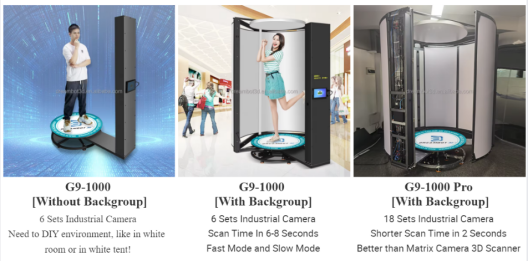

Full Body 3D Scanner

G9-1000Pro Full Body 3D Scanner

- three rods ,with 18 lens and three computres

- 1-2 seconds to scan/collection

- 324 photos ,10 minutes to build model drawing

- it can scan up to 5-6 peoples,good for family /team

- capacity 500kg, strong stabilty

- High efficiency rotation scanner

1.Scan

2.Create

3.Repair

4.Print

5.Post-Processing

6.Shipping

Test your part

We provide sample testing service, allowing you to check the working quality of our 3D printer before placing an order

Step 1: Scanning

The customer stands on the 3D body scanner, and the scanning process takes only a few seconds to complete.

Step 2: Modeling

After scanning, the system captures over 300 images, which are used to build the 3D model. This modeling process typically takes about 10 minutes.

Step 3: Model Refinement

Once the model is generated, a modeler needs to refine it, making it clean and detailed enough for 3D printing. This refinement process takes approximately 30 minutes to 2 hours, depending on the skill level of the modeler.

Step 4: Printing

After the model file is finalized, it can be sent for 3D printing. One batch can print 40–44 models at 9 cm height simultaneously. The printing time is mainly determined by the model height, so whether printing a few models or a full batch, the time is similar—around 10 to 13 hours per batch.

Step 5: Support Removal

Once the printing is complete, the excess support structures need to be carefully removed from the models.

Step 6: Post-Processin

This includes polishing, sandblasting, cleaning, curing, and oiling the models. For one full batch, the post-processing takes about 1–2 hours.

In summary, from scanning to the final finished model, the entire process can be completed in as fast as one day, or up to two days depending on workflow. With a well-organized team working in parallel, it’s possible to complete 40 to 80 models in one day.

If you only have scanner , you just need to do the scan and create models.

1. Scanning: The customer stands in front of the scanner device and just few seconds can finished the scanning.

2. Create the 3d model drawing: After scanning,there will be over 300 photos(G9-1000). We wil appy a software, the modeling process willtakeapproximately 10 minutes by software auto working.

1. Cutting-Edge Hardware Specifications

Ultra-Fast Scanning

Completes full-body capture in 1-2 seconds (industry-leading speed)

18 high-speed industrial cameras (Sony 12MP CMOS) capturing 324 images (3.89 billion pixels aggregate) at 1.2μm/pixel resolution

Robust Mechanical Design

Central rotating arm system supports 500kg payload (2-3 simultaneous subjects)

Compact footprint (2.5×2.4×0.37m) with 1800W power consumption (220V/110V compatible)

2. Precision & Professional-Grade Performance

| Parameter | G9-1000 Pro | Industry Average |

|---|---|---|

| Accuracy | 0.1mm (medical-grade) | 1-2mm |

| Output Formats | DICOM/STL/OBJ multi-format | Basic OBJ/STL only |

| Lighting System | Flicker-free LED + PLC control | Standard flash |

Medical Certification: DICOM-compliant for prosthetics/surgical planning

3. Industry-Specific Solutions

A. Healthcare & Rehabilitation

40% more accurate scoliosis monitoring vs. traditional methods

Prosthetic socket scanning time reduced to 15 minutes (vs. 2 hours manually)

B. Bespoke Fashion

<0.5mm garment pattern error with dynamic pose capture

Seamless CLO3D integration for digital pattern-making

C. Industrial Design

Direct CAD export (CATIA/UG) for ergonomic validation

4. Intelligent Software Ecosystem

DREAMBOT 3E™ Control System:

AI-powered mesh repair (e.g., hair gaps)

Auto-generates 20+ anthropometric reports (ISO 20685 compliant)

Cloud collaboration for remote medical consultations

5. Commercial Value Proposition

High ROI: 200+ scans/day possible ($50/scan = 3-6 month payback)

Low Maintenance: Modular camera/lighting replacement

Success Cases:

Shanghai Tier-3 Hospital: 90% faster burn wound measurement

Italian luxury shoemaker: 70% reduction in last rework

Competitive Comparison

| Metric | G9-1000 Pro | Standard Scanners |

|---|---|---|

| Speed | 1-2 sec/scan | 5-10 sec/scan |

| Accuracy | 0.1mm (sub-millimeter) | 1-2mm |

| Upgradability | Future AI posture add-ons | Fixed functionality |

| Device name | Parameter | DREAMBOT 3E™ |

|---|---|---|

| Model number | G9-1000 Pro | |

| Image capture chamber | Equipment structure | Central rotating platform is equipped with a single arm image acquisition mechanism |

| Equipment weight | 250kg | |

| Equipment carry weight | 500kg | |

| Equipment size | 250cm*240cm*37cm | |

| Service power of equipment | 1800W | |

| Input voltage | 220V (110v can be customized) | |

| Image acquisition system | Camera type | Hd high speed industrial camera |

| Camera chip | Full color Sony CMOS,1.2μmX1.2μm, 12Mpix | |

| Lens | 1/1.7″ Large sensitivity and depth of field industrial camera lens | |

| Number of cameras | 18 sets | |

| System control mode | Dedicated software system intelligent control | |

| Image acquisition mode | Acquisition mode | Continuous image acquisition mode during fast rotating motion |

| Acquisition time | 1-2s | |

| Image quantity | 324 photos max.(3.89 billion pixel images) | |

| Data transmission system | USB3.0 or above high-speed data transmission management system, super Class 6 shielded network cable | |

| Lighting system | Lamp source | High display refers to the LED light group module without screen flashing |

| Control system | PLC system + program control | |

| Power supply configuration | Power input 220V, output 24V | |

| Auxiliary equipment configuration (computer and monitor) | By the customer’s own configuration. Minimum configuration; 24 inch display, iSCPU, 16GB memory, 1TB hard disk | |

More Scanners For You to Choose

Structured Light 3D Scanner

A wide range of industries and applications that demand precise and thorough 3D data about item geometry rely heavily on structured light 3D scanners.

FDM 3d printer

The L-200 desktop 3D printer is used to create 3D prototypes of objects for various industries such as dental, automotive, marine, aerospace, toys, decorations, etc.

FAQ Guide Full Body 3D Scanner

- 1. Is big difference definition for one scaner one càmara , 2 càmaras 3 camaras ? Can you send me pictures of 3 types to see difference ?

- 2. I buy one scan machine, then I send you information . Do you produces the pieces painted and send me ? Or I must but the printed machine and raw material and produce in Argentina?

- 3. If you produce , how much is the cost for piece in 9cm finished?

- 4. What is the weigth of one piece 9cm ?

- 5. Do all pieces 9cm have same cost ?

- 6. I sow for example one piece with 2 person and one baby . Is same cost one person?

- 7. After send you information , how many time do you need to send me by courrier?

- 8. Can you samples with free cost ?

- 9. How many samples without cost can you send?

- 10. How many persons can scan in same piece ? I sow in tik tok at 5 person of one team

- 11. What do you suggest me? to buy scan machine only and send information you to produce pieces or to buy printed too ?

- 12. What is the time to emsably and disambly ?

- 13. Can you give me the HS of scan machine to calculate tax here?

1. Is big difference definition for one scaner one càmara , 2 càmaras 3 camaras ? Can you send me pictures of 3 types to see difference ?

Model | Number of cameras | Number of shots | Scanning time |

G9-1000 | 1 set(6 pcs) | 300 Photos | 7-10 s |

G9-1000 Pro | 3 sets(18 pcs) | 324 Photos | 1-2 s |

2. I buy one scan machine, then I send you information . Do you produces the pieces painted and send me ? Or I must but the printed machine and raw material and produce in Argentina?

Generally, making full-color 3D human figurines involves two devices: a 3D scanner and a full-color 3D printer. There are two corresponding solutions:

- If you want to open a store, you only need to purchase one device: the human figure 3d scanner.

You can send the collected data back to the manufacturer for printing, and the manufacturer will ship the finished models to the customer (the printing time is about 3-5 days, and the express time is about 4-6 days, for a total of 8-13 days).

Many customers in major cities in China and many countries in Southeast Asia have made human figurines using this way. The initial stage only requires the purchase of a human figure 3d scanner, and a shop area of 10 square meters or more can be easily opened.

- If you have sufficient budget and want high efficiency, you can purchase both the 3D scanner and the full-color 3D printer at the same time.

The full-color 3D printer set is about USD 120000, so most customers will choose solution 1 when they have a small printing volume and a low budget in the initial stage.

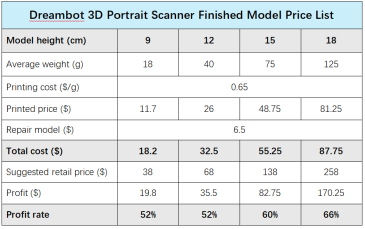

3. If you produce , how much is the cost for piece in 9cm finished?

We usually have four model sizes: 9,12,15,18 cm. The smallest 9cm model costs about $18.

Need consider the oversea express cost to door too,

5. Do all pieces 9cm have same cost ?

It’s different. We charge according to the materials we consume.

The fee for a normal adult, as shown above, is about $18.

But for example, a child is 9cm, squatting, and wearing heavy clothes. This increases the volume of the print.

6. I sow for example one piece with 2 person and one baby . Is same cost one person?

The larger the size, and the greater the weight, so the more materials consumed, the more expensive the price.

7. After send you information , how many time do you need to send me by courrier?

the printing time is about 3-5 days, and the express time is about 3-5days, for a total of 6-10 days

8. Can you samples with free cost ?

I am so sorry, sample is not free, As you can see, printing cost is not cheap to make a figurine.

9. How many samples without cost can you send? Can you prepare samples for me ?

All the samples we will charge the cost . Yes, we can prepare some samples for you .

10. How many persons can scan in same piece ? I sow in tik tok at 5 person of one team

Our scanner”s plate based is 1m diameter with thickness frame, it can hold on 6 to 8 person no problem . But for consider the details effect, we recommend scanning up to 2 adults and 1 child at a time.

If you need to scan more people at one time, for example 5 to 8 people , better to purchase the G9-1000 pro , it can make sure the details . Many person scan in a time, that must be matrix camera scanner, many cameras.

There will be some places that can not be scanned, the scanning effect is not as good.

I think it depend of plate base .

Can you speak about this ?

The diameter of our base is 1m. It can be customized up to 1.2m

11. What do you suggest me? to buy scan machine only and send information you to produce pieces or to buy printed too ?

This kind of printer is very expensive. The printing process is complicated.

If you just buy one scanner to set up a shop ,we don’t recommend all the client to consider printer for start a small business.

But if you want to carry out this business throughout Argentina,plan to open 10 or even more shops, then I recommend that you need to buy a printer

13. Can you give me the HS of scan machine to calculate tax here?

3D scanner: 9031499090

3D printer: 8485200000

I am really interest in your product , more my intention is to visit you in few months, but I would like to begin advance

Welcome to visit our factory, we are waiting for your arrival.