Large Industrial 3D Printer

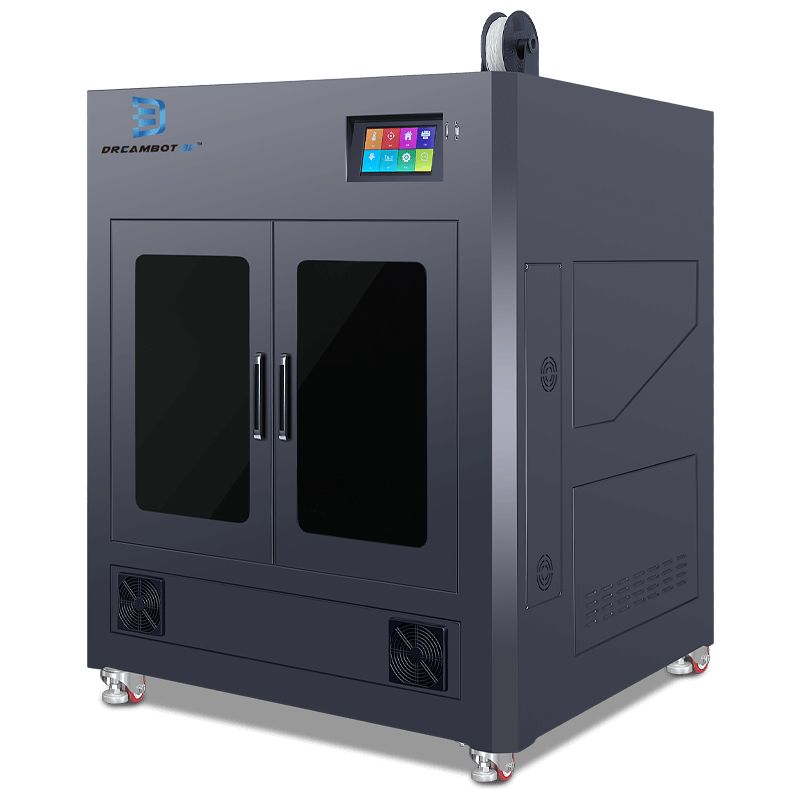

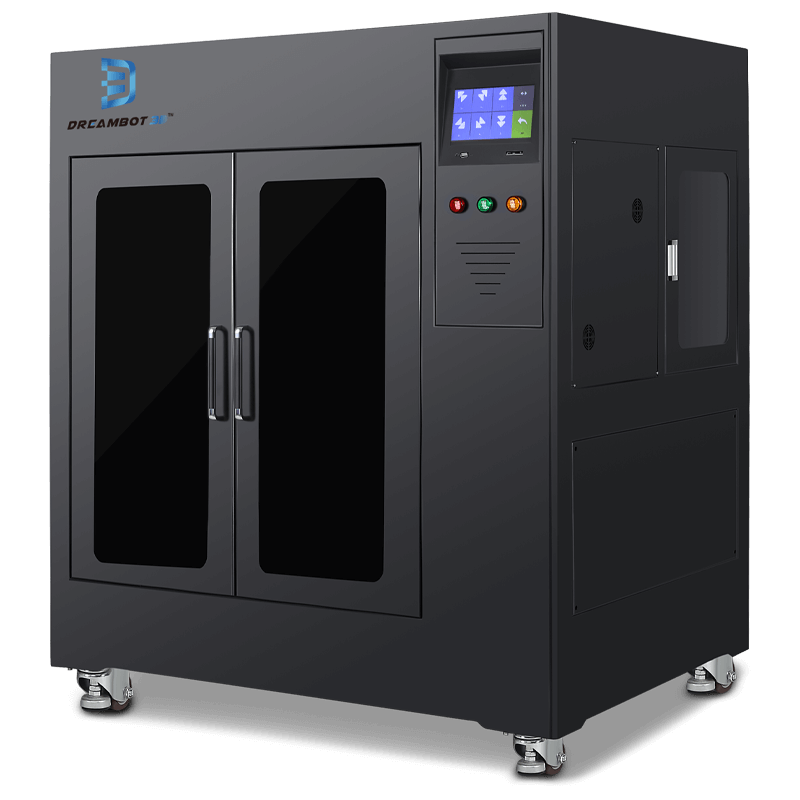

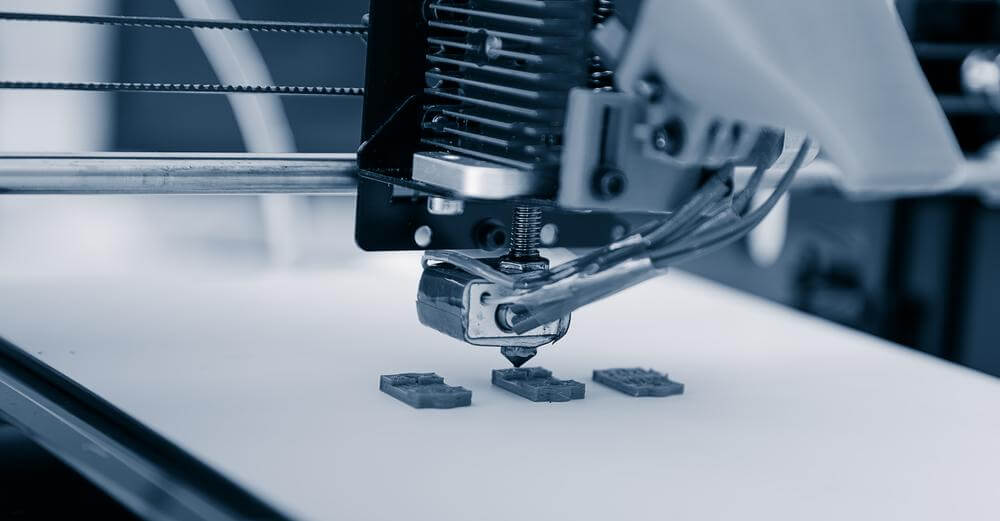

Dreambot3d large industrial 3d printer is used for printing delicate parts and functional prototypes. The industrial 3d printer has a high resolution and incredible precision for printing 3D objects.

The 3D printer is fast and provides lower printing costs. Dreambot3d large industrial 3D printer is used in industries like automobile, dental, construction, etc.

Contact Us

industrial FDM 3D printers

- The high printing speed and precision of printing 3D printers result in lower costs of printing.

- The process of printing is straightforward with the LCD touchscreen and multi-language software.

- Dreambot3d industrial 3D printer is made with high-quality materials that guarantee long-lasting use.

Dreambot3D Large Industrial 3D Printer list

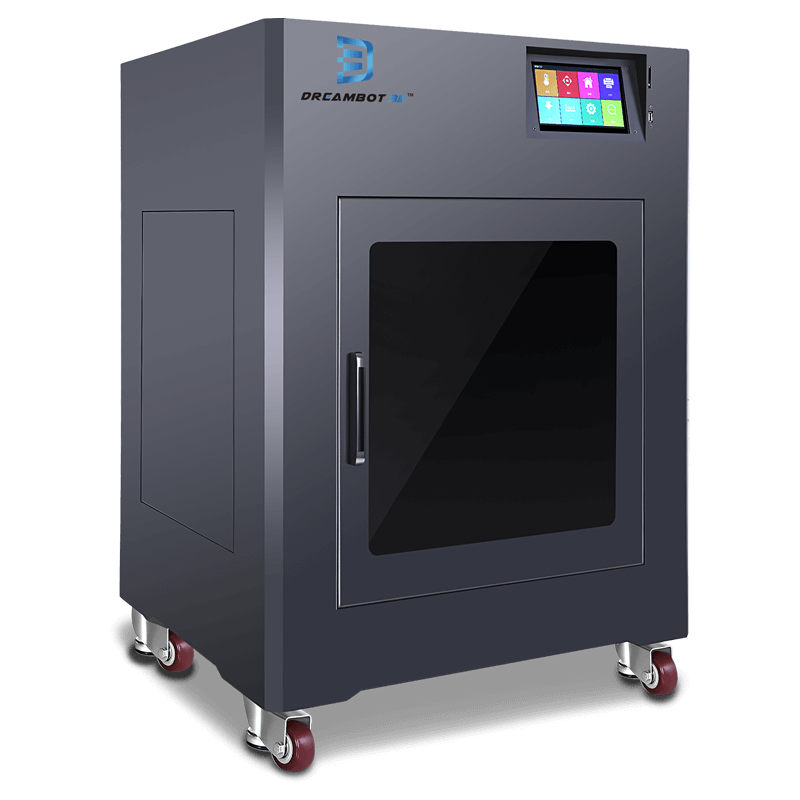

The L-200 3D printer prints at the volume of 200*200*200mm. It prints at a speed of 20-150mm.

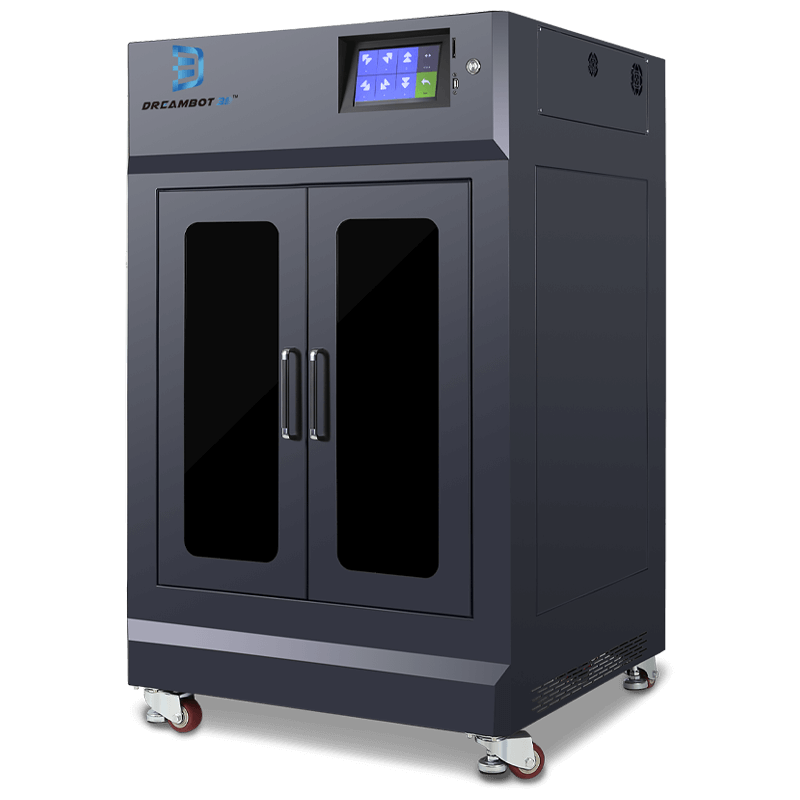

The L-300 3D printer has a build volume of 300*300*400mm. The consumable diameter is 1.75mm.

The L-400 FDM printer has a printing volume of 400*400*500mm. The printer prints at the speed of 20-150mm.

The L-500 FDM printer prints at the volume of 500*500*800mm. The printing layer thickness is 0.05-0.3mm.

The L-600 FDM prints objects at the size of 600*600*800mm. The nozzle diameter is between 0.2 to 0.8mm.

The L-800 FDM printer has a printing volume of 800*800*800mm. It prints at a fast rate of 20-150mm.

The L-1000 FDM printer prints objects at the volume of 1000*1000*1000mm. It has a precision of 0.05mm.

Test your part

We provide sample testing service, allowing you to check the working quality of our 3D printer before placing an order

6 points why choose us

Automatic resume printing

Full enclose stable frame

The whole machine case is thickened by CNC cutting, with accurate hole position, better assembly stability, and higher positioning accuracy of printer operation.

Allow offline printing

Use U disk or SD card to print without connecting to a computer to print. After starting to print, the data is automatically saved and the U disk or SD card can be removed.

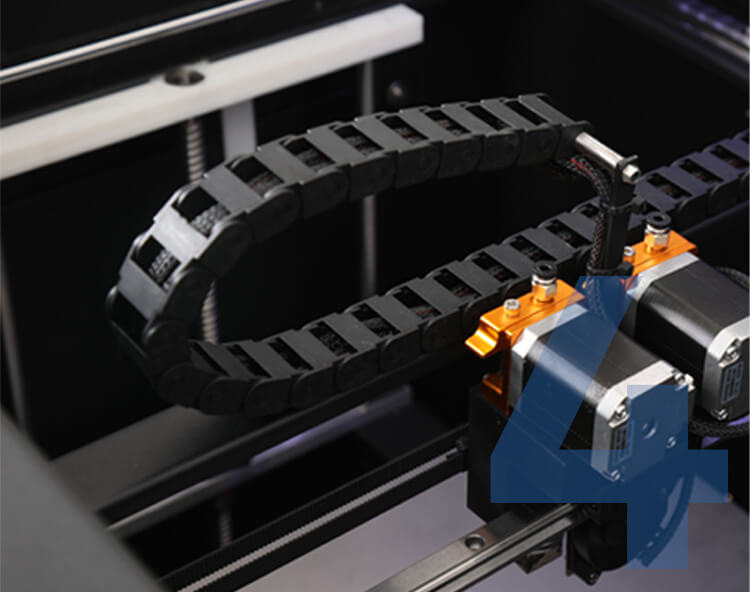

Drag chain wiring design

The wire is installed in the inner casing of the drag chain to effectively ensure that the wire will not be damaged for a long time when the printer moves at high speed.

Precision ball screw

Using the latest Taiwan ball screw, it has higher straightness, lower friction coefficient, better smoothness, higher positioning accuracy and more stability during printing.

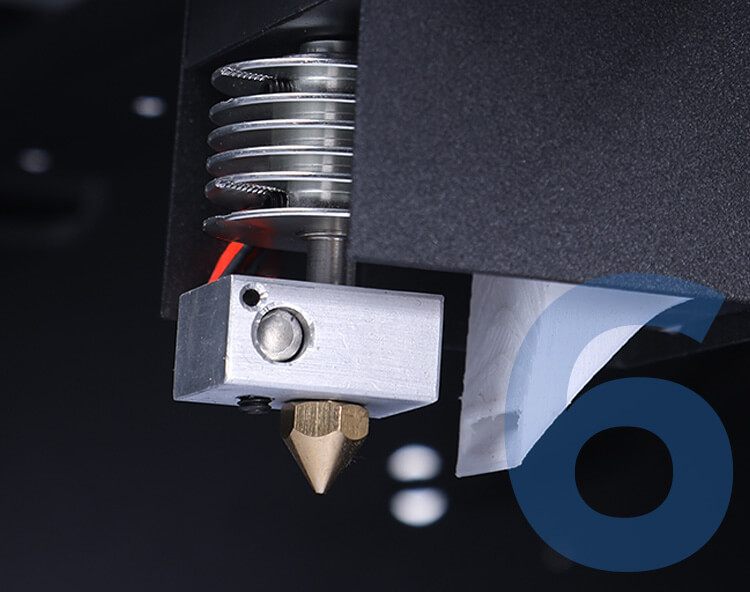

Alloy nozzle

Independently developed a unique bullet nozzle with uniform heating and a patented head assembly, so that it can work smoothly without interruption.

What Our Customers Say

Large Industrial 3D Printer buying guide

Speaking about large industrial 3d printer, such printers are generally used by different companies on the factory floor for producing end parts. In some cases, such printers can also be used to manufacture items like fixtures, jigs, or high-grade and durable tooling for manufacturing.

Millions of hearing aids, dental intermediates, dental crowns, and jewelry pieces are produced using a 3D printer. So, if you are running a manufacturing unit, this is the right time to invest in a large scale 3d printer.

As large format 3d printing is getting popular in different industries, 3D printer manufacturers are also introducing new machines with different features, making it quite challenging which one to choose.

There is a growing market for large industrial 3D printers aimed at small to large businesses and consumers. Why? A sizeable 3d printer has been tested and proved to be very useful for exploring different product development stages. Besides, the machines facilitate easy, rapid prototyping and don’t have to invest in any full-scale industrial 3D printing solution.

Whether you are a manufacturer looking to go on for a big project or a small-scale company searching for an ideal 3D printer, various large 3D printers will perfectly suit your production requirements. But how to choose the best one?

There is no such thing as ‘The Best’

In this industry, the term “best” depends on various factors. Depending on the space you have, the 3D printing material you are using, your 3D printing workflow, and the 3D objects that you want to print, one or other 3D printers could work better. Besides, depending on the details, size, part’s wall thickness, and strength, many factors can make a huge 3d printer a perfect choice.

This particular large scale 3D printer buying guide will serve as an ideal source of information for manufacturers like you to add a professional 3D printer to their manufacturing processes. This guide will offer you a comprehensive idea of an FDM 3D printer, how it works, its applications, and things to consider before and while buying the printer. Before going to the actual topic, let’s know about additive manufacturing, for which you are getting a 3D printer.

What do you mean by additive manufacturing?

Additive manufacturing or 3D printing is a process where 3D printers produce 3D objects from a CAD file. Talking about 3D printing, it is one subset of additive manufacturing, and using this printing technique, people and manufacturing units fabricate 3D objects.

This printing method is gradually paving the way for low-cost and faster prototyping and model making. When it comes to enjoying the best 3D printing, you can always go for a large format FDM printer. Keep reading to know all about FDM 3D printers and how to choose the best one.

FDM 3d printer introduction

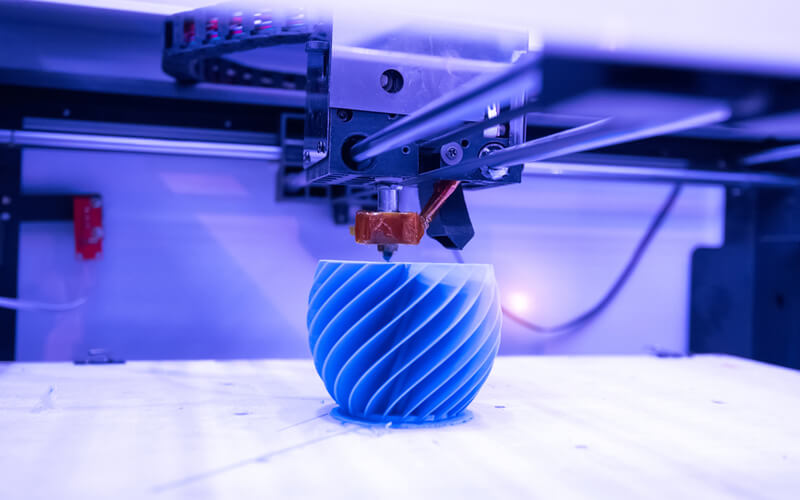

You will find many different 3D printing technologies, but the most popular 3D printing method of FDM- Fused Deposition Modeling that FDM 3D printers use to print 3D models.

These printers use high-quality thermoplastic filaments, which are heated to melt and then extruded by the nozzle layer by layer to produce three-dimensional objects.

FDM’s technology was first invented during the 1980s by the chairman and co-founder of Stratasys Ltd, Scott Crump. Then MakerBot, a Brooklyn-based company owned by Stratasys, was established on a nearly similar technology called FFF- Fused Filament Fabrication.

An FDM 3D printer can use different types of printing materials, for example, chocolates, thermoplastic, pastes, different filaments, and different types of exotic printing materials, such as a metal-infused thermoplastic.

FDM 3D printers are a very cost-effective and quickest way of creating proof of concepts, prototypes, mock-ups, and more. However, the industrial-grade FDM 3D printers can be used to manufacture different complex parts. Let’s know how it can be beneficial compared to third-party suppliers and machining in-house.

Let’s talk about ROI

An FDM 3D printer is a large investment and can help your company in different ways. If you have not started using such printers for your manufacturing process, you may not have adequately calculated the possible ROI. With the addition of an industrial 3D FDM printer, you can drastically lower the manufacturing costs for parts, such as tools and prototypes. To know more about it, here is a short comparison to third-party suppliers and machining in-house.

- Sending out the parts to the third-party supplier

Sending your part out to a third party can be an easy way to produce a part without consuming your internal manufacturing resources. However, it can be a very costly affair when it comes to producing low-volume parts. If you are outsourcing your part manufacturing requirements, you will have to for it to be made and then shipped to you. Besides, if you want to make a little iteration, you also have to pay for that and the shipping cost. Furthermore, you cannot go for modifications until you get the parts.

- Machining in-house

Machining a part in-house needs enormous money spent on material, equipment, machinist time, and more. If the value of the machinist time is USD 70 per hour, and it takes him five hours to configure and set the machine, the total cost will be USD 350 per part. Besides, there is the material cost that you will have to consider.

- In-house 3D printing

3D printing an object or part in-house requires ongoing material cost but one-time machine cost. The advanced and big FDM printer will support cloud technology, and the machinists can manage every print through cloud-connected software. Some professional FDM 3D printers come equipped with advanced software to let you know how many parts you plan to print.

Best for use with different plastic materials

One of the significant issues is the limited range of printing materials you can use with FDM printers. It is fun to create a DIY plastic garden and household products using your 3D printer. Still, not all plastic materials can meet the commercial and industrial demand for more robust material.

The SLS- Selective Laser Sintering technique, along with powdered filament, is generally used for 3D printing. It is essential to consider that FDM 3D printers act as ideal for office and home use. The reason behind this can be the printer’s potentially explosive nature of powdered-filaments. These printing materials are developed for 3d printing large objects suing industrial-grade FDM 3D printers.

Some advantages of FDM printers

Arguably, a significant benefit of FDM 3D printers is that they have made the 3D printing method more accessible. On the other hand, FDM materials have the lowest cost, and you can go for different types of materials to create different 3D objects.

For example, you can go for TPU, PLA, ABS, material blends made of ceramic, carbon fiber, and more. When it comes to choosing colors, you will get complete freedom.

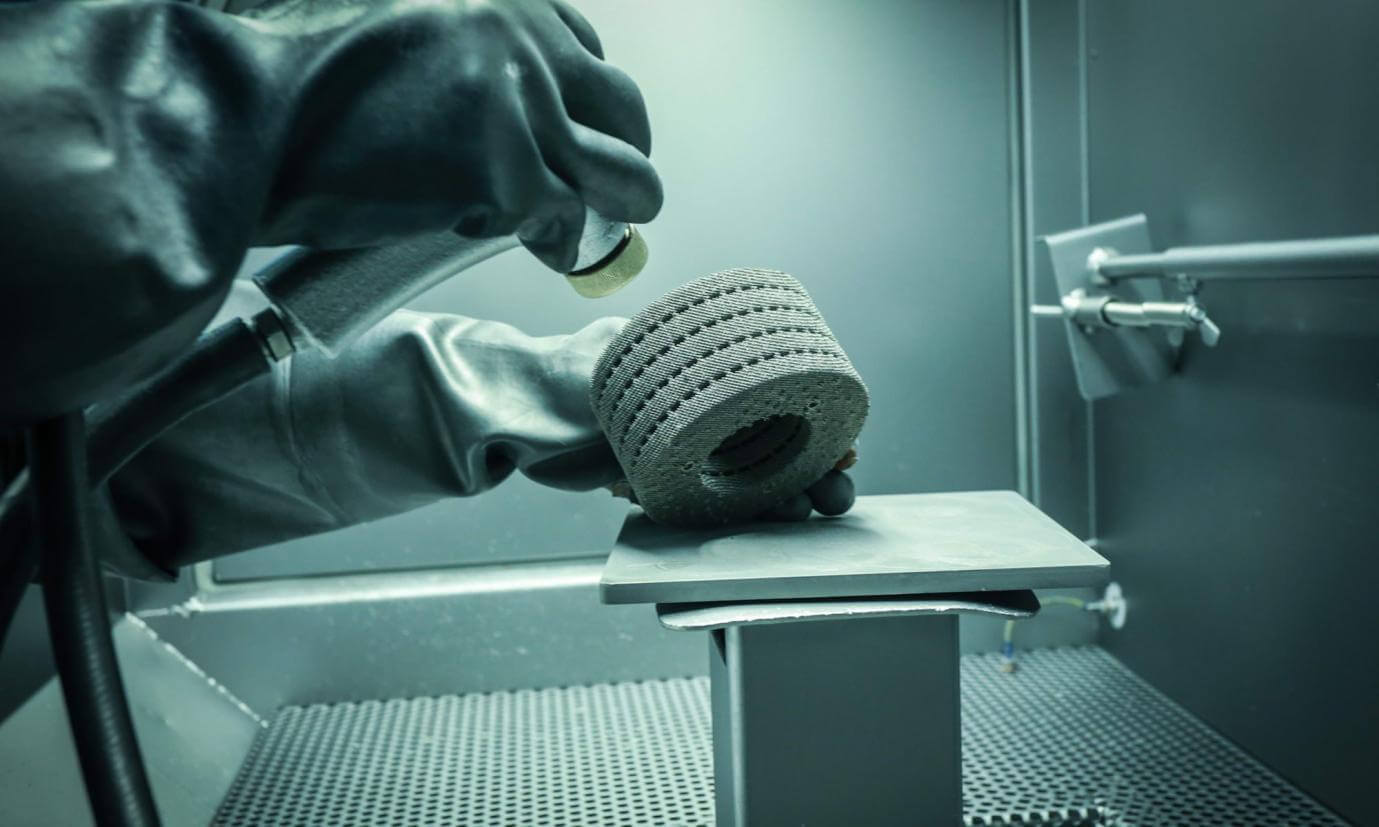

Coming to the post-processing part, the post-processing task of an FDM 3D printer is quite simple. Sometimes, you will only have to remove the excess plastic from the 3D object, and that’s it. You can come up with a smooth surface utilizing sandpaper.

Another significant benefit of using the FDM 3D printers is you will enjoy a better level of scalability. When you have a good machine, you can scale it to print any size you want.

You might be wondering about how? The only factor that can affect the build area size is the gantry’s movements. If you can make the gantry rail move a little longer, you can make the build area ready to print large 3D objects.

Even though you will encounter some minor problems, but no other printers can offer you such a facility.

No matter what you want to print, these machines can be easily operated to print correctly. By adopting this printing technology, you can significantly boost your business operation, lower the cost, and improve efficiency. These are some significant reasons why FDM 3D printers are so popular.

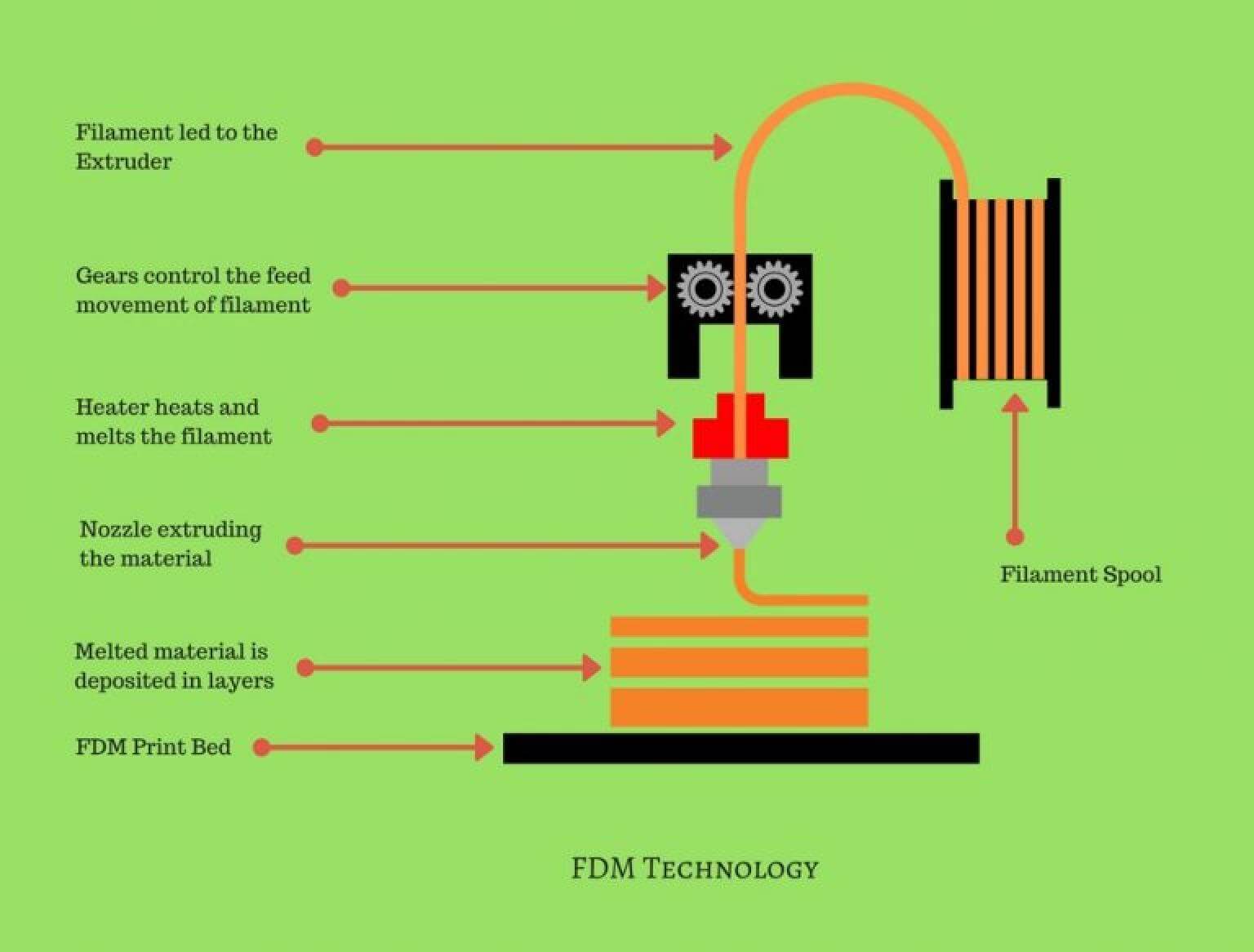

1.1, Principle of FDM 3d printer

To understand the principle of an FDM 3D printer, you first need to know the significant FDM 3D printing technology components.

- Heater- The heat of the FDM printer heats the filament to melt it for printing.

- Filament- This is the printing material for your FDM printer in the form of filament. The spool of a filament is attached to the sides or back of the 3D printer and then fed into the printer’s extruder.

- Extruder- In simple words, the extruder is one type of gear mechanism used to pull the printing material and then push it toward the heater. It can also be termed as a “Cold end.”

- Hot end- This section of an FDM 3D printer includes the heat sink, nozzle assembly, and cooling fan.

- Nozzle-The last element of your print head is the nozzle. This element deposits the hot printing material onto the printer’s build platform based on the design.

- Build platform- This the build bed on which the printing material is carefully deposited through the nozzle. The printing material will stick to the build platform, and the 3D object will be created. This can be non-heated or heated.

Understanding the printing process

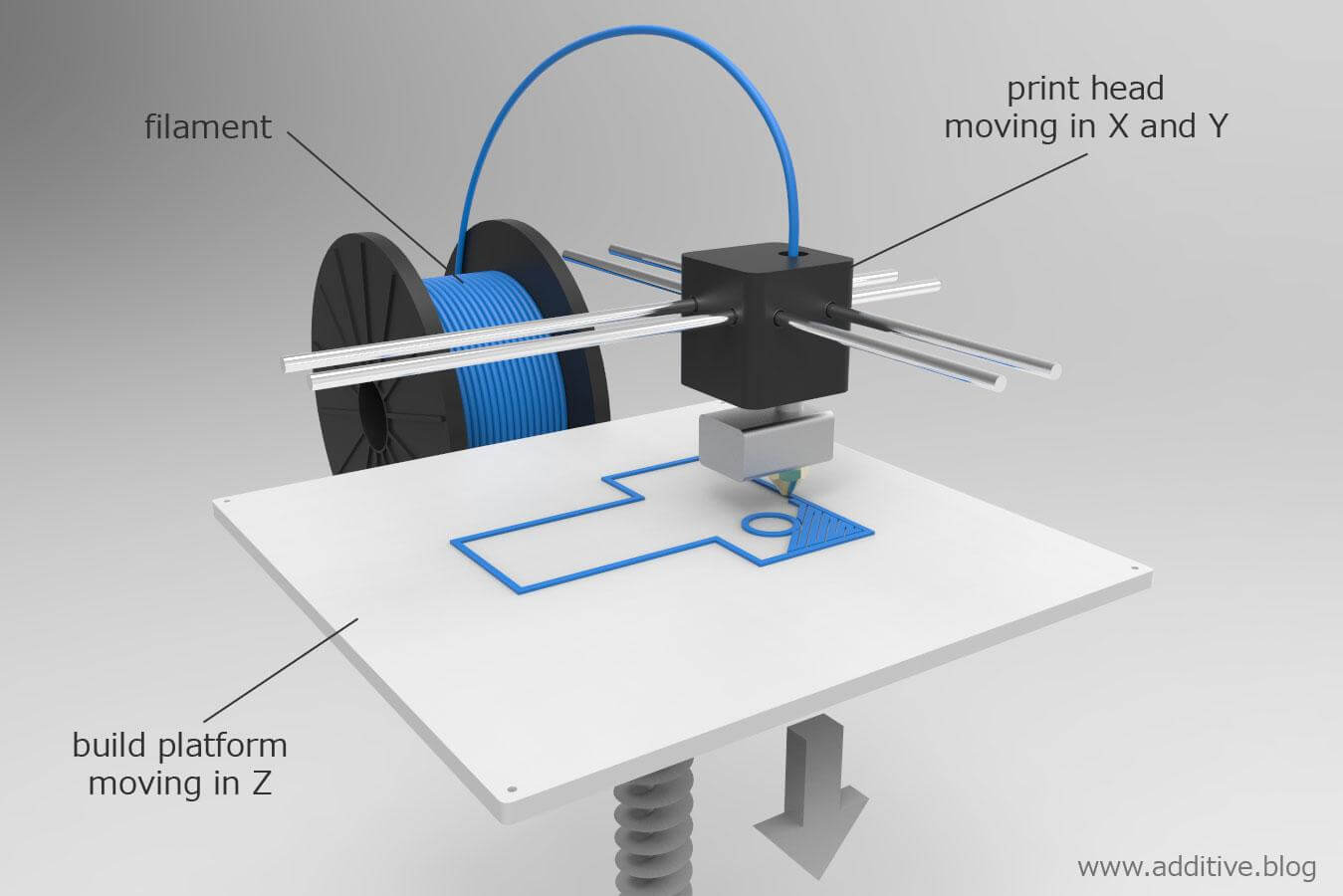

It is a fact that FDM printers are the Cartesian types of 3D printers. If you don’t know about Cartesian, it refers to the highly coordinated systems used by most of the printers for the movement of build plat and print head.

In such printers, you will find three major rails corresponding to each axis, such as X, Y, and Z. Then the printhead, the nozzle, and extruder assembly move precisely in the X and Y direction, whereas the build plate will move in the Z-direction. Now, let’s have a look at the printing process.

First of all, the printing material or filament is fed into the machine’s extruder. In general, FDM printers’ filaments come in two different diameters, such as 1.75 mm and 3 mm.

You can use only one type of filament in the printer. The printer’s extruder has a gear mechanism that pulls the material and sends it to the heater to melt the material.

Here, you should know about the melting temperature. It completely depends on the filament type you are using. Based on that, the melting temperature can range from 190-degree C for PLA material to around 300-degree C for polycarbonate material. Once the filament melted, it moves to the nozzle.

The nozzle generally comes in two different diameters, i.e., 0.2 mm and 0.4 mm. However, with different machines, you can go for different dimensions.

The diameter of the nozzle can influence the print quality and thickness of the layer. The nozzle precisely applies the printing material onto the build platform based on the product’s geometry.

After getting the instruction, the nozzle will move in the X and Y direction, creating layers. After completing the first layer, the build platform will drop down by a few inches, equal to the layer’s thickness, and the nozzle will start to create the second layer. As the layers remain hot, they are perfectly fused for a robust bond. This process will continue till the object is completed.

After done with the printing, the object is removed carefully from the build platform using a scrapper or by hand. Remember that the parts or models printed through the FDM printers can have visible layer lines and quite coarse. You can post-process the objects by polishing, priming, sanding, acetone vapor smoothing, and more.

In general principle, FDM 3D printed part is recommended for fitment and form testing, fixture and jigs, and prototyping. The parts come with better dimensional accuracy, but you may find them a little coarse in aesthetics.

1.2, What materials can be printed by FDM 3d printer

Choosing an ideal printing material to print a 3D model object is getting more challenging, as the 3D printing industry witnesses the rapid emergence of radically new printing material.

In FDM 3D printing, ABS and PLA have been considered primary polymers for 3D printing. However, nowadays, you can go for different materials based on the objects that you want to 3D print.

To help you choose the right material, we have listed down some major printing materials that can be used by FDM 3D printer.

- ABS

One of the most common 3D printing materials is ABS. This material is generally used for the bodywork of appliances, cars, smartphones, and more.

It is one type of thermoplastic that contains elastomers and polybutadiene. These are the elements that make it resistant to shocks and flexible. You can also get it in powder form for powder-based processes, for example, SLS.

The ABS’s melting point in FDM 3D printers is 230-degree C to 260-degree C. As a robust material, it can easily withstand -20-degree C to 80-degree C.

The best thing is ABS is recyclable and can work great with the chemical process. However, while using ABS, it is advisable to use close chamber FDM 3D printers like the printers that Dreambot offers to lower particles’ emissions.

- PLA

PLA, called polylactic acid, has the advantage of being highly biodegradable, which is not possible in ABS. In general, PLA is produced utilizing different renewable raw materials, for example, corn starch.

Even though it can shrink a little after printing, it is the easiest to print material. While printing with PLA, you don’t have to use a heated platform. It also prints at a relatively lower temperature, between 180-degree C to 230-degree C.

Due to its high-level of solidification and cooling speed, you may find it a little difficult to manipulate the material. Besides, the 3D models can get affected by water.

- PETG

It is a variant of PET and developed by combining Glycol to get the desired effects, for example, a better level of transparency. On the other hand, PETG material can be processed at a lower temperature with an increased flow speed of around 100mm per second.

As a result, you will enjoy a faster printing process. Components of PETG are highly resistant to weather and widely used for outdoor applications such as garden appliances. Another major selling point of this material is the food-safety feature.

- ASA

It comes with some similar properties to ABS. However, unlike ABS, it offers better resistance to UV rays. While using ABS, you need to print with a heated build platform to eliminate the warping issue.

The same rule applies to ASA printing with a little bit of extra care. Prefer to use it with the printers having an enclosed chamber as the material releases styrene.

- Nylon

Considering its super strength and flexibility, nylon can be a perfect choice for different applications, from the arts to engineering. Sometimes, it is considered as white plastic. Among all the FDM 3D printing material, the nylon’s layer bonding is quite robust than all.

When you want to print objects with good mechanical and tensile strength, you can go for nylon filament.

The prints made of nylon come with a rough surface, but you can polish them. They are strong, chemically resistant, and flexible. It may be noted that nylon can degrade due to humidity. So, keep the objects last longer; you will have to keep them in airtight containers.

- PET

PET- Polyethylene Terephthalate is commonly used for manufacturing disposable plastic bottles. This printing material is rigid and offers a good level of resistance quality towards chemicals.

To get the best result in PET 3D printing, keep the temperature between 75-degree C to 90-degree C. It is generally sold as translucent filament. While printing, it doesn’t produce odors, and you can completely recycle the material.

- PC- Polycarbonate

Polycarbonate is one type of high strength material developed for engineering applications. PC has a good temperature resistance feature and can easily resist any physical deformation up to about 50-degree C. However, there is one thing that you need to keep in your mind that it can easily absorb moisture from the air.

The AM industry widely uses this material as it offers a better level of transparency and strength. What’s more? It comes with a lower density level than glass, so you can use it to produce a decorative object, optical parts, and protective screens.

- High-performance polymers

Family distinguishes some high-performance polymers such as ULTEM, PEKK, and PEEK, for example, PEI- Polyetherimides and PAEK- Polyaryletherketones.

Such filaments offer better level thermal along with mechanical resistance. Even though they are quite robust, you will find them lightweight. So, these are widely used in the medical, automotive, and aerospace industries.

- Hybrid materials

You can find different types of hybrid materials made of plastics and powder to get a new finish, color, and better material properties. Generally, based on PLA, hybrid materials are made of 30 percent hybrid material with 70 percent PLA.

For instance, wood-based filaments, like wood dust, cork, bamboo, and more. These materials are combined with PLA to produce hybrid filament. Besides, some also come with metal powders for FDM printing.

There are more such materials that you can go for if you are using a large FDM printer. All the materials can be divided into 3 major categories, i.e., process, mechanical performance, and visual quality. Your choice of material will depend on what you want to print.

1.3, Why is Dreambot’s FDM 3d printer so prominent?

Are you looking for the best FDM 3D printer for your manufacturing unit under your budget? If yes, you can always go for FDM 3D printers manufactured by Dreambot3D, one of the most reputed FDM 3d printer manufacturers. Whether you want to buy a small 3D printer or a large-size FDM 3D printer, the company has a huge collection of products for you. What makes Dreambot3D’s printers popular? Here are some points that describe the reasons.

- Most of the 3D printer manufacturers develop machines with a simple structure and acrylic outer box. You may not find them very stable and durable. Now coming to the Dreambot3D’s FDM printers, they all come with enclosed chassis made of high-quality integral metal sheets. The structure is very stable. One of the crucial factors of an FDM 3D printer is its XYZ axis. The XYZ axis in Dreambot3Dprinters can print quite stably while running faster. So, you will witness the maximum level of printing accuracy. If you want to enjoy high-quality 3d printing for mass manufacturing, buy Dreambot3D’s printers.

An FDM printer can offer a better result when the temperature remains constant during the printing process. Printers use the Constant Temperature System that you may not find in standard 3D FDM printers. However, Dreambot3D has installed this system in every printer. But with L-300, you will not get this feature.

Now, your heat-resistant materials, such as ABS, carbon fiber, PC, Nylon, and more, will not be drawn or wrapped during printing.

- All the machines come with an easy to use and simple operating system. Within just a few minutes, you can start using the machine for creating your desired 3D objects.

- A small display may cause a slight issue while configuring the printer. Some printers come with a 5-inch color screen. You will not find it comfortable. On the other hand, with Dreambot3D’s printers, you will get a sizeable 7-inch crystal clear color screen, which is super easy to use. What’s more? They support different types of languages.

- As one of the largest 3d printer manufacturers, with Dreambot3D, you will get a massive selection of different FDM 3D printers of different sizes. We have been working in this industry for years and has a stable market condition. You can go for L5-400/500/600/800/1000, L8-400/500/600, and more 3D printers. Most of the 3D printer manufacturers will offer you a maximum of two regular sizes, and you need to customize them separately to use them. Besides, their market condition is not stable.

- Dreambot3Dhas specialized and well-known for producing industrial-grade and durable 3D printers. With more than 8 years of experience, we have placed ourselves as one of the biggest 3d printing companies. With a robust production capacity, we have a greater level of R&D capability. Many 3D printer producers only deal with desktop-level printers that you can only use for small projects. Besides, they don’t have such experience and R&D capabilities to deal with industrial-grade machines.

- We produce large-size machines available in different styles, sizes, and always maintain our machines’ sufficient stock. So, after placing the order, we will ship the machine within only 3 to 5 days. What’s more? With us, you can also go for customized styles. But such machines can only be shipped within 10 to 15 days.

When choosing some big 3d printing companies in the world, you can always trust Dreambot3D. Please feel free to contact us for more details about our machines and place your order.

Application field of FDM 3d printer

By this point in life, chances are you have used a hot glue gun at least once. Hot glue guns are the most common household tools that can be used for different types of projects. FDM 3D printers also are the same type. Just like your glue guns, FDM printing is one type of additive manufacturing tool.

The rapid advancement of technology and the introduction of powerful and advanced FDM 3D printers have taken 3D printing to a whole new level.

3D printers are now widely used in various applications, such as architecture, custom art, manufacturing, medicine, research, automotive, aerospace, and more.

As the competition level in different industries worldwide is increasing rapidly, most companies are now implementing 3D printers to increase their production capacity and enhance the business processes.

When it comes to choosing a perfect and cost-effective solution for rapid prototyping, manufacturing spare parts for machines, tooling, and more, FDM 3D printers will be the best option.

Want to 3D print any complex geometry? Such printers will get it done for you. Below are some significant applications of FDM 3D printers.

2.1, For industrial research and development

It is a fact that the introduction of industrial FDM 3D printers has brought a great revolution in the process of manufacturing or production. These printers have changed the way the Research and Development team used to work. As this can be used to make bespoke and specialized geometry, 3D printing can be advantageous.

A team from the University of Glasgow, the UK, in 2012 proved that 3D printing technology could be used to help produce chemical compounds. What they did was, first, they printed chemical reaction vessels. After that, they used the printer to apply reactants into the vessels.

Besides, FDM 3D printing can be utilized in research labs as a perfect alternative method to produce components that can be used in different experiments, for example, vacuum components and shielding.

Material versatility is a massive benefit to using FDM 3D printers. In addition to ABS, you can go for printers that can run PC-ABS and ASA along with PC, ABS-ESD, Nylon, ULTEM, and more. Different types of engineering-grade materials can be used to make a different object.

No matter what type of business you have, your R&D section will play a significant role as they keep working to introduce new products. They develop necessary strategies to optimize the cycle of product innovation. FDM 3D printers can significantly help them in this.

While developing new prototypes, you can attain maximum quality and precision using such printing technology. What’s more? If your production level is low, 3D printing offers you a cost-effective and rapid prototyping solution. So, developing new spare parts for machines will not be a challenging task anymore.

On the other hand, 3D printing technology is also used to make the product more perfect based on consumer preference. Unliked the traditional printing process, FDM 3D printing will take a few minutes or hours to create new prototypes.

It has been proved that such a machine generates less waste. Furthermore, FDM 3D printers are well-known for enhancing the application of Lean and Agile methods in various manufacturing methods.

So, don’t think much and give your R&D process a perfect boost using a huge 3d printer to develop and test the new products as soon as possible.

2.2, For the production of animation figures

This is a fact that 3D printing has had a significant impact on different kinds of objects, including all action figures. Well-known brands, such as DC Comics, have signed long-term deals with different 3D printing companies’ 3D print some of their famous action figures.

On the other hand, 3D printing also plays a significant role in stop motion. Speaking about stop motion, this much depends on three different factors, such as specifically poseable, physical effects, and customizable dolls.

Here, it is essential to move the objects incrementally along with the frame. Using 3D printing, one can create many facial expression variations, characters, props, and more.

For example, popular animation studio LAIKA is famous for its unique stop motion animated features, such as “Kubo and the Two Strings,” “Caroline,” and more. For “Caroline,” the company has 3D printed more than 20,000 different heads to attain various facial expressions.

Besides, around 40,000 heads were created for “ParaNorman.” Gilles Deschaud, a filmmaker, spent around two years designing and 3D printing 2500 pieces for the stop motion called “Chase Me.”

So, it is now possible to print action and cartoon figures using 3D printers. To make the process a little more effortless, some scientists from Harvard University have introduced software that can translate game characters, such as Bat Man, Super Mand, Mario, Lara Croft, and more into the movable figure.

Here, you can also take the example of a digital creative art studio named Polygonal Mind. Using color 3D printing, they have created a lot of 3D models. They first developed 3D sculpts using polymer.

After that, they developed a new surface and maintained a perfect flow of polygon. They fixed the topology of the 3D models using Maya software and came up with a better color combination, and printed the models using FDM 3D printers.

If you want to create your action and cartoon figures or fantasy miniature from scratch, then making 3D models of mechanical parts, mold, architectural models, and models for rapid prototyping won’t help you a lot.

As a result, your output will be non-organic and a little edgy. However, you don’t have to worry about that as there is advanced digital sculpting software that you can use to create models and print them using an advanced FDM 3D printer.

If you want to start a business and sell action or cartoon figures, you can easily do it with the FDM 3D printers. Get the best printers now with Dreambot. To know which 3D printer will work better for this, you can get in touch with our experts anytime you want.

2.3, For model making: etc.

Model making is an integral part of different industries, for example, medical, architecture, automotive, energy, and more.

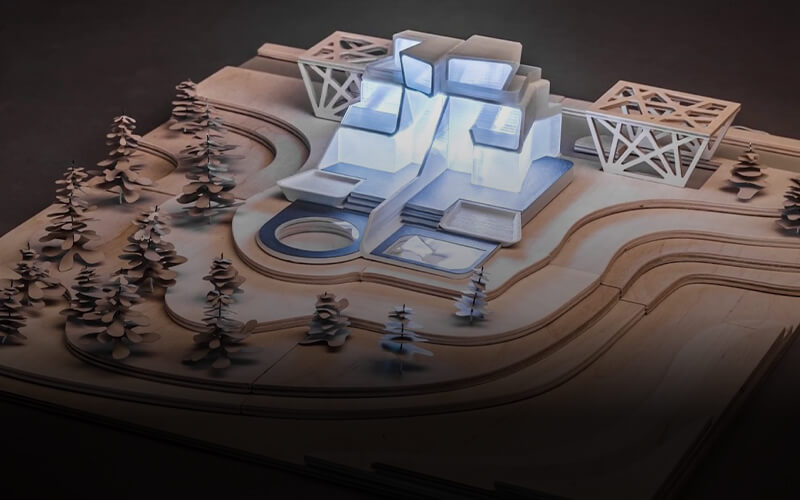

Architectural industry

Speaking about the architecture industries, professional architects and AES professionals use FDM 3D printers to create stunningly beautiful, highly-detailed, and physical architectural models.

They can now effectively showcase the ideas and impress the clients by offering them a well-developed tangible model. Every architectural project requires a concept model for idea visualization.

A highly-detailed 3D model can be created using a CAD program and 3D printers, and you can use different materials and colors for this. Besides, it is also possible to 3D print a house using sustainable materials within a few weeks. For example, ICON’s construction technology company in Austin, Texas, developed a 3D printed house prototype.

Another example can be the Urban Cabin. This small 3D printed house is 25 cubic meters in size. Using sustainable bio-plastic materials, the house was developed by FDM 3D printing. Dreambot3D’s 3D printers are quite good in this.

Medical industry

3D printing is considered bioprinting in the medical sector, termed as the biological cousin of 3D printing. This process is used to deposit living cells into a particular shape to create organs and tissues.

Scientists are bioprinting simple-structured organs, such as hearts and bladders, and transplanting them into the body. For example, in 2013, Organovo, U.S. based medical research company, utilized living cells and bio-print a liver tissue via 3D printing.

e-NABLE is known for producing the first-ever 3D printed prosthetic limb after developing a working bionic hand utilizing the designs from Ivan Owen, an American artist. Another company called Robohand informs it can offer artificial 3D printed fingers, hands, and arms for around USD 500 to USD2000.

On the other hand, companies like Lazarus 3D in Houston have the 3D printing capability to crate realistic and soft-polymer silicone modes of organs and tissue. The models are being used by various universities, such as Baylor University, to train medical students.

3D printing can also be used to 3D print dental tools, like bonding trays, dentures, drill guides, crowns, night guards, bridge models, and more. A Boston-based startup, LightForce Orthodontics, has introduced the first 3D printed and customized brackets. These small pieces can correctly cement to teeth and connect the ties.

Recently, Aprecia Pharmaceutical introduced the first-ever 3D printed drug, which can treat seizures.

The drug is produced by placing a powdered form of the medicine between different liquid materials and then applying a microscopic bonding process. The best thing is that these 3D printed pills can dissolve rapidly when they come into contact with liquids.

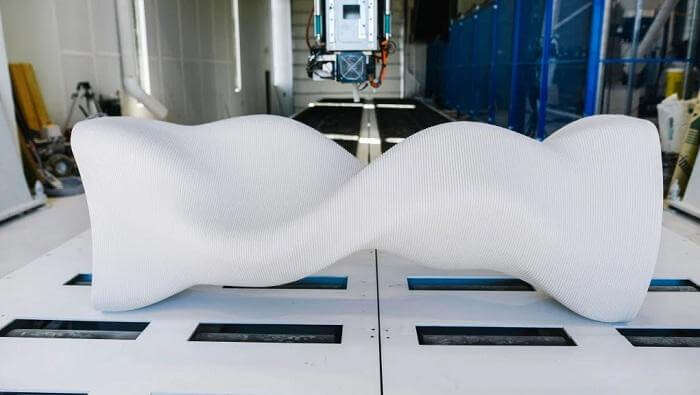

Mannequin models

3D printing techniques can save considerable time and offer unlimited possibilities in mannequin model design freedom. It will take around 2 days to entirely 3D print a mannequin, compared to a few weeks when mannequins are made by hand. Besides, to lower the CO2 footprint, you can use biodegradable filaments made of sugar cane or corn starch.

The arrival of advanced 3D printers has provided a win-win opportunity to the mannequin makes that didn’t exist a few years back. Using a large industrial 3d printer, you can quickly produce customized or custom mannequins at lower costs.

You can create a personalized display that can be made from any images and designs. If you want, you can also digitally scan any character, brand mascot, and celebrity to 3D print them in different poses, matching the customers’ expectations.

Drone model making

3D printing can be a handy technique to craft a drone or begin with the drone making project. This printing technology can be utilized to work on resistance and design of the drone. FPV quadcopter drone, pocket drone, micro drone, and more can come to life with 3D printing.

For example, “The Dark Matter” drone. This is based on the modularity concept. The drone comes with fully detachable legs, arms, and a payload attachment system that works great.

The team did the in-house prototyping, designed the drone’s custom parts from carbon fiber, and 3D printed them to make the tailored and specific details required for the drone.

Another example can be the CargoCopter 3D printed drone. The demand for delivery services is getting higher with time. You might have heard a lot of things about the delivery services that can be done using drones.

That has become a reality and is made possible with a fully 3D printed drone called CargoCopter. This drone can transport cargo weighing around 5kg at a speed of 150 km per hour. This efficient and powerful drone can deliver goods covering a long distance.

Robot birds

Birds are the most unique and beautiful creatures, but sometimes they can endanger passengers’ safety by damaging airplanes, ruining crops, and spreading different types of diseases.

Clear Flight Solution has developed “Robirds” using 3D printed parts to deal with such a situation. The bird comes with a realistic appearance and weight. These “Robirds” can be used at waste sites, fields, orchards, and airports to scare away peskier birds. They have created two “Robirds,” i.e., the Falcon and the Eagle.

2.4, Used in aerospace and automotive industry

The first-ever 3D-printed parts used in the aerospace industry was in an Airbus test aircraft. The company produced a small titanium bracket, a pylon’s position used to properly secure the engine.

After that, the use of 3D printing has gone up rapidly. However, companies are still exploring different opportunities to adopt this solution to enjoy the benefits, like lower cost, shorter time to the market, better output, and increases production.

With 3D printing, companies with a massive stockpile of orders can reduce their production time. For instance, in 2018, Airbus reported around 7000 aircraft backlogs.

On the other hand, 3D printing can lighten an aircraft by around 55 to 60 percent. A few years back, Airbus developed 3D printed parts from titanium for aircraft production. About 1000 parts of Airbus A 350 are 3D printed.

On the other hand, NASA is now using 3D printers of Stratasys to produce and test a space rover with 70 3D printed parts made through FDM printing technology.

In the automotive industry, 3D printing helps the industry meet the growing demands and helps the manufacturers produce powerful cars. For example, the 2020 Shelby GT500 has two structural brake components that are 3D printed for Ford’s new car.

The components are 3D printed using DLS- Carbon’s Digital Light Synthesis printing technology and EPX 82 material. Likewise, adopting 3D printing in 2017, Volkswagen saved around EURO 325,000.

How to choose a suitable FDM 3d printer for your industry

3D printing technology is gradually covering different sectors, offering them a perfect solution to optimize their production process while reducing the cost. SMEs are becoming a primary consumer of 3D printers, and they cover more than 75 percent of the total 3D printer customer base across the world.

These machines are getting affordable, and the easy-to-understand OS has made it easier to operate the machine with little technical. Suppose you are running a manufacturing unit and deals with large parts, general-purpose parts, and rapid prototyping.

While FDM 3D printers work better, you may find a little reduction in the resolution. Such printers can create layers having sizes range from 100microns to 300 microns.

For a better result, you need to choose the right one from a good brand, like Dreambot3D. So, here are some points that you can consider for this.

3.1, Your application industry

The primary application of FDM or Fused Deposition Modeling in the field of rapid prototyping. Why? Using this, you can produce low-cost copies of the design that you have in mind.

With this, you can print, analyze, test, modify, and enhance the plan as many times as you want. This is trustable printing technology to get a higher level of accuracy along with flexibility.

Dreambot3d is continuously innovating to ensure that the 3D printing applications create the tone for better advancement across all the sectors. Different industries benefit most from 3D printing. Have a look at those industries.

- Aerospace

You can lower the lead time using3D printers that support the global aerospace industry’s production requirements, including production castings, prototypes, sand molds, and more.

- Automotive

This is one of the earliest industries to utilize 3D printing technology. Most well-known automotive manufacturers have integrated printing systems into their product floors for rapid prototyping and serial production of engines, transmission housing, and other components.

- Decorative art

With this, you can quickly eliminate creative barriers with unlimited design freedom, and you can create custom and highly decorative fixtures and hardware, signs, figurines, and more.

- Firearms and defense parts

FDM 3D printers can produce small runs of intricate parts within a few hours and at a lower cost compared to the traditional manufacturing methods. You can create recoil spring plugs for the personalized back panel. 3D printers leverage industrial-grade highly durable material for the firearms industry.

- Medical and dental

3D printing has made it possible to produce accurate and functional custom prosthetics. All you need to have an updated digital design file to create a new model. The dental and medical industry can use this to make dental implants, instruments, bridges, and more.

- Shoes making

The shoes making industry is also utilizing the power of 3D printing. For example, Columbia’s Montrail. These trail running shoes are designed for trail runners and elite athletes. The shoes come with a 3D printed cage and make them very lightweight.

Besides, this technology is also very useful in shoe soles production, and you can also 3D print shoe soles that will combine fashion and personal style. The foot scanning system will collect that data and then will be sent to the 3D printer. Based on the size of the individual pressure point distribution, the printer will create an insole.

Many such industries are leveraging 3D printers to enjoy more profits and better growth. So, with a big FDM printer, you can earn more profits and increase your production efficiency.

3.2, Print size requirements

Here the print size requirements mean the dimension of the object that you want to make. The size will vary based on the types of 3D models you are making.

For industrial purposes, you will have to go for an FDM 3D printer. With such printers, you can print around 400 mm in height and 280 mm in diameter. So, consider the size and see if the printer can print that size of the object or not.

3.3, Printing material requirements

Not all printers can support different types of material. But it will be better for you to choose one that can help multiple types of filaments. While working with 3D printers, you can go for the following materials:

- Nylon- Possesses better mechanical properties and resistant to impact.

- PET- Resistance to heat and impact and also easy to print.

- PLA- Offer excellent visual printing quality.

- ABS- Can withstand a greater level of temperature.

- PETG- Perfect to manufacture food-safe grade products.

There are more such materials that you can use for different purposes. So, select one using which you can play with other materials.

FDM 3d printer buying guide

3D printing is the new buzzword, and every enthusiast, hobbyist, student, and the industry is now gearing up to buy a 3D printer. However, choosing the best and optimal FDM 3D printers can be a challenging task.

3D printers come in various sizes along with features. First, you need to consider all those things. However, don’t worry at all, as we have listed some essential points that you need to consider while large FDM 3d printer. Have a look at those points.

4.1, Choose a reliable brand

Why choose a reliable brand? When it comes to buying the best, only a reputed brand like Dreambot3d can offer you a world-class product. When you go for the regular brand, you will get machines with simple and poor structure and not feel durable.

You can’t even use them at a higher level. But the printers from Dreambot3d are very durable, and their XYZ axis will operate smoothly at the highest speed. Go for the best brand for better printing accuracy.

4.2, Safety configuration of the machine

Some of the hazards that you can encounter with 3D printers are heat & ultrafine particle generation, risks from moving parts, ultraviolet light, high voltage, and more. All these factors are harmful to health so make sure the 3D printers are safe to use. Choose a printer that has an enclosed structure.

4.3, Resolution requirements of the machine

The quality and detail level of the 3D printed parts can be affected by the printer’s resolution capacity. An FDM 3D printer moves in XY and Z direction to create the model, and the movement will affect the resolution level.

If the movement is small, the printing resolution will be good. Consider this while buying a printer if you want to achieve better details.

4.4, Consider whether the price of the machine is acceptable

3D printers are developed to meet a wide range of requirements, with prices ranging from USD 500 to USD 20,000 and more. A USD 500 3D printer will not offer the quality and features you will get with a 3D printer with a price tag of USD 3000.

However, make sure that you are getting the best features under your price range. For example, if you are paying USD 80,000, make sure that the printer supports different material and printing configurations. Don’t forget to check the safety features that you are getting with the printer.

4.5, Consider the supplier’s after-sales service capability

Printer breakdown can happen anytime, without any notice. When such a situation arises, you should take the necessary steps to resolve the issue faster.

This can be possible if you are getting better after-sale services from the manufacturer. It is advisable to choose a company that offers 24×7 customer care services. That’s why most people prefer to go for Dreambot3d.

FAQ guide

What is the largest 3d printer available?

In general, 3D printing is limited by the 3D printer’s build volume. 3D printers are designed and developed in different sizes. Based on the application, well-known companies are now developing large 3D printers. Most of the large or huge-size 3D printers run on FDM technology. You can guess the 3D printer size because 3D printers are also used to build homes and offices. For example, a company from Massivit3D in Israel has specialized in producing large-size 3D printers, and the printers can measure around 5’9’’ height x 4’9’’ width x 3’9’’ depth. Another example is that in 2015, WASP developed the biggest delta printer having a diameter of 20 feet and a height of 40 feet.

How big can a 3d printer print?

With the advancement in technology, 3D printers are now coming with unique features and robust capabilities. For example, 3D printers can be used for furniture manufacturing and in the architecture industry. The 3D printers’ size can vary based on their usage and the industry they will use.

What is a good size 3d printer?

The size of the printer can significantly influence the maximum size of the object the printer can create. In the case of 3D printers, the length is measured in XYZ dimensions. For example, 10 inches wide (x) by 10 inches deep (Y) by 10 inches high (Z). The size of the printer depends on the build platform of the printer. If you go for a printer with a smaller build area, that can create limitations, but you can split the printing task into smaller parts and combine them. This can be a little time taking. To enjoy a decent result, choose one with a build area of 400x400x400mm.

What is the standard for 3d printing units?

If you are looking for a perfect commercial FDM 3D printer, then the standard size should be 400 x 400 x 400mm. All our machines come with a perfect size and sufficiently large enough for most of the printed parts.

How much are commercial 3d printers?

Most of the enthusiast 3D printers will cost around USD US$1,500 to US$20,000. The printers that come under the Industrial category will differ from the performance class in different ways. Such printers can print in high quality at a decent speed. These printers are truly industrial and come with durable construction, a slick interface, along with fabricated exteriors. While such printers are highly durable and reliable, their cost can only be ideal for large enterprises that can afford their costly price tag.

Can 3d printers be used for mass production?

The introduction of the latest technology has made some 3D printing technology, such as SLM- Selective Laser Melting and FDM, more affordable and advance. On the other hand, 3D printing for metal end-use parts is now made possible. This shows that 3D printers can handle mass part production. Besides, the largest FDM printer can be used for rapid prototyping. However, when considering whether 3D printing is ideal for mass production or not, you need to look at what they can bring to the table. As discussed above, one of the crucial benefits of 3D printing is its fantastic ability to produce different shapes that you can imagine. For instance, the well-known sports brand Adidas used a 3D printer to create midsole for the FutureCraft 4D sneakers. They come with complex geometry that is not possible to make through traditional manufacturing techniques.

How durable are 3d printed items?

When it comes to 3D printing, you can use and combine different printing materials to get the desired level of strength. 3D printed objects can be durable like the traditionally produced counterparts. It may be noted that 3D printed thermoplastic can be 50 to 80 percent stronger than the same polymer processed through injection molded. You can use 3D printed parts for different purposes and in other applications like in the automotive industry, aerospace, medical, construction, and more. So, you can trust 3D printed items when it comes to getting durable products.

What is the strongest plastic for 3d printing?

As per different studies, Polycarbonate is the most robust material for 3D printing. The strength level that the polycarbonate material offer can surprise you. If you compare this with Nylon, you will find that Nylon produces around 7000 psi of tensile strength. However, on the other hand, Polycarbonate’s tensile strength is 9,800 psi. What’s more? Polycarbonate has a lower density than glass, making it ideal for designing optical parts, decorative objects, and more. On the other hand, this filament can easily withstand around -150-degree C to 140-degree C of temperatures range. So, this can be an ideal option for high-strength, functional components.

Can a car be 3d printed?

Previously, 3D printers were used for rapid prototyping. However, now the 3D printing technology has brought a great revolution. Now a car can be 3D printing, and it is true. Most car manufacturers are now using industrial-grade 3D printers to produce car parts. On the other hand, 3D printers have introduced new design possibilities in this industry. For instance, The PUV. This 3D printed vehicle is produced for the AMIE project by the Oak Ridge National Laboratory. The researchers of the company used 3D printing to manufacture its body panel from carbon-fiber-reinforced plastic. The top speed of the car is 35MPH.

Is PETG stronger than PLA?

To understand this, let’s know what PLA and PETG are. PLA, called Polylactic Acid, is a polyester plastic and widely used for 3D printing. Most of the first-time 3D printer users go for this. This can be a perfect go-to printing material to play with before moving to other 3D printing material. On the other hand, PETG, also called Polyethylene terephthalate glycol-modified, has an average reputation and easy to print. However, this material can offer the same physical properties that you will find with ABS. Even though both the materials are user-friendly, PETG is more stringer and durable than PLA. For 3D objects with the impact-resistant feature, you should use PETG.

What happens if you print PLA too hot?

If the 3D printer’s extruder is very hot, the PLA printing material will become very flimsy and extra soft. As a result, your prints will come out limp and messy. So, at what temperature should you print PLA? As per the expert, 185-degree C to 250-degree C can be the ideal temperatures range for PLA 3D printing.

Will PLA melt in the sun?

It has been seen that PLA begins to deform at around 120- Degree F to 130-Degree F or 50-55-degree C. So, PLA filament can be a non-starter for outdoor purposes. This material is biodegradable and will breakdown under the sun. If you are manufacturing in a hot place with direct sunlight access, you can face defamation issues.

How many hours will a 3d printer last?

One of the common questions that every buyer asks while buying a 3D printer is how long it last? Well, that depends on the usage rate and its maintenance. With proper use and care, you can keep the machines running for around 10 years. Regular cleaning, attentive service, and replacement will significantly maximize lifespan and 3D printing hours.

Will 3d printing replace traditional manufacturing?

Most of the experts say that 3D printing will not replace traditional manufacturing methods completely. This modern printing technology can be a part of manufacturing and can help in enhancing production processes. Even though a 3D printer’s usefulness in modeling is quite impressive, the printers have some limitations. For example, the materials available for this process are limited. However, to enjoy faster manufacturing, you should combine 3D printing with the traditional manufacturing process.

Does 3d printing have a future?

Yes, 3D printing will play a very crucial role in different industries in the coming years. The automobile sector is widely using 3D printing for rapidly prototyping various new car mode. In the aerospace industry, this technique is used to produce replacement and spare parts. Besides, the healthcare industry has a massive variety of 3D printing applications, such as molds in prosthetics, dentistry, models for different surgeries, and more. As per the experts, the future of global 3D printing is set for explosive growth. In 2016, the market was valued at USD 5.8 billion, and by the end of 2027, it is expected to reach USD 55.8 billion, with 23 percent of the Annual Compound Growth Rate.

Is 3d printing cost-effective?

It has been proved that 3D printing is both time and money-saving. This can significantly help you in enhancing your manufacturing operations. If you are dealing with small volume production, you should go for 3D printing. However, you will have to spend money to set up the 3D printing system in your factory.

Why Guard bands are used in FDM?

Different signals are sent simultaneously on the same FDM network, allocating separate frequency bands or channels to each signal. Here, guard bands are utilized to avoid interference between two successive channels. FDM is widely used for AM and FM radio.

What is the main use of 3d printing?

To understand this, we will have to cover all the primary applications of 3D printing. Some of them are:

- Concept Modelling- 3D printing lets you easily conceptualize your ideas by printing your 3D design, and you can come up with a better-finished product.

- Tooling-3D printed tool masters, molds, and tools are the whole new layer of cost-efficiency and great flexibility. You can come up with highly cost-effective tools for testing prototype, and it will also help produce low volume parts.

- Prototyping- This allows you to enter into the market faster by creating prototypes quickly. Besides, this will also help you to correct your errors and improve the products rapidly.

- Jigs & Fixtures- By using job-specific assembly fixtures and jigs, you can significantly improve manufacturing efficiency. Using 3D printing, you can get things done within a few hours.

- End-use parts- With 3D printing, you can develop customized and low volume durable parts having fine details. The surface will be very smooth.

- Aerospace and defense-With additive manufacturing and FDM technology, prototypes of highly intricate engine designs can be made possible. This also offers opportunities to create lightweight parts.

Is rapid prototyping the same as 3d printing?

First, let’s know what 3D printing is. Speaking about 3D printing, this advanced manufacturing process takes digitally designed 3D models and converts them indto a 3D physical object. Under this process, a printing material is used to fabricate through a nozzle. It may involve different types of printing technology. Speaking about rapid prototyping, this is one type of application widely used in additive manufacturing to produce models faster than the traditional process. Rapid prototyping is generally done by additive manufacturing or 3D printing technology. So, it can be said that the terms rapid prototyping and 3D printing are the same but used in different industries. Whether you are using rapid prototyping or 3D printing, both can be quite beneficial for your business. They will bring better opportunities for your product development process, and you can explore different types of intricate designs.

Conclusion: Why our FDM 3d printer is the one of the best choices?

As the 3D printing speeds have improved and raw materials have increased, 3D printing is now letting people improve functionality, durability, and aesthetics by changing the material composition. 3D printing technology fits perfectly in the new paradigm that people called “Industry 4.0”.

This has created a whole new and efficient manufacturing process and promised to change manufacturing and people’s daily lives. Even though the market is full of different types of FDM 3Dprinters from different brands, you will have to choose the right one to enjoy maximum benefits. However, you can always trust Dreambot for this.

We understand that factors like rapid prototyping, great functional movements, better fluid-flow, parts consolidation, and lightweight 3D printing can dramatically benefit your organization. That’s why we have developed our FDM 3D printers keeping these things in mind. Let us tell you in detail for a better understanding.

Many printer manufacturers produce 3D printers with a simple structure and are not stable enough to offer quality prints. On the other hand, our FDM 3D printers come with integral sheet metal made enclosed chassis, making the machines very durable.

Besides, using them can prevent the risk of harmful gas leaks that happens while processing filaments. On the other hand, the XYZ axis can print quite stably while running at a higher speed. You don’t have to compromise on the printing accuracy.

To create a perfect 3D model, the filaments need to be heated at the right temperature, and the printing system’s temperature needs to remain constant during the process.

For this, we have added a continuous temperature system in our machines. While printing materials like nylon, carbon fiber, PC, ABS, PETG, or more, you won’t face material wrapping. However, not all manufacturers use this constant temperature system.

A more prominent display makes it easier to input instruction and manage the machine. Some of our competitors only offer a 5-inch color screen with their printers.

But our FDM 3D printers come equipped with a large 7-inch color screen. Besides, all our machines come with an easy-to-use operating system. Use them now to see the difference.

3D printing requirements may vary from industry to industry, and for this, the different sectors will need different types of printers. That’s why we have a complete range of sizes.

We have printers for all. On the other hand, the market condition is also very stable. You can go for out models like L5-400/500/600/800/1000 and L8-400/500/600. Worried about the after-sale service? We offer24x7 support throughout the year.

Some companies only offer one to two sizes, and their market condition is also not good. So, choose wisely and work in a better way.

As one of the most reputed public 3d printing companies, we are committed to serving the industry by offering world-class products. We have been manufacturing industrial-grade 3D printers for more than 8 years.

Besides, our R&D capability and production capacity are robust. When it comes to choosing the best, you can trust Dreambot. You shouldn’t buy a 3D printer from a manufacturer that only deals with producing desktop-level machines and has low-quality R&D capabilities. Their devices won’t last for a long time.

Dreambot follows a strict procedure to produce large-size industrial FDM 3D printers and maintain a sufficient stock level. After getting the order, we can ship the product within 3 to 5 days. We can also offer you customized styles, and such products can be shipped within 10 to 15 days.

When you are with Dreambot, you don’t have to worry about buying world-class and industrial-grade FDM 3D printers. Want to know more about the types of printers that we can offer? Feel free to call us anytime you want.