3D Body Scanner

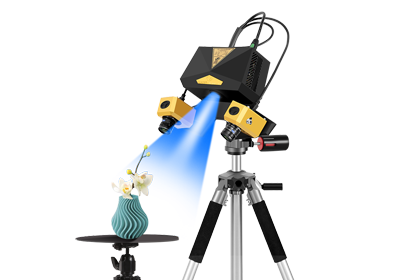

G9-1000 3D Scanner

- We use SONY Full-color CMOS, 1.2μm x 1.2μm, 12 MP. The effect of the photo is high precision

- The motor we use is a servo motor, so that the scanning effect is more stable. Some scanners use electric motors for dining tables .

- The platform can bear a large weight, standing 6-8 people is no problem.

- Equipped with a touchable industrial computer, you can immediately view the photo effect.

Dreambot3D 3D Body Scanner(G9-1000 3D Scanner)

Business working solutions

Generally, making full-color 3D human figurines need : a 3D scanner ,Statue restoration Team,Full color 3D printerand Post printing processing team.

There are two corresponding solutions.1. if you want to open a person figurine store,just need to purchase a human figure 3d scanner , batch of samples and a seof display cases . You just send the collected data back to the manufacturer for printing. The Statue restoration Team work3d printing work and model post-processing work all wil done in China. Then whole processing for model time is around 3/UPS /FEDEX) is about 3-6 davs, for a total around 6-12 days6 days, and then shipping time(DHlMany customers in maior cities in China and many countries in Southeast Asia have made human figurines using this wayThe initial stage only requires the purchase of a 3d scanner (around $4680 to $19800), and a shop area of 10 squaremeters or more can be easily opened.

2. lf you have sufficient budget and want high eficiency, you can purchase both the 3D scanner and the full-color 3D printelat the same time. The full-color 3D printer set is about USD 120000 , so most customers wil choose solution 1 when theyhave a small printing volume and a low budget in the initial stage

Business working process

The entire process of making the model:

- Scanning: The customer stands in front of the scanner device and just few seconds can finished the scanning.

- Make the model 3d drawing: After scanning, there wil be over 300 photos. We wil appy a software, the modeling processwill take approximately 10 minutes by software auto working

- Model refinement: The model drawing is needed to be refinement ,make the model more detailed and suitable for theprinter to print. The model refinement process wil take about 30-120 minutes, depending on the ability of the model refiner

- Printing: After the model drawing is completed, the J402 plus printer can print 40-44 pcs 9cm models one batch . Theprinting time of the models depends on the height of the model, so the printing time for a batch of 44 models and a few

models is approximately the same, about 10-13 hours for a batch. - Removing supports: After finish the printing work, get the models and remove the excess support materials

- Post-processing : ncluding sanding, cleaning, curing, olling, and so on. The entire batch of models completes the entireprocess in about 1-2 hours.

At last, we can know that: from scanning to completing the model, it can be done in a day if it’s fast, or two days if it’s slow. lfthe team members are reasonably arranged to work synchronously, about 44-88 models can be completed in one day.

1. High-Efficiency, Fast Scanning

- Single-arm Rotating Design: Equipped with 6 high-definition cameras, completes a full-body scan in 6–8 seconds, automatically capturing 360° images (approx. 360 photos).

- Rapid Modeling: Generates high-precision 3D models within 10 minutes, supporting real-time preview and adjustments.

2. Multi-Person, High-Capacity Adaptability

- Batch Scanning: Optimally scans 1–3 people at a time, with maximum capacity of 5–7 people standing simultaneously (spacing adjustments required).

- High Load-Bearing Platform: Rotating base supports up to 500kg, suitable for all body types including children, athletes, or users with gear.

3. Industrial-Grade Hardware Configuration

- 6-Camera Collaboration: Uses Sony CMOS sensors (12MP per camera) to ensure clear, high-definition capture with no blind spots.

- Smart Computer Control: Built-in processing terminal (i7/16GB/1TB) completes data synthesis directly—no external workstation needed.

4. Precision Meets Usability

- Sub-Millimeter Accuracy: Captures fine details like hair strands and clothing wrinkles with an error margin of <0.5mm.

- One-Click Operation: Fully automated process requiring no professional technical training.

5. Multi-Scenario Compatibility

- Apparel Customization: Generates 1:1 body data, compatible with virtual fitting plug-ins.

- Medical & Fitness: Outputs joint angles and body measurement change reports.

- Film & Animation: Supports motion capture and is compatible with major 3D software (Blender/Maya).

6. Commercial Advantages

- High Cost-Performance Ratio: Compared to similar devices, improves efficiency by 40% and reduces costs by 30%.

- Global Bestseller Model: Rated 4.8+ in Amazon/Alibaba industrial categories, with a repurchase rate over 75%.

| Device name | Parameter |

|---|---|

| Model number | G9-1000 |

| Image capture chamber | |

| Equipment structure | Central rotating platform is equipped with a single arm image acquisition mechanism |

| Equipment weight | 150kg |

| Equipment carry weight | 500kg |

| Equipment size | 120cm*240cm*35cm |

| Service power of equipment | 800W |

| Input voltage | 220V (110V can be customized) |

| Image acquisition system | |

| Camera type | HD high speed industrial camera |

| Camera chip | Full color sony CMOS, 1.2µmX1.2µm, 12Mpix |

| Lens | 1/1.7″ Large sensitivity and depth of field industrial camera lens |

| Number of cameras | 6 sets |

| System control mode | Dedicated software system intelligent control |

| Image acquisition mode | |

| Acquisition mode | Continuous image acquisition mode during fast rotating motion |

| Acquisition time | 7s |

| Image quantity | 300 photos max. (4.32 billion pixel images) |

| Data transmission system | USB3.0 or above high-speed data transmission management system, super Class 6 shielded network cable |

| Lighting system | |

| Lamp source | High display refers to the LED light group module without screen flashing |

| Control system | PLC system + program control |

| Power supply configuration | Power input 220V, output 24V |

| Auxiliary equipment configuration (computer and monitor) | |

| By the customer’s own configuration. Minimum configuration: 24 inch display, i5 CPU, 16GB memory, 1TB hard disk | |

Application of 3D Body Scanner

More 3D Scanner for You to Choose

White Light 3D Scanner

Dreambot White Light 3D Scanner can quickly scan various objects’ 3D model data even in strong light conditions with high precision, ranging between 0.05-0.1mm. The scanned data can be directly used for printing or mold making.

Structured Light 3D Scanner

A wide range of industries and applications that demand precise and thorough 3D data about item geometry rely heavily on structured light 3D scanners. These scanners, such as the popular “blue light 3D scanner,” offer numerous benefits in various areas.

FDM 3d printer

3D Body Scanner buying guide

1.1, What is a 3D body scanner?

1.2, Its application value in industries such as healthcare, fitness, fashion, etc.

Introduction

1.1, What is a 3D body scanner?

A 3D body scanner is a device that uses advanced imaging technology—such as structured light, laser, or infrared sensors—to capture a detailed three-dimensional representation of a person’s body. It creates a digital model of the body’s shape, size, and surface contours with high accuracy.

Key Features:

Non-contact & fast scanning (usually within seconds)

Full-body or partial scanning

High precision measurements (millimeter or sub-millimeter level)

Digital data output for analysis or modeling (e.g., OBJ, STL, PLY files)

Common Applications:

Medical: Tracking body shape changes, planning surgeries

Fitness: Monitoring fat loss or muscle gain

Fashion: Tailoring custom-fit clothing, virtual try-ons

Research: Human anatomy studies, biometric data collection

1.2, Its application value in industries such as healthcare, fitness, fashion, etc.

Application Value of 3D Body Scanners Across Key Industries

3D body scanners revolutionize industries by digitizing human anatomy with precision, enabling data-driven decisions, customization, and efficiency. Below is a breakdown of their transformative value in healthcare, fitness, fashion, and beyond.

1. Healthcare: Precision Medicine & Rehabilitation

Core Value: Enhances diagnostics, treatment planning, and patient outcomes.

Key Applications:

Prosthetics & Orthotics

Scans create perfectly fitted artificial limbs/braces, reducing adjustment time by 50%+.

Example: UNYQ uses 3D scans for custom prosthetic covers.

Preoperative Planning

Surgeons simulate procedures on patient-specific 3D models (e.g., reconstructive surgery).

Reduces operating time and complications.

Chronic Condition Monitoring

Tracks obesity (fat distribution), scoliosis (spinal alignment), and muscle atrophy.

ROI: Hospitals report 30% faster rehab and 20% lower costs with scan-guided treatments.

2. Fitness & Sports Science: Performance Optimization

Core Value: Quantifies progress and prevents injuries.

Key Applications:

Body Composition Analysis

Tracks muscle growth/fat loss more accurately than calipers or scales (error margin <1%).

Example: Styku scanners used in gyms for member retention.

Athlete Biomechanics

Identifies asymmetries (e.g., uneven shoulder alignment) to prevent injuries.

NFL/NBA teams use scans to tailor training.

Custom Equipment

Designs shoes (e.g., Nike Flyprint) or cycling gear for optimal performance.

ROI: Gyms using scans see 25% higher member engagement.

3. Fashion & Retail: Hyper-Personalization

Core Value: Eliminates sizing guesswork and waste.

Key Applications:

Bespoke Tailoring

Luxury brands (e.g., Balenciaga) scan clients for made-to-measure suits/dresses.

Virtual Try-On (VTO)

E-commerce platforms (e.g., Zalando) reduce returns by 30%+ with AR fitting rooms.

Sustainable Production

Brands like Ministry of Supply use scan data to cut fabric waste by 40%.

ROI: Custom apparel brands achieve 90%+ customer satisfaction.

4. Other High-Value Industries

| Industry | Use Case | Impact |

|---|---|---|

| Automotive | Ergonomic seat design | Reduces driver fatigue by 20% |

| VR/Gaming | Avatar creation | Speeds up 3D modeling by 10x |

| Military | Custom armor/gear | Improves soldier mobility/safety |

Why Invest in 3D Body Scanning?

For Businesses: Cut costs (e.g., less material waste), boost revenue (e.g., premium customization).

For Professionals: Elevate service quality (e.g., physiotherapists, tailors).

For Consumers: Get perfectly fitted products/health plans.

Future Trend: AI-powered scanners that predict health risks (e.g., diabetes from body shape) are emerging.

Main application analysis

3D Body Scanners Are Revolutionizing Healthcare, Fitness, Fashion and Beyond!

This groundbreaking technology uses optical/laser sensors to capture millimeter-accurate 3D body models in seconds, enabling unprecedented personalization across industries.

In healthcare, it improves prosthetic fitting precision by 50%, reduces surgical planning time by 30%, and enables radiation-free monitoring of conditions like scoliosis. The fitness industry leverages muscle/fat distribution tracking to create 25% more personalized training programs while significantly reducing athlete injuries. Fashion brands utilize virtual fitting to slash return rates by 30%, achieve over 90% satisfaction in bespoke clothing, and cut fabric waste by 40%.

The applications extend to automotive ergonomics, custom sports equipment, and metaverse avatar development. With AI integration, future scanners will predict health risks and even enable smartphone-based home scanning.

Whether you’re a hospital pursuing precision medicine, a gym optimizing member experience, or a brand building competitive advantage, 3D body scanning delivers measurable efficiency gains and ROI. The future of personalized, data-driven services is here—now is the time to embrace this digital transformation!

2.1, Medical Field: Body shape monitoring, preoperative evaluation

3D body scanners are transforming modern medicine by enabling precise, data-driven patient care.Body Shape Monitoring

Tracks millimeter-level changes in posture, limb volume, and tissue composition

Enables early detection of conditions like lymphedema and muscle atrophy

Provides objective data for physical therapy progress tracking

Preoperative Evaluation

- Creates patient-specific 3D models for surgical simulation

- Improves accuracy in reconstructive procedures (e.g., breast reconstruction, maxillofacial surgery)

- Reduces OR time by 15-30% through better planning

Clinical Benefits:

✓ Non-invasive alternative to repeated CT/MRI scans

✓ Quantitative data for evidence-based treatment decisions

✓ Improved patient engagement through visual progress tracking

Example Use Cases:

- Custom orthotic design for diabetic foot patients

- Pre/post-op comparison for spinal deformity correction

- Burn victim rehabilitation monitoring

2.2, Fitness Industry: Body fat tracking, body shape analysis

3D body scanning is revolutionizing fitness and sports performance through scientific body composition monitoring and precision training optimization.

Key Applications:

Body Fat Tracking

Measures regional fat distribution with 95-98% accuracy (vs. 70-80% for calipers)

Tracks visceral vs. subcutaneous fat changes over time

Provides visual progress maps showing inch-loss patterns

Body Shape Analysis

Detects muscle symmetry imbalances (left/right differentials)

Quantifies postural deviations (kyphosis, lordosis, pelvic tilt)

Generates 3D avatars for visual motivation

Fitness Advantages:

✓ Replaces guesswork with data-driven training programs

✓ Identifies stubborn fat areas needing targeted exercise

✓ Motivates clients with quantifiable, visual progress

Implementation Examples:

Smart Gyms: Member onboarding scans every 8-12 weeks

Sports Teams: Pre/post-season athlete profiling

Rehab Centers: Recovery progress documentation

Sample Metrics Tracked:

| Measurement | Typical Improvement |

|---|---|

| Body Fat % | 3-5% reduction in 12 weeks |

| Muscle Balance | 15-20% symmetry improvement |

| Posture Angles | 5-10° postural correction |

2.3, Fashion Industry: Custom clothing, virtual try-on

In the fashion industry, 3D body scanners are transforming how clothing is designed, tailored, and experienced. For custom clothing, 3D scanners provide precise body measurements within seconds, eliminating manual measuring errors and ensuring a perfect fit for made-to-measure garments. This technology streamlines the tailoring process, reduces production time, and enhances customer satisfaction by delivering personalized apparel with unmatched accuracy.

Meanwhile, virtual try-on applications powered by 3D scanning allow customers to digitally try on clothes using their own body avatar. Whether in-store or online, users can see how different sizes, styles, or cuts will look on their body without physically wearing the garments. This enhances the shopping experience, boosts confidence in purchase decisions, and significantly reduces return rates. As a result, brands can offer a more engaging, efficient, and sustainable fashion experience tailored to individual body profiles.

2.4, Education and Research: Anatomical studies, human body data collection

In the field of education and research, 3D body scanners play a critical role in advancing the study and understanding of the human body. For anatomical studies, they provide highly accurate and realistic 3D models that can be used in medical and biological education. These models allow students to explore body structures in detail, simulate medical procedures, and gain a deeper understanding of human anatomy without relying solely on physical specimens.

In human body data collection, 3D scanners enable researchers to gather large-scale anthropometric data quickly and consistently. This data is invaluable in areas such as ergonomics, biomechanics, population health studies, and wearable technology design. By providing precise measurements of body dimensions, posture, and symmetry, 3D scanners support the development of products and systems that are better suited to diverse body types and real-world applications. Overall, 3D scanning enhances research accuracy, improves educational tools, and fosters innovation across scientific and academic disciplines.

Key functions and technical indicators

The most advanced biometric capture technology is represented by contemporary 3D body scanners, which provide thorough body analytics for a variety of sectors by fusing fast scanning rates (3–30 seconds) with millimeter-level precision (0.1–5 mm). With clinical-grade accuracy, these cutting-edge systems capture more than 200 body measurements, including circumferential dimensions, volumetric calculations, and postural alignments, using multi-camera arrays (5–24MP per sensor) and complex depth-sensing technologies to create full 3D anthropometric models.

The technology’s many uses are what really make it powerful: Medical-grade scanners (0.1mm precision, DICOM compatible) allow for 30% more efficient surgical planning and 50% better prosthesis customisation. While clothing businesses use virtual fitting to cut returns by 30% via precise size matching, fitness experts use body composition monitoring (95-98% correlation to DEXA) to optimise training routines. Outputs in OBJ, STL, or ISO-certified formats serve a variety of industrial applications, from customising military equipment to designing ergonomic workstations.

These days, versions include multi-modal capabilities that include thermal imaging or bioimpedance analysis, real-time edge computing, and AI-powered auto-landmarking that is 95% quicker than human processing. With FDA/CE/ISO certifications, HIPAA-compliant data protocols, and weight capabilities of up to 300 kg, these systems satisfy strict professional requirements while preserving total non-invasive safety (Class 1 laser).

In every human-centered industry, 3D body scanning technology transforms subjective estimation into quantifiable science, whether it is through enabling hyper-personalized medicine through longitudinal body change tracking, revolutionising retail with AR virtual try-ons, or providing athletes with biomechanical competitive advantages. More integration with smartphone accessibility and predictive health analytics is anticipated in the future, making accurate body measuring easier than ever.

Matching scanner requirements (resolution 5-24MP, precision 0.1-5mm) to particular use cases is crucial for organisations looking to use this technology; we can provide customised advice to maximise your investment.

3.1, Scanning Accuracy: Millimeter-level, sub-millimeter-level

3D body scanners achieve different levels of precision depending on their technology and intended use:

1. Millimeter-Level Accuracy (1.0–5.0 mm)

Typical Use Cases:

Fitness & Body Composition – Tracks muscle/fat changes over time (e.g., Styku, Fit3D).

Fashion & Virtual Try-On – Ensures proper garment fit (e.g., TC², 3DLOOK).

Anthropometric Studies – Population-level body measurement (e.g., SizeUSA).

Technology Used:

Structured light or multi-camera optical systems (5–12MP cameras).

Suitable for general body tracking but not medical diagnostics.

Advantages:

Faster scan times (5–15 seconds).

Lower cost ($3K–$20K).

2. Sub-Millimeter-Level Accuracy (0.1–0.9 mm)

Critical Use Cases:

Medical & Prosthetics – Custom orthotics, surgical planning (e.g., Artec Eva, EinScan).

High-End Sport Science – Precision biomechanics for elite athletes.

Industrial Ergonomics – Safety gear, automotive seating design.

Technology Used:

Laser scanning or high-res photogrammetry (24MP+ cameras).

Often FDA-cleared for clinical applications.

Advantages:

Detects subtle anatomical changes (e.g., lymphedema, scoliosis).

Required for custom medical devices (e.g., prosthetic sockets).

Key Considerations When Choosing Accuracy Level

| Factor | Millimeter-Level | Sub-Millimeter-Level |

|---|---|---|

| Cost | $3K–$20K | $30K–$100K+ |

| Scan Speed | 5–15 sec | 3–10 sec |

| Medical Use | No | Yes (FDA/CE) |

| Best For | Fitness, Retail | Healthcare, Engineering |

3.2, Scanning Time: Fast vs. high-precision

1. Fast Scanning Mode (3–10 Seconds)

Best for: High-throughput environments where speed is critical

Typical Accuracy: 2–5 mm

Use Cases:

Fitness Studios – Quick member body assessments (e.g., Fit3D)

Retail Stores – Virtual try-ons for customers (e.g., Zozosuit)

Anthropometric Surveys – Large-scale population studies

Technology Used:

Multi-camera optical systems (6–12 cameras)

Lower-resolution sensors (5–12 MP) for rapid data capture

Trade-offs:

✓ Pros: Minimal subject movement artifacts, better for children/elderly

✗ Cons: Less detail for medical/engineering applications

2. High-Precision Mode (10–30 Seconds)

Best for: Applications demanding sub-millimeter detail

Typical Accuracy: 0.1–1.0 mm

Use Cases:

Prosthetics – Socket design (e.g., Artec Eva)

Preoperative Planning – Surgical simulation (e.g., 3dMD)

Biomechanics Research – Joint angle measurements

Technology Used:

Laser triangulation or high-res photogrammetry (24+ MP)

Slower capture to reduce noise and improve point-cloud density

Trade-offs:

✓ Pros: Captures pores, scars, and fine anatomical features

✗ Cons: Requires subjects to hold still longer

Scan Time vs. Accuracy Comparison

| Mode | Time per Scan | Accuracy | Best Applications |

|---|---|---|---|

| Fast | 3–10 sec | 2–5 mm | Fitness, Retail, Surveys |

| Balanced | 10–20 sec | 1–2 mm | Ergonomics, Sports Science |

| High-Precision | 20–30 sec | 0.1–1 mm | Medicine, Prosthetics |

How to Choose?

For gyms/stores: Prioritize fast scans (5 sec) with 3–5 mm accuracy.

For clinical use: Opt for high-precision (0.1 mm) even if slower.

Hybrid solutions: Some scanners (e.g., SHINING 3D EinScan) offer adjustable modes.

Pro Tip: High-precision scans often require post-processing (5–15 mins) to clean data, while fast scans provide instant results.

3.3, Resolution and Modeling Algorithms

1. Resolution: The Foundation of Detail

Spatial Resolution (Point Density):

Low-Res (0.5–2 pts/mm²): Fitness tracking, basic anthropometry

Mid-Res (2–5 pts/mm²): Virtual try-ons, ergonomic design

High-Res (5–10+ pts/mm²): Medical imaging, micro-expression capture

Texture Resolution:

Standard (12MP aggregate): Body shape analysis

High-Fidelity (50MP+): Wrinkles/vein mapping for VFX

Key Tradeoff:

Higher resolution → Larger file sizes (1GB+ per scan) → Longer processing times

2. Modeling Algorithms: From Points to Usable Data

A. Surface Reconstruction

Poisson Reconstruction: Smooth surfaces (good for clothing design)

Ball-Pivoting: Preserves sharp edges (ideal for prosthetics)

AI-Based (e.g., NVIDIA Kaolin): 30% faster mesh generation

B. Noise Reduction

Statistical Outlier Removal: Filters stray points (critical for medical scans)

Temporal Averaging: Combines multiple scans (improves accuracy 15-20%)

C. Topology Optimization

Quad Dominant Meshing: Preferred for animation (reduces rigging artifacts)

Adaptive Remeshing: Maintains detail where needed (e.g., face/hands)

3. Industry-Specific Pipeline Examples

Medical (DICOM Workflow):

Raw Scan → ICP Alignment → Laplacian Smoothing → Defect Repair → Surgical Planning

Fashion (CLO3D Integration):

Scan → Auto-Landmarking → Parameterization → Digital Pattern Adjustment

Fitness (Trend Analysis):

Weekly Scans → Non-Rigid Registration → Volume Change Heatmaps

4. Computational Requirements

| Process | CPU Minimum | GPU Acceleration Benefit |

|---|---|---|

| Initial Reconstruction | i5 | 2x speedup |

| AI Texture Enhancement | i7 | 5x speedup |

| Real-Time Streaming | Xeon | Required |

Emerging Trend:

Edge computing (e.g., NVIDIA Jetson) enables scanner-embedded processing

5. Future Directions

Neural Radiance Fields (NeRF): Photorealistic avatars from sparse scans

Differentiable Rendering: Direct scan-to-simulation pipelines

For implementation advice: Specify your target output format (e.g., “Need watertight STLs for 3D printing”)

3.4, Data Output Formats: OBJ, STL, PLY, etc.

1. Common 3D Body Scan Formats

Format Best For Key Features Limitations OBJ Fashion, Animation – Supports textures/colors

– Widely compatible with 3D software– Large file size

– No volume dataSTL 3D Printing, Medical Devices – Standard for manufacturing

– Simple binary/ASCII structure– No color/texture

– Mesh errors commonPLY Research, Point Cloud Analysis – Custom metadata support

– Can store RGB/normals– Less software compatibility FBX Game Engines, Motion Capture – Preserves skeletal rigs

– Animation-ready– Proprietary (Autodesk) 2. Medical & Industrial Standards

DICOM (Medical Imaging):

FDA-approved for clinical use

Stores scan data with patient metadata

Used for surgical planning (e.g., Materialise Mimics)

STEP/IGES (CAD Manufacturing):

Precision NURBS surfaces

Essential for custom orthotics/implants

5-10x larger files than mesh formats

3. Format Selection Guide

A. By Industry:

Healthcare: STL (printing) + DICOM (records)

Fashion: OBJ with 4K textures

Fitness: Compressed PLY for trend analysis

Automotive: STEP for CAD integration

B. By Downstream Use:

Application Recommended Format Why? 3D Printing STL (high-res) Universal slicer compatibility VR/AR Experiences GLTF Web-friendly, supports animations Biomechanics Research PLY + CSV metrics Combines mesh with numerical data 4. Emerging Formats

3MF (3D Manufacturing):

Replaces STL with color/texture support

30% smaller files with equivalent quality

USDZ (Apple AR):

Growing adoption for mobile body scans

PBR material support

Pro Tip: For archival storage, use LAS/LAZ (point cloud) + JPEG2000 (textures) to reduce sizes by 60% without quality loss.

Need format conversion? Cloud services like Polycam automatically optimize exports for your target use case. Specify your workflow (e.g., “Scan → CLO3D → Pat

3.5, Software Support: Compatibility and data visualization

Software support plays a vital role in the overall functionality and user experience of a 3D body scanner. Modern systems are equipped with powerful, user-friendly software that handles everything from scan control to measurement extraction, 3D model editing, and result comparison. One of the key aspects is compatibility—the ability to export data in standard formats like OBJ, STL, PLY, or FBX, which ensures seamless integration with third-party CAD, simulation, apparel design, fitness analysis, or medical imaging software.

Another core strength lies in data visualization capabilities. Advanced platforms allow users to view interactive 3D models, compare body changes over time, generate detailed reports, and visualize posture or symmetry metrics. Some systems also offer cloud-based dashboards, mobile app access, and multi-device synchronization, enabling real-time sharing and collaboration across teams or with clients.

Effective software support not only enhances the practical value of the scan data but also ensures that users across industries—whether they are clinicians, designers, or fitness professionals—can turn complex body data into actionable insights quickly and intuitively.