screen, its competitors offer the machine with a small 5-inch color screen. That’s why there is an excellent demand for Dreambot3D 3D printers.

- With the competitors’ products, you will get only a few options in the regular sizes. Sometimes, based on your requirements, the machine needs to customize. This can further add up to the cost. On the other hand, the market test is also insufficient, and they don’t have a stable market demand. However, Dreambot3D offers a complete range of sizes. Based on your requirements, you can choose the printers, and there is no need to do any customization.

- What’s more? Dreamboat’s market condition is relatively stable. Some of the most popular models you can try out are L5-400/500/600/800/1000 and L8-400/500/600. Visit the official site and check out the products now.

- You should prefer to buy the FDM 3D printers from a manufacturer with years of experience in this. Dreambot3D has more than 8 years of experience in producing industrial-grade machines. The company has a strong track record in manufacturing industrial-grade FDM 3D printers. Besides, the company has a rich production capacity with a robust R&D capability. It has been seen that some of the 3D printer manufacturers only deal with producing desktop-level printers, and that won’t match your bulk 3D printing need. These companies won’t be able to offer you the desired services as they have an insufficient market, experience, and R&D capability. Besides, they only provide identical models.

- Dreambot3D manufacture powerful and superior quality, industrial-grade 3D printers that come in different styles and sizes. Besides, the company always maintains sufficient stock of the machines to ship the product within just 3 to 5 days after placing the order. You can also go for the customized FDM3D printers that can be dispatched within 10 to 15 days. With other manufacturers, you may face a delay in product delivery.

With Dreambot3D’s FDM 3D printers, you won’t face any downtime as they also offer 24×7 hours technical support to keep the machine running at its maximum level. Don’t think much and buy Dreambot3D Industrial FDM 3D printers to boost up your production capacity.

Application field of FDM 3d printer

With the advancement in 3D printing technology, FDM 3D printers are performing much better than before. The machines’ performance level will surely impress you. The rise in popularity of these printers has dramatically reduced the cost of running an FDM 3D printer machine.

The industrial-grade FDM 3D printers’ production capacity is much better than the desktop 3D printer, and they can complete a large order quite faster. What’s more? These printers come with a larger printing area, which means that they can produce larger complex parts in one print. Besides, you can print more 3D objects at the same time.

It may be noted that industrial FDM printers are developed for reliability and repeatability. These machines can be used to manufacture the same object or parts multiple times. But these printers will require a high level of user maintenance. Before using it, you need to calibrate the machine.

There is no doubt that industrial design 3d printing and FDM is a popular printing technology as using this, you can manufacture high-quality parts from different types of durable materials, which can easily retain all their mechanical properties for years. On the other hand, these printers’ dimensional accuracy is perfect for modelling, low-volume product manufacturing, and prototyping. So, all most all the industries are now using FDM 3D printer. However, here are some primary application of industrial-grade FDM printers.

2.1, For industrial research and development

After introducing industrial 3D printers, the production process in different sectors has gone through a significant revolution. As a result, they are now enjoying faster product development. Besides, this technology has also influenced the process management for different stages of productions.

No matter what type of industry you have, without a robust R&D process, you won’t survive long in the market without a concentrated R & D process. How can you make your R&D process robust and effective? It can only be possible by adding modern technology like 3D printing. It gives opportunities to try out different new things.

Let’s understand this with an example. In 2012, a team of researchers from the University of Glasgow in the UK conducted some studies and proved that 3D printing technology can manufacture chemical compounds. How they did it? First, the 3D printed different chemical reaction vessels and then apply reactants into the vessels using 3D printers.

On the other hand, you can create different objects using 3D printing for your experiment purposes, such as shielding and vacuum components.

As R&D is an essential part of different industries, you can neglect it. To keep your business unit running smoothly, you need to make sure that your products are continually evolving and they are perfect for the current trends. Besides, you also need to ensure that your product innovation lifecycle is also useful. For this, you can always use 3D printing technology.

One of the significant benefits of FDM 3D printing is its material versatility. You can use ABS, Nylon, PC, PETG, ULTEM, and more. Some notable services that can be considered are:

- It offers you the maximum level of flexibility to work with different options in terms of design complexities, geometries, materials, and colors.

- Besides, this method facilitates better design iterations, and you can do effortless design modifications and replication.

- You can make the prototype quite faster to carry out the design and utility test of the product. You can also use the prototype to create more business opportunities.

If you want to improve your R&D process and develop the best products in the market, it’s time to bring the best industrial FDM printer.

2.2, For the production of animation figures

Animation figures have become a significant element of the film industry. As a multi-billion-dollar industry globally, TV and film production crews are generally tasked with the considerable burden of bringing the visions to life.

This is where 3D printing comes to play. Using this, the designers can now manifest their unique imagination into the amazing looking physical reality Animation or cartoon models are considered the coolest sculptures.

Both old and young love to have their cartoon characters. Besides, it is a fantastic experience to see your favorite cartoon characters in front of you, such as Pikachu, Sponge Boob, Charlie Brown, Bugs Bunny, and more. This is all possible by using 3D printing.

The advanced technologies are creating phenomenal next-generation cartoon and game characters. Model makers across the world have combined the proven skills of sculpting and foam cutting with 3D printing, 3D digital, and 3D cutting. The characters look realistic.

This also plays a significant role in the field of stop motion. Stop motion depends on three crucial factors, such as customizable dolls, poseable and physical effects. Here, the objects need to move based on the frame speed. When it comes to creating a different facial expression, props, and more, 3D printing works better.

Consider the example of LAIKA, a famous studio in the world. It is well known for producing fantastic quality animated figures, like Caroline, Kubo and the Two Strings, and more. For the projects, LAIKA has 3D printed around 20 000 different heads to obtain facial expressions. They also worked on a project called ParaNorman, and for this, they developed 40,000 heads.

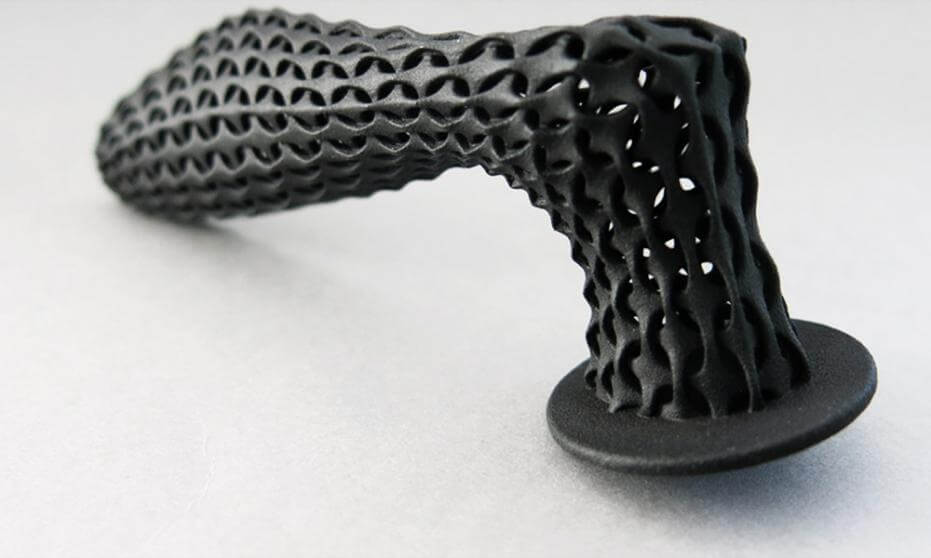

3D printed Demogorgon for Stranger Things

The film production company Aaron Sims Creative used the 3D printing technology to create the intricate design of the Demogorgon, a creature that you can see in the show “Stranger Things.” 3D printing was the ideal way for them to give the digital model a perfect physical shape. It has been proved that 3D printing is the best method to work on the Research and Development of character designs. With this, you can quickly come up with highly detailed characters.

3D printing in Jurassic World

3D printing is used to craft perfect replications of prehistoric artifacts for the famous film “Jurassic World.” For this, the designer scanned the original fossils and bones and give that a physical shape. They have been able to 3D print replications of real dinosaur bones to produce effects that look realistic. 3D printing is not just a cost-effective method but also produces faster results. You will get complete freedom to change the design of the characters for a better appearance.

3D printed suit for Iron Man

It was Jason Lopes who was working on designing the suit for Iron Man movie. He was a part of the Avengers and Iron Man 2 movie and wanted to form objects that can be worn on set. However, he also wanted to eliminate the molding process, making this consumes a lot of time.

As the best solution, he uses 3D printing technology to print some particular objects. Without taking much time, he manufactured the suit that was perfect for the actor. It has been proved that 3D printed props are the right solution to bring the real objects on the screen. It works much better than CGI technology.

So, if you want to establish a business unit for cartoon and action figure models, you can always go for FDM 3D printing. Wondering where to buy the best FDM printers? Don’t worry at all and get in touch with Dreambot3D. For more details, you can feel free to get in touch with us anytime you want.

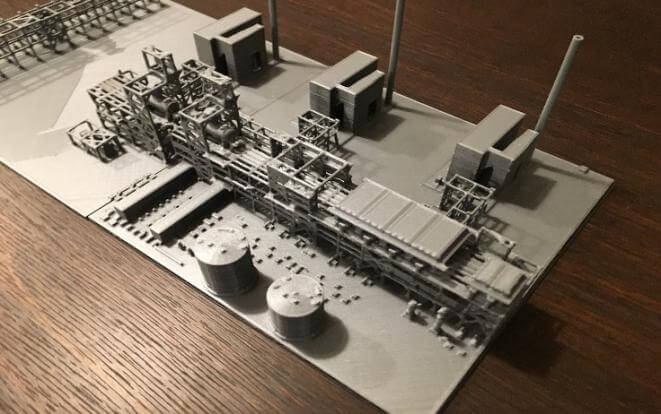

2.3, For model making

What is model making? Model making is the process of creating small models of real products for testing and valuation purposes. There is no need to do testing with the natural product and waste your money when using 3D printed models.

Besides, you can change the design base on the final result quite easily using 3D printing. Model making is a significant part of various industries, like architecture, medical, automotive, education, and more. Let’s talk about this in detail.

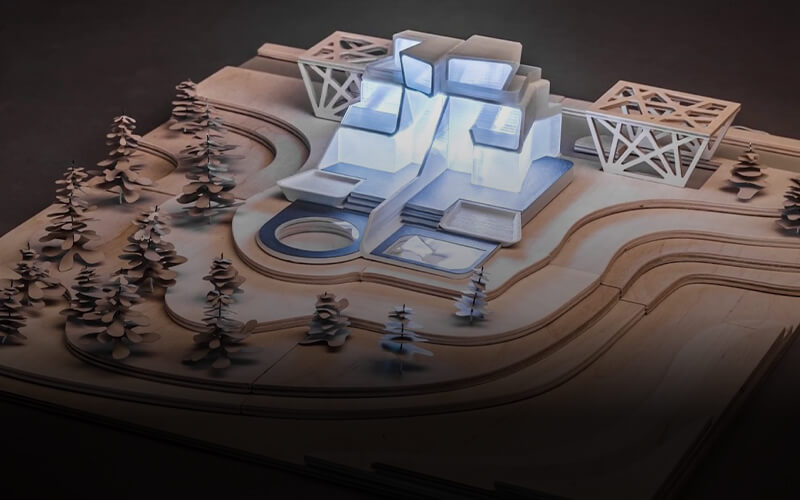

- Architectural industry

AES professionals and architects use high-quality FDM printers in the architecture industries to build amazingly looking physical architectural models with a superb detailed level. Using this, they are now showcasing their ideas better, which, in turn, helps them impress their clients.

Before starting working with any architectural projects, it is better to have a perfectly designed concept model to visualize ideas. The technology has become so advanced that you can now 3D print a house using the right type of material. In Austin, ICON Constriction Company build a 3D printed house prototype that is quite durable. So, use this technology and enhance your architectural services.

Mannequin models

The introduction of 3D printing has offered unlimited designing possibilities in the making of mannequin models. Besides, now you can create a complete mannequin within a few days, around 2 to 3 days. What’s more? You will also enjoy the freedom of choosing different materials for 3D printing, for example, Nylon, biodegradable filaments, PVC, and more. Using industrial design 3d printing, it is now possible to create a customized mannequin under your budget.

The traditional method of mannequin prototyping is using clay. Besides, traditionally producing them is very expensive and can take time. But with 3D printing, you can do it within a few days. Using the software, you can scan the object and give it the desired shape.

Robot birds

Like Clear Flight Solution, some companies have produced “Robirds” by utilizing 3D printed parts, which can be used to keep the real birds away from airports, crops, and more. The birds have a nearly accurate, realistic look and weight much lighter.

Drone models

Is it possible to 3D print drones? Yes, advanced 3D printing has made it possible. Using this, you can make the drone durable and develop a unique design to make the drone operate fast. 3D printing is now used to create a micro drone, pocket drone, quadcopter drone, and more. Here you can consider the example of CargoCopter. This drone is developed to support the delivery industry. With a weight of 5kg, this can operate at 150 km per hour.

2.4, Used in aerospace and automotive industry

3D printed objects are so durable that you can use them in the automotive and aerospace industry. The technology has lowered the production time and helped many airlines to reduce aircraft weight. Airbus, in 2018, 1000 3D printed parts from titanium.

Not just Airbus, other companies like Safran, GKN, GE, Boeing, and more are using this technology to create tooling, functional prototypes, and lightweight components. IT has also covered defence applications like small surveillance drones, brackets, and the element for the jet engine, submarine hulls, and more.

Coming to the Space Industry, NASA is using Stratasys 3D printers for manufacturing and testing the space rover that has around 70 3D printed parts. The parts are created using FDM printing technology. Latecoere, a well-known French aerospace company, has used 3D printing to lower the lead time for manufacturing custom tooling.

Previously, the company was using CNC milling, and it used to take around six weeks for tool manufacturing. However, with FDM 3D printers, the company is now producing those parts in just a few days, reducing the production time by around 95 percent.

Besides, the company has informed that with 3D printing, it has managed to cut the cost by approximately 40 percent. It may be noted that the tools are customized ergonomically, which has made the job of the operators easier.

The Moog Aircraft Group is also using FDM 3D printing to create produce tools. The company used to outsource those parts, with the entire outsourcing process taking 5 to 6 weeks. Now the company produces those tools within just 20 to 30 hours.

How to choose a suitable FDM 3d printer for your industry

Finding it difficult to choose the right machine for you? Don’t worry at all. By considering the below-mentioned points, you can easily buy the best one.

3.1, Your application industry

The primary use of the FDM 3D printer is for rapid prototyping. This lets you manufacture a low-cost model of the design, use limited material, and spend less money. Now, a lot of industries are using 3D printers, for example:

- Automotive- This industry uses 3D printing for prototyping and producing engines, housing for transmission, and more.

- Aerospace- This is the best option for production casting, sand molds, prototypes, and more. You can also 3D print metal components.

- Medical and dental-Using this highly functional and accurate customized prosthetics can be made. It is also used to create dental bridges, implants, and more.

- Shoemaking industry- Adidashas used 3D printed midsoles for the FutureCraft 4D shoes using Digital Light Synthesis technology. The shoes have 20,000 struts.

Every industry is now using 3D printing to enjoy faster and cost-effective production. Deploying this, you can increase your profit-earning level.

3.2, Print size requirements

This refers to the build volume of the printer. It will vary based on your requirements. For instance, in the automotive industry, a printer with 300 x 300 x 300mm of build area may not work correctly. However, this can work best if you are making jewelry. The cost of the printers will vary based on the printer’s build volume. So, choose the size carefully.

3.3, Printing material requirements

Not all 3D printers can process various 3D printing materials. However, if you have the budget, then choose a machine that supports different types of filaments. Choose a printer that can process:

- PET- It works great under high temperatures, and this material is resistant to impact.

- Nylon- This material offers better mechanical properties.

- ABS- It can easily withstand a higher level of temperature and quite common in all industries.

- PETCG- This is good to produce food-safe grade products.

These are some of the examples of filaments. There are more options than you can choose to create different types of products.

FDM 3d printer buying guide

With so many options out there, you can find it challenging to pick the top industrial 3d printers. To help you with this, we have listed down some points that you can consider for this. Have a look at those points.

4.1, Choose a reliable brand

It is advisable to buy the FDM 3D printers from a reliable and trusted brand. Why? This will increase your chances of getting the best products. Generally, a normal brand will produce machines with low structure and won’t print faster.

You may also face an issue in printing resolution. But printers from a trusted brand, like Dreambot3D, works better while producing a better solution. Besides, with a metal body, they look studier. So, go for a good brand. After all, you are investing a considerable amount of money, and you can’t take the risk of buying a low-quality product.

4.2, Safety configuration of the machine

While 3D printing uses different materials, you may face gas leaks, the risk from parts, high voltage, UV light, and heat. Such factors can be very harmful. So, you need to check the safety features offered by the machine. For example, it will be useful to choose a printer with an enclosed structure. Besides, make sure that the machine has a temperature control unit.

4.3, Resolution requirements of the machine

The resolution of the printer can severely affect your product quality. While creating models, the printer nozzle and build platform moves in XY and Z direction. If they move fast, you will get a low resolution. Make sure the printer has a decent resolution, and you can control the printing speed.

4.4, Consider whether the price of the machine is acceptable

3D printers are here to fulfill your 3D printing requirements, and the costs of these machines can range from USD 600 to USD 25,000. However, the quality will vary. For example, you can’t expect the bests printing quality with a USD 100 printer compared to a USD 10,000 printer. But when buying one, make sure you are getting the best feature under your budget. Ensure the FDM printer supports various printing speed configurations, materials, constant heat generation features, and more.

4.5, Consider the supplier’s after-sales service capability

As a technical product, your 3D printer can face technical issues while functioning. When it happens, you will want to resolve the issue as soon as possible. This can be done if the manufacturer offers a better after-sales service. Go for a company that can offer you 24×7 technical support, like Dreambot3D.

FAQ guide

What is the best FDM printer?

The best 3D printers are now getting more accessible to all. Thanks to the advancement in 3D printing technology, you can grab the best one quickly online. When you have the best industrial FDM 3D printer, you can quickly develop the complete products and spare parts for different projects. Besides, you don’t have to create a vital technical skill to operate these machines. Even though the best FDM printer will range widely in size, price, use case, and functionality, you can go for Dreambot3D FDM 3D printers for better results. Why? They come equipped with the latest technology and durable enclosed structure to work stably at an incredible speed. Check out the products now, or for more details, you can call us.

How do I increase the resolution on my 3d printer?

To increase the resolution of your 3D printer, you need to consider a lot of factors. For example, before printing, make sure the printer bed and the nozzle height are at the perfect level. Besides, make sure the temperature level is also suitable for the material that you want to use. Sometimes, it will be better for you to use the slicers. When it comes to enjoying better resolution from your 3D printing, you can always go for FDM 3 printers of Dreambot3D.

What does an FDM printer mean?

As discussed above, FDM printers utilize the Fused Deposition or Fused Filament Fabrication printing method. These printers are considered the best printers in the field of additive manufacturing. Here, the printers create objects by carefully depositing different filaments in the pre-determined path layer-wise. Such printers can support different types of 3D printing material, for example, ABS, PLA, PC, Nylon, PETG, and more. Compared to other printers, FDM printers offer better 3D print quality.

What is a good resolution for 3d printing?

It is quite essential to evaluate the 3D printer’s resolution so that you can easily determine the design that can greatly affect the final result of your product. You can attain good 3D printing resolution by working on different factors, such as printing software, size of the nozzle, filament type, printing speed, support structure, and temperature regulation system. As per the 3D printer experts, you can go for 10 microns on the XY axis for a decent level of details, and for the Z-axis, 50 microns of resolution will be the best option. Sometimes, you can even go for 1000 microns of lower resolution if you don’t need products with useful details.

How can I improve print quality?

In some cases, by lowering the printing speed, you can enhance your FDM 3D printer’s print quality. When you increase the printing speed, you will get low quality as here, the nozzle will move faster from one point to another. Besides, take care of high acceleration and deceleration as this can develop unwanted shadows. So, if you are not in a hurry, print a little slowly. However, Dreambot3D’s FDM 3D printers perform relatively better at a higher speed as they come with a robust structure.

What is the largest 3d printer available?

As per the report, in2019, scientists from the University of Maine introduced the world’s largest 3D printer. They also unveiled the largest 3D-printed boat, called 3Drigo, which weighs around 5000 pounds and approximately 25 feet. This 3D printer can print a 3D object 100 feet long, 10 feet high, and 22 feet wide.

How big can a 3d printer print?

The advancement in 3D printing technology has made it possible to build large parts using a 3D printer. For example, there are some types of Industrial 3D printers that can be used for furniture painting. A 3D printer can also print an object 22 feet wide, 10 feet high, and 100 feet long. In the near future, you may see 3D printers with the capacity to print even more significant objects.

What is the right size 3d printer?

Here the size of the 3D printer means the build area. The build area is usually measured in the XYZ dimension, for example, 20 inches wide (X) by 20 inches deep (Y) by 20 inches high (Z). A small build area can affect your production capacity, but you can create smaller parts and then combined them together in the end. However, in general, a build area of 13 x 13 x 13 CM or 5 x 5 x 5 inches should be sufficient for most printed parts. This can vary based on your printing requirements.

What is the standard for 3d printing units?

Even though it ultimately depends on your printing requirements, however, you can go for the printers with 13 x 13 x 13 CM of build area. This is the standard unit for 3D printing.

Can 3d printers be used for mass production?

The introduction of advanced technology has made various 3D printing technologies, like FDM and Selective Laser Melting, quite affordable. Besides, it is now easy to 3D prig metal parts. That clearly proves mass part production is possible using 3D printers. On the other hand, you can do rapid prototyping using an industrial FDM 3D printer. When it comes to using 3D printers for mass production, you need to think about what this technology can come up with. Using this, it is now possible to manufacture different types of shapes using the design you have in your mind. Adidas’s FutureCraft 4D sneakers can be the best example of this.

How durable is 3d printed items?

Do you know what the best part of 3D printing is? By combining different types of 3D printing material, the desired level of durability. Just like the traditionally manufactured products, 3D printed products also can be very durable. For example, thermoplastic can be used in 3D printing and injection molded methods, but the 3D printing option will be 60 to 80 percent more durable than the injection-molded option. They are so durable that you can use the 3D printed objects or parts for construction, medical, aerospace, industry, education, and more. So, for durable products, you can go for 3D printers. It will be better for you to go for FDM 3D printers of Dreambot3D as the machines work better.

What is the most robust plastic for 3d printing?

As per the experts, the strongest and durable 3D printing plastic is Polycarbonate. In fact, it’s strength level will definitely surprise you. To understand this, let’s compare this with nylon filament. The tensile strength level of Nylon will be around 7000 psi. On the other hand, you will find around 9,800 psi of tensile strength with Polycarbonate. It has been proved that this printing material can easily withstand -150-degree C to 150-degree C of temperature. You can trust this material to produce functional components.

Is PETG stronger than PLA?

For a better understanding, let’s discuss these two materials. Polylactic Acid or PLA is one type of polyester plastic and a standard 3D printing material. Before start using other printing materials, users prefer to work with PLA first. Speaking about PETG, it comes with an average reputation. PETG can demonstrate ABS-like physical properties. Even though they are reasonable, you will find that PETG is immensely durable than Polylactic Acid. To give your 3D printed object an impact-resistant feature, you can use PETG.

What happens if you print PLA too hot?

If the temperature level is more than the standard limit, PLA will turn out flimsy, and you will get a very soft material. You will get messy and droopy prints. So, what should be the ideal temperature to print PLA? You can keep the temperature between 185-degree C to 250-degree C while printing.

How many hours will a 3d printer last?

This is the most common question that buyers ask while purchasing a 3D printer. The accurate answer for this will vary based on the maintenance level and the usage rate. By taking good care of your printer, you can keep the machine running for around 8 to 10 years. Timely replacement, attentive service, and cleaning will increase lifespan. Using these printers 2 hours per day, you can use the printers for more than 3700 hours.

Will 3d printing replace traditional manufacturing?

Looking at the current situation, it can be said that 3D printing will not be able to replace traditional manufacturing. However, instead of that, it becomes a significant part of conventional manufacturing, increasing the process of production. Even though 3D printed models’ end result will look impressive, these printers come with some limitations. The material available for these printers is limited, and it requires costly one-time investment. However, you can combine these two methods for faster and effective manufacturing.

Is 3d printing cost-effective?

Yes, different studies have proved that 3D printing is money-saving and time-saving. On the other hand, using this, you can give your manufacturing process a perfect boost. If the production volume is low, go for this without any worry.

What is the main use of 3d printing?

Thanks to its innovative technology and capability to support different types of 3D printing material, you can use 3D printing for various purposes in various industries. Some primary uses of 3D printing can be:

- Prototyping- With 3D printing, you can enter into the market faster by developing prototypes much quicker. On the other hand, you can also enjoy rapid error correction and the product’s design alteration with this.

- Modeling- Do you have any idea in your mind and want to give it a perfect shape? With 3D printing, this is now possible. Using the right type of printing material, you can have a better finish product.

- Aerospace- It is the modern 3D printing technology and FDM printing process that has made it possible to develop highly intricate engine design that can be used for different purposes. Besides, now it is also possible to produce lightweight yet durable parts.

- Tooling- 3D printing has introduced flexible and cost-effective ways to manufacture 3D printed tools, tool masters, and mold. Using this, you can develop a highly accurate prototype for testing before making your final products.

- Architecture- The architecture industry is now using 3D printing technology to make 3D models of the house, buildings, and other construction projects. It helps the professionals in elaborating the project in a detailed way.

- End-user parts- It is possible to manufacture highly customized and durable components with an outstanding detail level. In fact, you will enjoy the smooth surface.

Is rapid prototyping the same as 3d printing?

To understand this, let’s know what rapid prototyping is, and what is 3D printing? Talking about rapid prototyping, this is a significant application of additive manufacturing or 3D printing. This helps in producing 3D objects faster. It is carried out through 3D printing technology. On the other hand, 3D printing is all about taking 3D model designs and then converting them into 3D objects. Here, you will use different types of 3D printing material to develop the product using a nozzle. This process includes various printing technology. From the definition, it can be said the even though they sound the same, they are used for different industries. However, both are important for a business. Combining them, you can enjoy better product development opportunities and can play with complex designs. For high-quality 3D printing and rapid prototyping, you can always choose the FDM 3D printers of Dreambot3D.

Conclusion: Why our FDM 3d printer is one of the best choices

Using 3D printing, it is now possible to improve durability, functionality, along with the aesthetic factor of the 3D models. Besides, using different types of filaments, you can come up with highly durable products.

But to get the best result and maximum benefits of 3D printing, you need to buy the best quality FDM 3D printer considering the FDM 3d printer price. Remember that a 3d printer for industrial use will vary from a 3D printer for home use. So, you need to choose wisely.

Where to find the best 3D printers? Don’t look here and there and visit the official site of Dreambot3D. The company is well-known for offering the best industrial-grade 3D printers that can be used in different industries.

We know the importance of rapid prototyping and high-quality end parts for your business. So, we have developed our machines to keep these things in mind. Why should you choose our FDM printers?

We produce highly durable machines that come with metal made enclosed chassis. You won’t find this with our competitors’ printers. There will be no risk of getting into contact with harmful printing material. The XYZ axis that plays a significant role in printing resolution works quite stably, even if you are running the machine faster. So, when it comes to getting the maximum level of accuracy, you can trust our machines.

A small change in the temperature can affect your filament processing, and you need to keep the temperature at a constant level during the printing. For this, our FDM 3D printers come equipped with the “Continuous Temperature System.” So, you can confidently use a material like PETG, ABS, PC, fiber, and more without worrying about wrapping. Not all the printers that are available in the market have this system.

Our machines come with 7-inches large color screens to let you use them conveniently. Furthermore, the operating system is also easy to understand. Just install the device, and you can start working on your 3D printing project. These features are missing in the products that our competitors offer.

Based on your printing requirement, you will have to buy printers of different sizes. Keeping this thing in mind, we have brought you a complete range of sizes. For example, you can buy L5-400/500/600/800/1000 and L8-400/500/600.

No matter how good a company is, if it doesn’t offer the best quality after-sale service, people won’t prefer to buy their products. As a reputed company, we are offering 24×7 technical support. This will help you to keep your machine running smoothly.

We have produced top-quality industrial 3D printers or the best 3d printer for industrial design for more than 8 years. With our robust R&D capability, we always introduce new technologies in our machines. You can buy an FDM 3D printer at the lowest cost from a manufacturer that only deals with desktop-level machines.

But they won’t perform well when it comes to producing 3d printed industrial parts. You will waste both your time and money with this. However, our printers are capable of handling different types of projects.

We also offer faster shipment of the machines, and once the order is placed, we initiate the shipping process within 3 to 5 days. IF you are looking for the ideal 3d printer for industrial use, call us now.